Introduction

Solder paste plays a vital role in modern electronics assembly, especially when working with fine pitch components. These tiny parts, often found in compact devices, require precision to ensure reliable connections on printed circuit boards (PCBs). For electronic hobbyists, mastering the use of solder paste, along with tools like soldering irons and flux, can elevate project quality. This article explores the essentials of solder paste application, focusing on fine pitch components. It covers technical principles, practical tips, and industry standards to guide hobbyists through the process. Whether you are assembling a small circuit or troubleshooting a complex board, understanding solder paste and its interaction with wire solder and flux is key to success.

What Is Solder Paste and Why It Matters

Solder paste is a mixture of tiny solder particles suspended in a flux medium. This combination allows it to be applied to PCB pads before components are placed. When heated, the paste melts, forming electrical and mechanical connections between components and the board. Its importance lies in enabling surface mount technology (SMT), which is common for fine pitch components with closely spaced leads or pads.

For hobbyists, solder paste simplifies working with small parts that are hard to solder manually with wire solder. Fine pitch components, often with lead spacing below 0.5 mm, demand accuracy that traditional soldering irons struggle to achieve. Solder paste, applied through a stencil or syringe, ensures even distribution. This reduces the risk of shorts or insufficient joints. By understanding its role, hobbyists can tackle advanced projects with confidence, ensuring reliable and professional results.

Technical Principles of Solder Paste Application

Solder paste functions through a combination of physical and chemical processes. The solder particles, typically a mix of tin and other metals, provide the material for forming joints. The flux within the paste cleans surfaces by removing oxides, ensuring proper wetting when the solder melts. This is critical for fine pitch components, where even small contaminants can cause defects.

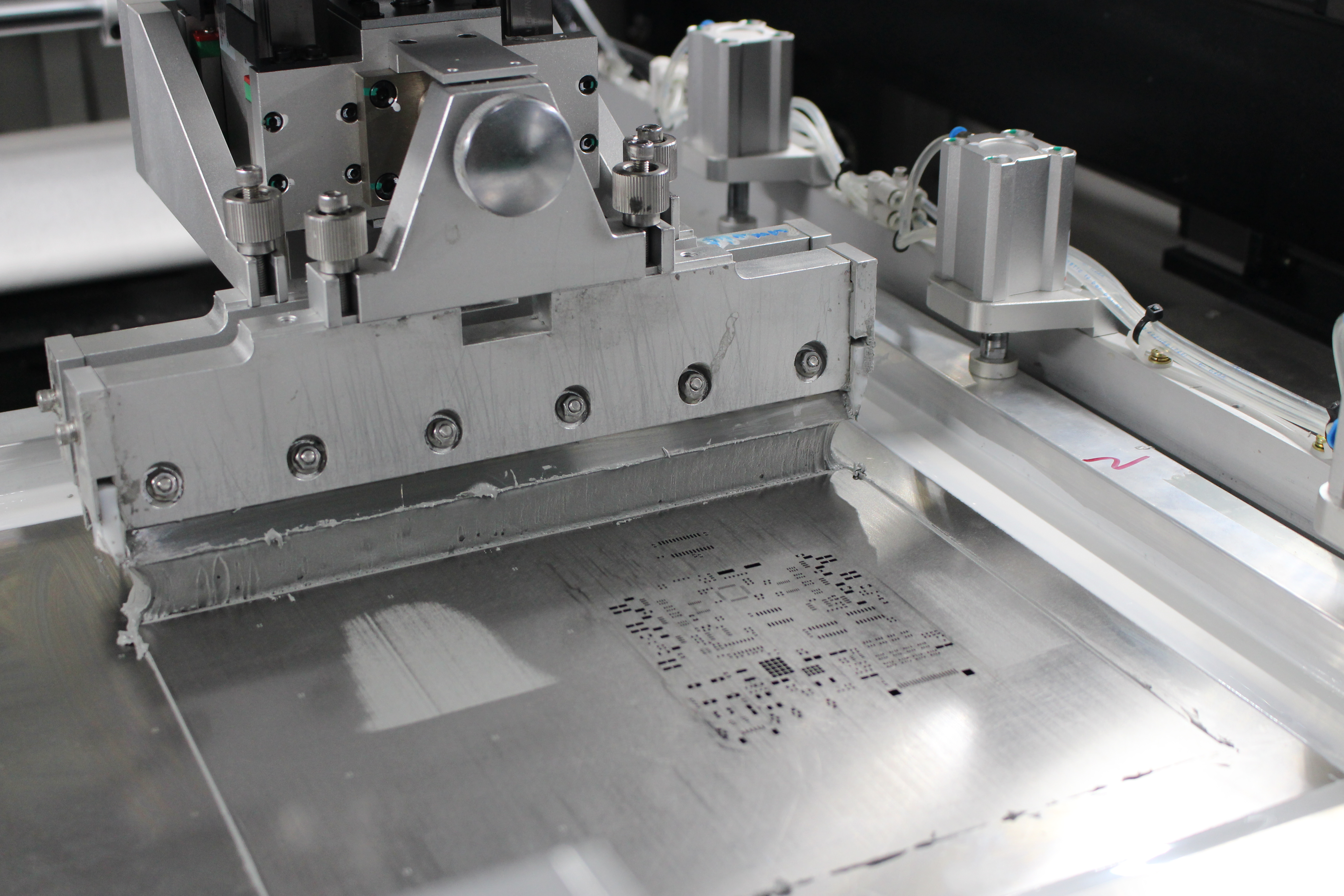

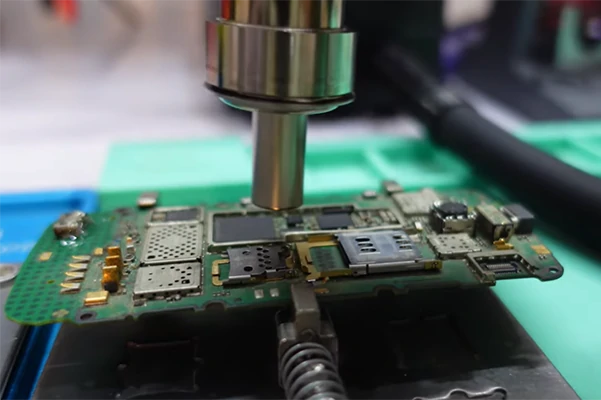

During application, solder paste must be deposited precisely on PCB pads. Stencils are often used to control the amount and placement, especially for components with tight spacing. The paste's viscosity affects how it flows and holds shape before reflow. Once applied, the board undergoes heating, often via a reflow oven or hot air tool. The flux activates first, cleaning surfaces, then the solder melts and solidifies into joints.

Standards like IPC-7527 provide guidelines for solder paste printing processes. These ensure consistent application, minimizing defects like bridging between closely spaced pads. For fine pitch components, the particle size in solder paste matters. Smaller particles, often classified as Type 4 or higher, are preferred for better resolution on tiny pads as per industry practices.

Related Reading: Optimizing Solder Paste Application with Step Up Stencils

Challenges with Fine Pitch Components

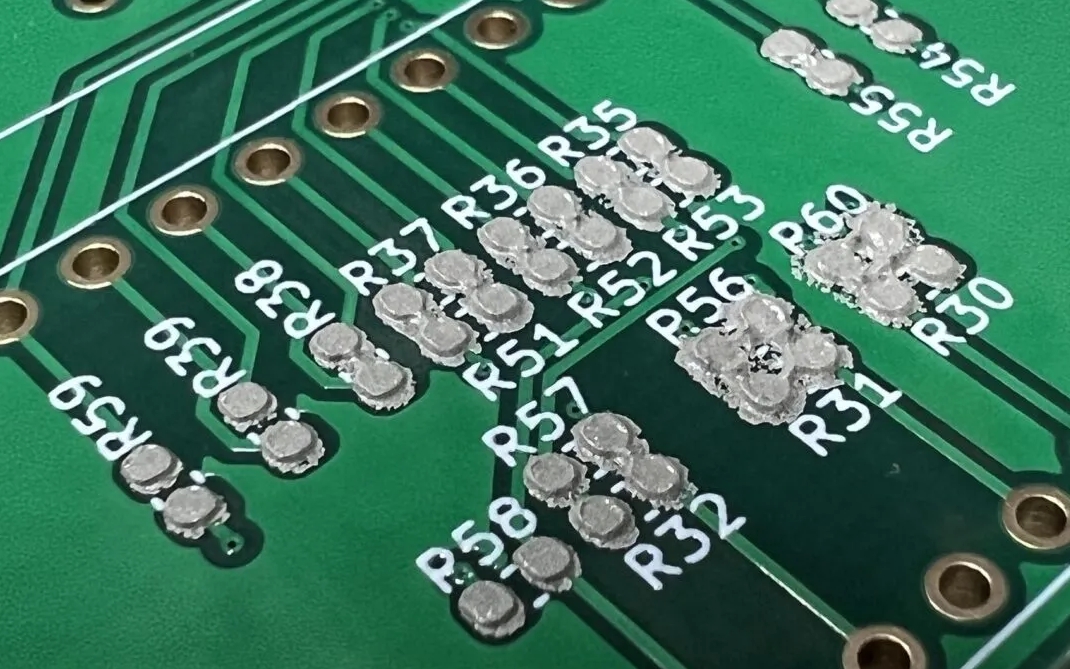

Fine pitch components present unique challenges due to their small size and close lead spacing. Bridging, where solder connects adjacent pads, is a common issue. Insufficient solder can lead to weak joints, while excess paste causes shorts. Hobbyists must also consider component alignment, as even slight misplacement disrupts connections.

The thermal profile during reflow is another concern. Fine pitch parts are sensitive to heat, and uneven heating can cause tombstoning, where components lift off one side. Standards like JEDEC J-STD-020E outline moisture sensitivity and reflow guidelines to prevent such issues. Following a controlled heating curve ensures the solder melts uniformly without damaging parts.

Flux choice within the paste impacts results too. Rosin-based or no-clean fluxes are often used for hobbyist projects due to ease of use. Water-soluble fluxes offer strong cleaning but require thorough residue removal to avoid corrosion. Understanding these elements helps in selecting the right solder paste for specific fine pitch applications.

Related Reading: Fine-Pitch SMT Stencils: Achieving Precision in High-Density PCB Assembly

Practical Solutions for Hobbyists

Working with solder paste and fine pitch components requires preparation and the right techniques. Here are actionable steps to achieve reliable results.

Choosing the Right Solder Paste

Select a solder paste with small particle sizes, ideally Type 4 or 5, for fine pitch work. These ensure precise deposition on small pads. Check the alloy composition, often tin-lead or lead-free, based on your project needs. Lead-free options align with environmental standards but may require higher melting temperatures.

Application Methods

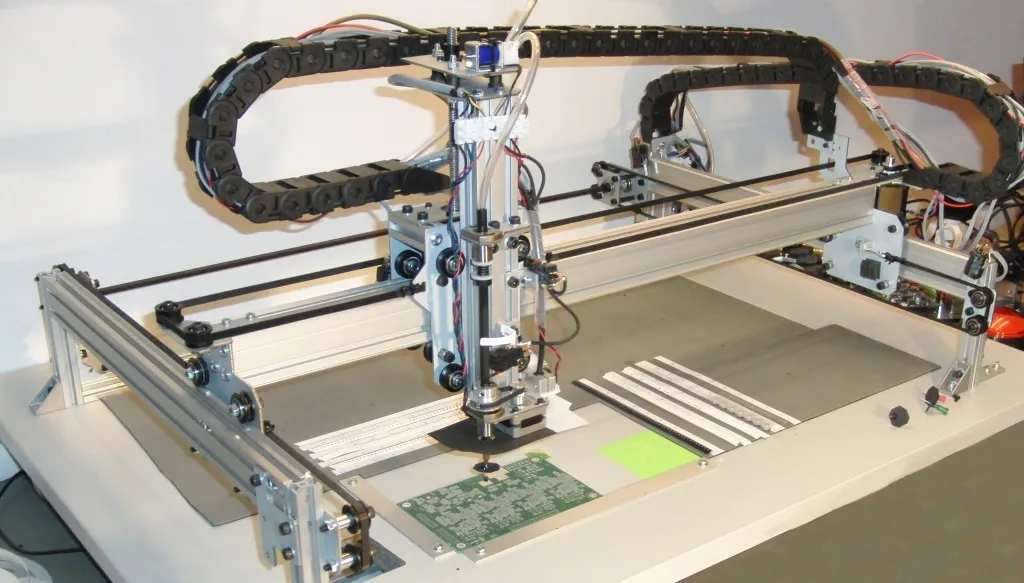

For small projects, a syringe with a fine tip allows manual application of solder paste. Apply small dots on each pad, avoiding excess. If working on multiple components, consider a stencil. Align it over the PCB and use a squeegee to spread paste evenly. This method ensures consistency for fine pitch spacing.

Using Flux and Wire Solder as Support

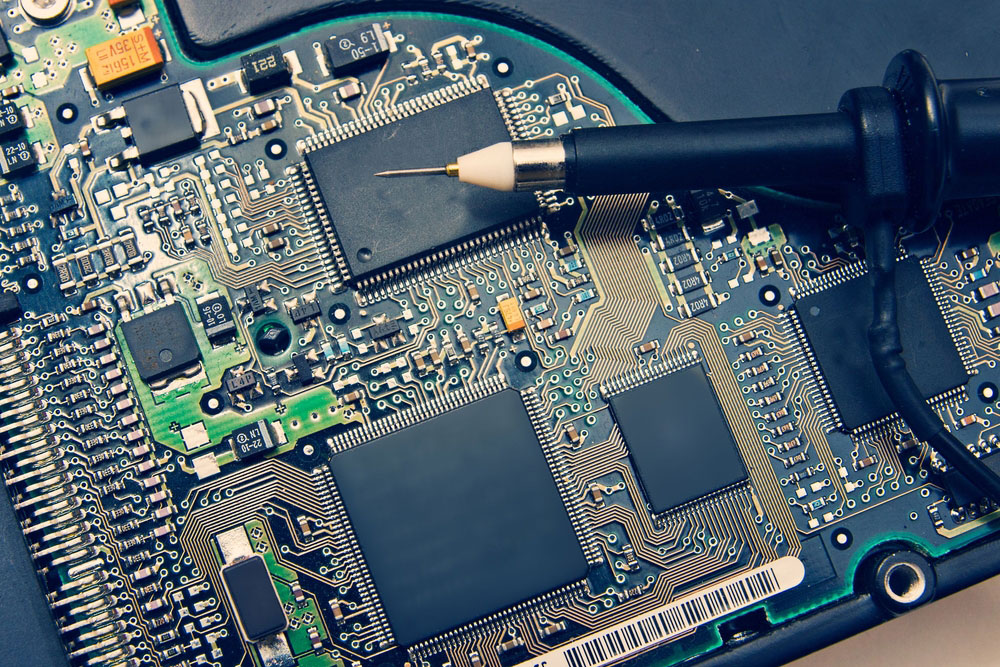

Flux is critical when reworking or troubleshooting. Apply additional flux with a brush or pen to improve solder flow on stubborn joints. If manual touch-up is needed, use thin wire solder with a fine-tip soldering iron. Keep the iron at a controlled temperature to avoid overheating delicate components.

Reflow Techniques

For reflow, a hot air station or small reflow oven works well for hobbyists. Preheat the board gradually to activate flux, then ramp up to the melting point of the solder. Follow thermal profiles suggested by standards like JEDEC J-STD-020E to prevent thermal shock. Monitor the process to ensure even heating across fine pitch areas.

Inspection and Cleanup

After reflow, inspect joints under magnification. Look for shiny, smooth connections without bridges or voids. Use isopropyl alcohol and a brush to clean residues if using water-soluble flux. No-clean fluxes may not require this step, saving time for hobbyists.

Tools and Tips for Soldering Iron Use

A soldering iron is often a hobbyist's go-to tool for touch-ups or small-scale assembly. When working with fine pitch components, choose an iron with adjustable temperature control. Set it to match the solder paste or wire solder melting point, typically between 260 to 300 degrees Celsius for lead-free alloys. Use a fine, pointed tip for precision on small pads.

Keep the tip clean by wiping it on a damp sponge or using a brass wire cleaner. Apply a thin layer of fresh solder to the tip before each use to improve heat transfer. This practice, known as tinning, prevents oxidation and ensures better contact with joints.

When soldering fine pitch leads, avoid prolonged heat exposure. Touch the pad briefly, allowing solder to flow naturally with the help of flux. Excess heat can lift pads or damage components. Practice on scrap boards to build confidence before working on critical projects.

Troubleshooting Common Issues

Even with careful preparation, issues can arise when using solder paste with fine pitch components. Bridging between pads often results from too much paste. Remove excess solder with a clean soldering iron tip and flux, or use desoldering braid for cleanup. If joints appear dull or grainy, insufficient heat or poor flux activity may be the cause. Reheat the area with fresh flux to improve wetting.

Tombstoning, where one end of a component lifts, indicates uneven heating or pad design issues. Ensure both pads receive equal heat during reflow. If components misalign, use tweezers to reposition them before the solder solidifies. Always inspect under magnification to catch defects early.

Following guidelines from IPC-A-610, which covers acceptability of electronic assemblies, helps hobbyists identify and correct faults. This standard provides visual criteria for acceptable solder joints, ensuring hobbyist projects meet professional quality levels.

Conclusion

Solder paste is an invaluable tool for electronic hobbyists working with fine pitch components. Its ability to create precise, reliable connections transforms complex assemblies into manageable tasks. By understanding the principles behind solder paste, flux, and reflow processes, hobbyists can avoid common pitfalls like bridging or weak joints. Practical techniques, such as using stencils and controlled soldering iron temperatures, further enhance success. Adhering to industry standards ensures consistent results, even in small-scale projects. With the right approach, hobbyists can master fine pitch soldering and elevate their electronics skills.

FAQs

Q1: How do I choose solder paste for fine pitch components?

A1: Selecting solder paste for fine pitch components involves checking particle size, ideally Type 4 or 5, for precise application. Consider the alloy type, whether tin-lead or lead-free, based on melting temperature needs. Ensure the flux type matches your cleaning capabilities. Following industry practices for small pad applications ensures better results for hobbyist projects.

Q2: What role does flux play when using solder paste?

A2: Flux in solder paste cleans surfaces by removing oxides, ensuring proper solder wetting during reflow. It prevents new oxide formation and improves flow on fine pitch pads. Additional liquid flux can assist in rework with a soldering iron. Choosing the right flux type, like no-clean, simplifies post-soldering cleanup for hobbyists.

Q3: Can I use a soldering iron for fine pitch components with solder paste?

A3: Yes, a soldering iron can be used for touch-ups on fine pitch components after applying solder paste. Use a fine tip and control temperature to avoid overheating. Apply flux for better solder flow. Limit contact time to protect components and pads, ensuring reliable joints in small areas.

Q4: What are common mistakes when soldering fine pitch components?

A4: Common mistakes include applying too much solder paste, causing bridging, and uneven heating during reflow, leading to tombstoning. Misalignment of components and insufficient flux activity also cause poor joints. Inspecting under magnification and following thermal profiles prevents these issues for hobbyists working with wire solder or paste.

References

IPC-7527 — Guidelines for Printed Board Solder Paste Printing. IPC, 2012.

IPC-A-610 — Acceptability of Electronic Assemblies. IPC, 2021.

JEDEC J-STD-020E — Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices. JEDEC, 2014.