What is PCB Depaneling and Its Significance in Manufacturing?

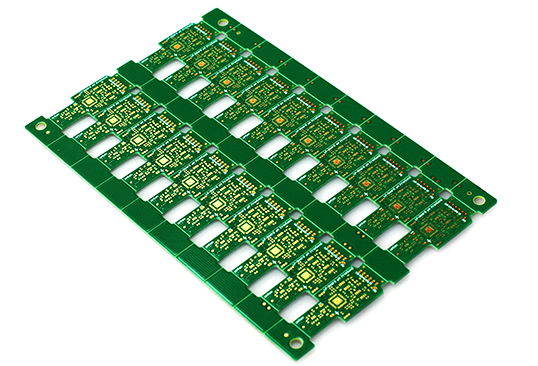

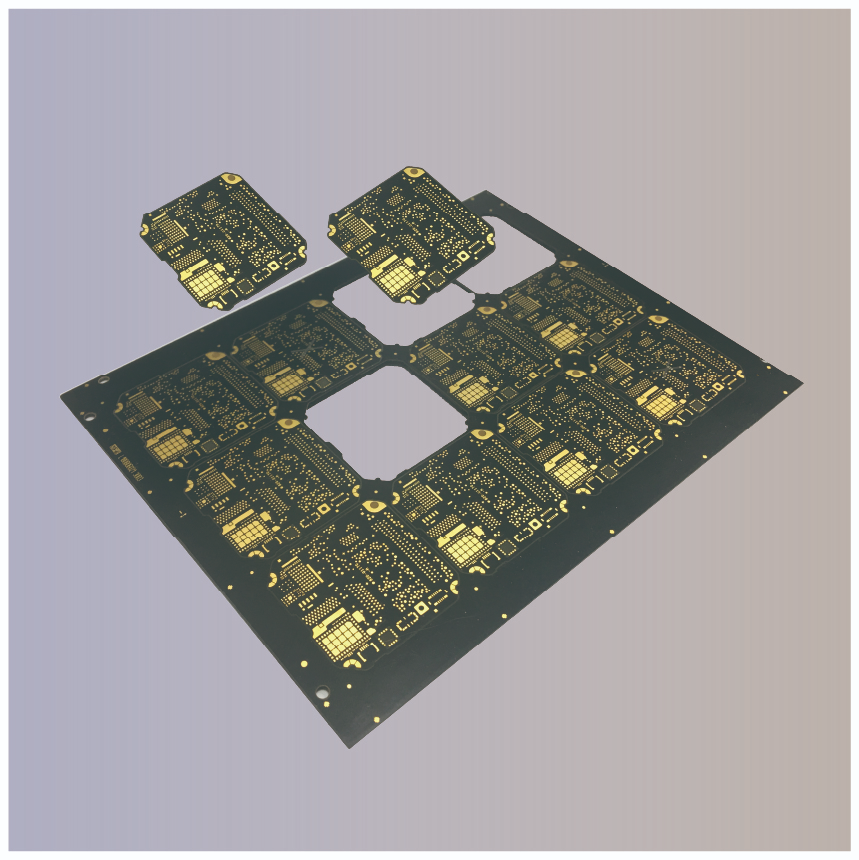

PCB depaneling is the essential process of separating individual circuit boards from a larger panel after they have completed the manufacturing cycle. Panelization is a common strategy in PCB fabrication, as it allows multiple boards to be produced, assembled, and tested concurrently, thereby streamlining the overall production workflow. However, once these processes are finished, the individual boards must be carefully separated from the panel to prevent any damage to delicate components or sensitive traces situated near their edges.

The selection of the appropriate depaneling method is critically important because it directly impacts the final quality of the finished circuit board, influences production costs, and affects the overall efficiency of the manufacturing operation. Among the various techniques available, V-scoring and routing stand out as two of the most commonly employed methods, each possessing its own unique advantages and disadvantages. This guide will thoroughly examine these two primary PCB depanelization methods to help you determine which one is best suited for your specific project requirements.

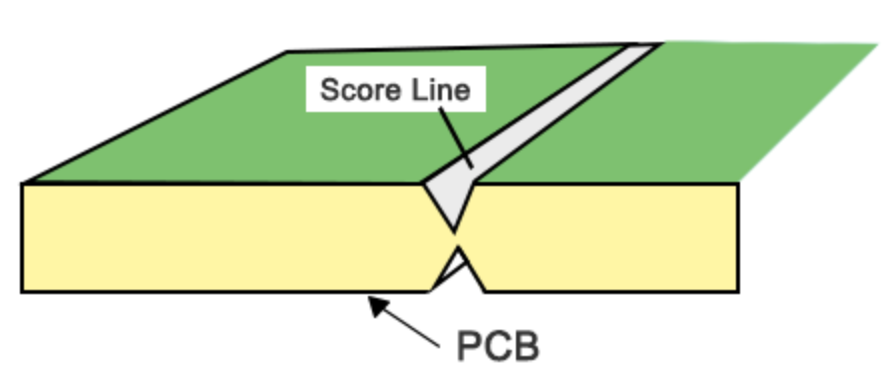

Understanding V-Scoring: A Cost-Efficient Depaneling Technique

V-scoring, also widely recognized as V-grooving, is a prevalent depaneling technique characterized by the creation of V-shaped grooves on both the top and bottom surfaces of the PCB panel, precisely along the intended separation lines. These grooves effectively weaken the board material, making it relatively simple to snap the individual boards apart either by hand or with minimal mechanical assistance. This method is particularly favored in high-volume manufacturing environments due to its inherent simplicity and speed.

Advantages of V-Scoring

● Cost-Effectiveness: V-scoring is generally a more economical option compared to other depaneling methods. The process requires minimal specialized tooling and can be executed quickly during the initial stages of board fabrication, which significantly reduces pcb cost. For large-scale production, this can lead to substantial savings when evaluating V-scoring cost against routing cost.

● High Efficiency: Since V-scoring is seamlessly integrated into the initial PCB manufacturing process and does not demand additional, complex steps like programming intricate cutting paths, it is a much faster method for separations that follow straight lines.

● Minimal Component Stress: When performed correctly, the act of snapping boards along V-scored lines typically imparts less mechanical stress on nearby components compared to other manual separation techniques.

Disadvantages of V-Scoring

● Limited to Straight Lines: A major limitation of V-scoring is that it is only applicable for straight separation lines. If your PCB design incorporates curves, irregular shapes, or non-linear outlines, this method will not be suitable.

● Edge Quality Concerns: The V-scoring edge quality can often be rougher than that achieved with other methods. The snapping process may leave behind small burrs or result in uneven edges, which might not meet the aesthetic or precision requirements of certain high-end applications.

● Material Constraints: V-scoring is generally not recommended for very thin or highly flexible PCBs. The depth of the V-grooves (typically 30-50% of the board's total thickness per side) can excessively weaken the panel, risking premature breakage or damage during subsequent handling before final separation.

Understanding Routing: Precision and Adaptability in Depaneling

Routing, often referred to as tab routing or CNC routing, involves the use of a computer-controlled cutting tool (a router bit) to mill away the material that separates individual PCBs within a panel. Small tabs or breakaway points are commonly left intact to hold the boards securely within the panel during the assembly process. These tabs are then snapped or cut away after assembly. This method offers a much greater degree of control and precision, making it an excellent choice for complex and intricate designs.

Advantages of Routing

● Superior Edge Quality: The routing edge quality is typically far smoother and more consistent than that achieved with V-scoring. The CNC milling process produces clean, precise cuts with minimal burrs, which is an essential requirement for applications where aesthetics, tight dimensional tolerances, or the integrity of edge-mounted components are critical.

● Flexibility for Complex Shapes: Unlike the limitations of V-scoring, routing can effectively accommodate curved, irregular, or entirely custom separation lines. This versatility makes it ideal for unique board shapes or designs that feature intricate outlines and internal cutouts.

● Better for Delicate Boards: Routing allows for precise control over the cutting parameters, which helps to significantly reduce mechanical stress on components situated near the board edges. This attribute makes it a superior choice for densely populated or fragile PCBs where component integrity is paramount.

Disadvantages of Routing

● Higher Cost: When comparing V-scoring cost against routing cost, routing is generally the more expensive option. It necessitates specialized CNC equipment, requires custom programming for each distinct panel design, and involves longer processing times. These factors can accumulate, particularly for large-volume production runs.

● Slower Process: Routing is inherently a more time-consuming process than V-scoring. Each individual separation path must be programmed and cut separately, which slows down the overall depaneling operation.

● Dust and Debris Generation: The milling process inevitably generates fine dust and debris. If not properly managed and extracted, this particulate matter can potentially contaminate the circuit board, necessitating additional cleaning steps to ensure product quality.

V-Scoring vs. Routing: A Detailed Factor-by-Factor Comparison

To assist you in making an informed decision between these two prominent PCB depanelization methods, let’s conduct a detailed comparison across several key factors: cost, edge quality, design flexibility, and overall production speed.

1. Cost Comparison: V-Scoring Cost vs. Routing Cost

Cost is often a paramount consideration in PCB manufacturing. V-scoring consistently emerges as the more budget-friendly option, particularly for high-volume production. The V-scoring process is seamlessly integrated into the initial panel fabrication stage and typically requires no additional specialized equipment beyond the initial setup. For instance, in a large production run of 10,000 units, V-scoring could potentially offer savings of 20-30% in depaneling costs compared to routing, primarily due to reduced labor and machine operating time.

Conversely, routing involves higher initial costs stemming from the necessity of specialized CNC machinery and the requirement for custom programming tailored to each unique panel design. For smaller production runs or prototyping, this cost disparity might be negligible, but for extensive large-scale production, the difference can become quite substantial. If your project operates under strict budget constraints and your design permits straight-line separations, V-scoring is likely the more advantageous choice.

2. Edge Quality: V-Scoring Edge Quality vs. Routing Edge Quality

Edge quality is another critical factor, especially for applications where the aesthetic appearance of the board or a precise mechanical fit is paramount. V-scoring edge quality tends to be rougher. The snapping process can leave behind small burrs, nubs, or uneven surfaces along the break line. While this might be acceptable for internal components or less demanding applications, it can pose significant issues for designs incorporating edge-mounted connectors, or those requiring tight mechanical tolerances for integration into enclosures.

In stark contrast, routing edge quality is consistently much smoother and more uniform. The precision of the CNC milling process ensures clean, accurate cuts with minimal imperfections, often eliminating the need for any post-processing or deburring. If your project demands impeccably smooth and high-quality edges—such as for premium consumer electronics, medical devices, or aerospace applications—routing is unequivocally the superior option.

3. Design Flexibility

Design constraints play a substantial role in the choice between V-scoring and routing. V-scoring is strictly limited to straight separation lines, meaning it is best suited for rectangular or square boards arranged in a rectilinear grid pattern. If your PCB design incorporates features such as rounded corners, internal cutouts, or any non-linear shapes along the separation boundary, V-scoring simply will not be a viable option.

Routing, however, offers a significantly greater degree of design flexibility. It can accommodate virtually any board shape or panel layout, making it the ideal choice for custom designs or boards featuring unique, intricate outlines and internal cutouts. While this versatility comes with an increased cost, for complex projects, the investment is often justified by the design freedom it provides.

4. Production Speed and Scalability

Speed is a crucial consideration in manufacturing, especially for high-volume production runs. V-scoring is inherently faster because it is a simpler, more direct process that does not require individual programming or cutting paths for each board. Panels can be V-scored in bulk during the initial fabrication stages, and the subsequent separation can often be performed manually or with relatively basic tools.

Routing, while providing superior precision, is a slower process due to the time required to program the CNC machine and individually mill each separation path. For small batches or prototype runs where the emphasis is on quality over raw speed, this difference in processing time may not be a major concern. However, for large-scale production, routing can potentially create bottlenecks if the process is not efficiently managed and scaled.

When to Opt for V-Scoring in Your PCB Project

V-scoring is the most appropriate choice for projects where cost-efficiency and rapid production are paramount, and the design inherently allows for straight-line separations. Here are specific scenarios where V-scoring offers distinct advantages:

● High-Volume Production: If you are manufacturing thousands of identical, simple boards, V-scoring can yield considerable savings in both time and money.

● Simple Board Designs: For rectangular or square boards devoid of complex edge shapes or internal cutouts along the separation lines, V-scoring presents a practical and highly efficient method.

● Strict Budget Constraints: When keeping production costs to an absolute minimum is a critical objective, V-scoring provides a reliable solution without compromising fundamental functionality.

It is important to remember that V-scoring necessitates careful design planning. The V-grooves must be positioned at least 0.3 mm away from any traces or components to prevent damage during the snapping process. Furthermore, the panel material should possess sufficient thickness (typically 1.0 mm or greater) to maintain structural integrity and withstand handling prior to final separation.

When to Opt for Routing in Your PCB Project

Routing is the superior choice for projects that demand exceptional precision, high design flexibility, or impeccable edge finishes. Consider routing in the following situations:

● Complex Board Shapes: If your design features curves, intricate cutouts, non-standard outlines, or internal slots, routing is often the only viable and effective depaneling method.

● High-Quality Edge Requirements: For applications where smooth, clean, and aesthetically pleasing edges are absolutely essential—such as in consumer-facing products, medical devices, or precision enclosures—routing consistently delivers the best possible results.

● Small Batch or Prototype Runs: For smaller production batches or prototype runs where the total cost is less of a primary concern than achieving design accuracy and quality, routing offers the flexibility to test and refine designs without being constrained by separation limitations.

Routing also requires specific design considerations. Breakaway tabs, which hold the individual boards in the panel, should be strategically placed to minimize any stress on nearby components during the final tab removal. A minimum clearance of at least 0.5 mm from critical components or traces is generally recommended to prevent accidental damage during the milling process.

Concluding Thoughts on Optimal PCB Depaneling Choices

The decision between V-scoring versus routing for PCB depaneling ultimately hinges on a careful balance of cost, desired quality, and the specific design requirements of your project. V-scoring offers a cost-effective and efficient method, particularly suited for mass production of pcb, though it may involve some compromise on edge quality. Routing, while generally more expensive and time-consuming, provides unparalleled precision and design flexibility, making it the ideal choice for complex designs or projects where pristine, smooth edges are critical.

By thoroughly understanding the inherent strengths and limitations of each depaneling method, you can confidently select the technique that best aligns with your project's unique needs. Whether your primary concern is balancing V-scoring cost against routing cost, or prioritizing V-scoring edge quality versus routing edge quality, meticulous planning and close collaboration with your manufacturing partner are essential for achieving a successful outcome. At AIVON, we are dedicated to assisting you in navigating these important choices with expert guidance and providing high-quality manufacturing solutions precisely tailored to your specifications.