Introduction

High-density interconnect (HDI) PCBs enable compact designs with fine-pitch components and microvias, making them essential for modern electronics. In flex and rigid-flex applications, HDI PCB flex and HDI PCB rigid-flex configurations combine these density advantages with mechanical flexibility, supporting devices like wearables, medical implants, and aerospace systems. Flexible circuit design in HDI contexts addresses space constraints while maintaining signal integrity and reliability under bending stresses. Engineers must consider unique challenges such as material selection and via reliability when integrating HDI features into these structures. This article explores structured design principles for HDI PCB flex and rigid-flex boards, drawing on industry standards to guide optimal performance.

Understanding HDI PCBs in Flex and Rigid-Flex Contexts

HDI PCBs incorporate microvias, finer line widths, and higher layer counts compared to standard boards, typically using build-up processes for density. HDI PCB flex refers to fully flexible substrates with HDI features, while HDI PCB rigid-flex hybrids integrate rigid sections for components with flexible transitions for folding. These designs matter in applications requiring 3D packaging, where traditional rigid boards fail due to size or movement. Flexible circuit design allows routing in confined spaces, reducing interconnect lengths and improving electrical performance. Reliability hinges on balancing density with flex endurance, particularly in dynamic environments. Industry adoption grows as components shrink, demanding HDI capabilities in non-planar formats.

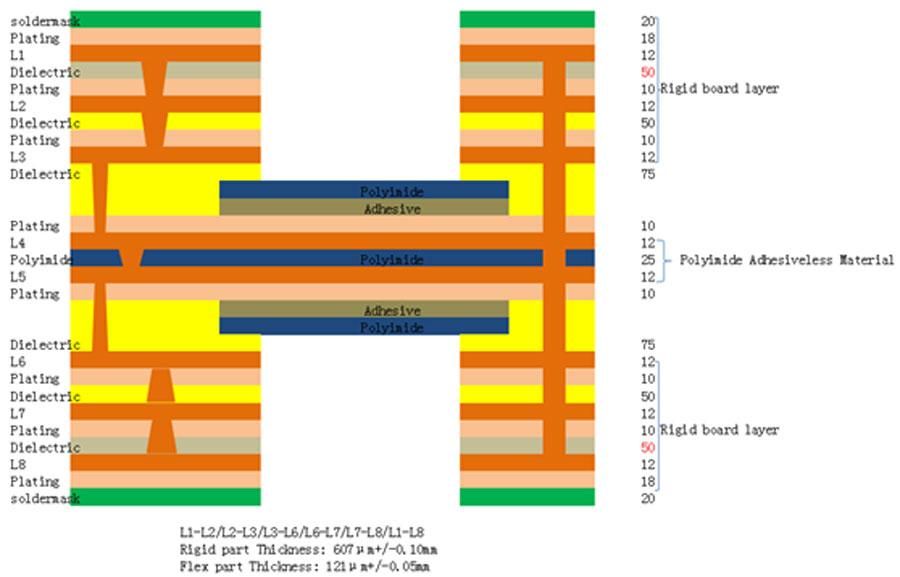

Rigid-flex structures often place HDI in rigid areas to leverage microvia stacking, while flex sections prioritize bendability. This segmentation prevents stress concentrations at high-density zones. Engineers benefit from reduced assembly steps, as rigid-flex integrates multiple boards into one unit. Signal integrity improves with shorter paths, minimizing crosstalk in high-speed signals. However, material compatibility and process controls become critical to avoid delamination during flexing.

Technical Principles of HDI Integration in Flex Designs

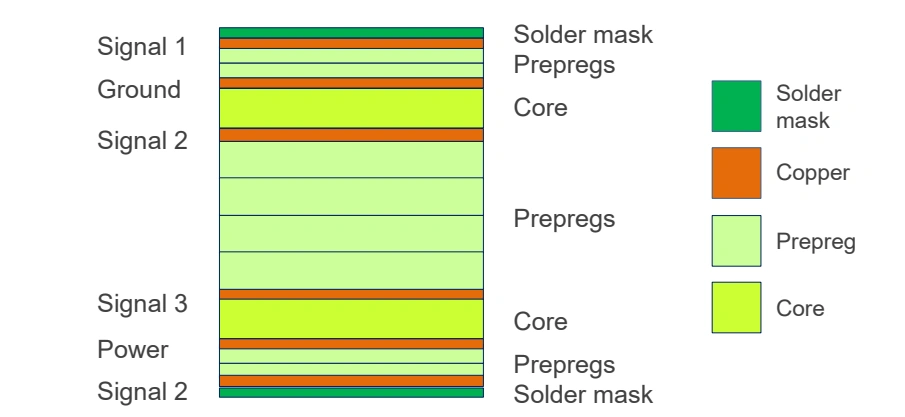

HDI features like stacked and staggered microvias require thin dielectrics and precise laser drilling, but flex substrates introduce constraints due to their thinness and ductility. In HDI PCB flex materials, polyimide films provide thermal stability and low moisture absorption, essential for via formation and plating. Adhesiveless laminates enhance peel strength, reducing risks during repeated bending. Copper ductility affects microvia reliability; thinner foils accommodate flex without cracking. Stackup design must account for flex core thickness, influencing overall bend characteristics.

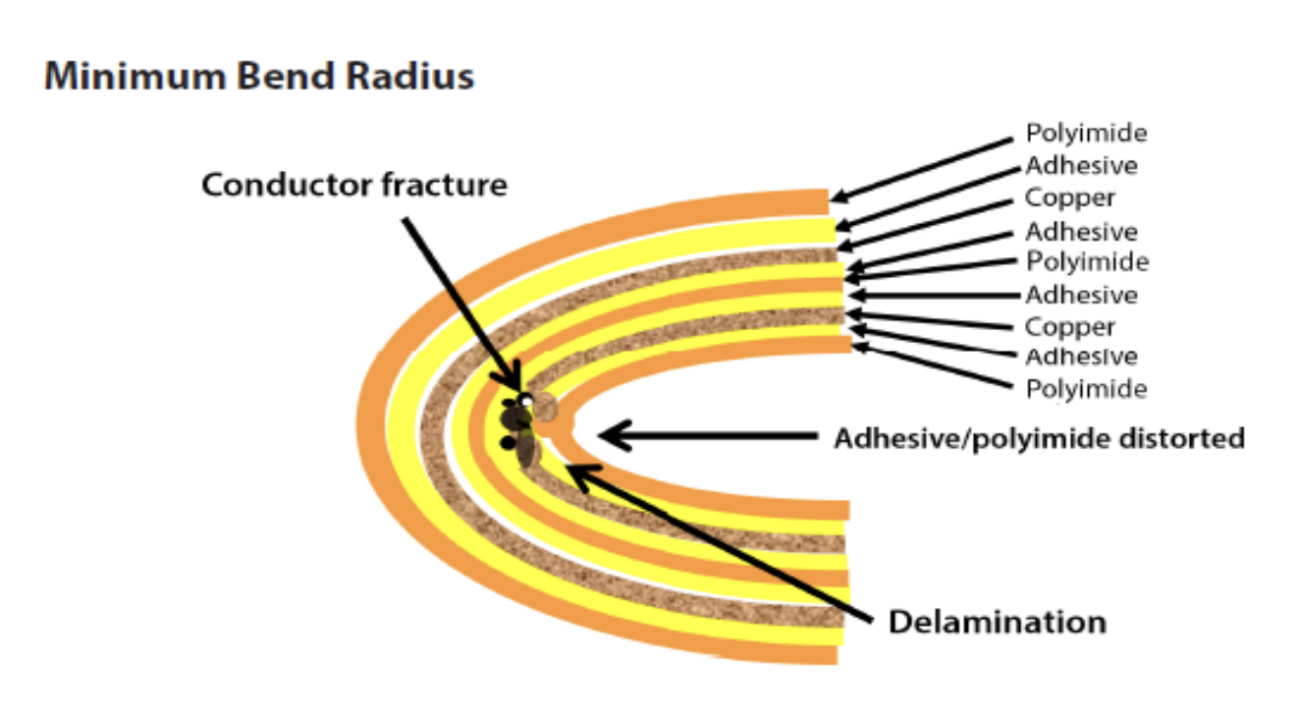

Bend radius in HDI PCB flex demands careful via placement, as microvias near curves experience shear forces. IPC-2223 outlines design rules for flexible and rigid-flex boards, emphasizing minimum radii based on layer count and copper thickness to prevent fatigue. Flex areas typically avoid dense HDI to limit stress risers, confining microvias to rigid or semi-rigid zones. Material CTE mismatch between rigid FR-4 and flex polyimide requires controlled transitions. Thermal expansion during soldering can warp hybrids, necessitating symmetric builds.

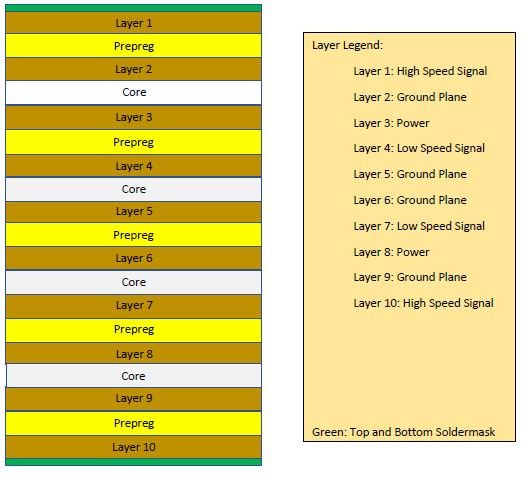

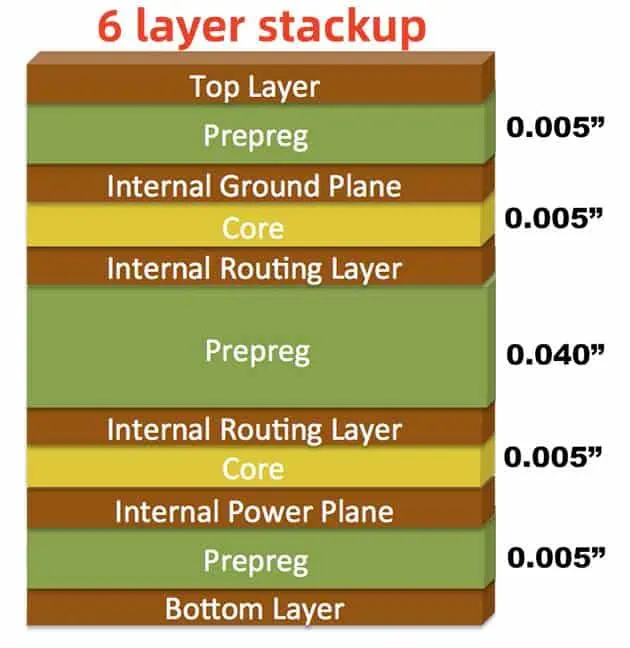

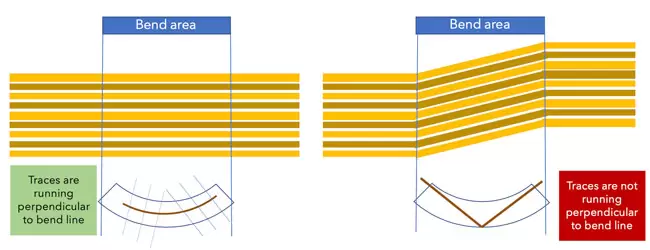

Trace routing in bend regions follows curved paths parallel to the flex axis, distributing strain evenly. HDI PCB rigid-flex stackups layer rigid cores with flex extensions, using coverlays for protection. Via-in-pad designs suit HDI but demand filled vias in flex for planarity. Impedance control challenges arise from varying dielectric thicknesses, requiring simulation for high-frequency signals.

Best Practices for HDI PCB Flex and Rigid-Flex Design

Start with stackup planning, defining rigid and flex zones early to align HDI buildup with mechanical needs. Position microvias in rigid sections, using blind vias from outer layers to inner signals without penetrating flex cores. For HDI PCB bend radius, calculate based on dynamic or static use, ensuring traces avoid acute angles. IPC-6013 specifies qualification for flexible boards, guiding dielectric integrity post-via formation. Simulate strain using FEA tools to predict failure points in bend areas.

Material selection for HDI PCB flex materials favors low-Dk polyimides for signal speed, with coverlay thicknesses matched to copper for balanced flex. Transition zones employ beaded or bookbinder bends for gradual curvature, minimizing copper cracking. Panelization aids manufacturing, with fiducials for alignment in multi-layer builds. Solder mask on flex sides prevents contamination, while rigid areas use LPI for fine features.

Component placement favors rigid islands, with fine-pitch BGAs supported by HDI fanouts. Avoid vias in constant-flex regions; use flying leads if needed. Reliability testing per IPC standards verifies cycle life, including thermal shock and flex endurance. Design for assembly includes stiffeners on flex tails for connector mating.

Common Challenges and Engineering Solutions

Delamination at rigid-flex interfaces stems from adhesive degradation, solved by adhesiveless builds and controlled cure cycles. Microvia cracking in HDI PCB rigid-flex occurs under vibration, mitigated by larger landing pads and sequential lamination. Warpage from asymmetric stacks requires filler materials or balanced copper distribution. Signal loss in flex demands ground planes for shielding, with hatching in non-critical areas to relieve stress.

HDI buildup sequencing integrates flex cores mid-stack, using carrier panels for handling. Environmental factors like humidity affect polyimide, so bake-out precedes lamination. Troubleshooting involves cross-section analysis to inspect via barrels post-flex cycles.

Suggested Reading: HDI PCB Design: Overcoming Challenges in High-Density Interconnect

Conclusion

HDI PCB design for flex and rigid-flex applications demands a structured approach to merge density with durability. Key principles include strategic via placement, material optimization, and adherence to bend radius guidelines. Flexible circuit design thrives when HDI features enhance rigid sections without compromising flex integrity. Engineers achieve reliable boards by following IPC standards and simulating mechanical stresses. These practices enable compact, high-performance electronics in demanding form factors.

FAQs

Q1: What materials are best for HDI PCB flex applications?

A1: HDI PCB flex materials like polyimide offer superior thermal resistance and flexibility compared to polyester, supporting microvia processes and repeated bending. Adhesiveless constructions improve reliability by minimizing peel issues. Select based on operating temperature and bend cycles, ensuring compatibility with HDI buildup. IPC-6013 provides qualification criteria for these substrates.

Q2: How does bend radius impact HDI PCB rigid-flex reliability?

A2: HDI PCB bend radius determines fatigue life, with tighter radii increasing copper strain in microvia areas. Design flex zones with adequate radius per application, avoiding HDI features nearby. Static uses allow smaller radii than dynamic ones. Follow IPC-2223 for structured guidelines to prevent cracks.

Q3: What are key design rules for flexible circuit design in HDI PCBs?

A3: Flexible circuit design prioritizes curved traces in bends, microvias in rigid parts, and symmetric stackups for HDI PCB flex. Limit layer count in flex to maintain bendability. Ensure via protection with fills and coverlays. Simulate impedance and strain for optimal performance.

Q4: Can HDI features be fully integrated into pure flex PCBs?

A4: HDI PCB flex supports limited microvias, best in low-flex zones due to strain risks. Rigid-flex hybrids excel for full HDI, combining densities. Material ductility and via sizing control reliability. Reference standards like IPC-2223 for feasible configurations.

References

IPC-2223C — Sectional Design Standard for Flexible Printed Boards. IPC, 2019

IPC-6013D — Qualification and Performance Specification for Flexible Printed Boards. IPC, 2014

IPC-6012DS — Qualification and Performance Specification for High Density Interconnect (HDI) Printed Boards. IPC, 2015