Introduction

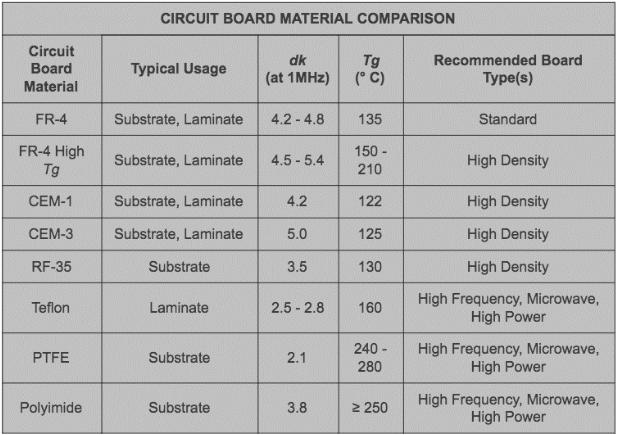

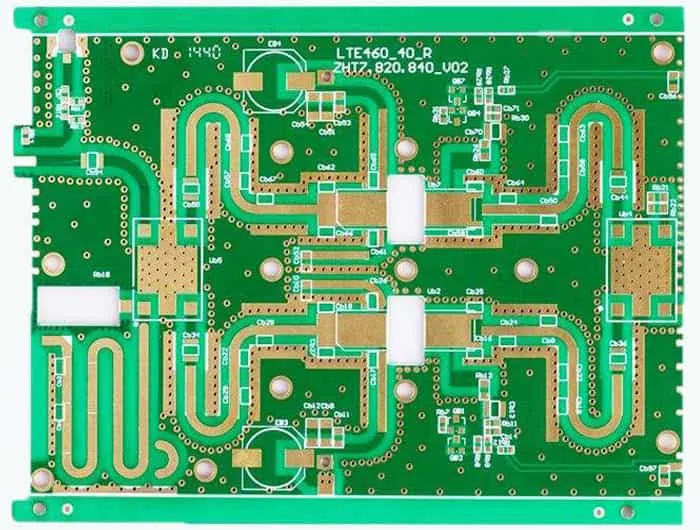

In the realm of printed circuit board design, selecting the right substrate material is a critical decision that impacts performance, reliability, and cost. For embedded component PCBs, where active and passive components are integrated within the board layers, substrate choice becomes even more pivotal. While FR-4 has long been the standard due to its balance of cost and performance, it often falls short in high-frequency applications or designs requiring low dielectric constant (Dk) materials. This article explores alternatives to FR-4, focusing on PCB substrate options tailored for embedded component PCBs. It addresses key PCB material properties, high-frequency materials, and low Dk materials to guide electrical engineers in optimizing their designs for advanced applications.

For many years, FR-4, a glass-reinforced epoxy laminate, has dominated as the go-to material due to its affordability and versatility. However, as designs push into high-frequency domains or require miniaturization with embedded components, FR-4's limitations, such as higher dielectric loss and limited thermal conductivity, become apparent. Selecting an appropriate FR-4 alternative can enhance performance in specialized applications, ensuring signal fidelity and structural integrity under demanding conditions.

Related Reading: Beyond FR-4: Exploring Advanced PCB Materials for High-Frequency Applications

What Is a PCB Substrate and Why It Matters

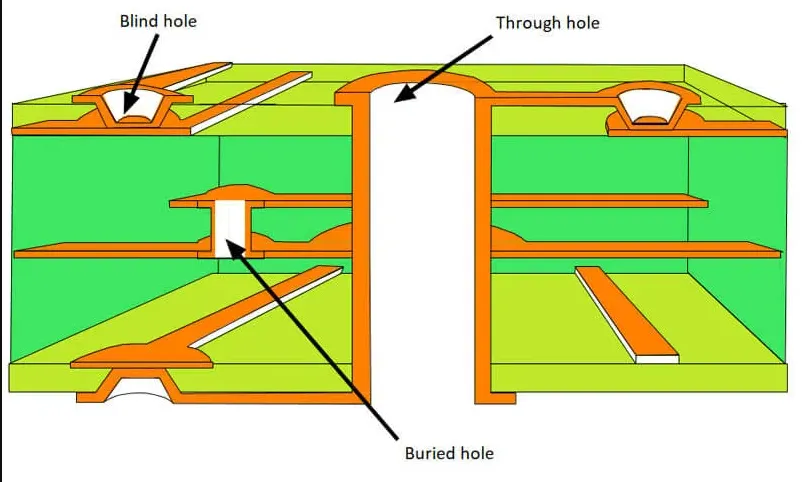

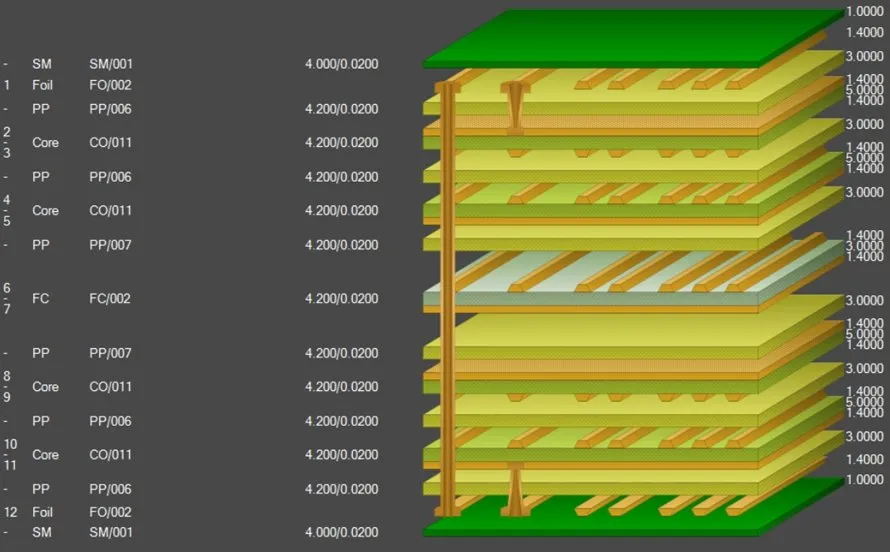

A PCB substrate serves as the insulating foundation between conductive layers, providing mechanical support and electrical isolation. In embedded component PCBs, the substrate must also accommodate components buried within its layers, demanding exceptional dimensional stability and compatibility with manufacturing processes. The choice of substrate directly influences signal integrity, thermal management, and overall board reliability.

For many years, FR-4, a glass-reinforced epoxy laminate, has dominated as the go-to material due to its affordability and versatility. However, as designs push into high-frequency domains or require miniaturization with embedded components, FR-4's limitations, such as higher dielectric loss and limited thermal conductivity, become apparent. Selecting an appropriate FR-4 alternative can enhance performance in specialized applications, ensuring signal fidelity and structural integrity under demanding conditions.

Technical Principles of PCB Substrate Selection for Embedded Component PCBs

Understanding the core properties of PCB materials is essential when moving beyond FR-4 for embedded component designs. Key factors include dielectric constant (Dk), dissipation factor (Df), thermal conductivity, and coefficient of thermal expansion (CTE). These properties determine how well a substrate supports high-frequency signals, manages heat, and withstands mechanical stress during fabrication and operation.

Dielectric constant, or Dk, measures a material's ability to store electrical energy in an electric field. For high-frequency applications, a low Dk material is preferred to minimize signal delay and reduce crosstalk. FR-4 typically has a Dk around 4.2 to 4.5, which can be too high for frequencies above a few gigahertz. Low Dk materials, often below 3.0, are critical for maintaining signal integrity in such scenarios.

Dissipation factor, or Df, indicates energy loss as heat during signal transmission. High-frequency designs require substrates with a low Df to prevent signal attenuation. FR-4 often exhibits a higher Df compared to specialized high-frequency materials, making it less suitable for applications like RF and microwave circuits.

Thermal conductivity and CTE are vital for embedded component PCBs, where heat dissipation and dimensional stability are concerns. Materials with higher thermal conductivity help manage heat from embedded active components, while a low CTE ensures alignment during multilayer lamination processes. Standards such as IPC-6012E provide guidelines on material performance for rigid boards, emphasizing the need for thermal and mechanical compatibility in advanced designs.

Key PCB Material Properties for Embedded Component Designs

When selecting a substrate for embedded component PCBs, engineers must evaluate specific material properties against design requirements. Below is a breakdown of critical characteristics to consider.

- Dielectric Constant (Dk): Affects signal speed and impedance. Low Dk materials are essential for high-frequency applications to reduce signal propagation delay.

- Dissipation Factor (Df): Determines signal loss. A lower Df is necessary for minimizing energy loss in high-frequency circuits.

- Thermal Conductivity: Influences heat dissipation. Higher values are beneficial for managing thermal loads from embedded components.

- Coefficient of Thermal Expansion (CTE): Impacts dimensional stability. Matching CTE between substrate and components prevents delamination or cracking during temperature changes.

- Moisture Absorption: Affects long-term reliability. Low moisture uptake is crucial for maintaining electrical properties in humid environments.

These properties must align with fabrication constraints and end-use conditions. For instance, IPC-A-600K outlines acceptability criteria for printed boards, including substrate integrity under thermal stress, which is particularly relevant for embedded designs.

FR-4 Alternatives for High-Frequency and Embedded Component PCBs

Several FR-4 alternatives offer superior performance for embedded component PCBs, especially in high-frequency and low Dk applications. Below are notable categories of high-frequency materials, each with distinct advantages.

Hydrocarbon-Based Laminates

Hydrocarbon-based materials provide a lower Dk, often in the range of 2.5 to 3.5, and a reduced Df compared to FR-4. These properties make them suitable for high-frequency designs up to tens of gigahertz. They also offer good thermal stability, supporting the integration of embedded components without significant dimensional changes during processing.

PTFE-Based Materials

Polytetrafluoroethylene (PTFE) substrates are renowned for their extremely low Dk and Df values, making them ideal for RF and microwave applications. Their chemical inertness and low moisture absorption enhance reliability in harsh environments. However, they can be challenging to process due to softness and higher cost, requiring careful consideration during design and fabrication.

Ceramic-Filled Laminates

Ceramic-filled materials combine a low Dk with high thermal conductivity, addressing heat dissipation challenges in embedded component designs. They are often used in power electronics and high-frequency circuits where thermal management is critical. Their rigidity can pose manufacturing constraints, but they excel in applications demanding stability.

Polyimide Substrates

Polyimide offers excellent thermal resistance and flexibility, making it a candidate for embedded component PCBs in high-temperature environments. While its Dk is higher than some high-frequency materials, its mechanical properties support complex multilayer structures. It is often selected for applications requiring durability under thermal cycling.

Standards like IPC-6012E provide performance specifications for such materials in rigid printed boards, ensuring they meet the mechanical and electrical demands of embedded designs.

Practical Solutions for Selecting the Right Substrate

Choosing a PCB substrate for embedded component designs involves balancing performance, cost, and manufacturability. Below are actionable steps to guide engineers in this process.

- Define Application Requirements: Identify frequency range, thermal loads, and environmental conditions. High-frequency designs prioritize low Dk materials, while thermal management may favor high-conductivity substrates.

- Evaluate Material Properties: Compare Dk, Df, CTE, and thermal conductivity against design needs. Use industry standards like IPC-A-600K for acceptability benchmarks.

- Consider Fabrication Compatibility: Ensure the substrate supports embedding processes, such as laser drilling or lamination, without compromising integrity.

- Assess Cost Impact: Balance performance benefits with budget constraints. Specialized high-frequency materials often carry a higher cost than FR-4.

- Test and Validate: Prototype with selected substrates to verify signal integrity and thermal performance under real-world conditions.

Related Reading: PCB Material Costs: Choosing the Right Substrate to Balance Performance and Price

Collaboration with fabrication experts during the design phase can prevent issues related to material mismatch or processing limitations. Adhering to guidelines in IPC-6012E ensures that the chosen substrate meets qualification standards for multilayer boards.

Challenges and Insights for Embedded Component PCB Substrates

Embedding components within PCB layers introduces unique challenges for substrate selection. Dimensional stability during lamination is critical to avoid misalignment of embedded elements. Materials with a low CTE are preferred to match the expansion rates of copper and components, reducing stress.

Signal integrity is another concern, especially in high-frequency designs. Substrates with a high Dk can cause impedance mismatches, leading to signal distortion. Engineers must prioritize low Dk materials and validate designs through simulation and testing to ensure performance.

Thermal management remains a hurdle, as embedded active components generate heat within confined spaces. Substrates with enhanced thermal conductivity help mitigate this, but careful layout planning is equally important to distribute heat evenly.

Conclusion

Selecting the right PCB substrate for embedded component PCBs requires a deep understanding of material properties and application demands. While FR-4 remains a reliable choice for many designs, its limitations in high-frequency and thermally intensive applications necessitate exploration of FR-4 alternatives. High-frequency materials and low Dk materials offer tailored solutions for signal integrity and performance, while adherence to industry standards like IPC-6012E ensures reliability. By carefully evaluating PCB material properties and aligning them with design goals, engineers can achieve optimal results in advanced embedded component designs.

FAQs

Q1: What are the key PCB material properties to consider for an embedded component PCB?

A1: For embedded component PCBs, focus on dielectric constant (Dk), dissipation factor (Df), thermal conductivity, and coefficient of thermal expansion (CTE). Low Dk and Df are vital for signal integrity, especially in high-frequency designs. High thermal conductivity aids heat dissipation from embedded components, while a matched CTE prevents mechanical stress during thermal cycles.

Q2: Why is FR-4 often replaced by a high-frequency material in modern designs?

A2: FR-4 has a higher dielectric constant and dissipation factor, leading to signal delays and losses at high frequencies. High-frequency materials offer lower Dk and Df, ensuring better signal integrity for RF and microwave applications. They also provide improved thermal stability, making them suitable for advanced embedded component PCBs.

Q3: How do low Dk materials benefit embedded component PCB performance?

A3: Low Dk materials reduce signal propagation delay and minimize crosstalk in embedded component PCBs. This is crucial for high-frequency applications where timing and signal clarity are paramount. They also support tighter impedance control, enhancing overall electrical performance in compact, multilayer designs with embedded elements.

Q4: What standards guide the selection of a PCB substrate for embedded designs?

A4: Standards like IPC-6012E and IPC-A-600K provide critical guidelines for PCB substrate selection. IPC-6012E outlines performance specifications for rigid boards, including those with embedded components. IPC-A-600K focuses on acceptability criteria, ensuring substrates meet mechanical and electrical requirements for reliable multilayer constructions.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.