Introduction

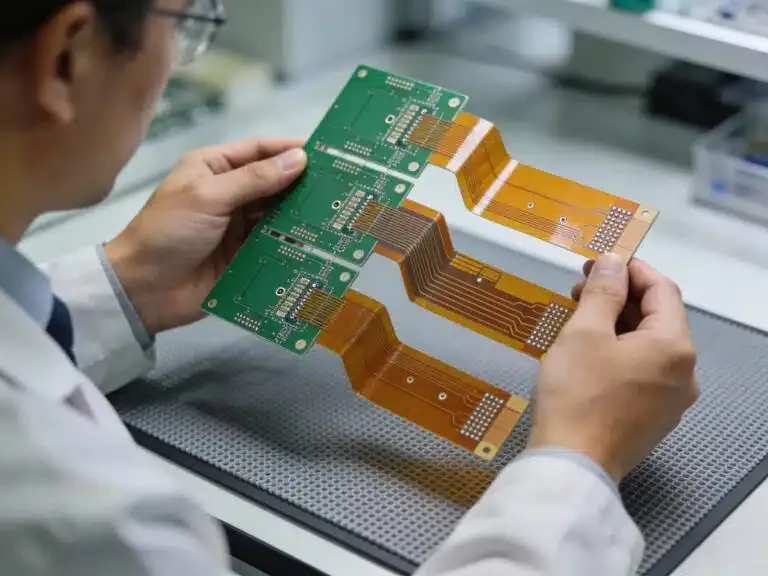

High Density Interconnect (HDI) technology has transformed the design and manufacturing of printed circuit boards (PCBs), especially for flexible circuits. HDI microvia for flex PCB enables engineers to achieve greater functionality in compact spaces by utilizing advanced via structures. These structures, such as blind and buried vias, stacked micro-vias, and laser-drilled vias, allow for intricate routing and improved signal integrity. As devices become smaller and more complex, understanding the role of microvias in flex PCBs is critical for electrical engineers. This article explores the technical principles behind HDI microvias, their application in flexible circuits, and best practices for design and fabrication. The focus remains on meeting industry standards while addressing challenges in high-density designs for modern electronics.

What Are HDI Microvias and Why Do They Matter

HDI microvias are small diameter vias, typically less than 150 micrometers, used to connect different layers of a PCB. In flexible boards, these vias are essential for creating compact, lightweight, and reliable interconnections. Unlike traditional through-hole vias, microvias are often formed using laser drilling, allowing precise placement in high-density layouts. Their significance lies in enabling finer pitch components and reducing signal path lengths, which enhances electrical performance.

For electrical engineers, the importance of microvias in flex PCBs extends to applications like wearable devices, medical equipment, and mobile technology. They support complex multilayer designs while maintaining flexibility and durability. By incorporating blind and buried vias or stacked micro-vias, designers can optimize space and improve thermal management. This technology is a cornerstone of modern electronics, addressing the demand for miniaturization without compromising reliability or functionality.

Technical Principles of HDI Microvias in Flex PCBs

Understanding Blind and Buried Vias

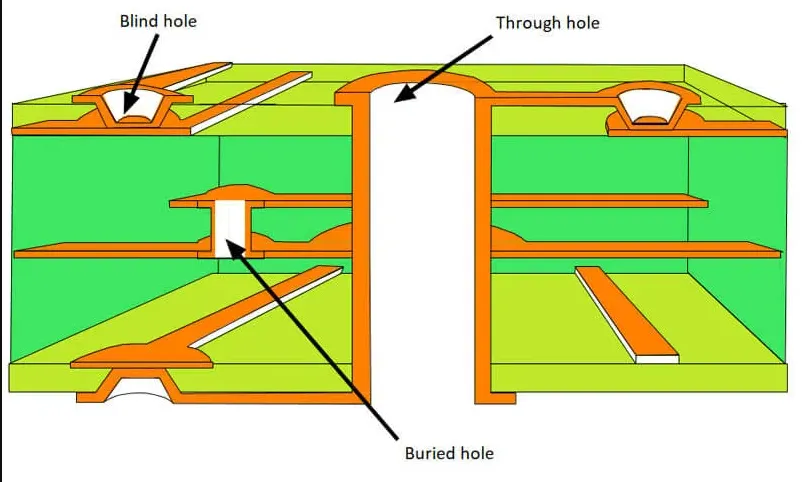

Blind and buried vias are critical elements of HDI technology in flex PCBs. A blind via connects an outer layer to an inner layer without passing through the entire board. A buried via, on the other hand, connects internal layers and remains hidden from the surface. These structures reduce the need for through-hole vias, saving space and allowing tighter component placement.

The use of blind and buried vias improves signal integrity by shortening interconnect lengths. They also minimize parasitic capacitance and inductance, which is vital for high-speed applications. In flex PCBs, these vias must withstand mechanical stress during bending. Adhering to standards like IPC-6013D, which governs flexible printed boards, ensures that these vias maintain reliability under dynamic conditions.

Stacked Micro-Vias for Enhanced Density

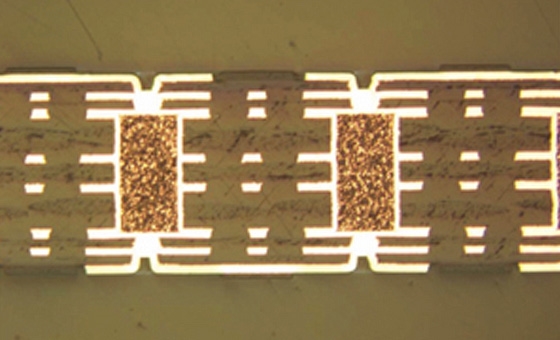

Stacked micro-vias involve placing multiple microvias on top of each other to connect several layers in a PCB. This technique is particularly useful in flex PCBs where space is limited, and multilayer designs are common. Stacked micro-vias allow for higher wiring density without increasing the board’s footprint, supporting advanced packaging technologies like chip-scale packages.

Fabricating stacked micro-vias requires precision to avoid misalignment or structural weaknesses. Industry guidelines, such as those in IPC-2226, provide design rules for HDI structures, including aspect ratios and pad sizes. For electrical engineers, understanding these constraints ensures that designs remain manufacturable while achieving the desired electrical performance in flexible circuits.

Laser-Drilled Vias for Precision and Reliability

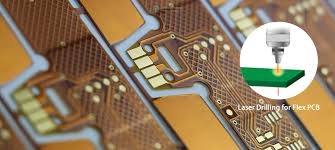

Laser-drilled vias are the backbone of HDI microvia technology. Unlike mechanical drilling, laser drilling creates smaller, more precise holes with diameters as low as 50 micrometers. This precision is essential for flex PCBs, where thin substrates and delicate materials are common. Laser drilling also produces cleaner via walls, reducing the risk of defects during plating.

The process supports the formation of blind and buried vias, as well as stacked micro-vias, with minimal thermal damage to surrounding materials. Following standards like IPC-A-600K for acceptability criteria ensures that laser-drilled vias meet quality requirements. For high-frequency applications, these vias help maintain signal integrity by minimizing discontinuities in the transmission path.

Practical Solutions for Implementing HDI Microvias in Flex PCBs

Design Considerations for Optimal Performance

When designing flex PCBs with HDI microvias, engineers must prioritize layer stack-up planning. Proper alignment of blind and buried vias reduces manufacturing complexity and ensures signal paths remain short. Using design software that adheres to IPC-2226 guidelines helps define via sizes, spacing, and aspect ratios accurately.

Material selection also plays a key role. Flexible substrates like polyimide require specific via structures to handle bending stress. Engineers should specify via fill materials and plating processes that comply with IPC-6013D to prevent cracking or delamination. Additionally, maintaining a low via aspect ratio improves reliability during fabrication and PCBA assembly.

Fabrication Challenges and Mitigation Strategies

Manufacturing HDI microvias for flex PCBs presents unique challenges, including registration accuracy and via integrity. Misalignment during laser drilling can lead to open circuits or weak connections. To mitigate this, fabricators must follow strict process controls as outlined in IPC-A-600K for inspection and acceptability.

Another concern is the thermal stress during lamination and reflow processes. Stacked micro-vias are particularly vulnerable to cracking under high temperatures. Adhering to IPC-6012E for rigid-flex integration provides guidelines on thermal management and via construction. Regular testing for via continuity and resistance ensures long-term reliability in flexible applications.

Signal Integrity and Thermal Management

Signal integrity is a primary concern in HDI designs with microvias. Blind and buried vias help reduce signal loss by minimizing stub effects in high-speed circuits. Engineers should simulate impedance matching and crosstalk using tools compliant with industry standards to predict performance.

Thermal management is equally important in flex PCBs, as heat dissipation is limited by thin materials. Laser-drilled vias can be strategically placed to conduct heat away from critical components. Following design rules in IPC-2226 for thermal vias ensures efficient heat transfer without compromising structural integrity.

Troubleshooting Common Issues with HDI Microvias in Flex PCBs

HDI microvias in flex PCBs can encounter issues like via failure, delamination, or poor plating. Via failure often results from excessive mechanical stress during bending. Engineers can address this by limiting bend radii and reinforcing via locations with additional copper, as recommended by IPC-6013D.

Delamination between layers may occur due to improper lamination or material mismatch. Ensuring that fabrication processes align with IPC-A-600K helps detect and prevent such defects through visual and cross-sectional inspection. Poor plating in laser-drilled vias can lead to high resistance or open circuits. Specifying uniform plating thickness and verifying it against IPC-6012E standards resolves this issue.

For stacked micro-vias, alignment errors during sequential lamination can disrupt connectivity. Implementing automated optical inspection during manufacturing, as per industry best practices, minimizes these risks. Engineers should also collaborate with fabricators to define clear design rules based on established guidelines.

Conclusion

HDI microvia technology is a vital enabler for flex PCBs, offering solutions for high-density interconnects in compact and flexible designs. By leveraging blind and buried vias, stacked micro-vias, and laser-drilled vias, electrical engineers can meet the demands of modern electronics. Understanding the technical principles and adhering to industry standards ensures reliable performance in applications ranging from wearables to medical devices. Practical design and fabrication strategies, coupled with rigorous troubleshooting, help overcome challenges in implementing microvias. As technology advances, staying aligned with evolving guidelines will remain essential for optimizing flex PCB designs.

FAQs

Q1: How do blind and buried vias improve flex PCB designs?

A1: Blind and buried vias save space by connecting specific layers without penetrating the entire board. This allows for denser routing in flex PCBs, essential for compact devices. They also reduce signal path lengths, improving electrical performance. Following standards like IPC-6013D ensures these vias withstand bending stress while maintaining reliability in dynamic applications.

Q2: What are the benefits of stacked micro-vias in HDI flex PCBs?

A2: Stacked micro-vias enable multilayer connections in a small footprint, ideal for high-density flex PCB designs. They support finer pitch components and complex layouts without increasing board size. Adhering to IPC-2226 design rules ensures manufacturability and structural integrity. This approach enhances functionality in space-constrained applications like wearables.

Q3: Why are laser-drilled vias preferred for HDI flex PCBs?

A3: Laser-drilled vias offer precision for creating small diameter holes in thin flex PCB substrates. They minimize damage to surrounding materials and ensure clean via walls for better plating. This method supports blind and buried vias with high accuracy. Compliance with IPC-A-600K ensures quality and reliability in high-speed electronic designs.

Q4: What standards govern the use of HDI microvias in flex PCBs?

A4: Industry standards like IPC-6013D for flexible boards and IPC-2226 for HDI design provide guidelines for microvia implementation. IPC-A-600K addresses acceptability criteria for via quality, while IPC-6012E covers rigid-flex integration. These standards ensure consistent performance and reliability in manufacturing and application of flex PCBs with microvias.

References

IPC-6013D — Qualification and Performance Specification for Flexible and Rigid-Flexible Printed Boards. IPC, 2017.

IPC-2226 — Sectional Design Standard for High Density Interconnect (HDI) Printed Boards. IPC, 2003.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.