Why Is Audio Amplifier PCB Prototyping Essential?

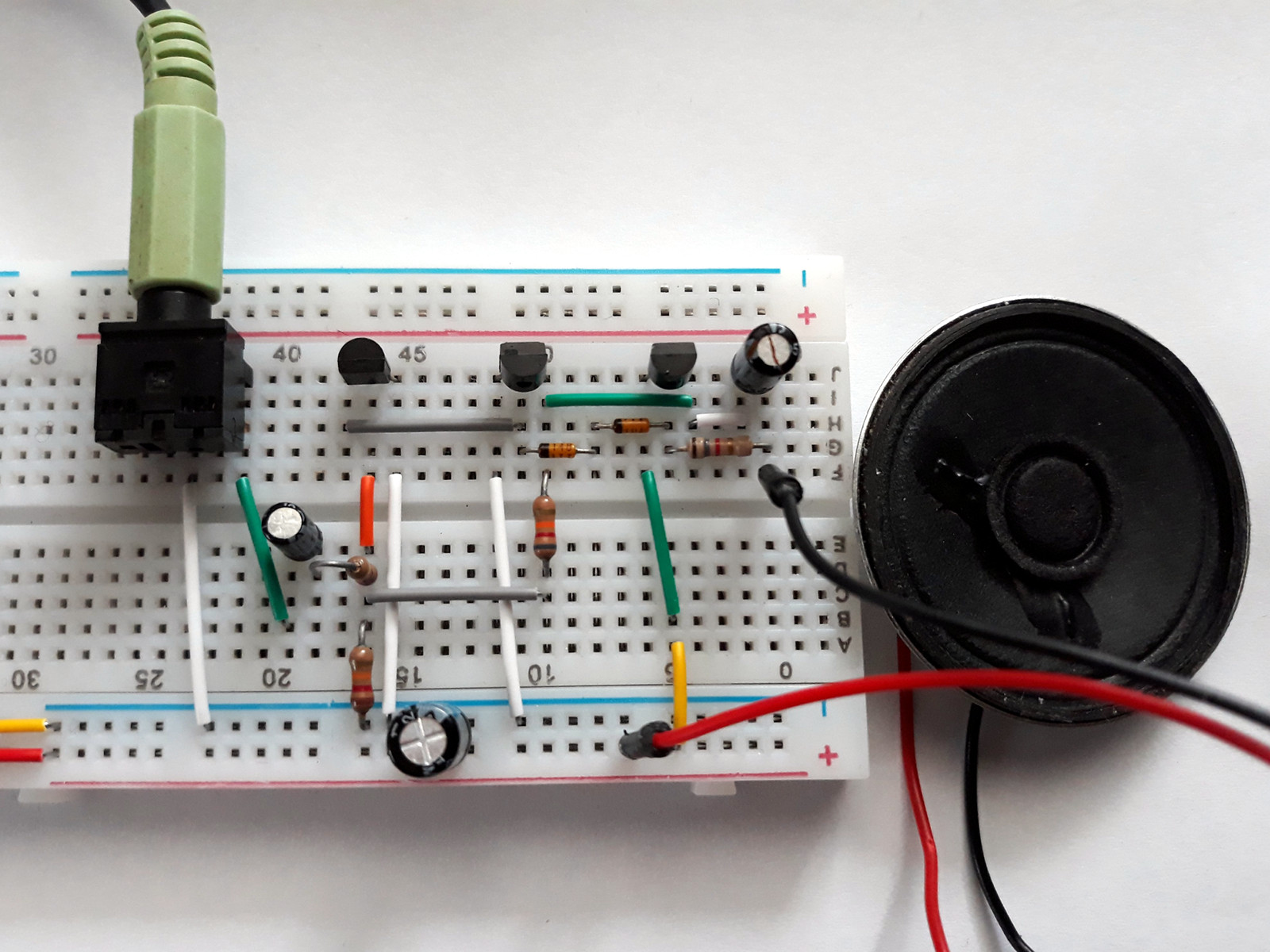

Audio amplifiers form the core of sound systems, responsible for boosting low-power audio signals to drive speakers with clarity and power. Prototyping these intricate circuits on a printed circuit board (PCB) is a foundational step in validating and refining designs before committing to full-scale production. A meticulously executed prototype serves as a crucial diagnostic tool, helping to pinpoint potential issues such as noise interference, signal distortion, or thermal inefficiencies early in the development cycle, thereby saving significant time and resources down the line.

For engineers engaged in audio projects, the dual requirements of speed and accuracy in prototyping are non-negotiable. Given the often-tight project timelines and the necessity for multiple design iterations, strategically utilizing quick-turn PCB services and employing efficient design methodologies can dramatically influence project success. This guide explores the most effective practices for audio amplifier PCB prototyping and illustrates how online PCB services can significantly accelerate the development process.

Unique Challenges in Audio Amplifier Prototyping

Before diving into solutions, it's important to understand the specific hurdles inherent in prototyping audio amplifier PCBs. These challenges frequently dictate the choice of fabrication and assembly methods and tools.

● Signal Integrity: Audio amplifiers demand pristine signal paths to prevent unwanted noise and distortion. A poorly conceived PCB layout can easily introduce interference, particularly at higher frequencies (e.g., above 20 kHz, which, while beyond human hearing, can still impact perceived sound quality).

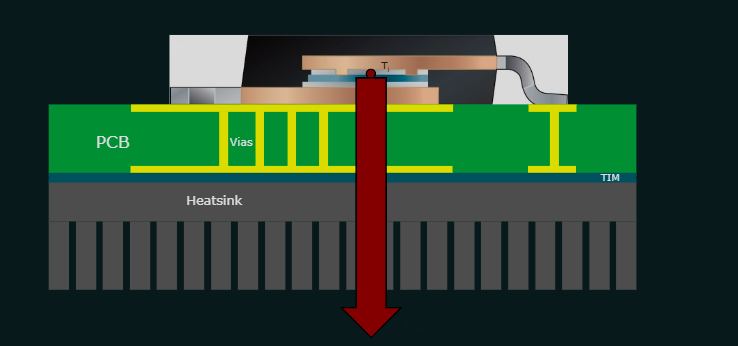

● Thermal Management: Amplifiers generate considerable heat, especially in high-power configurations. Inadequate heat dissipation can lead to the premature failure of critical components, such as power transistors, resulting in a prototype that does not accurately reflect real-world performance.

● Component Placement: The physical arrangement of components critically affects both signal flow and noise levels. For instance, placing input coupling capacitors too far from the amplifier IC can increase impedance, thereby degrading overall audio quality.

● Time Constraints: Many development projects operate under intense pressure for rapid iterations to thoroughly test various design approaches, making quick-turn PCB fabrication an absolute necessity.

Overcoming these challenges requires a synergy of intelligent design practices and dependable fabrication services. Let’s explore the most effective strategies for achieving fast and efficient audio amplifier PCB prototype manufacturing.

Related Reading: Enhancing Audio Quality: An Electrical Engineer's Guide to DSP Noise Cancellation

Optimizing Your Design for Rapid Prototyping

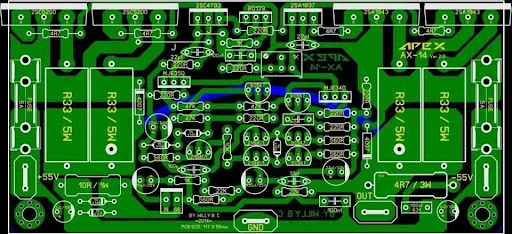

The cornerstone of a successful prototype lies in a meticulously conceived design. By tailoring your PCB layout specifically for audio amplifier characteristics, you can effectively minimize errors and significantly expedite the testing and validation phases.

Layout Focused on Signal Quality

In audio amplifier designs, the PCB layout plays an overwhelmingly significant role in determining final performance. It is crucial to keep signal paths as short as possible to minimize parasitic resistance and inductance. For example, ensuring a robust and continuous ground plane is essential to prevent ground loops, which are a common source of audible humming noise at power line frequencies (typically 50-60 Hz). If your design incorporates both analog and digital sections, it is imperative to segregate them to prevent digital switching noise from contaminating sensitive analog audio signals.

Related Reading: Enhancing USB Performance: A Guide to Optimal PCB Layout and Signal Integrity

Designing for Thermal Efficiency

High-power audio amplifiers frequently handle currents ranging from 1 to 5 amperes or even higher, leading to substantial heat generation. To manage this, employ wider traces (e.g., 20-30 mils for power lines) to ensure they can safely conduct high currents without excessive heating. Strategically place heat sinks or integrate thermal vias near power-dissipating components to facilitate effective heat transfer away from sensitive areas. Utilizing thermal simulation tools can help predict potential hot spots before fabrication, ensuring your prototype does not fail prematurely due to thermal issues.

Leveraging Standard Components

For accelerated prototyping, prioritize the use of readily available components with standard footprints. This approach significantly reduces potential delays in sourcing parts during the prototype assembly phase. For example, opting for common resistor values such as 1kΩ or 10kΩ and standard capacitor packages (e.g., 0805 or 1206) ensures that you can quickly populate your board without procurement bottlenecks.

Expediting Fabrication with Quick-Turn PCB Services

Once your design is finalized, the next crucial step is to get the PCB fabricated as swiftly as possible. Quick-turn PCB services are specifically engineered to meet demanding deadlines, often delivering bare boards within 24 to 48 hours following file submission.

What Defines Quick-Turn PCB Fabrication?

Quick-turn PCB fabrication refers to expedited manufacturing processes that prioritize speed without compromising the quality of the end product. These services are ideally suited for engineers who need to test multiple iterations of an audio amplifier design within a compressed timeframe. By selecting a reputable provider, you can receive bare boards, ready for assembly, in record time, allowing you to dedicate more effort to the critical testing and refinement stages.

Advantages for Audio Amplifier Projects

For audio amplifier prototyping, quick-turn services offer several distinct benefits. Firstly, they drastically reduce downtime between design iterations, enabling faster testing and fine-tuning of your circuit. Secondly, many providers implement stringent quality control measures, such as automated optical inspection (AOI), to verify that your board adheres to all design specifications—a critical aspect for maintaining signal integrity in demanding audio applications. Finally, expedited global shipping options ensure that your boards can be delivered anywhere in the world within a few days.

AIVON specializes in delivering rapid fabrication solutions precisely tailored to your project’s needs, ensuring that your audio amplifier prototypes are available exactly when required. Our streamlined processes and rigorous testing protocols guarantee high-quality boards, even under the tightest production schedules

Streamlining Prototyping with Online PCB Services

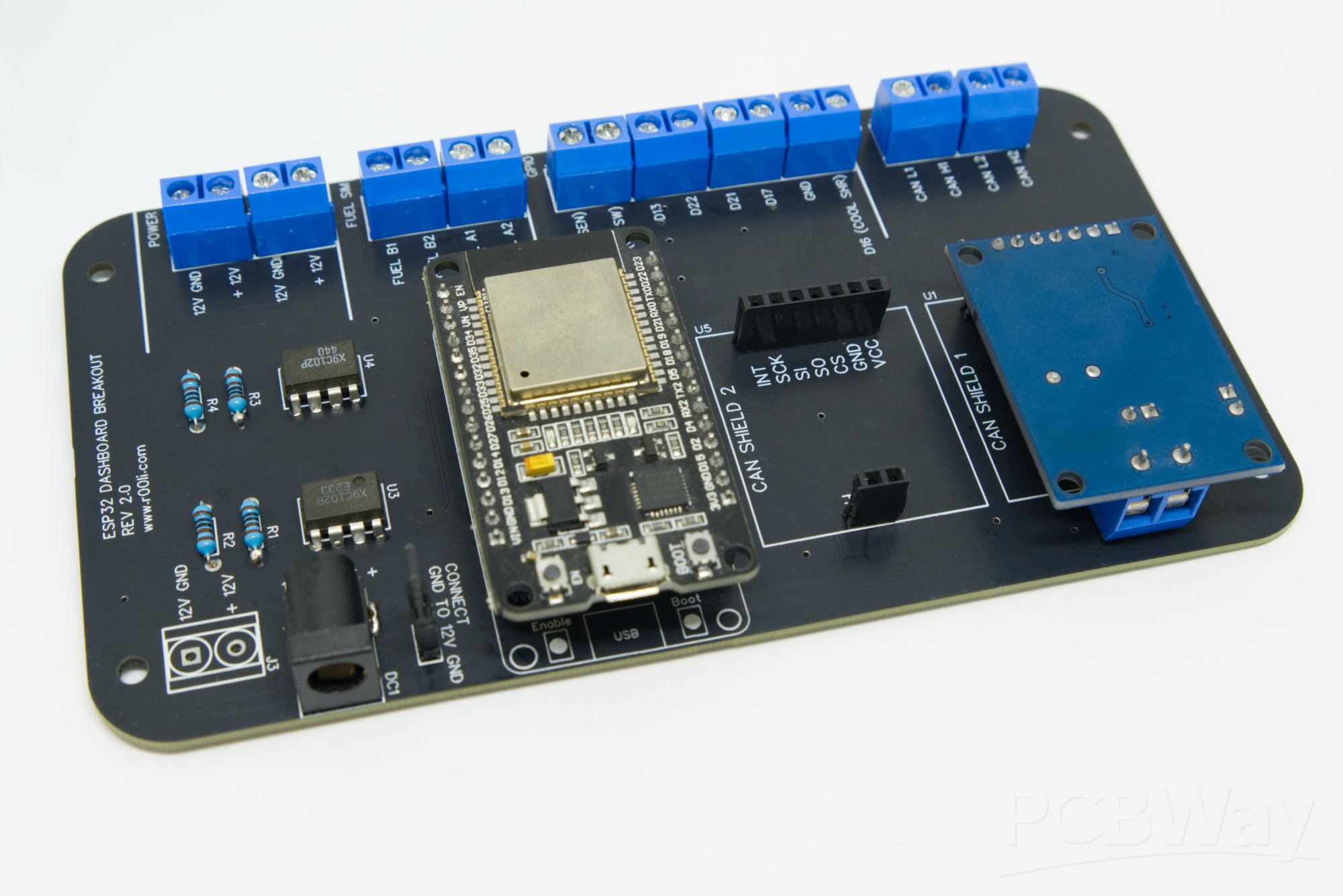

Online PCB services have fundamentally transformed the approach engineers take to prototyping. These platforms empower you to upload design files, customize manufacturing specifications, and order PCBs from virtually anywhere globally—all with just a few intuitive clicks.

The Value of Online PCB Platforms

Online PCB services offer a compelling blend of convenience and efficiency. You can instantaneously receive quotes based on your design parameters, such as desired board thickness (with 1.6mm being a common choice for standard audio PCBs) or the number of layers (typically 2-4 layers for amplifier circuits). Many platforms also integrate automated design rule checks (DRC) to flag potential errors, such as insufficient trace spacing (e.g., below 6 mils), before the fabrication process even begins.

Enhancing Audio Amplifier Prototyping

For audio amplifier projects, online services are particularly advantageous because they frequently support small-batch orders. This is perfect for testing a limited number of prototypes without the commitment to large-scale production runs. Furthermore, some platforms offer integrated assembly services, allowing you to have components soldered onto your boards, which saves considerable time on manual assembly.

With AIVON’s online platform, you can effortlessly upload your Gerber files, select quick-turn manufacturing options, and monitor your order’s progress in real time. Our user-friendly interface ensures that even intricate audio amplifier designs are handled with precision and delivered promptly.

Accelerating the Prototype Assembly Phase

Once your fabricated PCB arrives, the assembly process represents the final step in creating a fully functional audio amplifier prototype. Employing efficient assembly methods can significantly reduce lead times and enhance the accuracy of subsequent testing.

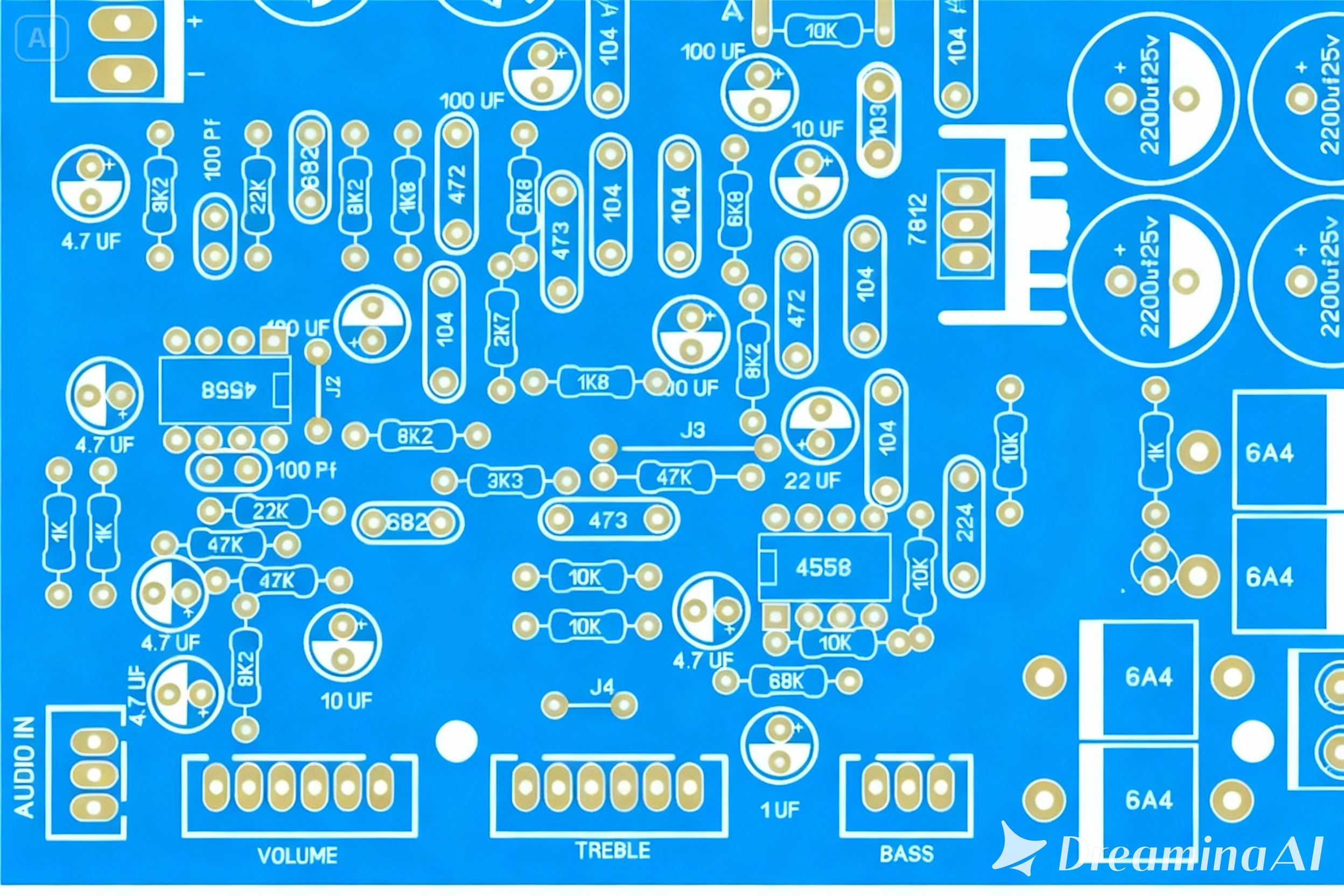

Pre-Assembly Preparation

Before your bare boards even arrive, gather all necessary components and required tools. Create a comprehensive Bill of Materials (BOM) listing every single part, from resistors to integrated circuits like operational amplifiers (op-amps). Double-check that all component values precisely match your design specifications—for example, confirm that coupling capacitors are rated for the correct voltage (e.g., 16V or higher for typical audio circuits) to prevent premature failure under load.

Considering Automated Assembly

For complex audio amplifier designs laden with numerous surface-mount components, manual soldering can introduce errors such as cold joints or misalignments. Automated prototype assembly services leverage pick-and-place machines to position components with exceptional accuracy, accommodating even fine-pitch ICs with pitches down to 0.4mm. This precision is especially crucial for preserving signal integrity in audio circuits, where even minor deviations can contribute to audible noise.

Immediate Post-Assembly Testing

Immediately after assembly, subject your prototype to rigorous testing under realistic operating conditions. Utilize an oscilloscope to check for any signal distortion across the entire audio frequency range (e.g., 20 Hz to 20 kHz, the full audible spectrum). Measure the output power to ensure it aligns with your design objectives—for instance, a Class AB amplifier might aim for 10W into an 8-ohm speaker load. Early and comprehensive testing helps in quickly identifying issues like incorrect component placement or soldering defects before proceeding to the next design iteration.

AIVON offers integrated assembly solutions that perfectly complement our fabrication services, ensuring your audio amplifier prototypes are built with unparalleled precision and are ready for immediate, thorough testing.

Additional Strategies for Faster and More Efficient Prototyping

Beyond these core methods, several supplementary tips can further streamline your audio amplifier PCB prototyping process:

● Initial Simulation: Begin your project by simulating your circuit using specialized software before initiating fabrication. Simulation tools can effectively model signal behavior and thermal performance, significantly reducing the probability of costly design flaws later on.

● Order Additional Boards: When utilizing quick-turn PCB services, it's a wise practice to order a few extra boards (e.g., 5-10 units). This provides a buffer against potential assembly errors or allows for parallel testing if needed.

● Comprehensive Documentation: Maintain meticulous records for each prototype iteration, including detailed test results, observed behaviors, and any design modifications made. This disciplined approach aids in tracking progress and prevents the recurrence of past mistakes.

● Expert Collaboration: If you are new to the intricacies of audio amplifier design, actively seek advice from experienced engineers or leverage online forums and communities for insights on optimal layout strategies and component selection.

Conclusion: Accelerating Your Audio Projects with AIVON

Audio amplifier PCB prototyping does not need to be a protracted or frustrating endeavor. By strategically optimizing your design for superior signal quality and effective thermal management, capitalizing on quick-turn PCB fabrication services, utilizing convenient online PCB platforms, and streamlining the prototype assembly process, you can bring your innovative audio concepts to fruition faster than ever before. Every stage, from the initial layout design to the final rigorous testing, plays a pivotal role in ensuring that your amplifier performs precisely as intended—whether its ultimate application is for a home audio system, professional sound equipment, or a portable device.

At AIVON, we are deeply committed to supporting engineers and innovators by providing rapid, dependable, and premium-quality PCB solutions. Our quick-turn services, intuitive online platform, and comprehensive assembly options are meticulously designed to meet the unique and demanding requirements of audio amplifier prototyping. Are you ready to embark on your next project? Upload your design today and experience the unparalleled speed and efficiency that distinguish our services.

Equipped with these refined methods and practical tips, you are now exceptionally well-prepared to confidently tackle audio amplifier PCB prototyping. Continue to iterate, continue to test, and observe as your audio designs materialize with precision and remarkable speed.