Why Are PCB Surface Finishes Critical for Board Performance?

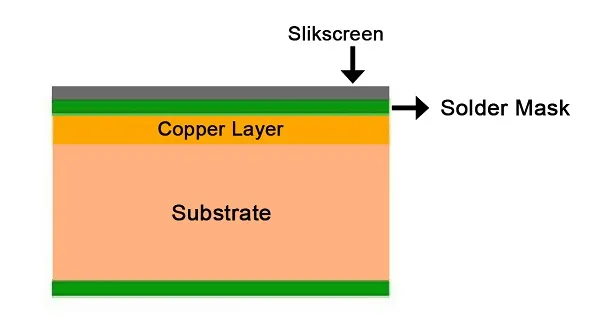

Printed Circuit Board (PCB) surface finishes serve a fundamental purpose: they shield the exposed copper traces from environmental degradation and ensure the board’s ability to be soldered correctly. Without an appropriate protective layer, copper can oxidize and corrode, leading to compromised electrical connections, reduced operational lifespan, and potential product failure.

Even when the correct finish is applied, imperfections can arise from various factors including improper application techniques, environmental conditions, or material inconsistencies. These flaws not only detract from the board's appearance but also critically impair its function and long-term durability. This guide from AIVON aims to equip designers and engineers with the knowledge to tackle these challenges effectively.

What Are the Most Frequent PCB Surface Finish Problems?

Before delving into solutions, it's essential to recognize the typical surface finish defects and their root causes. Each type of finish, such as Hot Air Solder Leveling (HASL), Electroless Nickel Immersion Gold (ENIG), Organic Solderability Preservative (OSP), or Immersion Silver, has its own unique vulnerabilities.

HASL Uneven Coating

HASL is a popular and cost-effective finish, but it's prone to inconsistent solder thickness. This variation can lead to unreliable solder joints and misaligned components during assembly.

● Causes:

○ Fluctuating air knife pressure during the HASL process, which disrupts solder distribution.

○ Surface contamination prior to coating, hindering uniform solder adhesion.

○ Inadequate flux application affecting solder flow.

○ Board design variations, creating uneven thermal distribution.

● Impact: Even slight thickness differences (e.g., 1-2 micrometers) can increase joint failure risk by up to 15% in demanding applications.

ENIG Black Pad

ENIG offers excellent flatness and corrosion resistance, but a serious defect known as "black pad" can occur. This involves corrosion of the nickel layer beneath the gold, resulting in a dark, tarnished appearance that compromises solderability.

● Causes:

○ High phosphorus content in the nickel layer, making it susceptible to corrosion.

○ Poor control of the immersion gold bath, causing aggressive etching of the nickel.

○ Contaminants in the plating solution disrupting chemical balance.

○ Incomplete rinsing between plating steps, leaving corrosive residues.

● Impact: Black pad can reduce solder joint strength by 20-30%, posing a risk in critical applications like aerospace.

OSP Oxidation Issues

OSP is an environmentally friendly and economical finish, but its organic layer is vulnerable to oxidation from humidity or extended storage. This leads to tarnishing and diminished solderability.

● Causes:

○ Exposure to moisture or high temperatures, degrading the organic coating.

○ Improper storage, such as unpackaged boards in humid conditions.

○ Insufficient coating thickness (typically below 0.2 micrometers) for adequate protection.

○ Handling contamination, like fingerprints, breaking down the OSP layer.

● Impact: Oxidized OSP can increase soldering defects by up to 25% due to poor solder wetting.

Immersion Silver Tarnishing

Immersion Silver provides excellent solderability and flatness but is highly sensitive to tarnishing from environmental sulfur or chlorides, resulting in a yellow or brown discoloration that impairs soldering.

● Causes:

○ Exposure to sulfur-rich environments or unsealed packaging.

○ High humidity accelerating reactions between silver and contaminants.

○ Lack of post-plating anti-tarnish treatment.

○ Extended shelf life without proper protective packaging.

● Impact: Tarnished immersion silver can reduce solder joint reliability by 10-15% because the tarnish acts as a barrier.

How Can You Effectively Troubleshoot PCB Surface Finish Problems?

Diagnosing surface finish issues requires a systematic approach to identify the root cause and implement lasting corrective actions. Here are practical troubleshooting steps for each defect type:

Resolving HASL Uneven Coating

● Process Review: Scrutinize HASL air knife settings for consistent pressure (e.g., 2-4 psi).

● Pre-Cleaning: Ensure thorough board cleaning with solutions like isopropyl alcohol to remove contaminants before HASL.

● Flux Optimization: Verify even flux application, aiming for a thickness of 1-2 micrometers, to promote proper solder flow.

● Design Adjustments: If issues persist, consider design modifications to balance thermal mass and prevent hot spots.

Addressing ENIG Black Pad

● Nickel Analysis: Test the nickel layer for phosphorus content, targeting 7-9% to reduce corrosion risk during gold plating.

● Gold Bath Monitoring: Maintain immersion gold bath parameters (e.g., pH 4.5-5.5, temperature 80-85°C) to avoid excessive nickel etching.

● Rinsing Enhancement: Implement rigorous rinsing with deionized water between plating stages to eliminate chemical residues.

● Inspection: Conduct microscopic inspections (50x magnification) to detect early signs of black pad, allowing for potential rework.

Managing OSP Oxidation Issues

● Storage Control: Store OSP-finished PCBs in vacuum-sealed bags with desiccants, keeping temperatures below 30°C.

● Thickness Verification: Use a gauge to confirm OSP layer thickness (0.2-0.5 micrometers) for adequate protection.

● Handling Protocols: Ensure personnel wear gloves to prevent contamination from skin oils.

● Reapplication Option: If oxidation is present before assembly, consider stripping the old layer with a mild acid and reapplying OSP under controlled conditions.

Tackling Immersion Silver Tarnishing

● Environmental Assessment: Identify and mitigate exposure to sulfur-rich environments; use sulfur-free packaging.

● Anti-Tarnish Treatment: Ensure an anti-tarnish coating (approx. 0.1 micrometers) is applied immediately after silver plating.

● Humidity Control: Maintain storage humidity below 50% and use sealed packaging.

● Surface Testing: Utilize tarnish tests (e.g., hydrogen sulfide exposure) to evaluate silver layer resistance.

Practical Solutions for Repairing PCB Surface Finish Defects

While preventing defects is always the goal, repair is sometimes necessary. These methods can help salvage boards and ensure they meet functional requirements.

Repairing HASL Uneven Coating

Minor unevenness can often be corrected with localized rework. Use a fine-tipped soldering iron at 260-300°C to apply additional solder to thin areas, aiming for a uniform layer. For severe cases, the HASL layer can be stripped with a solder stripper and reapplied under controlled conditions.

Repairing ENIG Black Pad

Repairing black pad is challenging due to underlying nickel corrosion. For localized defects, chemically etch away the affected gold and nickel, then replate the area. For widespread issues, replacing the board and adjusting the plating process for future batches may be more economical.

Repairing OSP Oxidation Issues

Oxidized OSP layers can often be restored by gently cleaning the surface with a mild acid solution, such as 5% citric acid, to remove the degraded layer. After thorough drying, reapply a fresh OSP coating via a dip process. Prompt assembly is crucial to prevent re-oxidation.

Repairing Immersion Silver Tarnishing

For tarnished immersion silver, use a silver cleaner or a mild abrasive pad to reveal the fresh silver beneath. Care must be taken to avoid excessive scrubbing, which can reduce the silver layer thickness (e.g., 0.05-0.1 micrometers per cycle). After cleaning, apply an anti-tarnish coating and store the board appropriately.

How Can You Prevent PCB Surface Finish Defects Proactively?

Preventing defects significantly reduces time and cost. Here are some best practices:

● Manufacturing Quality Control: Implement stringent process controls for surface finish application, including regular equipment calibration and chemical bath testing. Consistent control is particularly critical for multilayer PCBs with fine features and multiple copper layers.

● Optimized Storage: Store finished PCBs in environments with low humidity (below 50%) and minimal exposure to contaminants.

● Informed Material Selection: Choose surface finishes based on the application's specific environmental and performance demands. For instance, ENIG is suitable for high-reliability applications, while OSP works well for short-shelf-life, cost-sensitive projects.

● Staff Training and Handling: Provide comprehensive training on proper handling techniques to prevent contamination, especially for sensitive finishes like OSP or immersion silver, requiring the use of protective gear.

Final Thoughts on Maintaining High-Quality PCB Surface Finishes

Navigating PCB surface finish defects, from HASL unevenness to ENIG black pad, OSP oxidation, and immersion silver tarnishing, can present significant hurdles in manufacturing and assembly. However, by deeply understanding their origins, employing systematic troubleshooting, and utilizing effective repair strategies, you can uphold the superior quality and reliability of your PCBs. AIVON, a well-known large PCB manufacturer, is dedicated to empowering engineers and manufacturers with the necessary resources and expertise to confront these challenges directly.

By integrating the practical steps detailed in this guide, you can substantially reduce defects, minimize rework, and guarantee that your circuit boards meet the most stringent performance benchmarks. Whether you're addressing a specific flaw or aiming to enhance your overall process, a proactive stance is vital. This involves establishing robust quality controls, ensuring correct board storage, and selecting the most appropriate surface finish for each application. With these strategies, you will be well-prepared to overcome any surface finish obstacles.