Introduction

Flexible printed circuit boards (FPCs or flex PCBs) are integral to modern electronics, enabling compact, lightweight, and adaptable designs in industries like aerospace, medical, and consumer electronics. For electrical engineers, understanding the cost dynamics of flexible PCB design is crucial to balancing performance with budget constraints. This article explores the key pricing factors, including flexible PCB cost drivers, material choices, and manufacturing processes. It also provides actionable insights on reducing flexible PCB costs and optimizing flex PCB design for cost efficiency. By addressing prototype flex PCB cost and broader production expenses, engineers can make informed decisions to enhance project outcomes while maintaining quality and reliability in accordance with industry standards.

What Are Flexible PCBs and Why Do Costs Matter

Flexible PCBs are thin, lightweight circuits made from flexible substrates, allowing them to bend and conform to complex shapes. Unlike rigid boards, they offer unique advantages in space constrained applications, such as wearable devices and automotive systems. Their ability to reduce weight and improve reliability in dynamic environments makes them indispensable in high tech sectors. However, the specialized materials and manufacturing processes involved often result in higher costs compared to traditional rigid boards. For electrical engineers, managing flex PCB material costs and manufacturing expenses is vital to project feasibility. High costs can impact prototype development and mass production, making it essential to identify flexible PCB cost drivers and implement cost saving strategies without compromising performance.

Key Flexible PCB Cost Drivers

Several factors influence the overall cost of flexible PCBs, spanning design complexity, material selection, and production techniques. Understanding these drivers helps engineers anticipate expenses and refine designs for affordability.

Material Selection and Flex PCB Material Costs

The choice of substrate and conductive materials significantly affects pricing. Polyimide is a common substrate for flex PCBs due to its thermal stability and flexibility, but it is more expensive than rigid board materials like FR4. Adhesive layers, coverlays, and copper thickness also contribute to material expenses. Thinner copper layers may reduce costs but can impact conductivity and durability in high current applications. Engineers must balance material properties with budget constraints to avoid unnecessary expenses while meeting performance requirements.

Suggested Reading: PCB Material Costs: Choosing the Right Substrate to Balance Performance and Price

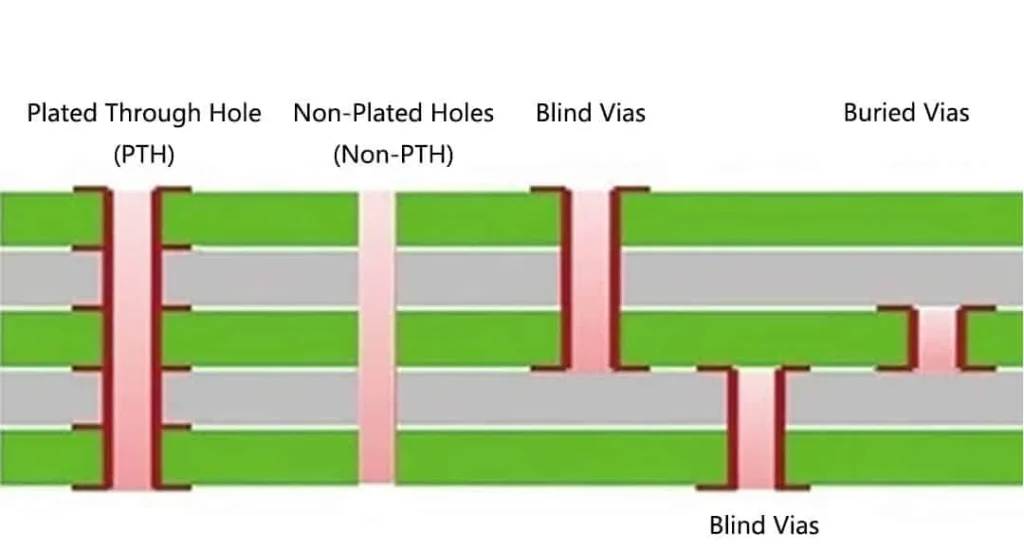

Layer Count and Design Complexity

The number of layers in a flex PCB directly correlates with cost. Single layer designs are the most affordable, while multilayer configurations increase expenses due to additional materials and processing steps. Complex designs with tight tolerances, intricate routing, or high density interconnects further elevate costs by requiring precision manufacturing. Simplifying layer count and avoiding overengineering during the design phase can help manage expenses without sacrificing functionality.

Panel Utilization and Size

The physical size of a flex PCB and how efficiently it utilizes manufacturing panels impact pricing. Larger boards or poor nesting (arranging multiple designs on a panel) lead to material waste, increasing costs. Standard panel sizes vary by region, often requiring custom setups for non standard dimensions, which add to expenses. Optimizing layout for maximum panel utilization is a practical step to lower per unit costs during production.

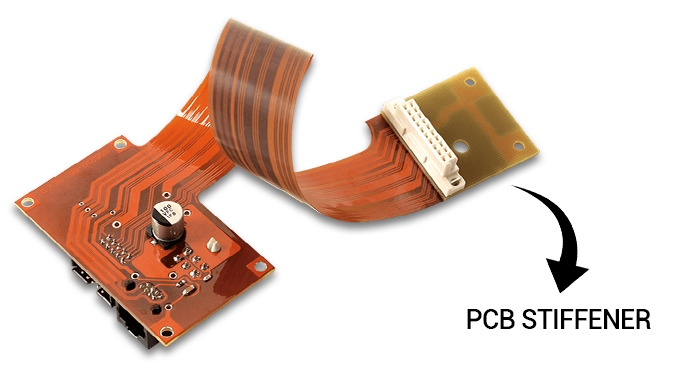

Stiffeners and Additional Features

Stiffeners, used to provide structural support in specific areas of a flex PCB, add to material and labor costs. Additional features like shielding, specialized surface finishes, or custom cutouts also contribute to higher pricing. While these elements may be necessary for certain applications, minimizing their use or selecting cost effective alternatives can help control expenses.

Suggested Reading: PCB Cost Calculator: How PCB and Assembly Pricing Is Estimated

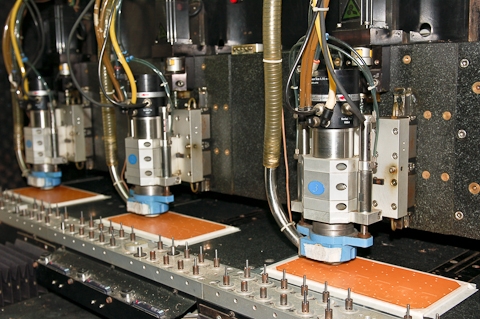

Flex PCB Manufacturing Costs

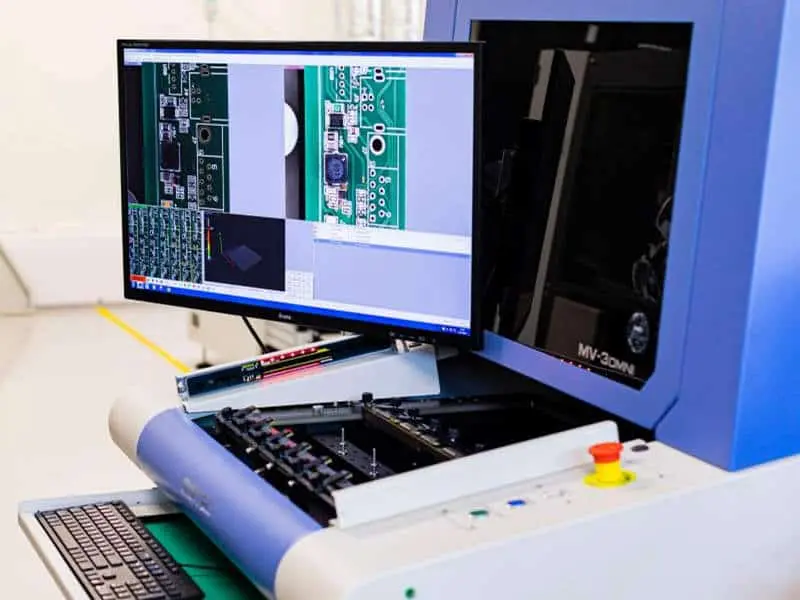

Manufacturing processes for flexible PCBs are inherently more complex than for rigid boards, leading to elevated costs. Key aspects of production that drive expenses include fabrication techniques, equipment requirements, and quality control measures.

Fabrication Challenges

Flex PCBs require specialized equipment for lamination, etching, and drilling due to their thin, pliable nature. These processes demand precision to avoid defects like delamination or tearing, increasing labor and machine time. Compliance with standards such as IPC 6013D, which governs flexible printed board performance, often necessitates additional testing and inspection steps, further adding to costs.

Surface Finishes and Treatments

Surface finishes protect conductive traces and ensure solderability, but they vary widely in cost. Options like immersion gold provide excellent reliability for high end applications but are more expensive than alternatives like organic solderability preservatives. Selecting a finish that meets application needs without exceeding budget is a critical decision during design.

Volume and Scale of Production

Production volume plays a significant role in determining per unit cost. Low volume runs, such as those for prototype flex PCB cost, are expensive due to setup fees and lack of economies of scale. Conversely, high volume production spreads fixed costs across more units, reducing individual expenses. Engineers should consider long term production goals when budgeting for initial prototypes.

Prototype Flex PCB Cost Considerations

Prototyping is a critical phase in flex PCB development, allowing engineers to test designs before full scale production. However, prototype flex PCB cost can be disproportionately high due to several factors. Small batch sizes mean setup costs are not amortized over many units. Custom tooling or non standard materials often required for prototypes further increase expenses. Additionally, rapid turnaround times for prototyping can incur premium charges. To manage costs, engineers can prioritize simpler designs for initial testing and consolidate multiple iterations into a single batch when possible.

Strategies for Reducing Flexible PCB Costs

Reducing flexible PCB costs requires a combination of thoughtful design practices and strategic manufacturing decisions. Below are actionable approaches to achieve cost savings while maintaining quality.

Optimizing Flex PCB Design for Cost

Design optimization is the foundation of cost reduction. Minimize layer count by simplifying circuitry where feasible. Avoid tight tolerances unless absolutely necessary, as they demand precision manufacturing and increase expenses. Use standard panel sizes to improve nesting efficiency and reduce material waste. Additionally, limit the use of stiffeners and specialized features to only critical areas of the board.

Material Selection for Cost Efficiency

Choosing cost effective materials without compromising reliability is essential. Evaluate substrate options based on thermal and mechanical requirements rather than defaulting to premium choices. Consider thinner copper layers for non critical applications to save on material expenses. Consulting industry standards like IPC 2223D for flexible circuit design can guide material choices that balance cost and performance.

Partnering with Manufacturing Experts Early

Engaging with manufacturing teams during the design phase helps identify potential cost drivers before production begins. Design for manufacturability principles, such as aligning with standard processes and minimizing custom requirements, can significantly lower expenses. Early collaboration ensures designs are practical and aligned with production capabilities, avoiding costly redesigns.

Scaling Production for Economies

Planning for higher volume production from the outset can reduce per unit costs. While initial prototype runs are expensive, transitioning to larger batches after validation spreads fixed costs over more units. Engineers should forecast demand and consider phased production to balance upfront expenses with long term savings.

Suggested Reading: Ways to Reduce PCB Manufacturing Costs

Practical Insight: Balancing Cost and Performance

For electrical engineers, the challenge lies in achieving optimal performance within budget limits. A practical approach is to prioritize critical requirements, such as signal integrity or thermal management, while scaling back on non essential features. For instance, using a hybrid design combining rigid and flexible sections may offer cost savings over a fully flexible board in some applications. Iterative testing during prototyping also helps identify overdesigned elements that can be simplified. By focusing on standards like IPC A 600K for acceptability criteria, engineers can ensure quality without unnecessary cost escalation.

Conclusion

Understanding the cost of flexible PCB design requires a comprehensive view of flexible PCB cost drivers, from material selection to manufacturing processes. Flex PCB material costs, design complexity, and production volume all play significant roles in determining expenses. By focusing on optimizing flex PCB design for cost and implementing strategies for reducing flexible PCB costs, electrical engineers can achieve efficient, high quality designs. Addressing prototype flex PCB cost through simplified initial designs and strategic planning further supports project success. With careful consideration of flex PCB manufacturing costs and adherence to industry standards, cost effective innovation becomes achievable in even the most demanding applications.

FAQs

Q1: What are the main flexible PCB cost drivers for engineers to consider?

A1: Flexible PCB cost drivers include material selection, layer count, design complexity, and manufacturing processes. Substrate choices like polyimide and features such as stiffeners add to expenses. Higher layer counts and intricate designs increase production time and material use. By understanding these factors, engineers can prioritize essential elements and simplify designs to manage costs effectively while meeting performance needs.

Q2: How can I reduce flex PCB manufacturing costs without losing quality?

A2: Reducing flex PCB manufacturing costs involves optimizing design for manufacturability. Use standard panel sizes to minimize waste, limit layer count, and avoid unnecessary features like excessive stiffeners. Select cost effective materials that still meet standards like IPC 6013D for performance. Early collaboration with manufacturing teams can also identify savings opportunities without compromising reliability or functionality.

Q3: What impacts prototype flex PCB cost during development?

A3: Prototype flex PCB cost is influenced by small batch sizes, custom tooling, and rapid turnaround needs. Limited production runs mean setup fees are not spread across many units, increasing per unit expenses. Non standard materials or expedited processing further elevate costs. Simplifying initial designs and batching multiple iterations can help manage expenses during this critical phase.

Q4: How does optimizing flex PCB design for cost improve project outcomes?

A4: Optimizing flex PCB design for cost ensures projects remain within budget while meeting technical requirements. Simplifying layer count, using standard sizes, and minimizing specialized features reduce expenses. This approach allows engineers to allocate resources to critical performance areas, enhancing reliability. Following guidelines like IPC 2223D supports cost efficient designs that maintain quality for successful outcomes.

References

IPC 6013D — Qualification and Performance Specification for Flexible and Rigid Flex Printed Boards. IPC, 2017.

IPC 2223D — Sectional Design Standard for Flexible/Rigid Flex Printed Boards. IPC, 2016.

IPC A 600K — Acceptability of Printed Boards. IPC, 2020.