Introduction

Surface finishes play a critical role in the performance of printed circuit boards, especially when dealing with thick PCBs used in demanding applications. Thick PCBs, often exceeding 2.4 mm in thickness, are common in industries like aerospace, automotive, and power electronics where reliability under harsh conditions is essential. The choice of PCB surface finish directly affects solderability, corrosion resistance, and long-term durability. This article explores how different surface finishes, such as ENIG finish, HASL finish, and immersion silver PCB coatings, impact the reliability and solderability of thick PCBs. By understanding the properties of each finish, engineers can make informed decisions to ensure optimal performance in their designs. The focus here is on technical insights and practical considerations for electric engineers working on robust PCB solutions.

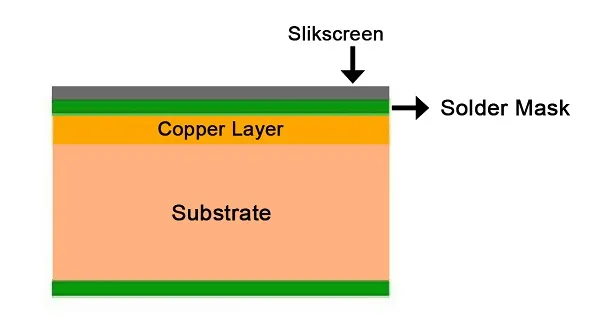

What Is PCB Surface Finish and Why It Matters

A PCB surface finish is a protective coating applied to the exposed copper traces of a printed circuit board. Its primary purpose is to prevent oxidation of the copper, which can degrade electrical connections over time. Additionally, the finish enhances solderability by providing a suitable surface for component attachment during assembly. For thick PCBs, the surface finish must withstand higher mechanical stress, thermal cycling, and environmental exposure compared to standard boards.

The importance of surface finish on thick PCBs cannot be overstated. These boards often support high current loads or operate in extreme conditions, making reliability a top priority. A poor finish can lead to solder joint failures, reduced shelf life, or compromised electrical performance. Selecting the right finish involves balancing factors like cost, application requirements, and manufacturing constraints. Common options include ENIG finish, HASL finish, and immersion silver PCB coatings, each with distinct advantages and limitations for thick PCB applications.

Related Reading: Advanced Surface Finishes: Choosing the Right Option for PCB Mass Production

Technical Principles of Surface Finishes on Thick PCBs

ENIG Finish: Composition and Characteristics

Electroless Nickel Immersion Gold, commonly known as ENIG finish, consists of a layer of nickel beneath a thin layer of gold. The nickel acts as a barrier to prevent copper diffusion, while the gold provides excellent corrosion resistance and solderability. For thick PCBs, ENIG is often favored due to its uniform coating and ability to handle fine-pitch components. However, the nickel layer can introduce stress in thicker boards, potentially leading to cracking under thermal or mechanical strain.

HASL Finish: Process and Properties

Hot Air Solder Leveling, or HASL finish, involves dipping the PCB into molten solder and then using hot air to remove excess material, leaving a thin solder layer on the copper. This finish is cost-effective and provides good solderability for through-hole components, which are common in thick PCBs used in power applications. The downside is the uneven surface it creates, which can pose challenges for surface-mount components and fine-pitch designs on thicker boards.

Immersion Silver PCB: Features and Performance

Immersion silver PCB finish involves a chemical process to deposit a thin layer of silver onto the copper surface. It offers excellent solderability and a flat surface, making it suitable for high-frequency applications often seen in thick PCB designs. However, silver is prone to tarnishing, which can affect long-term reliability if not stored or handled properly. This finish requires careful environmental control to maintain its performance over time.

Impact on Reliability and Solderability

Reliability in thick PCBs is influenced by how well the surface finish withstands thermal expansion, vibration, and moisture. ENIG finish excels in corrosion resistance but may suffer from nickel-related stress issues. HASL finish is robust for mechanical stress but struggles with surface flatness. Immersion silver PCB coatings provide good electrical performance but are sensitive to environmental degradation.

Solderability, the ability to form strong solder joints, also varies across finishes. ENIG offers consistent wetting for both reflow and wave soldering processes. HASL is ideal for wave soldering but less suited for precise surface-mount soldering. Immersion silver provides excellent wetting initially, though tarnishing can reduce solderability if the board is exposed to air for extended periods.

Factors Affecting Thick PCB Performance with Surface Finishes

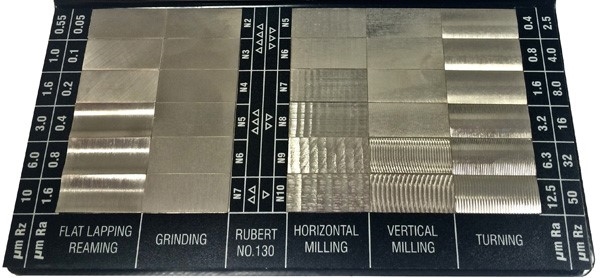

Thermal and Mechanical Stress

Thick PCBs often experience significant thermal cycling due to high-power applications. The surface finish must accommodate the board's expansion and contraction without cracking or delaminating. ENIG finish, with its nickel layer, can introduce brittleness in thicker boards under repeated thermal stress. HASL finish, being solder-based, aligns better with thermal expansion but may develop uneven stress points. Immersion silver PCB coatings are less prone to mechanical issues but require protection from humidity to prevent degradation.

Environmental Exposure

Thick PCBs in industrial or outdoor applications face exposure to moisture, dust, and chemicals. ENIG finish provides superior protection against corrosion, making it suitable for harsh environments. HASL finish offers moderate resistance but can corrode over time if not sealed properly. Immersion silver PCB surfaces are highly vulnerable to tarnishing in humid or sulfur-rich conditions, which can compromise reliability.

Manufacturing and Assembly Challenges

The manufacturing process for thick PCBs introduces unique challenges for surface finish application. ENIG requires precise control to ensure uniform nickel and gold deposition on thicker substrates. HASL can result in uneven solder distribution on larger or thicker boards, affecting component placement. Immersion silver PCB finishes demand strict handling protocols to avoid contamination during production or storage.

Practical Solutions for Selecting Surface Finish on Thick PCBs

Matching Finish to Application Requirements

Engineers must align the surface finish with the specific demands of their thick PCB application. For high-reliability needs in aerospace or medical devices, ENIG finish is often the preferred choice due to its corrosion resistance and consistent solderability, as outlined in standards like IPC-4552A for immersion gold finishes. Power electronics with through-hole components may benefit from HASL finish for its cost-effectiveness and robust solder joints. Immersion silver PCB coatings suit high-frequency designs where signal integrity is critical, provided environmental controls are in place.

Evaluating Cost and Performance Trade-offs

Cost remains a key consideration in surface finish selection for thick PCBs. HASL finish is typically the most economical option, suitable for less complex designs. ENIG finish, while more expensive, offers long-term reliability benefits that justify the investment in critical applications. Immersion silver PCB finishes fall in between, balancing cost with performance but requiring additional handling care to maintain quality.

Implementing Quality Control Measures

To ensure the chosen surface finish performs as expected, adherence to industry standards is essential. IPC-6012E, which governs the qualification of rigid printed boards, provides guidelines for inspecting surface finish integrity on thick PCBs. Regular testing for solderability, as per IPC J-STD-003C, helps identify potential issues before assembly. Engineers should also monitor storage conditions, especially for immersion silver PCB finishes, to prevent tarnishing or degradation.

Troubleshooting Common Issues with Surface Finishes on Thick PCBs

Addressing Solderability Failures

Solderability issues often arise from surface contamination or finish degradation. For ENIG finish, poor nickel deposition can lead to black pad defects, weakening solder joints. HASL finish may exhibit insufficient solder coverage on thick PCBs, causing incomplete wetting. Immersion silver PCB surfaces can lose solderability due to tarnish, requiring cleaning or re-coating if stored improperly. Testing per IPC J-STD-002E can help diagnose and resolve these problems.

Mitigating Reliability Concerns

Reliability failures in thick PCBs often stem from thermal or environmental stress on the surface finish. ENIG finish may crack under repeated thermal cycles, necessitating design adjustments to reduce stress concentration. HASL finish can corrode in humid conditions, requiring additional protective coatings. Immersion silver PCB finishes need controlled storage to avoid silver migration or tarnishing, which can lead to electrical shorts.

Related Reading: Troubleshooting & Repairing Common PCB Surface Finish Defects

Conclusion

The choice of PCB surface finish significantly influences the reliability and solderability of thick PCBs, particularly in demanding applications. ENIG finish offers excellent corrosion resistance and uniform coating, making it ideal for high-reliability designs despite its higher cost. HASL finish provides a cost-effective solution for through-hole soldering but struggles with surface flatness. Immersion silver PCB coatings deliver superior electrical performance for high-frequency applications, though they require careful handling to prevent tarnishing. By understanding the technical properties and practical implications of each surface finish, engineers can optimize thick PCB designs for performance and durability. Adhering to industry standards and implementing rigorous quality control ensures the selected finish meets the specific needs of the application.

FAQs

Q1: How does ENIG finish impact the reliability of thick PCBs?

A1: ENIG finish enhances reliability on thick PCBs by providing strong corrosion resistance and consistent solderability. Its nickel layer acts as a barrier against copper diffusion, while the gold layer protects against oxidation. However, the nickel can introduce stress under thermal cycling, potentially causing cracks in thicker boards. Following standards like IPC-4552A ensures proper application and minimizes risks, making ENIG suitable for critical applications.

Q2: What are the advantages of HASL finish for surface finish on thick PCBs?

A2: HASL finish is a cost-effective option for surface finish on thick PCBs, especially in power electronics with through-hole components. It offers good solderability for wave soldering and withstands mechanical stress well. Despite its uneven surface, which may challenge fine-pitch designs, HASL remains durable under thermal stress. It is a practical choice for less complex designs requiring robust solder joints.

Q3: Why choose immersion silver PCB finish for high-frequency thick PCBs?

A3: Immersion silver PCB finish is ideal for high-frequency thick PCBs due to its excellent electrical conductivity and flat surface, which supports signal integrity. It provides strong solderability for precise component attachment. However, silver tarnishes easily in humid or sulfur-rich environments, necessitating strict storage controls. When handled properly, it balances cost and performance for specialized applications.

Q4: How does surface finish affect solderability in thick PCBs?

A4: Surface finish on thick PCBs directly influences solderability by determining how well solder wets the copper pads. ENIG finish ensures uniform wetting for various soldering methods. HASL finish suits wave soldering but may struggle with surface-mount precision. Immersion silver PCB coatings offer excellent initial solderability, though tarnishing can degrade performance if not protected, emphasizing the need for proper handling.

References

IPC-4552A — Specification for Electroless Nickel/Immersion Gold (ENIG) Plating for Printed Boards. IPC, 2017.

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC J-STD-002E — Solderability Tests for Component Leads, Terminations, Lugs, Terminals and Wires. IPC, 2017.

IPC J-STD-003C — Solderability Tests for Printed Boards. IPC, 2017.