Introduction

Through-hole assembly remains essential for connectors, large capacitors, and high-power components despite the dominance of surface-mount technology. Two primary methods exist for soldering through-hole parts: wave soldering and hand soldering. Each process offers distinct advantages in speed, cost, quality, and flexibility. This article compares wave soldering vs hand soldering from real production experience to help engineers and procurement teams select the optimal approach for prototype, medium-volume, or high-volume projects.

Process Overview

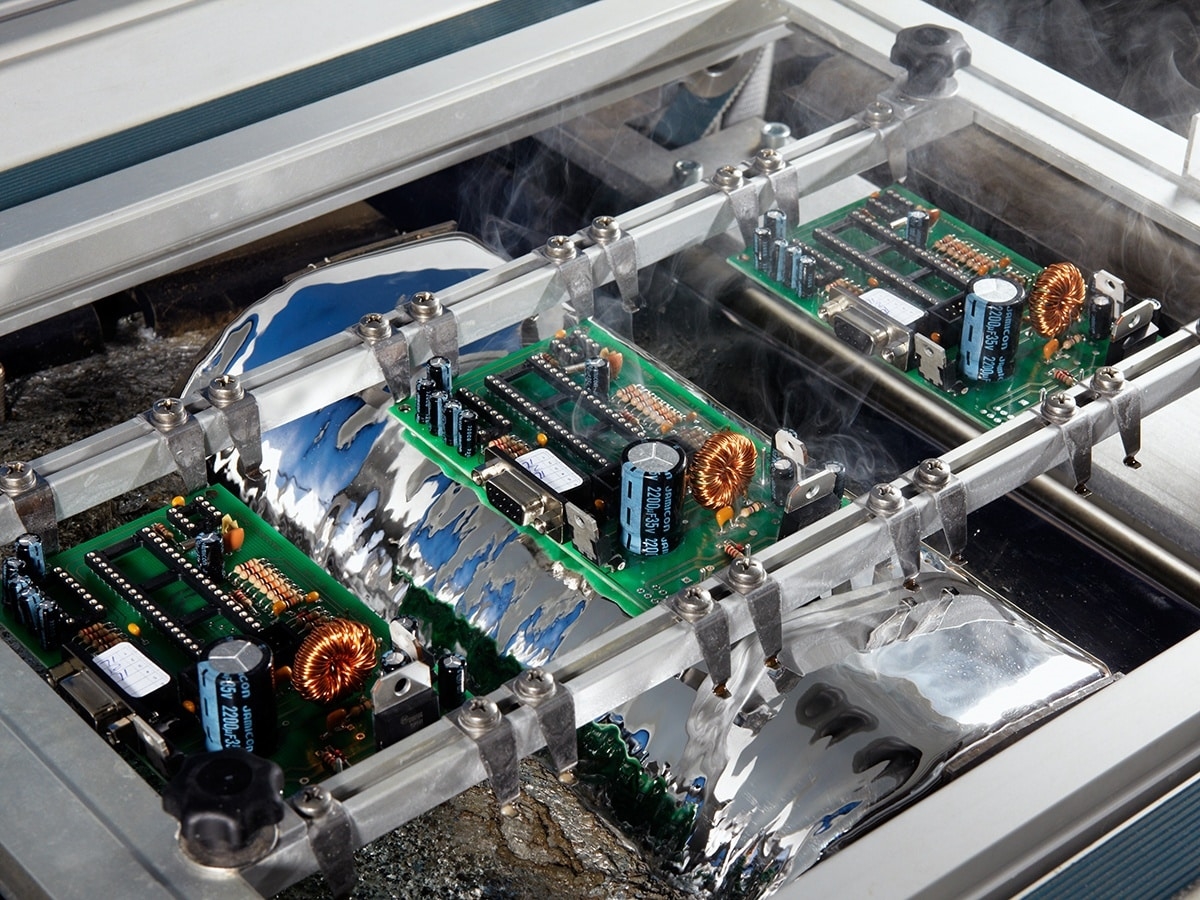

Wave Soldering

The board travels on a conveyor through flux application, preheating, and finally over a pumped molten solder wave. All joints form simultaneously when pins contact the wave. Modern nitrogen-capable machines reduce dross and improve wetting.

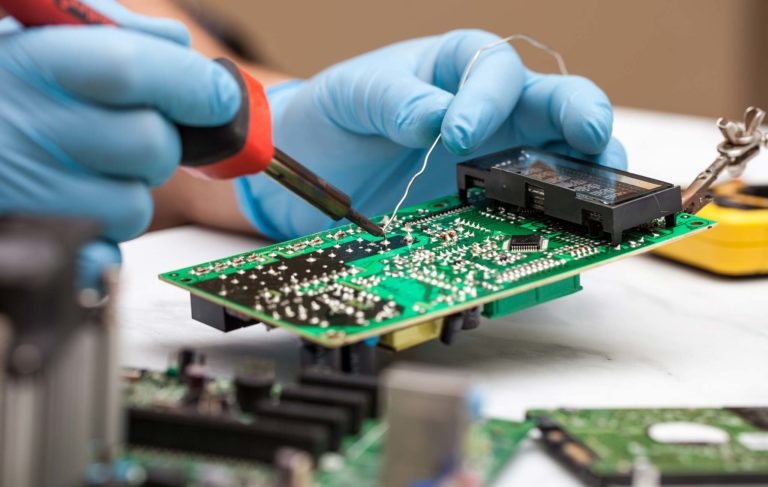

Hand Soldering

An operator individually solders each pin using a temperature-controlled iron. Flux application, solder feed, and joint inspection occur manually for every connection.

Speed Comparison

Wave soldering achieves dramatically higher throughput. A typical single-wave machine solders 60–120 boards per hour depending on pallet design and conveyor speed. Selective wave systems reach similar rates with mixed-technology boards.

Hand soldering speed depends heavily on operator skill and component density. An experienced technician solders approximately 80–150 pins per hour on medium-complexity boards. High-density or multi-row connectors drop this rate significantly.

Cost Analysis

Wave Soldering Costs

- High initial equipment investment

- Ongoing flux, solder bar, and nitrogen consumption

- Pallet or fixture design and fabrication

- Machine programming and maintenance

Hand Soldering Costs

- Low equipment cost (stations typically under $200 each)

- Minimal consumables beyond solder wire and flux

- No fixture expense

- Higher labor cost per board in mass production of PCB

Break-even point usually occurs between 200–500 boards per batch. Below this quantity, hand soldering remains cheaper. Above this threshold, wave soldering delivers clear cost-per-board advantage.

Quality and Reliability Comparison

Wave Soldering Advantages

- Consistent thermal profile across entire board

- Excellent fillet formation on all pins simultaneously

- Reduced thermal stress from single heat cycle

- Lower risk of cold joints when parameters stay optimized

- Superior results on tall connectors and heavy ground pins

Hand Soldering Advantages

- Individual joint inspection during soldering

- Easy correction of bridging or insufficient solder

- Better control on heat-sensitive components

- No masking required for nearby SMD parts

IPC-A-610H Class 3 inspection reveals wave-soldered joints typically show more uniform fillet shape and better wetting on large thermal mass pins. Hand-soldered joints occasionally exhibit slight variation in fillet size but rarely fail electrical testing when performed correctly.

For more differences between manual soldering and machine soldering, see our PCB Soldering guide: The Definitive Guide to PCB Soldering: Standards, Techniques, and Strategic Implementation

Process Compatibility Considerations

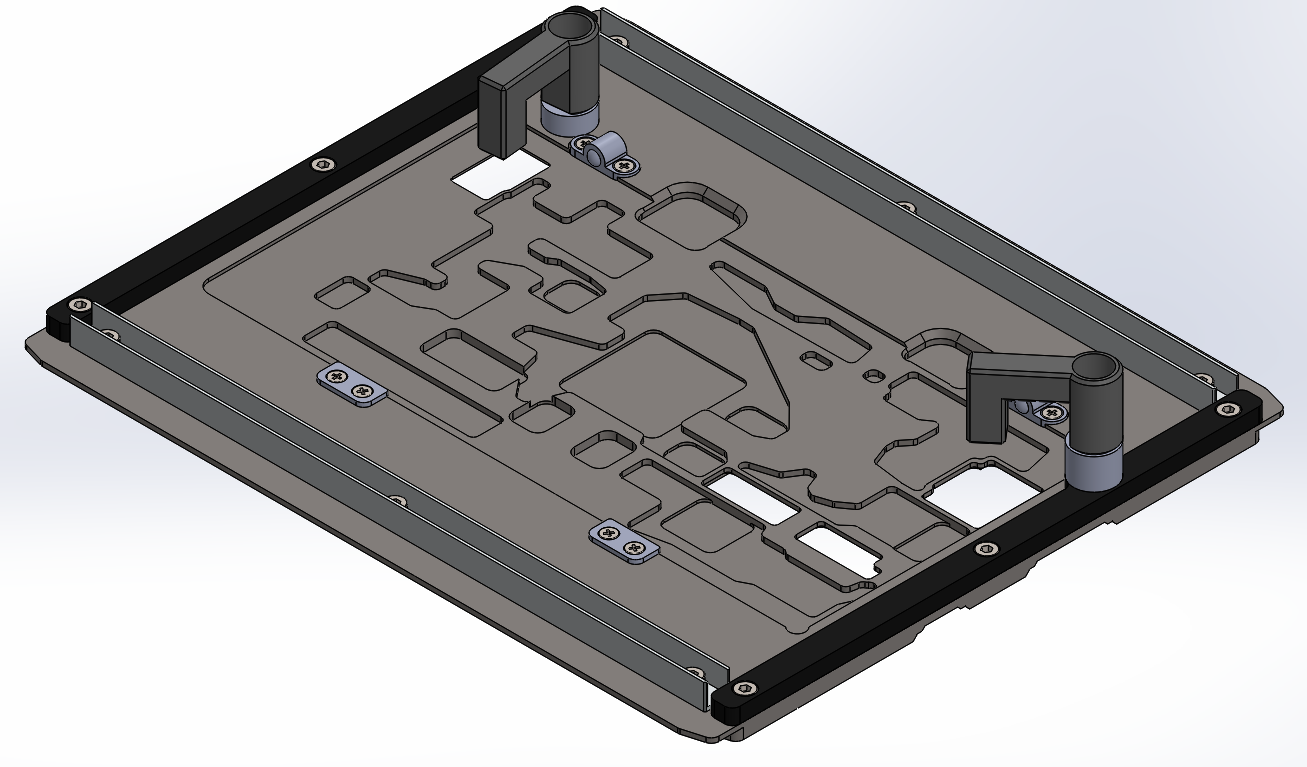

Wave Soldering Limitations

- Requires pallet or selective fixture for double-sided SMT boards

- Risk of solder theft on closely spaced SMD pads

- Difficult with heat-sensitive components

- Minimum board quantity to justify setup time

Hand Soldering Strengths

- Ideal for proto pcb boards and small runs

- Works with any board thickness or mixed technology

- No thermal damage to adjacent components

- Immediate design changes possible

Common Defects and Prevention

Wave Soldering Defects

- Bridging: Control wave height and conveyor angle

- Icicles: Optimize preheat and cooling rate

- Insufficient fill: Increase contact time or flux activity

Hand Soldering Defects

- Cold joints: Maintain proper tip temperature and dwell time

- Excess solder: Use correct wire diameter and feed control

- Pad lifting: Limit heat application duration

Decision Matrix

| Factor | Wave Soldering Best When | Hand Soldering Best When |

|---|---|---|

| Quantity | > 300 boards | < 200 boards |

| Board Complexity | High pin count, simple layout | Mixed technology, odd-form parts |

| Budget | Equipment investment available | Limited capital |

| Lead Time | Production scheduled | Urgent prototypes |

| Quality Requirement | Maximum consistency needed | Individual inspection preferred |

Conclusion

Wave soldering delivers unbeatable speed and cost advantages for medium-to-high volume through-hole or mixed-technology boards when proper fixturing exists. Hand soldering remains the practical choice for prototypes, low-volume production, and boards containing heat-sensitive or odd-form components. Most professional assembly houses maintain both capabilities and select the optimal method based on quantity, complexity, and quality requirements.

FAQs

Q1: When does wave soldering become cheaper than hand soldering?

A1: Wave soldering typically achieves lower cost per board above 200–500 units depending on component count and fixture complexity. Below this volume, hand soldering labor remains more economical.

Q2: Does wave soldering produce higher quality joints than hand soldering?

A2: Wave soldering generally creates more consistent fillet geometry and better hole fill on large pins when process parameters stay optimized. Hand soldering quality depends heavily on operator skill but allows immediate defect correction.

Q3: Can I wave solder double-sided SMT boards?

A3: Yes, using selective pallets or dedicated fixtures that protect surface-mount components while exposing only through-hole pins. Proper pallet design prevents solder theft and component movement.

Q4: Is hand soldering acceptable for Class 3 high-reliability assemblies?

A4: Yes, when performed by IPC J-STD-001 certified operators using temperature-controlled stations and following approved procedures. Many aerospace and medical products rely exclusively on skilled hand soldering.

References

IPC J-STD-001H — Requirements for Soldered Electrical and Electronic Assemblies. IPC, 2020.

IPC-A-610H — Acceptability of Electronic Assemblies. IPC, 2020.

IPC-7093A — Design and Assembly Process Implementation for Bottom Termination Components. IPC, 2019.

IPC-7530A — Guidelines for Temperature Profiling for Mass Soldering Processes (Wave and Reflow). IPC, 2017.