Introduction

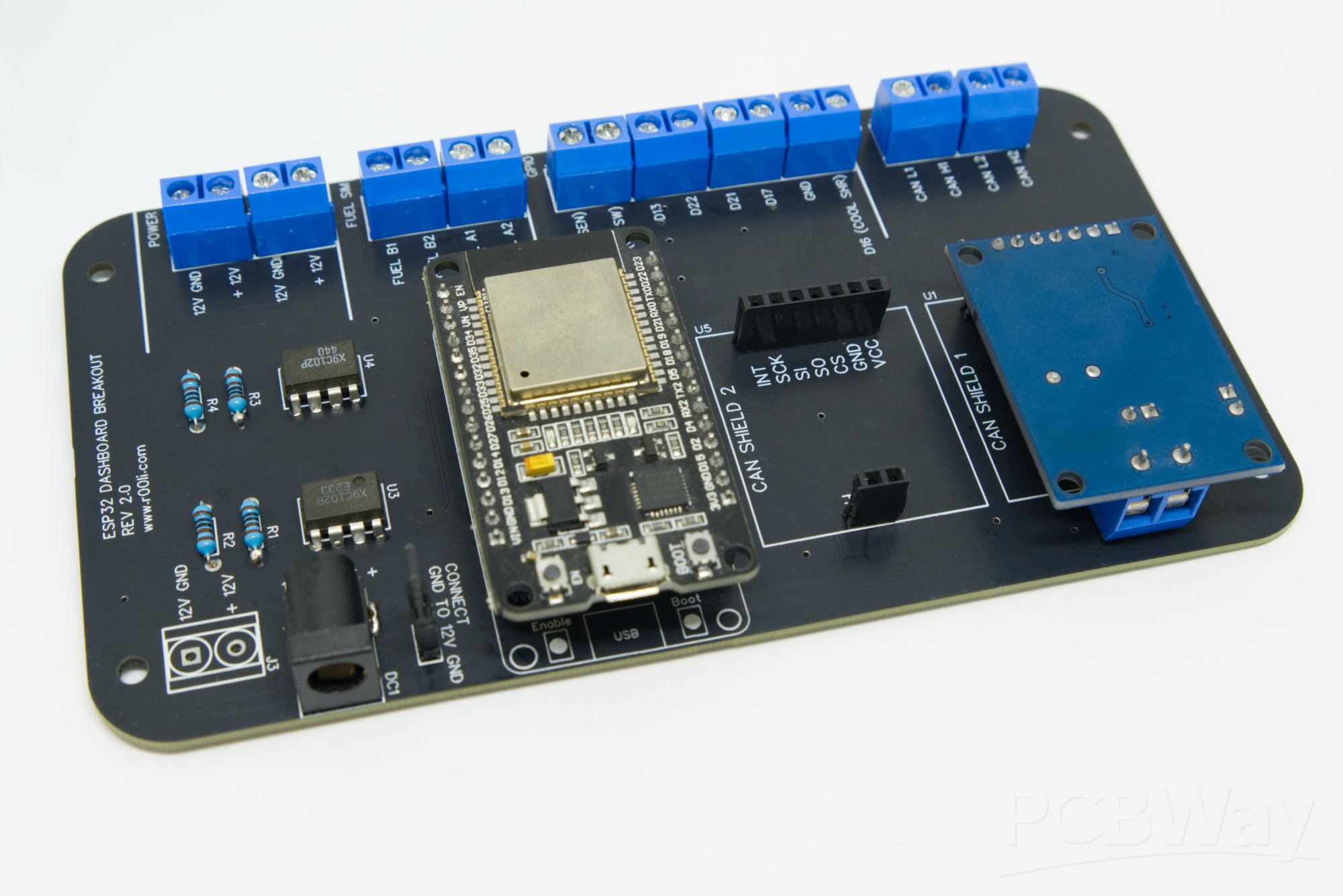

Printed Circuit Boards (PCBs) form the backbone of modern electronics, and their performance hinges on the careful selection of materials. For electrical engineers, choosing the right substrate involves balancing factors like dielectric constant, loss tangent, thermal conductivity, and glass transition temperature. These properties directly impact signal integrity, thermal management, and overall reliability, especially in high-frequency applications. With the aid of specialized software tools, engineers can simulate and analyze material behavior under various conditions, ensuring optimal PCB design. This article explores the critical aspects of PCB material selection, focusing on key parameters and how advanced software streamlines the process. By understanding these elements, professionals can design boards that meet stringent performance and durability requirements for diverse applications.

Why PCB Material Selection Matters

PCB material selection plays a pivotal role in determining the functionality and longevity of electronic devices. The substrate and laminate materials influence how signals propagate, how heat dissipates, and how the board withstands environmental stresses. For instance, in high-frequency designs, materials with a low dielectric constant and minimal loss tangent are essential to reduce signal loss and maintain integrity. Similarly, applications exposed to high temperatures require materials with elevated glass transition temperature to prevent deformation. Poor material choices can lead to signal degradation, thermal failures, or mechanical breakdown, impacting the entire system. Thus, selecting the right material ensures reliability, efficiency, and compliance with industry standards, directly affecting product success in competitive markets.

Key Parameters in PCB Material Selection

Dielectric Constant and Signal Integrity

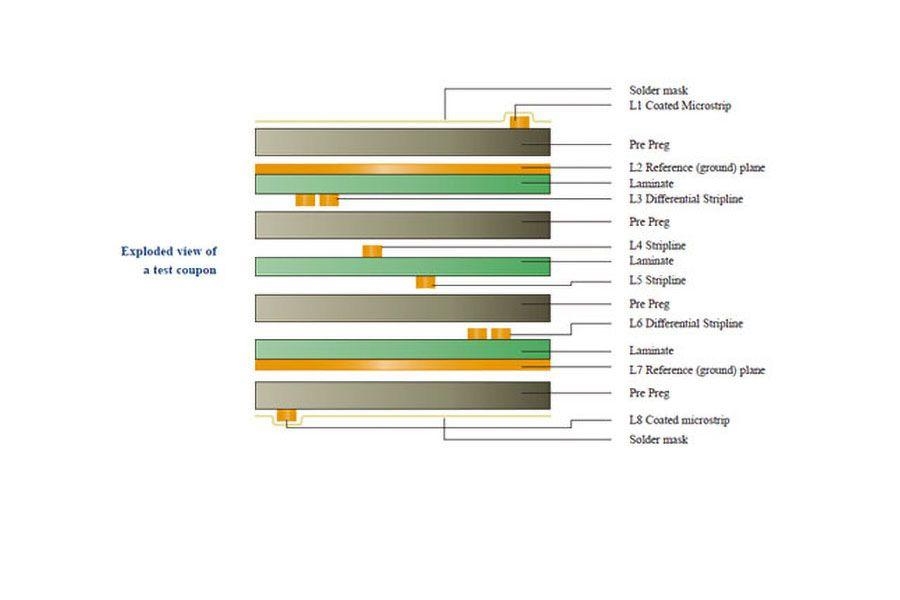

The dielectric constant, often abbreviated as Dk, measures a material's ability to store electrical energy in an electric field. It significantly affects signal speed and impedance in PCB traces. Materials with a low dielectric constant are preferred for high-frequency materials, as they allow faster signal propagation and reduce crosstalk. Typically, values range from 2 to 10 for common PCB substrates, with lower values suited for advanced applications. Engineers must match the dielectric constant to the design requirements to maintain consistent signal behavior across the board.

Loss Tangent and Signal Loss

Loss tangent, or dissipation factor (Df), indicates the energy loss in a material due to signal transmission. A lower loss tangent is critical for high-frequency designs, as it minimizes signal attenuation and heat generation. This parameter becomes especially important in applications like telecommunications or radar systems, where signal clarity is paramount. Materials with a high loss tangent can degrade performance, leading to inefficiencies and potential failures in sensitive circuits.

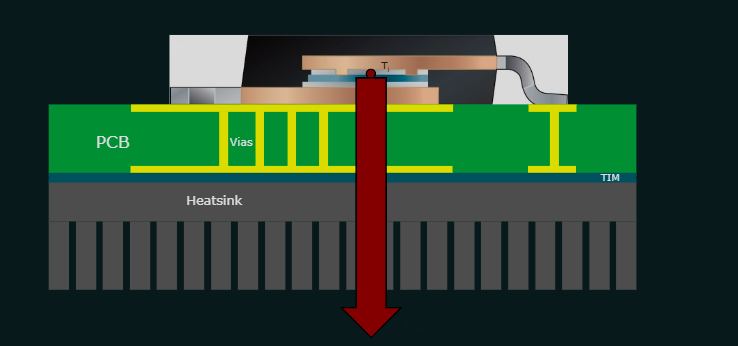

Thermal Conductivity for Heat Management

Thermal conductivity measures a material's ability to transfer heat away from critical components. In high-power applications, effective heat dissipation prevents overheating, which can compromise component lifespan and board integrity. Materials with higher thermal conductivity are ideal for designs involving significant heat generation, ensuring stable operation under demanding conditions. Balancing this property with electrical characteristics is often a challenge, requiring careful evaluation during material selection.

Related Reading: PCB Material Selection: Balancing Thermal Performance and Cost

Glass Transition Temperature and Structural Stability

Glass transition temperature, abbreviated as Tg, defines the point at which a material shifts from a rigid to a more flexible state. For PCBs, a higher Tg value indicates better resistance to thermal stress, preventing warping or delamination during soldering or operation. This property is vital for applications in harsh environments, where temperature fluctuations are common. Selecting a material with an appropriate Tg ensures the board maintains structural integrity throughout its lifecycle.

High-Frequency Materials and Their Importance

High-frequency materials are specifically engineered for applications where signal speed and minimal loss are critical. These materials typically exhibit low dielectric constant and loss tangent values, making them suitable for microwave, radio frequency, and 5G technologies. They support faster data transmission with reduced interference, which is essential for modern communication systems. Additionally, their enhanced thermal and mechanical properties cater to the rigorous demands of advanced electronics. Engineers working on cutting-edge designs must prioritize these materials to achieve optimal performance and meet evolving industry needs.

Related Reading: HDI PCB Materials Selection for High Frequency Applications

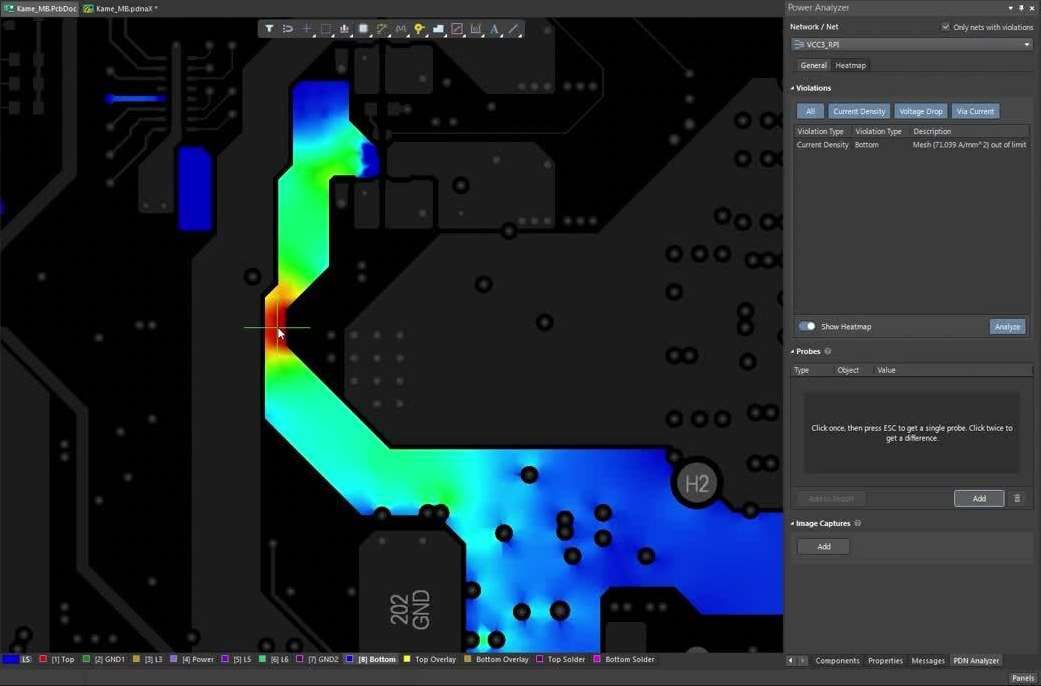

Software Tools for Material Selection

Advanced software platforms have revolutionized PCB material selection by providing simulation and analysis capabilities. These tools allow engineers to model how different materials behave under specific electrical, thermal, and mechanical conditions. By inputting parameters like dielectric constant, loss tangent, and thermal conductivity, designers can predict signal performance and heat distribution before physical prototyping. Such simulations reduce development time and costs by identifying potential issues early. Moreover, these tools often include databases of material properties, aligned with industry standards, enabling informed decision-making for optimal reliability and efficiency.

Best Practices for Optimizing PCB Performance

Matching Material to Application Needs

Selecting a material begins with understanding the specific requirements of the application. For high-frequency designs, prioritize substrates with low dielectric constant and loss tangent to minimize signal loss. In contrast, for power electronics, focus on high thermal conductivity to manage heat effectively. Additionally, consider environmental factors such as operating temperature range, which influences the choice of glass transition temperature. Aligning material properties with design goals ensures consistent performance and prevents costly redesigns.

Adhering to Industry Standards

Compliance with recognized standards is non-negotiable in PCB design. Specifications like IPC-6012E provide guidelines for material performance and qualification, ensuring reliability in production. Similarly, IPC-A-600K outlines acceptability criteria for finished boards, including material-related defects. Following these standards during material selection guarantees that the chosen substrate meets quality and durability expectations. Engineers must reference these documents to validate their choices and maintain consistency across manufacturing processes.

Evaluating Long-Term Reliability

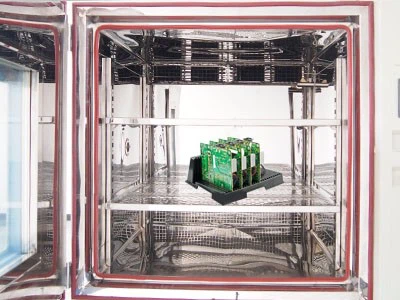

Beyond initial performance, long-term reliability is a critical consideration. Materials must withstand repeated thermal cycles, humidity, and mechanical stress without degrading. Testing for properties like glass transition temperature helps predict how a material will behave over time under operational stress. Incorporating safety margins during selection prevents premature failures, especially in mission-critical applications. Software simulations can aid in assessing durability by modeling aging effects and environmental impacts on material behavior.

Challenges in PCB Material Selection

Material selection is not without its complexities. Balancing electrical, thermal, and mechanical properties often involves trade-offs. For instance, materials with excellent thermal conductivity might have a higher dielectric constant, which is undesirable for high-frequency applications. Additionally, cost constraints can limit access to advanced high-frequency materials, forcing engineers to compromise on performance. Environmental regulations also play a role, as some materials may contain restricted substances. Navigating these challenges requires a deep understanding of material science and the ability to leverage software tools for accurate analysis.

Conclusion

Effective PCB material selection is a cornerstone of high-performing and reliable electronic designs. By carefully evaluating parameters like dielectric constant, loss tangent, thermal conductivity, and glass transition temperature, engineers can tailor their choices to specific application needs. High-frequency materials further enhance capabilities for cutting-edge technologies, while adherence to industry standards ensures quality and consistency. With the integration of advanced software tools, the process becomes more precise, allowing for simulations that predict performance and mitigate risks. Ultimately, a strategic approach to material selection empowers designers to create robust PCBs that meet the demands of modern electronics.

FAQs

Q1: What factors influence PCB material selection for high-frequency applications?

A1: For high-frequency applications, key factors in PCB material selection include dielectric constant and loss tangent. A low dielectric constant ensures faster signal propagation, while a low loss tangent minimizes signal loss. Thermal conductivity and mechanical stability also matter to handle operational stresses. Engineers must balance these properties to achieve optimal performance without compromising reliability.

Q2: How does glass transition temperature impact PCB reliability?

A2: Glass transition temperature, or Tg, determines a material's thermal stability in PCBs. A higher Tg prevents softening or deformation during high-temperature processes like soldering. This property is crucial for maintaining structural integrity in harsh environments. Selecting a material with an appropriate Tg ensures the board withstands thermal stress, enhancing long-term reliability.

Q3: Why is thermal conductivity important in PCB design?

A3: Thermal conductivity is vital in PCB design as it governs heat dissipation from components. High thermal conductivity materials prevent overheating, protecting sensitive parts and extending lifespan. This is especially critical in power-intensive applications. Proper heat management through material selection ensures stable operation and reduces the risk of thermal failures.

Q4: How do software tools assist with selecting high-frequency materials?

A4: Software tools aid in selecting high-frequency materials by simulating electrical and thermal performance. They analyze parameters like dielectric constant and loss tangent to predict signal behavior. These platforms help engineers compare materials and identify optimal choices before prototyping. This reduces errors and accelerates the design process for advanced applications.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

ISO 9001:2015 — Quality Management Systems. ISO, 2015.