Introduction

In-Circuit Testing (ICT) remains the gold standard for detecting manufacturing defects such as opens, shorts, wrong values, and missing components on loaded PCBs. The performance, uptime, and cost-per-test of an ICT station depend heavily on the fixture type: traditional vacuum fixtures or modern pneumatic fixtures. Each technology has distinct mechanical principles, throughput capabilities, maintenance needs, and sweet-spot applications. This practical comparison helps production and test engineers choose the optimal solution for low-volume prototypes, mid-volume consumer products, or high-volume automotive/industrial manufacturing.

How Vacuum Fixtures Work

Vacuum fixtures use atmospheric pressure to pull the quick turn PCB down onto spring probes.

- The board is placed on the probe plate

- A sealed box or cassette lowers over the assembly

- Vacuum (typically 60–80 kPa) evacuates air between the seal and the board

- 101 kPa atmospheric pressure forces the DUT onto thousands of probes simultaneously

Advantages

- Extremely uniform contact force across the entire board

- Excellent for double-sided or heavily loaded boards

- Proven technology used for >40 years

Disadvantages

- Long cycle time: 12–25 seconds just for vacuum/pull-down/release

- Large footprint and heavy cassette

- Vacuum pump noise and periodic seal/gasket replacement

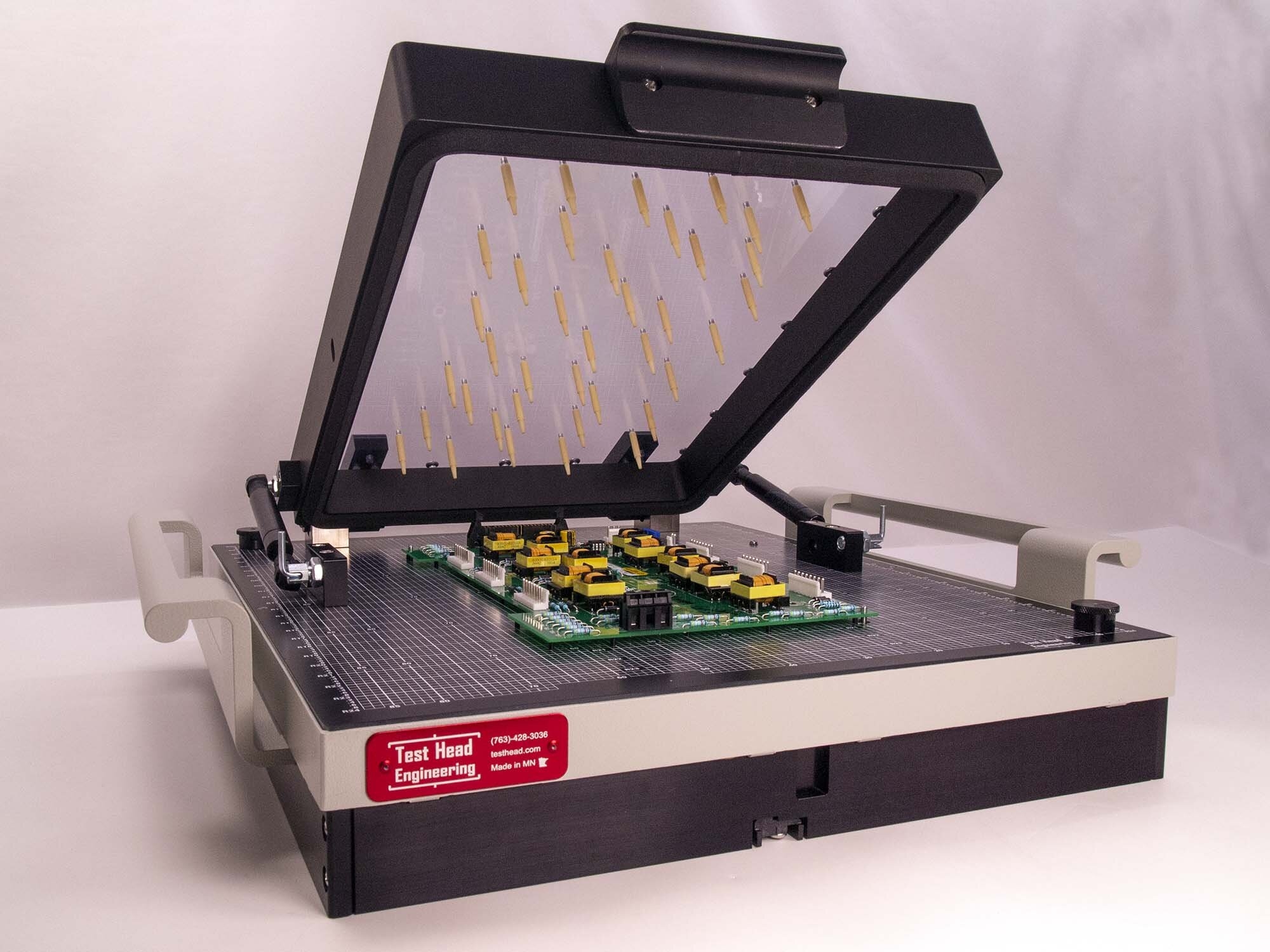

How Pneumatic Fixtures Work

Pneumatic fixtures replace vacuum with direct air pressure.

- Board placed on fixed probe plate

- Upper platen with push fingers driven by multiple pneumatic cylinders (6–16 bar)

- Press-down stroke 15–40 mm in <2 seconds

- Force applied only through rigid or spring-loaded push fingers

Advantages

- Fast cycle time: 3–6 seconds total actuation

- Smaller footprint and lower weight

- Quieter operation (no vacuum pump)

- Easier integration with automation (conveyors, robots)

Disadvantages

- Contact force less uniform on warped or flexible boards

- Requires careful push-finger layout design

- Higher initial customization cost

Head-to-Head Comparison

| Parameter | Vacuum Fixture | Pneumatic Fixture | Winner |

|---|---|---|---|

| Actuation time | 12–25 s | 3–6 s | Pneumatic wins |

| Maximum board size | Up to 650 × 550 mm | Typically ≤450 × 350 mm | Vacuum wins |

| Double-sided test capability | Excellent | Possible but complex | Vacuum wins |

| Throughput | 120–200 | 400–700 | Pneumatic wins |

| Maintenance frequency | Seals every 50k cycles | O-rings every 200k+ | Pneumatic wins |

| Noise level | 75–85 dB | <60 dB | Pneumatic wins |

| Warped board tolerance | ±3 mm | ±1 mm | Vacuum wins |

| Automation friendliness | Difficult | Excellent | Pneumatic wins |

| Typical fixture cost | 8k–18k | 12k–25k | Vacuum wins |

Application Sweet Spots

| Production Scenario | Recommended Fixture Type | Reason |

|---|---|---|

| High-volume consumer | Pneumatic | 500–1500 boards/day, inline automation |

| Automotive / aerospace | Vacuum | Warpage tolerance, double-sided probing |

| Mixed low-to-mid volume | Pneumatic (quick-change) | Fast changeover |

| Very large panels | Vacuum only | Pneumatic cannot apply uniform force |

| Lights-out automation | Pneumatic + robots | Cycle time and footprint |

Hybrid solutions now exist: vacuum-over-pneumatic (VOP) fixtures that use small pneumatic cylinders to assist vacuum pull-down and reduce cycle time to 7–9 seconds while retaining vacuum uniformity.

Real Factory Throughput Examples

| Product | Daily Volume | Layers | Board Size | Fixture Type | Effective UPH | Changeovers/day |

|---|---|---|---|---|---|---|

| Smartphone mainboard | 8000 | 12 | 160 × 90 mm | Pneumatic | 680 | 12 |

| Automotive ECU | 800 | 10 | 280 × 220 mm | Vacuum | 160 | 2 |

| Server CPU card | 200 | 20 | 580 × 450 mm | Vacuum | 110 | 1 |

| IoT module | 3000 | 6 | 120 × 80 mm | Pneumatic | 520 | 8 |

Maintenance and Long-Term Cost of Ownership

Vacuum fixtures

- Vacuum pump rebuild every 12–18 months

- Seal/gasket kit every 40–60k cycles

- Typical MTBA ≈ 30k cycles

Pneumatic fixtures

- Cylinder seal kits every 200–300k cycles

- Push-finger replacement only on wear

- MTBA >150k cycles common

Conclusion

Choose vacuum fixtures when maximum contact reliability, double-sided testing, or large/warped boards are essential, especially in aerospace, medical, and automotive. Choose pneumatic fixtures when production volume exceeds 1500 boards per week, automation integration is required, or fast product changeover is critical. Modern high-mix factories increasingly adopt pneumatic or hybrid fixtures to achieve >500 boards/hour while vacuum remains the safe choice for mission-critical, low-to-mid volume programs.

FAQs

Q1: Can pneumatic fixtures handle double-sided loaded boards?

A1: Yes, but require a board flipper or dual-access tester. Vacuum fixtures are simpler and more reliable for simultaneous double-sided probing.

Q2: How much faster are pneumatic fixtures in real production?

A2: Typical cycle-time reduction is 12–18 seconds per board. On a 4000-board/day line this translates to one fewer ICT station and operator.

Q3: Are vacuum fixtures becoming obsolete?

A3: No. They remain dominant in automotive, defense, and large-panel applications where contact quality cannot be compromised.

Q4: What is the maximum board warpage pneumatic fixtures can tolerate?

A4: Usually ±1.0–1.5 mm. Beyond that, vacuum or vacuum-over-pneumatic (VOP) designs are required.

References

IPC-9252B — Requirements for Electrical Testing of Unpopulated Printed Boards. IPC, 2018.

IPC-7711/7721C — Rework, Modification and Repair of Electronic Assemblies. IPC, 2017.

IPC-TM-650 2.6.7 — Contact Resistance Test Method for Electrical Connections. IPC, 2016.

IPC-J-STD-001H — Requirements for Soldered Electrical and Electronic Assemblies. IPC, 2020.