Introduction

Copper cladding lamination stands as a foundational step in the PCB manufacturing process, directly impacting the structural integrity and electrical performance of printed circuit boards. This process bonds copper foil to dielectric substrates, forming the basis for conductive pathways in electronic devices. For electrical engineers, understanding the nuances of the copper cladding lamination process is vital to ensure reliability and prevent failures such as delamination or poor adhesion. Key factors like lamination pressure, lamination temperature, and prepreg selection play critical roles in achieving optimal bond strength. This article explores the technical principles behind lamination, offers best practices for process control, and provides actionable insights to enhance PCB quality. Aimed at professionals in the field, the content aligns with established industry standards to support informed decision-making.

What Is Copper Cladding Lamination and Why It Matters

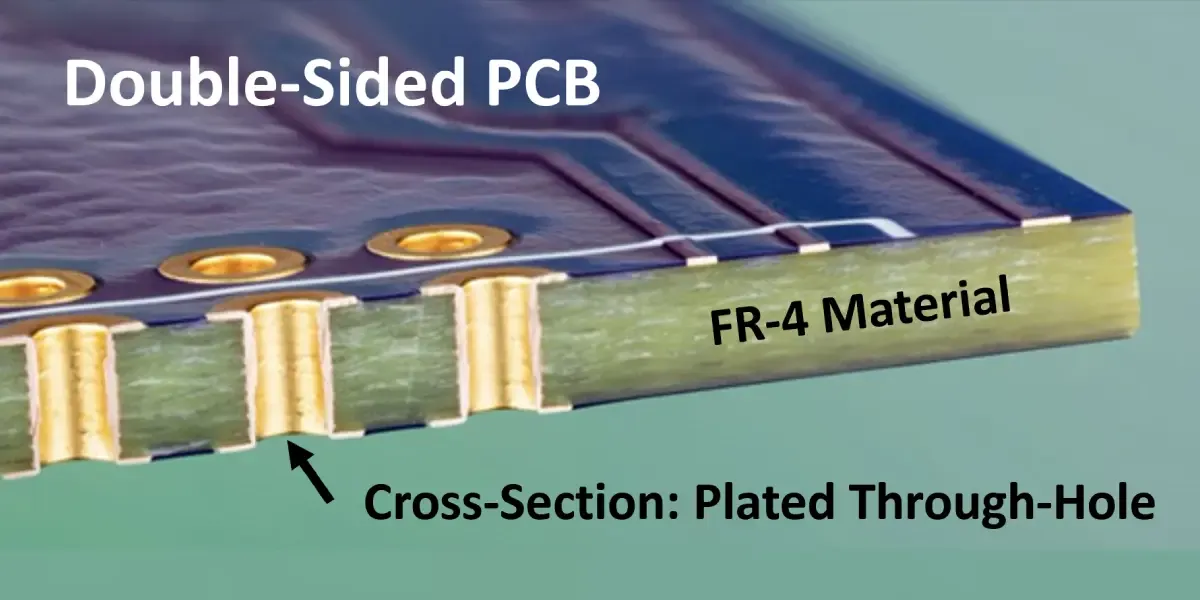

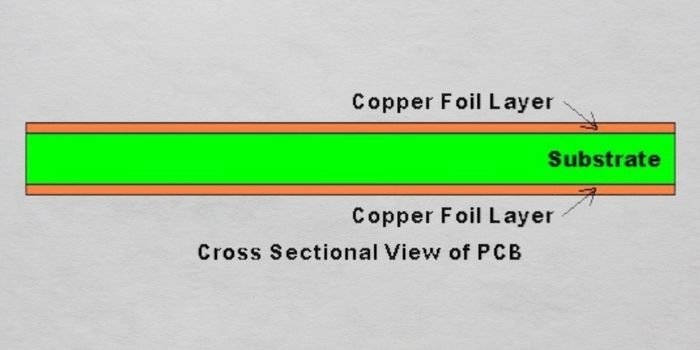

Copper cladding lamination refers to the process of bonding copper foil to a dielectric substrate, often using heat, pressure, and adhesive materials like prepreg. This forms the copper clad laminate, a core material in PCB manufacturing. The resulting structure provides both mechanical support and electrical conductivity, serving as the foundation for circuit patterns etched into the copper layer.

The importance of this process cannot be overstated. Poor lamination can lead to issues like delamination, where layers separate under thermal or mechanical stress, causing circuit failures. It also affects signal integrity and thermal management in high-performance applications. For engineers, ensuring a robust copper cladding lamination process means minimizing defects, improving yield, and meeting stringent reliability requirements in industries ranging from consumer electronics to aerospace. Mastery of this step is essential for producing durable and efficient quick turn circuit boards.

Technical Principles of Copper Cladding Lamination

The copper cladding lamination process relies on a combination of heat, pressure, and material properties to achieve a strong bond between copper foil and the dielectric substrate. Understanding these principles helps engineers optimize outcomes.

At its core, lamination involves curing a resin system within the prepreg, a fiberglass material impregnated with epoxy or other thermosetting resins. When subjected to heat, the resin softens, flows, and eventually hardens, creating a permanent bond with the copper foil and substrate. Lamination temperature controls the rate of this curing process, while lamination pressure ensures uniform contact and eliminates voids or air pockets that could weaken the bond.

Surface preparation of the copper foil also plays a critical role. Roughening the copper surface, often through chemical or mechanical treatments, enhances adhesion by increasing the contact area for resin bonding. Additionally, the dielectric material's properties, such as thermal expansion and dielectric constant, must align with application needs to prevent stress during thermal cycles. Standards like IPC-4101E provide guidelines for laminate material specifications, ensuring compatibility and performance.

Moisture control is another key factor. Excess moisture in prepreg or substrates can vaporize during lamination, forming bubbles or blisters. Pre-baking materials before lamination mitigates this risk, adhering to best practices outlined in industry standards.

Best Practices for Optimizing the Copper Cladding Lamination Process

Prepreg Selection for Compatibility and Performance

Prepreg selection directly influences lamination quality. Engineers must choose prepreg with resin content and flow characteristics suited to the specific PCB design and layer count. High resin content prepreg is ideal for filling gaps in multilayer boards, while low flow options suit designs requiring minimal resin bleed. Compatibility with the substrate material, often governed by standards like IPC-4101E, ensures thermal and mechanical stability. Testing prepreg behavior under simulated lamination conditions can prevent issues like incomplete curing or excessive flow.

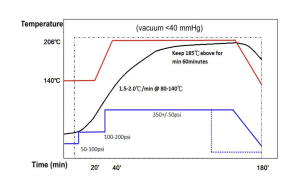

Controlling Lamination Temperature for Resin Curing

Lamination temperature must be carefully managed to optimize resin flow and curing. Typical ranges for standard epoxy-based prepreg fall between 170 to 200 degrees Celsius, though exact values depend on material specifications. Too low a temperature may result in incomplete curing, weakening the bond, while excessive heat can degrade the resin or cause warpage. Monitoring temperature uniformity across the lamination stack is critical to avoid hotspots. Adhering to curing profiles recommended by material standards ensures consistent results.

Applying Correct Lamination Pressure for Uniform Bonding

Lamination pressure ensures intimate contact between layers, eliminating voids and promoting uniform resin distribution. Pressure levels often range from 200 to 500 psi, depending on the stack up and material thickness, as guided by industry practices. Insufficient pressure can lead to air entrapment, while excessive pressure risks damaging delicate copper foils or causing resin squeeze out. Using calibrated equipment and maintaining even pressure distribution across the press plates are essential steps for success.

Surface Preparation of Copper Foil

Proper treatment of copper foil enhances adhesion during the copper cladding lamination process. Surface roughening, often achieved through micro-etching, increases the bonding area for resin. Cleanliness is equally important, as contaminants like oil or dust can impair adhesion. Following cleanliness protocols and verifying surface roughness per standards like IPC-4562A for copper foil specifications helps achieve reliable bonds.

Moisture Management to Prevent Defects

Moisture in prepreg or substrates can vaporize during heating, leading to blisters or delamination. Pre-baking materials at controlled temperatures, typically around 120 degrees Celsius for several hours, removes residual moisture. Storage in low humidity environments further reduces risks. These practices align with guidelines in IPC-A-600K for acceptable PCB conditions, ensuring defect-free lamination.

Monitoring and Testing for Quality Assurance

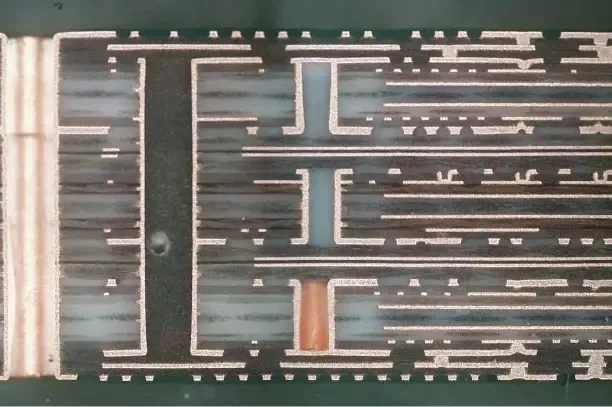

Post-lamination inspection is vital to verify bond strength and detect defects. Techniques like cross-sectional analysis reveal voids or incomplete bonding, while thermal stress testing assesses durability under operating conditions. Standards such as IPC-6012E outline performance criteria for rigid PCBs, providing benchmarks for acceptable quality. Implementing regular process audits and material testing ensures consistency in the PCB manufacturing process.

Common Challenges and Troubleshooting in Lamination

Even with best practices, challenges can arise during the copper cladding lamination process. Identifying root causes and applying targeted solutions is key for engineers.

Delamination often results from inadequate pressure, incorrect temperature, or moisture entrapment. Reviewing process logs to confirm parameter adherence and inspecting materials for pre-lamination condition can pinpoint issues. Adjusting pressure or extending pre-baking time often resolves this.

Warpage, another frequent problem, occurs due to uneven thermal expansion or non-uniform pressure. Ensuring stack symmetry and verifying press plate flatness mitigate this risk. Following material matching guidelines in IPC-4101E also helps.

Resin starvation, where insufficient resin fills gaps, can weaken bonds in multilayer designs. Selecting prepreg with appropriate resin content and optimizing lamination pressure addresses this concern. Regular equipment maintenance prevents mechanical inconsistencies that contribute to such defects.

Conclusion

Mastering the copper cladding lamination process is essential for producing high-quality HDI PCBs that meet the demands of modern electronics. By focusing on critical factors like lamination temperature, lamination pressure, and prepreg selection, engineers can achieve optimal bond strength and minimize defects. Implementing best practices, from surface preparation to moisture control, ensures reliability in the PCB manufacturing process. Adherence to industry standards further supports consistent outcomes, enabling professionals to address challenges effectively. With these insights, teams can enhance process control and deliver robust circuit boards for diverse applications.

FAQs

Q1: What factors influence the copper cladding lamination process most significantly?

A1: The copper cladding lamination process depends heavily on lamination temperature, pressure, and material compatibility. Temperature affects resin curing, while pressure ensures uniform bonding. Prepreg selection also plays a vital role, as resin content must match design needs. Following industry standards for material and process control helps maintain consistent quality and prevents issues like delamination.

Q2: How does lamination pressure impact PCB quality during manufacturing?

A2: Lamination pressure directly affects bond strength in the PCB manufacturing process. Insufficient pressure can cause voids or weak adhesion, leading to delamination. Excessive pressure risks damaging copper foil or causing resin squeeze-out. Maintaining pressure within recommended ranges, typically guided by material specifications, ensures uniform contact and reliable layer bonding.

Q3: Why is prepreg selection critical for successful lamination?

A3: Prepreg selection determines resin flow and bonding quality during lamination. Choosing prepreg with suitable resin content and flow properties prevents issues like resin starvation or excessive bleed. Compatibility with substrate materials, as per industry guidelines, ensures thermal stability. Proper selection supports strong adhesion and structural integrity in multilayer PCB designs.

Q4: How can incorrect lamination temperature affect PCB performance?

A4: Incorrect lamination temperature disrupts resin curing in the copper cladding lamination process. Low temperatures may cause incomplete bonding, weakening the structure, while high temperatures can degrade materials or induce warpage. This impacts electrical performance and durability. Adhering to specified curing profiles ensures optimal bond strength and long-term reliability.

References

IPC-4101E — Specification for Base Materials for Rigid and Multilayer Printed Boards. IPC, 2021.

IPC-4562A — Metal Foil for Printed Board Applications. IPC, 2008.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.