Introduction

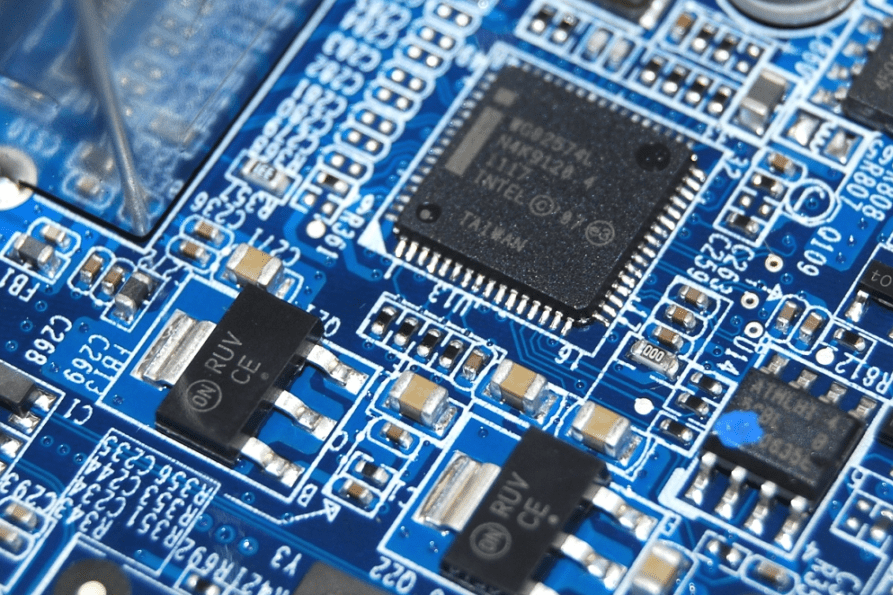

Solder mask plays a vital role in the functionality and durability of a circuit board. This protective layer, applied over the copper traces of a printed circuit board, prevents oxidation, reduces the risk of short circuits, and enhances the board's overall reliability. While its primary purpose is technical, the color and finish of the solder mask, such as green solder mask or blue solder mask, also influence visibility, contrast, and inspection efficiency. Among the various finishes, matte solder mask stands out for specific advantages in certain applications. This guide explores the significance of different solder mask colors, their impact on circuit board performance, and the unique benefits of a matte finish. Aimed at electrical engineers, this article provides detailed insights into surface treatment choices and their practical implications for design and manufacturing processes.

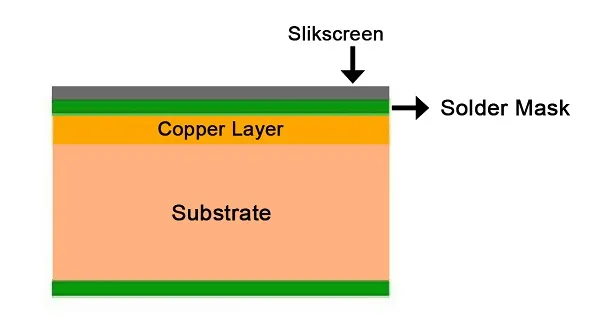

What Is Solder Mask and Why It Matters

Solder mask is a thin polymer layer applied to the surface of a circuit board to insulate copper traces and prevent unintended solder bridges during assembly. Beyond protection, it shields the board from environmental factors like moisture and dust, ensuring long-term reliability. The color of the solder mask, whether green, blue, or another shade, affects visual inspection and contrast between traces and pads. This becomes critical during manual checks or automated optical inspections, where clarity can impact defect detection rates.

The finish of the solder mask, such as matte or glossy, also plays a role in functionality. Matte finishes reduce glare, aiding visibility under bright lighting conditions often found in manufacturing environments. According to widely accepted industry practices, solder mask application must adhere to strict standards to ensure consistent performance across various circuit board designs. Its relevance extends to both aesthetic and technical domains, influencing how engineers approach design and quality control.

Technical Principles Behind Solder Mask Colors

Solder mask colors are not merely cosmetic; they have practical implications rooted in material properties and manufacturing processes. The most common color, green solder mask, became an industry norm due to its balanced performance in visibility and cost effectiveness. Green offers strong contrast against copper traces and white silkscreen markings, making it easier to spot defects during inspection. Blue solder mask, while less common, provides a different contrast level, often preferred in specific lighting conditions or for aesthetic differentiation in high end applications.

The choice of color can influence signal integrity in high frequency designs. Darker colors like black absorb more heat, potentially affecting thermal performance, while lighter colors may reflect light, causing glare during inspection. Surface treatment also matters. A matte finish scatters light, minimizing reflections compared to glossy finishes. This property enhances visibility for detailed work under direct light, a critical factor in precision assembly and troubleshooting.

Color and finish selection must align with the intended application of the circuit board. For instance, high reliability boards used in aerospace or medical devices may prioritize contrast and inspection ease over aesthetic appeal. Standards like IPC-A-600K guide the acceptability criteria for solder mask application, ensuring that color and surface treatment meet performance expectations without compromising quality.

Related Reading: Understanding Solder Mask: A Beginner's Guide to PCB Protection

Impact of Contrast on Circuit Board Inspection

Contrast between the solder mask and other elements on a circuit board directly affects the efficiency of quality control processes. Green solder mask, with its high contrast against copper and silkscreen, remains a preferred choice for many engineers. This color allows for quick identification of misaligned components or soldering defects under standard lighting. Blue solder mask offers a softer contrast, which can reduce eye strain during prolonged inspection but may be less effective in highlighting fine details.

Related Reading: Blue Solder Mask for PCBs: Enhancing Contrast and Readability

Automated optical inspection systems also rely on contrast to detect anomalies. A solder mask color that blends too closely with copper traces or markings can lead to missed defects, increasing the risk of failures. Matte finishes further enhance contrast by eliminating reflective surfaces, ensuring that light does not obscure critical areas during visual or machine based checks. Engineers must weigh these factors when specifying solder mask properties for a given design.

Benefits of Matte Finish in Solder Mask Application

A matte finish in solder mask application offers distinct advantages over glossy alternatives, particularly in environments requiring precision and clarity. By diffusing light, matte surfaces reduce glare, which is beneficial during manual inspection or when working under intense lighting. This characteristic makes it easier to identify small defects or soldering issues on a circuit board without visual interference.

Matte finishes also improve readability of silkscreen markings, as they minimize reflections that could obscure text or symbols. This is especially important for complex designs where component placement and orientation markings must remain clear. In terms of surface treatment, matte solder masks can provide a slightly rougher texture, which may enhance adhesion during assembly processes, though this depends on the specific formulation used.

From a practical standpoint, matte finishes are often chosen for high reliability applications where inspection accuracy is paramount. While glossy finishes may appear more polished, they can hinder visibility under certain conditions. Standards such as IPC-6012E outline performance specifications for solder mask finishes, ensuring that the chosen surface treatment aligns with the intended use of the circuit board.

Practical Guidance for Selecting Solder Mask Colors and Finishes

Choosing the right solder mask color and finish requires balancing technical requirements with practical considerations. Green solder mask remains a default for many designs due to its proven track record in providing contrast and visibility. However, blue solder mask can be a viable alternative for projects where differentiation or specific lighting conditions are factors. Other colors, such as red or black, may be selected for niche applications, though they often come with trade offs in heat absorption or contrast.

When considering a matte finish, evaluate the inspection environment and assembly needs. Matte is ideal for settings with bright lighting or where glare could impede quality checks. It also supports better readability of markings, which is crucial for manual assembly or troubleshooting. Engineers should consult standards like IPC-A-600K to ensure that the chosen solder mask meets acceptability criteria for thickness, coverage, and adhesion.

Testing different combinations of color and finish during the prototyping phase can help identify the optimal choice for a specific circuit board design. Collaboration between design and manufacturing teams ensures that the selected solder mask aligns with both functional and aesthetic goals. Documentation of these choices, as per guidelines in IPC-6012E, supports consistency across production runs.

Troubleshooting Common Solder Mask Issues

Solder mask application can encounter challenges that affect circuit board performance. Uneven coverage may expose copper traces, leading to oxidation or short circuits. This often results from improper surface treatment or insufficient curing during manufacturing. Adhering to standards like IPC-A-600K helps mitigate such issues by setting clear criteria for acceptable solder mask application.

Color inconsistency is another concern, particularly when contrast is critical for inspection. Variations in green solder mask or blue solder mask shades can occur due to batch differences or curing conditions. Regular calibration of equipment and adherence to process controls, as outlined in IPC-6012E, can prevent these discrepancies. For matte finishes, ensuring uniform texture is essential to maintain glare reduction benefits across the entire board.

Engineers should implement thorough inspection protocols to catch defects early. Visual checks under controlled lighting, combined with automated systems, can identify solder mask issues before they impact assembly. Documenting findings and adjusting processes accordingly ensures continuous improvement in solder mask application quality.

Conclusion

Solder mask colors and finishes significantly influence the performance, reliability, and inspectability of a circuit board. Green solder mask remains a staple for its excellent contrast and cost effectiveness, while blue solder mask offers an alternative for specific needs. The choice of a matte finish provides unique benefits by reducing glare and enhancing visibility during inspection, making it a valuable option for precision driven applications. By understanding the technical principles behind color and surface treatment, engineers can make informed decisions that align with industry standards like IPC-A-600K and IPC-6012E. Careful selection and rigorous quality control ensure that the solder mask contributes to the overall success of a circuit board design, supporting both functionality and durability in demanding environments.

FAQs

Q1: How does green solder mask improve circuit board inspection?

A1: Green solder mask enhances inspection by providing high contrast against copper traces and silkscreen markings. This clarity helps engineers and automated systems detect defects like misalignments or solder bridges quickly. Its widespread use aligns with industry practices, ensuring familiarity during quality checks. Following standards like IPC-A-600K ensures consistent application for optimal visibility.

Q2: What are the advantages of a matte finish on a circuit board?

A2: A matte finish on a circuit board reduces glare by diffusing light, improving visibility during inspection under bright conditions. It enhances readability of silkscreen markings and supports accurate defect detection. This finish is ideal for high precision environments, aligning with performance criteria in standards like IPC-6012E for reliable solder mask application.

Q3: Why consider blue solder mask over other colors for contrast?

A3: Blue solder mask offers a softer contrast compared to green, reducing eye strain during prolonged inspections. It performs well under specific lighting conditions and provides aesthetic differentiation. While less common, it still meets industry standards like IPC-A-600K, ensuring reliability. Engineers may choose it for unique visibility needs in circuit board designs.

Q4: How does surface treatment affect solder mask performance?

A4: Surface treatment impacts solder mask adhesion, durability, and appearance on a circuit board. Proper treatment ensures even coverage, preventing issues like oxidation or short circuits. Matte treatments reduce reflections, aiding inspection, while meeting standards like IPC-6012E guarantees performance. Correct processes are essential for maintaining protective and visual properties.

References

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.