Why Does Surface Finish Matter So Much in RF PCB Design?

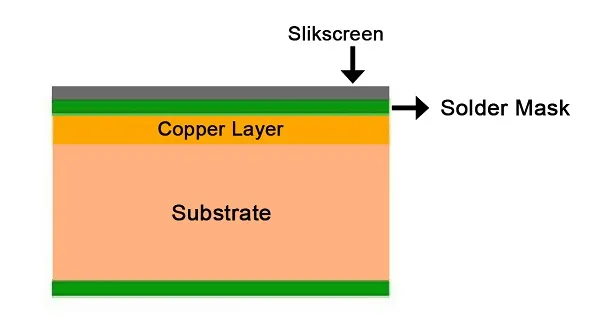

In the intricate world of RF PCB design, precision in every detail is paramount. The surface finish applied to a printed circuit board acts as a protective shield over exposed copper traces, guarding against oxidation and ensuring robust connections during assembly. However, for applications operating at high frequencies, this finish plays a far more extensive role; it directly influences signal integrity and the critical aspect of PCB impedance control. When signals operate above 1 GHz, even subtle variations in surface characteristics can lead to notable signal distortions. This is largely due to the skin effect, where signals primarily travel along the conductor's outermost layer.

A poorly chosen surface finish can inadvertently introduce undesirable resistance, amplify signal loss, and destabilize impedance matching. For instance, a rough surface texture can exacerbate signal attenuation by effectively lengthening the path high-frequency signals must traverse. Conversely, a meticulously selected finish can significantly improve signal transmission, mitigate noise, and ensure consistent performance. Grasping these profound impacts is the foundational step toward fine-tuning your RF PCB design for superior signal integrity.

What Key Factors Influence Surface Finish Selection for Signal Integrity?

Choosing the appropriate surface finish for RF PCBs necessitates a careful balancing act among several considerations. Below, we dissect the pivotal factors that directly affect signal integrity, particularly within demanding high-frequency environments.

Surface Roughness and Its Impact on Signal Loss

At elevated frequencies, electrical signals tend to migrate to the conductor's surface, a phenomenon known as the skin effect. Should the surface finish possess a rough texture, the signal's path becomes elongated and irregular, leading to increased PCB signal loss. For example, a finish with a roughness of 1.5 μm could potentially elevate signal loss by up to 20% at 10 GHz when compared to a smoother finish measuring 0.5 μm. Consequently, smoother options like Electroless Nickel Immersion Gold (ENIG) are frequently favored in RF PCB design to mitigate these losses.

Dielectric Properties and Precise Impedance Control

Maintaining precise PCB impedance control is non-negotiable for preserving signal integrity in RF applications. The surface finish can subtly influence impedance by altering the effective dielectric constant in the immediate vicinity of the conductor. Certain finishes, such as a thick Hot Air Solder Leveling (HASL) layer, may introduce inconsistencies in thickness, resulting in impedance fluctuations of up to 5 ohms in crucial traces. In contrast, finishes that are thinner and more uniform help to sustain consistent impedance, ensuring that signals propagate without undesirable reflections or distortions.

Thermal and Mechanical Stability Requirements

High-frequency PCB materials are often deployed in challenging environments where both thermal and mechanical stability are critical. Surface finishes must reliably endure temperature cycles during soldering and ongoing operation without showing signs of degradation. A finish that cracks or delaminates under thermal stress can expose the underlying copper, leading to oxidation and subsequent signal impairment. Selecting a finish with robust thermal stability guarantees the long-term reliability essential for RF PCBs.

Corrosion Resistance for Extended Longevity

Corrosion on the PCB surface can incrementally increase resistance and degrade signal quality over time. For RF PCBs destined for harsh conditions, such as those in telecommunications or aerospace, a corrosion-resistant finish is absolutely imperative. Finishes incorporating gold or silver layers offer exceptional protection against oxidation, ensuring consistent performance throughout the board's operational lifespan.

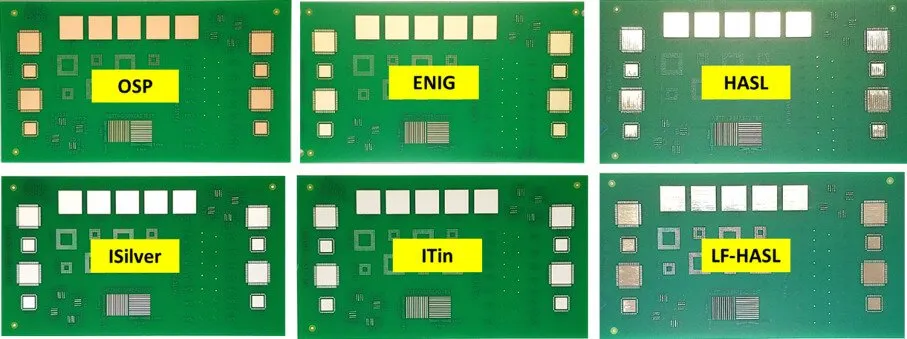

Which Common Surface Finishes Are Best for RF PCBs?

Let’s examine the most prevalent surface finishes utilized for RF PCBs, assessing their suitability for high-frequency applications and overall signal integrity.

Electroless Nickel Immersion Gold (ENIG)

ENIG stands out as a favored option for RF PCB design, praised for its inherently smooth surface and superior corrosion resistance. It comprises a slender layer of gold over a nickel base, providing a flat, uniform finish that effectively minimizes signal loss. ENIG is particularly adept at maintaining precise PCB impedance control, typically yielding variations of less than 1 ohm. However, it can be a more expensive choice, and the nickel layer might introduce minor magnetic losses at extremely high frequencies (exceeding 20 GHz).

● Advantages: Exceptionally smooth surface, excellent solderability, prolonged shelf life.

● Disadvantages: Higher production cost, potential for magnetic losses at very high frequencies.

Immersion Silver

Immersion Silver presents a budget-friendly alternative that offers a smooth finish well-suited for high-frequency PCB materials. It provides both low signal loss and good solderability, making it a compelling candidate for many RF applications. Nevertheless, silver is susceptible to tarnishing over time, which can increase resistance and compromise signal integrity if not properly handled. It generally performs best in controlled environments, demonstrating signal loss levels comparable to ENIG for frequencies up to 10 GHz.

● Advantages: Lower cost, smooth surface profile, minimal signal loss.

● Disadvantages: Prone to tarnishing, shorter practical shelf life.

Hot Air Solder Leveling (HASL)

HASL is a traditional finish that applies a layer of solder over the copper traces. While it is economical and widely available, it is generally not ideal for RF PCB design. The inherent unevenness of the HASL surface can increase signal loss by up to 15% at 5 GHz compared to smoother alternatives. It also struggles to maintain stringent impedance control, rendering it less suitable for critical high-frequency applications.

● Advantages: Low production cost, readily available.

● Disadvantages: Uneven surface texture, elevated signal loss, inconsistent impedance control.

Organic Solderability Preservative (OSP)

OSP is a thin organic coating designed to protect copper from oxidation. Although it is cost-effective and environmentally friendly, it typically isn't the optimal choice for RF PCBs. The organic layer can degrade under high temperatures, and its non-conductive nature may introduce variability into signal transmission. It is better suited for lower-frequency applications where signal integrity demands are less stringent.

● Advantages: Economical, environmentally conscious.

● Disadvantages: Limited thermal stability, generally unsuitable for high-frequency designs.

How Do Surface Finishes Interact with High-Frequency PCB Materials?

The effectiveness of a surface finish is intrinsically linked to the underlying PCB material. Materials for high-frequency PCB , such as those based on PTFE laminates or ceramic-filled substrates, possess specific dielectric constants and loss tangents that directly influence how signals behave. For instance, a material with a dielectric constant of 2.2 (common in RF designs) demands a surface finish that minimizes any additional signal loss. Pairing such materials with a smooth finish like ENIG ensures peak performance by reducing surface-related distortions.

Furthermore, it's crucial that the thermal expansion properties of the PCB material and the chosen surface finish are compatible. A mismatch in thermal expansion coefficients can lead to cracking or delamination during soldering or operation, thereby compromising signal integrity. For example, high-frequency materials characterized by low thermal expansion coefficients (around 10-15 ppm/°C) pair effectively with stable finishes to avert mechanical stress.

What Are Practical Tips for Selecting Surface Finish in RF PCB Design?

Navigating the choice of surface finish for your RF PCB project doesn’t have to be overwhelming. Here are actionable tips to guide your decision-making process and enhance signal integrity:

● Assess Frequency Requirements: For applications operating above 5 GHz, prioritize finishes with exceptionally smooth surfaces to minimize signal loss driven by the skin effect. Consider options such as ENIG or Immersion Silver for frequencies extending up to 20 GHz.

● Factor in Environmental Conditions: If your PCB will function in humid or corrosive environments, select a finish with robust corrosion resistance to preserve long-term signal integrity.

● Balance Cost with Performance: While premium finishes generally deliver superior performance, they come with a higher price tag. Carefully evaluate your project’s budget constraints and performance prerequisites to strike the optimal balance.

● Validate Impedance Control: Employ simulation tools to model how various finishes influence impedance within your specific design. Aim for impedance variations of less than 2 ohms for all critical RF traces.

● Collaborate with Manufacturing Partners: Work in close conjunction with your PCB fabrication vendor to confirm that the chosen finish is fully compatible with their manufacturing processes and your selected high-frequency PCB materials.

How Does Surface Finish Influence PCB Assembly and Overall Reliability?

Beyond its impact on signal integrity, the surface finish also plays a pivotal role in the assembly process and the overall reliability of the PCB. A finish with excellent solderability ensures the formation of strong, dependable connections during the mounting of components. For example, finishes like ENIG offer a consistently flat surface that greatly facilitates precise soldering, thereby reducing the likelihood of defects that could impair high-frequency performance.

Reliability is equally paramount in RF applications, where consistent performance over an extended period is non-negotiable. A durable surface finish safeguards against degradation caused by environmental factors, ensuring that the PCB maintains its signal integrity throughout its operational lifespan. For instance, a expertly applied gold layer can provide years of protection against oxidation, thereby preserving the board's critical electrical properties.

What Are Advanced Considerations for Ultra-High Frequency Designs?

For designs operating at ultra-high frequencies, specifically above 20 GHz, the selection of a surface finish becomes even more critically important. At these elevated frequencies, even minute surface imperfections can lead to substantial signal loss. Consequently, specialized finishes featuring ultra-smooth surfaces are frequently mandated to meet stringent performance benchmarks. Moreover, the intricate interaction between the chosen finish and the PCB material must be meticulously analyzed to avert parasitic effects that could disrupt signal transmission.

In such advanced scenarios, comprehensive testing and simulation are strongly recommended to accurately predict how the surface finish will perform under specific operating conditions. Tools like electromagnetic field solvers can effectively model signal propagation and pinpoint potential issues before physical fabrication, ultimately saving valuable time and resources.

Making the Right Choice for Optimal Signal Integrity

Selecting the appropriate surface finish for RF PCB design is a decisive step in guaranteeing robust signal integrity and minimizing undesirable PCB signal loss. By thoroughly understanding how factors like surface roughness, dielectric characteristics, and environmental conditions influence performance, you can make informed decisions that significantly enhance the capabilities of your high-frequency PCB materials. Whether you opt for a smooth and highly reliable choice like ENIG or a more budget-conscious alternative such as Immersion Silver, prioritizing signal integrity through diligent surface finish selection will invariably lead to superior outcomes for your RF projects.

AIVON, a well-known online PCB manufacturer, is dedicated to equipping engineers with the essential knowledge and resources required to optimize their designs. By concentrating on the intricate interplay between surface finish, PCB impedance control, and high-frequency performance, you can achieve consistently reliable and high-quality results in your next RF PCB endeavor. Take the necessary time to meticulously evaluate your available options, rigorously test your designs, and actively collaborate with fabrication experts to ensure resounding success.