Introduction

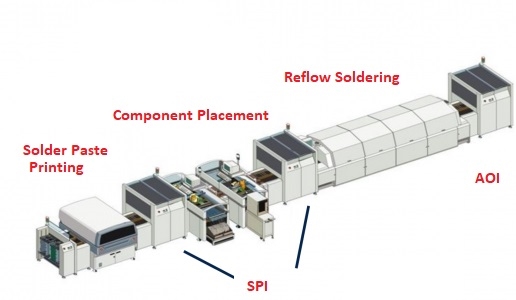

Reflow soldering remains the dominant method for attaching millions of surface-mount components daily in modern electronics manufacturing. The entire process chain (solder paste application, component placement, and controlled thermal profile) determines whether a board achieves 99.99% first-pass yield or suffers from tombstoning, voiding, head-in-pillow, or non-wetting defects. This article guides electrical engineers through each critical stage of SMT PCB assembly, offering practical, factory-floor insights into solder paste selection, stencil printing quality, pick-and-place accuracy, and reflow profile optimization to ensure consistent, high-yield production.

Step 1: Solder Paste Application – The Foundation

Solder Paste Types and Selection

- Type 3 (25–45 µm) → standard choice for 0603 and larger

- Type 4 (20–38 µm) → 0402, 0201, 0.5 mm pitch BGA

- Type 5/6 (5–15 µm) → 01005, 0.4 mm pitch and below, µBGA

No-clean, water-soluble, or ROL0/ROL1 flux classification must match downstream cleaning requirements and reliability needs.

Stencil Printing Best Practices

- 100–150 µm laser-cut, electro-polished stainless steel stencils

- Squeegee speed 20–80 mm/s, pressure 0.2–0.4 kg/cm

- Automated SPI (solder paste inspection) after printing is mandatory for <50 ppm defect rates

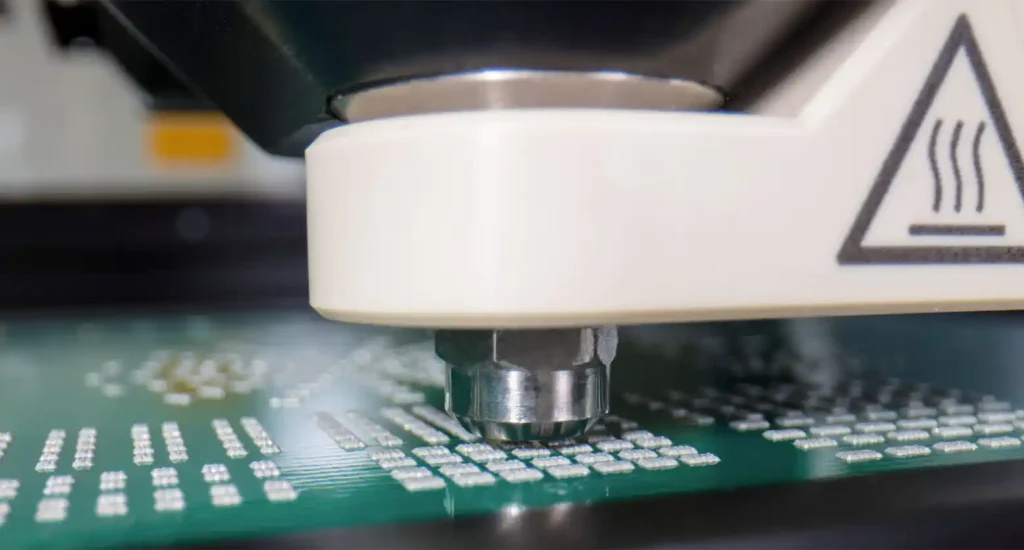

Step 2: High-Speed Pick-and-Place Machines

Placement Accuracy Requirements

- 0603/0402 → ±50 µm @3σ

- 0201/01005 → ±30 µm @3σ

- 0.4 mm BGA → ±25 µm @4σ

Common Placement Defects Caused by Poor Process

- Tombstoning → paste volume asymmetry or nozzle offset

- Skewed components → incorrect feeder setup or vision alignment failure

- Missing parts → vacuum pickup issues or tape advance errors

Modern pick-and-place machines with digital cameras and linear motors routinely place >100,000 components per hour with <10 ppm defects when properly maintained.

Step 3: The Reflow Soldering Process – Thermal Profile Development

Four Distinct Zones in a Reflow Profile

- Preheat (25–150 °C)

Ramp rate 1–3 °C/s to activate flux and prevent thermal shock. - Soak / Pre-reflow (150–180 °C, 60–120 s)

Evens out temperature across the assembly. - Reflow / Liquidus (peak 235–260 °C)

SAC305 liquidus = 217–221 °C. TAL 45–90 s. - Cooling

2–4 °C/s to prevent grain structure issues.

Lead-Free vs Leaded Profiles

Parameter: Peak temperature — Leaded: 215–235 °C — Lead-Free: 240–260 °C — Notes: Component max rating limits peak

Parameter: Time above liquidus — Leaded: 30–60 s — Lead-Free: 45–90 s — Notes: Longer TAL improves wetting

Parameter: Ramp rate — Leaded: ≤3 °C/s — Lead-Free: ≤3 °C/s — Notes: Prevents tombstoning

Parameter: Cooling — Leaded: 2–6 °C/s — Lead-Free: 2–4 °C/s — Notes: Faster cooling improves grain structure

Critical Defects and Their Root Causes

Defect: Tombstoning — Cause: Uneven heating — Prevention: Balanced apertures, <2 °C/s ramp

Defect: Head-in-pillow — Cause: Warped BGA — Prevention: Nitrogen reflow, fresh paste

Defect: Voiding — Cause: Flux outgassing — Prevention: Window-pane stencil, vacuum reflow

Defect: Non-wet — Cause: Low peak or TAL — Prevention: Extend TAL, raise peak

Defect: Bridging — Cause: Excess paste — Prevention: Reduce aperture size

Nitrogen vs Air Reflow

Air — Wetting: Good — Voiding: 10–25% — Cost: Low — Use: Consumer

Nitrogen (<500 ppm O₂) — Wetting: Excellent — Voiding: 3–8% — Cost: Higher — Use: High reliability

Profile Optimization Workflow Used on Factory Floor

- Attach 6–9 thermocouples

- Run initial linear ramp

- Adjust preheat zones to 1.5–2.5 °C/s

- Extend soak if ΔT >15 °C

- Ensure smallest component reaches 240 °C

- Verify TAL 60–75 s

- Confirm voiding <15% by X-ray

Conclusion

Mastering the reflow soldering process requires tight control at every stage: paste application, precise placement, and optimized thermal profile. While complexity varies among types of PCBs, the combination of Type 4/5 solder paste, SPI inspection, nitrogen-assisted reflow, and a well-tuned 10–12 zone oven commonly delivers yields exceeding 99.99%.

FAQs

Q1: How long can solder paste stay on a board before reflow?

A1: Maximum 4–6 hours at 20–25 °C and <60% RH for no-clean paste.

Q2: What is the ideal time above liquidus (TAL) for SAC305?

A2: 60–75 seconds. Less than 45 s risks non-wetting; over 90 s increases intermetallic growth.

Q3: Do I need nitrogen for consumer products?

A3: Not required for most commercial products.

Q4: Why do small 0201 components tombstone more easily than 0603?

A4: Smaller components have lower thermal mass and react faster to temperature differences.

References

IPC-J-STD-001H — Requirements for Soldered Electrical and Electronic Assemblies. IPC, 2020.

IPC-7095D — Design and Assembly Process Implementation for BGAs. IPC, 2018.

IPC-TM-650 2.6.27 — Thermal Stress, Convection Reflow Assembly Simulation. IPC, 2018.

IPC-J-STD-020E — Moisture/Reflow Sensitivity Classification. IPC/JEDEC, 2015.