The Hook & Industry Context

The "Nightmare" Scenario

It's the final stage of a high-stakes product launch. Your AI-integrated medical diagnostic tool—a project involving eighteen months of R&D—is undergoing final reflow soldering. Suddenly, a sickening "pop" echoes through the assembly line. Upon inspection, the once-pristine multilayer boards resemble blistered skin. Probing reveals that internal layers have separated, and critical signal traces are severed.

This isn't just a defect; it's a catastrophic failure that renders the entire batch of expensive components scrap.

Relevance in 2026

In an era of AI Servers and Autonomous Vehicle (EV) Modules, the margin for error is non-existent. As we push the boundaries of High-Density Interconnect (HDI PCB) design, the materials we use must withstand extreme thermal gradients. The culprit behind the "pop" is often a silent one: Hygroscopicity (the tendency of a material to absorb moisture from the air).

Macro-to-Micro Bridge

Think of a PCB like a high-performance sponge. While it looks solid, the epoxy resin in the laminate is porous. At a macro level, this moisture causes the board to swell and lose its "flatness." At a micro level, specifically at the Glass Transition Temperature (Tg) (the point where the resin shifts from rigid to rubbery), trapped water molecules vaporize into high-pressure steam. This internal pressure is what causes the delamination (layer separation) and blistering seen in the field.

Root Cause & Impact Analysis: The Physics of Failure

The transition from a functional board to a "potato chip" or a blistered mess is rarely accidental. It is the result of three converging factors:

The "Why": Design, Material, and Fabrication

Material Limitations (The Resin Factor): Standard PCB FR-4 utilizes epoxy resins that naturally attract water. If the Resin Content (RC%) is too high without proper moisture-barrier properties, the board becomes a liability in humid environments.

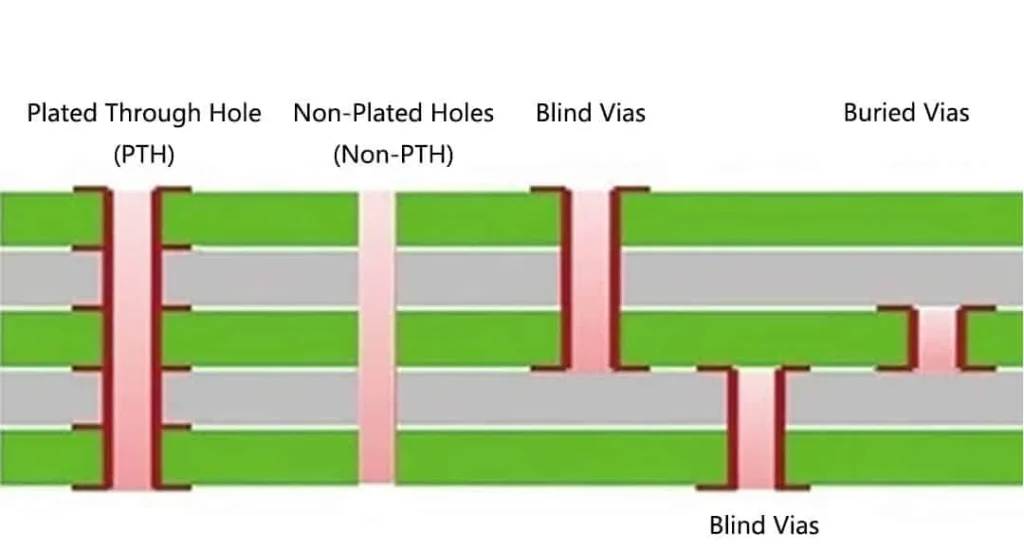

Design Flaws (Symmetry & Voids): Asymmetrical stack-ups create uneven stress during thermal expansion. Furthermore, large areas of copper without "venting" (small holes to let gas escape) trap moisture between layers.

Fabrication Errors (The Baking Gap): Skipping the vacuum drying stage or using atmospheric ovens that don't reach the core of the board leaves residual moisture (volatile content) trapped.

The "Cost" of Neglect

● Signal Loss (dB): Moisture increases the Dielectric Constant (Dk). A board that absorbed 0.5% moisture can see its signal integrity degrade by up to 15%, causing jitter in high-speed AI data lines.

● Thermal Throttling: Delamination creates air gaps. Since air is a poor conductor of heat (0.024 W/m·K), these gaps act as thermal insulators, causing components to overheat and fail.

● CAF Formation: Moisture facilitates Conductive Anodic Filament (CAF) growth—microscopic copper "whiskers" that grow internally, leading to sudden short circuits weeks after the product is in the field.

The AIVON Standard: Strategic Solutions

As a trustworthy online PCB manufacturer, we don't treat "warpage" as a statistical inevitability. We treat it as a manufacturing challenge solved through material science and advanced vacuum technology.

Advanced Fabrication: The Vacuum Drying Edge

While standard factories use traditional convection ovens, AIVON employs Advanced Vacuum Drying Systems.

● Physics of Success: By lowering the ambient pressure in the drying chamber, we reduce the boiling point of water. This allows us to extract moisture at lower temperature(e.g., 90℃ instead of $125℃) , preventing the "artificial aging" of the copper surface while ensuring the core is 100% dry.

● LDI (Laser Direct Imaging): We use LDI to ensure that even if there is a microscopic shift in dimensions due to initial material stabilization, the circuitry is perfectly registered to the actual physical state of the panel.

Proprietary Workflow: The CAM Intervention

Our Computer-Aided Manufacturing (CAM) engineers perform a "Moisture Escape Audit" on every file:

Copper Thieving: We add "thieving" (tiny copper dots) to balance the copper density across the board, ensuring uniform thermal expansion.

Automated Stack-up Validation: Our software calculates the Coefficient of Hygroscopic Expansion (CHE) to ensure the chosen materials won't warp under reflow.

Case Study: The "Everglades" IoT Project

● Before AIVON: A client's outdoor sensors had a 22% failure rate due to delamination in high-humidity environments. Standard FR-4 was absorbing moisture, which then "exploded" during field repairs (hand-soldering).

● The AIVON Intervention: We transitioned the design to a Low-Hygroscopicity Halogen-Free Laminate with a moisture absorption rate of <0.10%. We implemented a 4-hour Vacuum Bake at the factory followed by immediate Vacuum-Sealed MBB (Moisture Barrier Bag) packaging.

● The Result: Field failures dropped to 0.04%. The client saved over $450,000 in warranty and replacement costs in the first year alone.

AIVON's Ecosystem & Technical Edge

Choosing AIVON means gaining an engineering partner, not just a vendor. Our ecosystem is built on the principle of "Reliability First."

● DFM (Design for Manufacturing): Every order undergoes a rigorous DFM check. If our engineers see an imbalanced stack-up that will lead to a "bow and twist" defect exceeding 0.75% (per IPC-A-600), we pause and consult with you.

● Global Compliance: We adhere strictly to IPC Class 3 standards for high-reliability electronics, alongside ISO 9001:2015 and UL certifications.

● Green Manufacturing: By utilizing precision vacuum drying, we reduce energy consumption by 30% compared to traditional 24-hour atmospheric baking cycles. Additionally, our high "First Pass Yield" (FPY) means less material ends up in landfills.

Actionable Design & Ordering Guide

To ensure your boards remain flat and stable, follow this AIVON-approved checklist.

The "Do's and Don'ts" Checklist

● DO: Specify a High-Tg material (>170℃) if your board will undergo multiple reflow cycles (e.g., double-sided SMT).

● DO: Maintain Stack-up Symmetry. If Layer 2 is 1oz copper, Layer (N-1) should also be 1oz copper.

● DON'T: Leave large "islands" of empty space on internal layers. Use copper pours to balance the density.

● DON'T: Store boards in open air for more than 8 hours. If the "Floor Life" is exceeded, a re-bake is mandatory.

Pro-Tips for Optimization

Impedance Control: When moisture levels fluctuate, your impedance shifts. Ask AIVON for a TDR (Time Domain Reflectometry) report to verify your 50Ω lines are stable post-drying.

Vacuum Packing: Always request "Vacuum Seal + Desiccant + HIC (Humidity Indicator Card)" for shipping. This is the AIVON gold standard for long-term storage.

Executive Summary: The Partner You Can Trust

PCB warpage and blistering are not "acts of God"—they are predictable physical phenomena that can be managed with the right expertise. By combining Low-Hygroscopicity Materials, Vacuum Drying Processes, and Symmetrical Design principles, AIVON ensures that your boards arrive flat, stay flat, and perform flawlessly in the most demanding environments.