What Is ENIG and Why Is It Used in High-Frequency PCB Manufacturing?

Electroless Nickel Immersion Gold (ENIG) is a common surface finish applied to Printed Circuit Boards (PCBs). Its primary purpose is to safeguard the exposed copper traces from oxidation and to facilitate reliable soldering of components. This finish comprises a thin layer of gold deposited over a nickel barrier layer. It offers outstanding corrosion resistance and presents a uniformly flat, smooth surface, which are critical attributes for many electronic applications.

In the realm of high-frequency electronics, where signals can range from hundreds of megahertz to several gigahertz, maintaining signal integrity is paramount. Any degradation or interference can severely impact device performance, leading to data corruption or reduced operational efficiency. ENIG is frequently chosen for these demanding applications, including high frequency PCB, aerospace, and advanced wireless devices, largely due to its capacity to provide a consistent surface for precise impedance control and its compatibility with fine-pitch components.

How Does ENIG Affect High-Frequency Signal Performance?

The Role of Materials and Skin Effect

High-frequency signals behave uniquely compared to their lower-frequency counterparts. A key phenomenon at these frequencies is the "skin effect," where electrical current tends to flow predominantly along the surface of a conductor rather than through its entire cross-section. This means that the surface finish of a PCB, such as ENIG, directly influences how signals transmit. The performance of ENIG in high-frequency scenarios is inherently tied to the materials within its composition.

The nickel layer, which acts as a crucial barrier protecting the underlying copper, possesses higher resistivity than either copper or gold. This characteristic can contribute to increased signal loss as frequencies rise due to the skin effect. Industry analysis indicates that at frequencies above 1 GHz, the nickel in ENIG can cause measurable signal attenuation, potentially adding 0.1 to 0.2 dB of loss per inch in certain designs, depending on trace geometry and specific frequency. The very thin gold layer (typically 2-5 microinches) partially counteracts these losses by offering a low-resistance outer surface. The manufacturing challenge lies in carefully balancing the thickness of both the nickel and gold layers to optimize high-frequency performance while preserving durability and solderability.

Understanding Insertion Loss in ENIG Designs

Signal loss in high-frequency PCBs encompasses various forms, with insertion loss being particularly significant for RF applications. Insertion loss quantifies the reduction in signal power as it propagates through PCB traces, typically resulting from resistive losses, dielectric losses within the board material, and surface roughness of the conductors. For RF PCBs, minimizing this power reduction is essential for maintaining signal strength across longer traces or at elevated frequencies.

The nickel layer in ENIG can contribute to insertion loss due to its magnetic properties and higher electrical resistance. This effect becomes more pronounced above 5 GHz, where it can potentially lead to insertion loss values of 0.5 dB or more per inch on standard 50-ohm impedance traces. However, it's worth noting that ENIG provides a smoother surface compared to finishes like Hot Air Solder Leveling (HASL), which helps mitigate conductor losses caused by surface roughness—a critical factor in high-frequency designs. For perspective, an RF PCB operating at 10 GHz might experience a 10-20% increase in insertion loss with ENIG compared to a bare copper finish or other ultra-low-loss alternatives. This trade-off must be weighed against ENIG's distinct advantages, such as its exceptional flatness for fine-pitch component soldering and its long-term reliability.

How Does ENIG Facilitate Impedance Control for RF Boards?

Impedance control is a foundational element in high-frequency PCB design. Inconsistent impedance can cause signal reflections, leading to data corruption and a decline in overall performance. For RF PCBs, maintaining a stable characteristic impedance—commonly 50 ohms—is vital for efficient signal transmission without distortion.

ENIG supports precise impedance control by presenting a highly uniform surface. This uniformity minimizes variations in trace dimensions during the manufacturing process. The smooth gold layer ensures that etching procedures yield accurate trace widths and spacing, which are critical parameters for achieving target impedance values. For instance, a 50-ohm microstrip line built on a high-frequency laminate with an ENIG finish can typically maintain impedance tolerances within ±5%, meeting stringent industry standards such as IPC-2221. However, designers must factor in the dielectric properties of the PCB substrate material and the slight additional thickness from the ENIG layers when calculating impedance. Utilizing advanced electromagnetic simulation tools is highly recommended to accurately model these subtle effects, particularly for frequencies exceeding 1 GHz where even minor deviations can trigger substantial signal reflections.

When Is ENIG the Preferred Choice for RF PCB Applications?

Despite some inherent challenges related to signal and insertion loss at very high frequencies, ENIG remains a favored surface finish for RF PCBs in numerous applications. Its selection is often driven by a combination of factors:

● Reliability: ENIG effectively shields copper traces from oxidation, ensuring consistent long-term performance even in harsh operating environments, such as those found in aerospace or automotive systems.

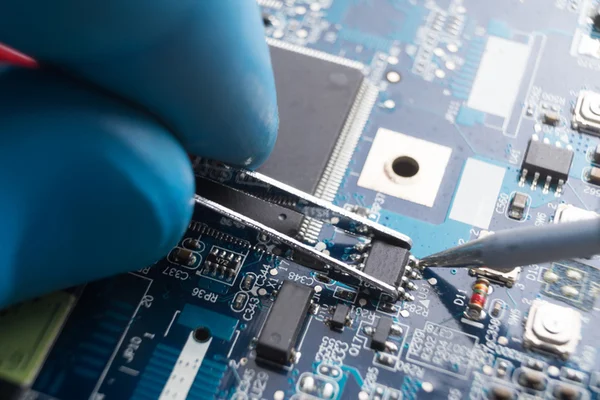

● Solderability: The gold outer layer provides excellent wettability, which is essential for achieving strong, reliable solder joints, particularly when assembling high-density RF components.

● Surface Flatness: The inherently smooth finish of ENIG is ideal for components with fine pitches and for maintaining the precise impedance control critical in high-frequency designs.

● Material Compatibility: ENIG is compatible with a wide array of high-frequency laminate materials, including PTFE-based substrates, often chosen for RF PCBs due to their low dielectric constants (e.g., Dk values between 2.2 and 3.5).

For applications operating below approximately 5 GHz, ENIG frequently offers an optimal balance of performance, circuit board cost, and durability. For designs targeting significantly higher frequencies, designers might explore alternative finishes or integrate ENIG with ultra-low-loss substrate materials to achieve the desired performance metrics.

Strategies to Mitigate Signal Loss with ENIG in High-Frequency Designs

While ENIG possesses certain limitations at very high frequencies, several design and manufacturing strategies can effectively minimize both signal and insertion loss:

● Precise Layer Thickness Control: Collaborate closely with your PCB manufacturer to tightly control the thickness of both the nickel and gold layers. A thinner nickel layer (e.g., 100-150 microinches) can reduce resistive losses while still providing adequate protection.

● Selection of Low-Loss Substrates: Pair ENIG with high-performance laminates that feature very low dissipation factors (Df typically below 0.002). This minimizes dielectric losses, which otherwise compound with conductor losses at higher frequencies.

● Minimize Trace Lengths: In RF layouts, keep signal trace lengths as short as possible to reduce the cumulative impact of insertion loss. For example, a 1-inch trace with ENIG at 10 GHz might contribute 0.5 dB of loss, whereas a 3-inch trace could triple that amount.

● Smooth Copper Foils: Opt for PCB base materials that utilize low-profile or ultra-smooth copper foils. This reduces losses caused by surface roughness, an effect that is significantly amplified at high frequencies, even with ENIG's relatively smooth finish.

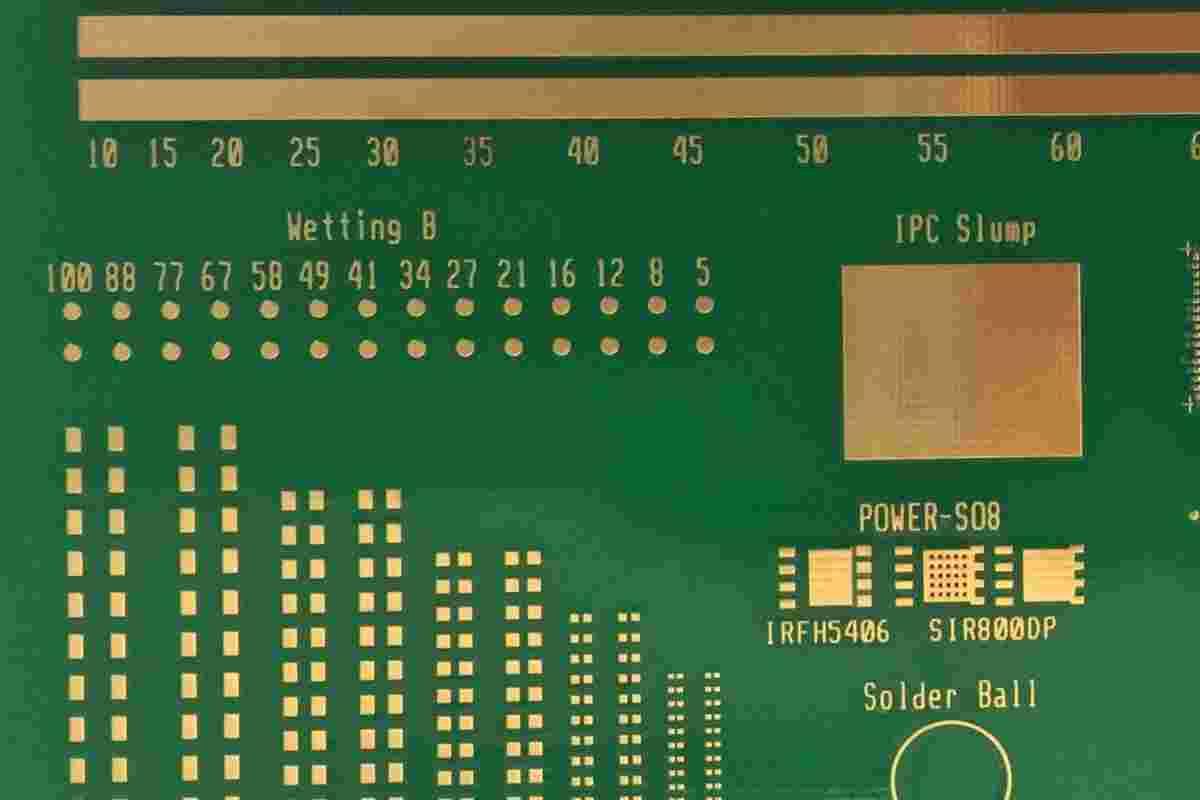

● Extensive Simulation and Testing: Employ electromagnetic simulation software to accurately model ENIG's influence on signal integrity. Validate your designs with test coupons, adhering to standards like IPC-TM-650, to confirm predicted impedance and loss characteristics.

How Does ENIG Compare to Other Surface Finishes in RF Applications?

To fully appreciate ENIG's position in high-frequency circuit boards, it's beneficial to compare it against other common PCB surface finishes:

● Immersion Silver (ImAg): Generally offers lower insertion loss than ENIG at high frequencies (often 5-10% less at 10 GHz) due to the absence of a high-resistivity nickel layer. However, Immersion Silver is more susceptible to tarnishing and might not be as suitable for long-term reliability in humid or challenging environments.

● Immersion Tin (ImSn): Provides good solderability but typically has higher resistive losses and is less durable than ENIG, making it a less optimal choice for demanding RF PCBs.

● Bare Copper with Organic Solderability Preservative (OSP): Can achieve the lowest signal loss among common finishes as it's essentially pure copper. However, OSP lacks the robust solderability and long-term protection of ENIG, often requiring more delicate handling and additional processing steps.

ENIG frequently serves as a balanced solution, effectively bridging performance, reliability, and cost considerations for a broad range of high-frequency projects. For extremely high-frequency designs (exceeding 20 GHz), specialized finishes or hybrid material and finish approaches might become necessary to satisfy stringent signal loss requirements.

Real-World Applications Leveraging ENIG in High-Frequency Designs

ENIG's versatility has led to its widespread adoption across various high-frequency applications:

● 5G Telecommunications: Base stations and antenna systems, often operating in the 3-5 GHz range, benefit from ENIG's precise impedance control and robust reliability, ensuring stable signal transmission over extended periods.

● Automotive Radar Systems: Vehicle radar units, frequently operating at 24 GHz or 77 GHz, utilize ENIG for its durability in harsh automotive conditions. In these cases, the selection of ultra-low-loss substrate materials is critical to counteract any insertion loss from the ENIG.

● Wireless Consumer Devices: Everyday electronics such as Wi-Fi routers (operating at 2.4 GHz and 5 GHz bands) often employ ENIG for cost-effective HDI PCB assembly, achieving acceptable signal performance for consumer-grade applications.

In each of these examples, designers must carefully tailor their approach, leveraging ENIG's strengths while strategically addressing its limitations to meet the specific frequency and loss requirements of the target application.

Concluding Thoughts: Is ENIG the Right Choice for Your High-Frequency PCB?

ENIG presents a compelling combination of reliability, excellent solderability, and consistent impedance control, positioning it as a strong candidate for many high-frequency applications, including RF PCBs. While inherent challenges such as elevated signal loss and insertion loss exist—particularly as frequencies climb above 5 GHz—these issues can frequently be mitigated through meticulous design practices, judicious material selection, and optimized manufacturing processes.

For engineers involved in high-frequency projects, a thorough understanding of ENIG's performance characteristics is crucial for making informed decisions. By effectively leveraging the benefits of ENIG and strategically addressing its limitations with the methodologies outlined in this discussion, designers can ensure robust signal integrity and achieve optimal results in their circuit board designs. Whether you are developing advanced 5G antenna arrays or compact wireless communication modules, ENIG can prove to be a dependable partner when integrated thoughtfully into your design process.