What is ENIG and Why is it Essential for Advanced Packaging?

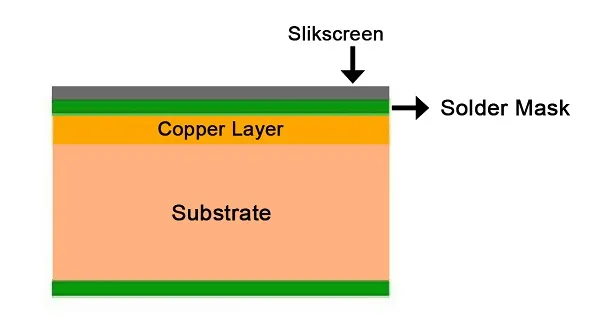

Electroless Nickel Immersion Gold (ENIG) is a specialized surface finish applied to Printed Circuit Boards (PCBs), crucial for various advanced electronic applications. It's composed of two distinct metallic layers: an initial layer of electroless nickel, typically ranging from 3 to 6 micrometers in thickness, followed by a much thinner layer of immersion gold, generally between 0.05 to 0.1 micrometers. The nickel acts as a protective barrier, preventing the underlying copper from migrating, while the gold layer serves to shield the nickel from oxidation, simultaneously providing an excellent surface for soldering.

This dual-layer structure makes ENIG a highly favored option in advanced packaging due to its remarkable attributes. Its exceptional flatness ensures consistent contact, its resistance to corrosion guarantees long-term durability, and its compatibility with various assembly techniques, including wire bonding, makes it incredibly versatile. These characteristics are particularly vital in high-density interconnects and miniaturized components, where a reliable and uniform foundation is paramount for performance.

How Does Wire Bonding Function in Advanced Electronic Assemblies?

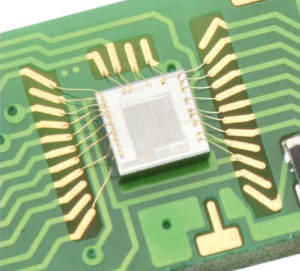

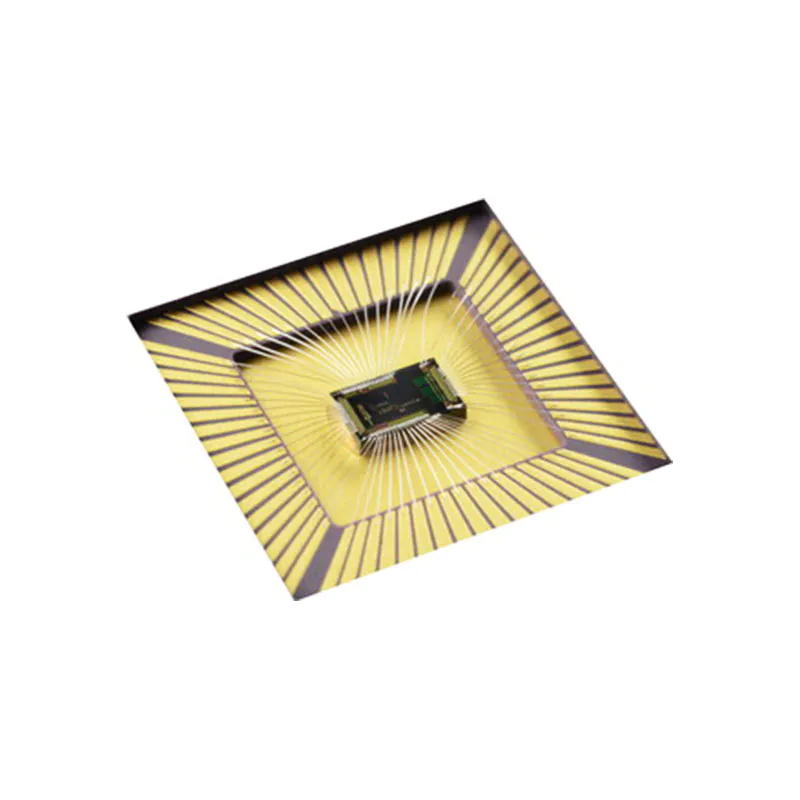

Wire bonding is a fundamental interconnection technique in the microelectronics industry, primarily used to establish electrical links between a semiconductor chip and its housing or substrate. This process involves precisely attaching fine wires, typically crafted from gold or aluminum, to designated bond pads on the chip and their corresponding connection points on the PCB or package. In advanced assemblies—especially HDI PCB where ultra-fine pitch components and high-density routing are common—wire bonding plays a crucial role in ensuring reliable chip-to-board connections. It is a critical step in preserving signal integrity within devices such as Integrated Circuits (ICs) and Microelectromechanical Systems (MEMS).

The efficacy of wire bonding is heavily dependent on the quality of the bonding pad's surface finish. Key factors influencing success include surface cleanliness, the inherent compatibility of materials, and the resulting bond strength. It is within this context that ENIG emerges as a vital solution, offering a surface finish capable of meeting the rigorous demands of contemporary wire bonding applications.

Exploring ENIG's Compatibility with Wire Bonding Techniques

ENIG is widely recognized for its strong compatibility with wire bonding, consistently facilitating the creation of dependable connections. The thin gold layer present in ENIG provides an ideal medium for wire bonding due to gold's inherent affinity for both gold and aluminum wires. However, designers and engineers must consider specific subtleties to optimize performance.

The very thinness of the ENIG gold layer means that, during the wire bonding process, the underlying nickel layer might become exposed or contribute to the overall bond integrity. While creating gold-to-gold bonds (when using gold wires) is often straightforward and yields excellent outcomes, aluminum wire bonding on ENIG necessitates meticulous attention to surface preparation and process parameters. This careful approach helps to prevent potential issues like the formation of undesirable intermetallic compounds or the creation of weak bonds. Studies and extensive industry practice affirm that ENIG can consistently deliver robust wire bonding results when appropriately optimized. For example, bond pull tests frequently demonstrate that ENIG-finished pads can withstand forces in the range of 5-10 grams for gold wire bonds, depending on wire diameter, indicating adequate strength for many diverse applications.

What Steps Are Key for Preparing ENIG Surfaces for Wire Bonding?

Achieving strong and reliable connections through wire bonding on ENIG surfaces critically depends on proper preparation. Despite ENIG's inherent cleanliness and resistance to oxidation, contaminants such as organic residues or thin oxide layers on the gold surface can significantly compromise bond quality. Adhering to specific preparation steps is therefore essential for success.

Thorough Cleaning Protocols

Employing plasma cleaning or chemical cleaning methods is vital for eradicating any organic contaminants or oxides that might be present on the gold surface. Plasma cleaning, in particular, can effectively enhance surface energy and improve bondability without causing damage to the delicate gold layer. This step ensures an unadulterated surface for optimal wire adhesion.

Rigorous Inspection and Verification

Regularly verifying the thickness and uniformity of the gold layer is crucial, often performed using techniques like X-ray fluorescence (XRF). A gold thickness falling below 0.05 micrometers could expose the underlying nickel layer, potentially diminishing bond strength and long-term reliability. Precision in this measurement is paramount for consistent bonding performance.

Controlled Storage Conditions

Storing ENIG-finished PCBs in a meticulously controlled environment is fundamental to prevent oxidation and contamination before the wire bonding process. Exposure to humidity, airborne pollutants, or improper handling can degrade the gold surface over time, directly impacting the quality and consistency of wire bonding. The online PCB manufacturer can significantly enhance the effectiveness of ENIG surfaces for wire bonding by diligently following these preparation steps, ensuring consistent, high-quality results even in high-volume production environments.

How Strong Are ENIG Wire Bonds in Advanced Packaging?

The strength of ENIG wire bonds is a critical metric that directly influences the overall reliability of interconnections in advanced packaging. This strength is typically assessed through standardized pull tests or shear tests, which quantify the force required to break the bond. For ENIG surfaces, bond strength is influenced by several factors, including the specific type of wire material used, the bonding parameters applied (such as ultrasonic energy and temperature), and the precise condition of the surface finish itself.

For applications involving gold wire bonding on ENIG, bond strengths frequently fall within a range of 5 to 12 grams of pull force for a 25-micrometer wire. These values consistently meet established industry benchmarks for the vast majority of applications. While aluminum wire bonding can be slightly more challenging due to the potential formation of brittle intermetallic compounds between aluminum and nickel, optimized processes can still achieve pull strengths of 4-8 grams. These strength values collectively demonstrate that ENIG provides a robust and reliable platform for wire bonding, provided that stringent process controls are meticulously maintained throughout manufacturing.