What Is PCB Lamination and Why Is Temperature Control Critical?

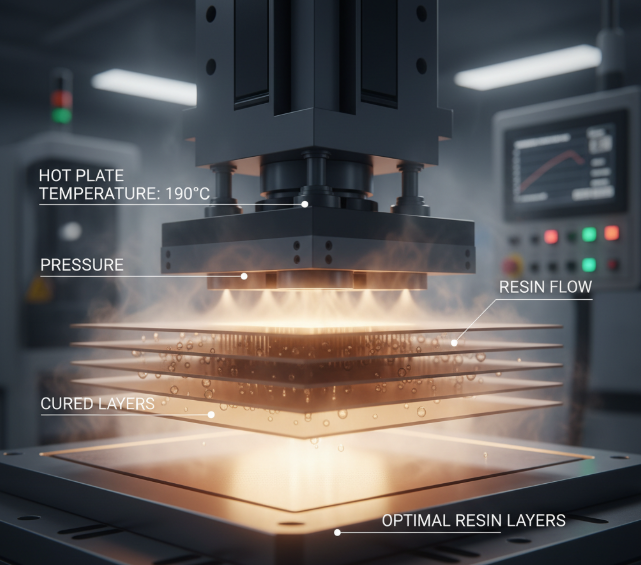

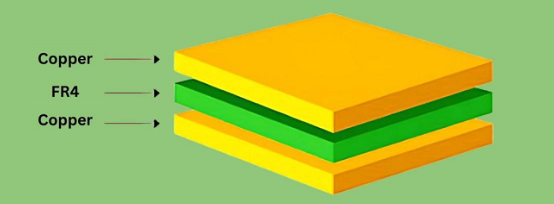

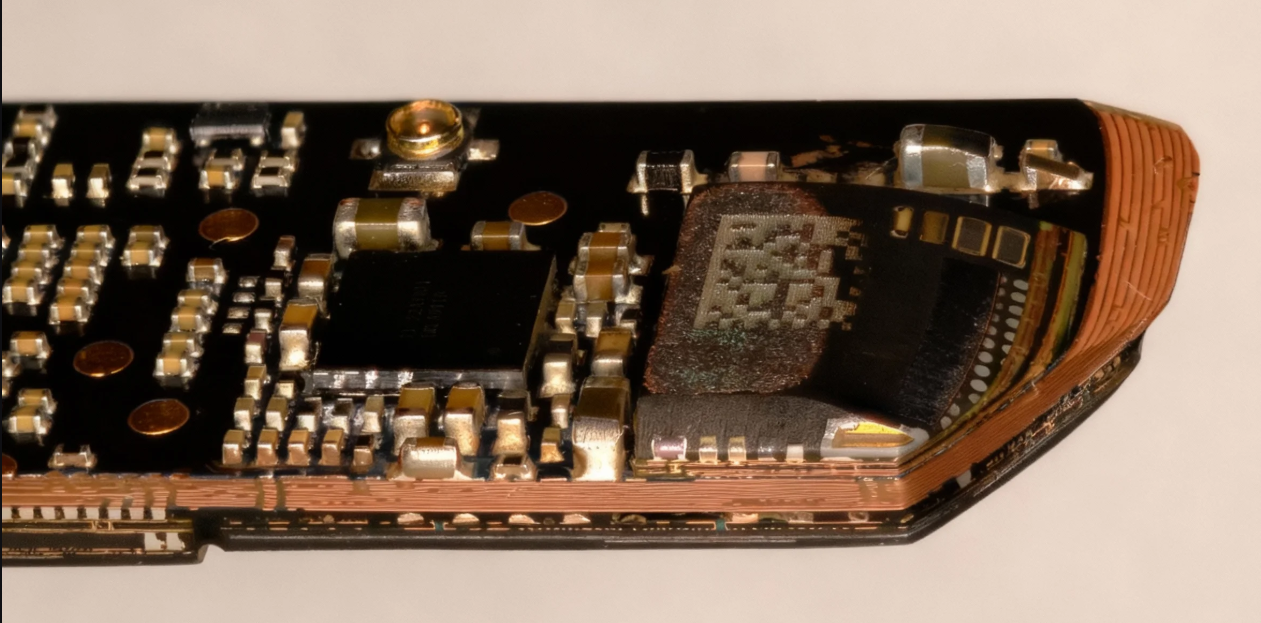

PCB lamination is a fundamental manufacturing process that involves bonding multiple layers of materials, typically copper foil and dielectric insulating substrates, to construct a multilayer printed circuit board. This process relies on a combination of heat and pressure to permanently fuse these layers, thereby ensuring both electrical connectivity and robust mechanical stability in the final product. The temperature maintained during PCB lamination plays an absolutely pivotal role, directly influencing the behavior of the resin within the prepreg (pre-impregnated composite fibers)—specifically, how it flows and subsequently cures.

Suboptimal temperature settings can lead to significant manufacturing defects. If the temperature is too low, the resin may not achieve proper flow characteristics, resulting in voids, incomplete filling, or weak adhesion between layers. Conversely, if the temperature is excessively high, the resin can cure prematurely and unevenly, potentially leading to material degradation. Therefore, achieving an precise balance with the hot plate temperature and the temperature ramp rate is not merely important but essential for a successful lamination process, particularly when working with ubiquitous materials like PCB FR-4 material.

Key Factors Influencing PCB Lamination Temperature Parameters

To ensure optimal outcomes in PCB lamination, several temperature-related variables demand meticulous management. Understanding and controlling these critical factors is paramount for producing high-quality multilayer boards.

The Role of Hot Plate Temperature

The hot plate temperature within a lamination press serves as the primary thermal energy source, driving the critical stages of resin flow and curing. For most standard FR-4 materials, the hot plate is typically maintained within a range of 180°C to 200°C (356°F to 392°F). This temperature window is specifically chosen to allow the epoxy resin in the prepreg to soften and flow effectively, filling all interstitial spaces between layers before it hardens during the curing phase.

Maintaining an absolutely uniform hot plate temperature across the entire surface of the panel is vital. Even minor temperature variations, as slight as 5°C, can lead to uneven resin distribution, which in turn results in defects such as delamination or incomplete bonding. Contemporary lamination presses often incorporate advanced temperature control systems that continuously monitor and dynamically adjust the hot plate temperature in real-time, thereby ensuring exceptional consistency throughout the process.

Suggested Reading: Delamination in PCB Lamination: Causes, Detection, and Prevention

Managing the Temperature Ramp Rate

The temperature ramp rate refers to the carefully controlled speed at which the temperature is increased or decreased during the lamination cycle. A precisely controlled ramp rate is essential to prevent thermal shock to the constituent materials, which could otherwise cause warping, cracking, or other forms of material stress. For FR-4 laminates, a typical heating ramp rate ranges from approximately 2°C to 5°C per minute until the desired peak temperature is achieved.

A slower heating ramp rate facilitates gradual resin heating, which promotes a more uniform resin flow and significantly reduces the likelihood of trapping air bubbles within the stack-up. Similarly, during the cooling phase, a controlled ramp rate (often between 2°C and 3°C per minute) is implemented to minimize internal stresses that could develop within the cured board. Adjusting this ramp rate based on the specific material composition and the overall stack-up design is a critical component of optimizing all PCB lamination parameters.

Specifics of FR-4 Lamination Temperature

FR-4 is a ubiquitous material in PCB manufacturing, prized for its balanced combination of cost-effectiveness and performance. Consequently, it has very specific temperature requirements for successful lamination. The optimal FR-4 lamination temperature typically falls between 180°C and 190°C for most standard grades. Within this range, the epoxy resin achieves the ideal viscosity for proper flow and then cures effectively to form a robust, permanent bond.

However, it's important to note that different grades of FR-4, such as high-Tg (glass transition temperature) or halogen-free variants, may necessitate slight modifications to this temperature profile. For example, high-Tg FR-4 materials, engineered for enhanced thermal resistance, often require a slightly elevated lamination temperature, around 200°C, to ensure complete and thorough curing. Always consult the material large pcb manufacturer's datasheet for precise recommendations regarding PCB lamination temperature and corresponding curing times for specific materials.

Optimizing Resin Flow and Curing for Enhanced Reliability

The twin processes of resin flow and curing are foundational to the mechanical and electrical integrity of the final PCB. Precise temperature control is crucial for both stages.

Enhancing Resin Flow

Resin flow is a critical aspect, dictating how effectively the prepreg material fills all spaces between copper layers and ensures robust bonding. Temperature directly influences the resin's viscosity: higher temperatures reduce viscosity, promoting better flow, while lower temperatures increase it, potentially leading to incomplete filling.

To optimize resin flow, consider these strategies:

● Preheat the Stack-Up: Before applying full lamination pressure, preheating the PCB stack-up at a lower temperature (around 100°C to 120°C) for 10-15 minutes can initiate resin flow gently without triggering premature curing.

● Controlled Pressure Application: Apply pressure incrementally, in tandem with the temperature increase, to prevent the resin from being squeezed out of the stack-up too rapidly, which can result in voids.

● Monitor Resin Content: The resin content within the prepreg (typically 40-50% by weight for FR-4) significantly affects its flow characteristics. Materials with higher resin content may require slightly lower temperatures to prevent excessive "flow-out."

Balancing temperature and pressure meticulously ensures that the resin flows uniformly, effectively filling all gaps and creating a consistent bond without excessive expulsion, which could lead to excessively thin dielectric layers or potential electrical issues.

Ensuring a Robust Curing Process

The curing process represents the final, critical stage of lamination, where the resin undergoes a chemical reaction to harden into a solid, durable structure. Proper curing is indispensable for the PCB's long-term mechanical strength and thermal stability. Temperature control during this phase directly impacts the degree of cross-linking within the epoxy resin, which, in turn, determines the material’s ultimate physical and thermal properties.

For FR-4 materials, curing typically occurs at the peak lamination temperature (180°C to 200°C) for a duration ranging from 60 to 120 minutes, depending on the material thickness and the complexity of the stack-up. Insufficient curing time or inadequate temperature can result in a partially cured resin, leading to compromised mechanical strength and the risk of delamination over time. Conversely, over-curing at excessively high temperatures can render the material brittle and more susceptible to cracking.

To guarantee a successful curing process:

● Maintain a consistently stable temperature throughout the entire curing phase to achieve uniform cross-linking across the entire board.

● Implement a controlled cooling phase after curing to mitigate thermal stress, which can otherwise cause warping or the formation of micro-cracks.

● Monitor the glass transition temperature (Tg) of the cured material, as this provides a clear indication of the final PCB's thermal performance. For standard FR-4, Tg typically falls between 130°C and 140°C, whereas high-Tg variants can achieve values of 170°C or even higher.

Addressing Common Challenges in Temperature Control

Even with sophisticated equipment, challenges in PCB lamination temperature control can arise. Identifying and resolving these issues is key to consistent quality.

Overcoming Specific Problems

1. Uneven Heating: Inconsistent temperature distribution across the hot plates can lead to non-uniform resin flow and curing. This often points to worn equipment or calibration issues. Regular calibration of the lamination press and thorough inspection of hot plates for damage are crucial. Utilizing thermal imaging cameras can help pinpoint and rectify specific hot or cold spots.

2. Thermal Shock: Rapid temperature fluctuations, particularly during the cooling phase, can induce thermal shock, leading to material stress and potential defects. Implementing a gradual temperature ramp rate for both heating and cooling cycles effectively minimizes this stress. For FR-4, cooling rates of 2°C to 3°C per minute are generally considered safe and effective.

3. Material Variability: Different production batches of prepreg or laminate materials may exhibit slight variations in resin content or curing characteristics, which can affect the optimal PCB lamination parameters. It is always advisable to test a small sample of new material batches under rigorously controlled conditions to fine-tune temperature and pressure settings before commencing full-scale production.

Best Practices for Superior PCB Lamination Temperature Control

To consistently achieve excellent results in PCB lamination, adhering to established best practices is essential.

Strategies for Consistent Quality

● Invest in Advanced Equipment: Prioritize modern lamination presses equipped with highly precise temperature and pressure control systems to ensure superior repeatability and accuracy.

● Thorough Parameter Documentation: Maintain detailed records of all PCB lamination parameters (including temperature profiles, ramp rates, and curing times) for every production run. This creates an invaluable reference database for efficient troubleshooting and ongoing process optimization.

● Comprehensive Staff Training: Ensure that all operators are extensively trained in managing complex temperature profiles and are adept at recognizing early indicators of improper lamination, such as voids or delamination.

● Collaborate with Suppliers: Foster close working relationships with material suppliers to gain a deep understanding of the specific temperature requirements for each batch of prepreg or laminate, especially when integrating specialized FR-4 variants into production.

Conclusion: The Cornerstone of High-Quality PCB Manufacturing

Effective PCB lamination temperature control stands as the bedrock for producing consistently reliable and high-performance multilayer circuit boards. By meticulously managing hot plate temperature, controlling the temperature ramp rate, and optimizing other critical PCB lamination parameters, manufacturers can precisely optimize both resin flow and the curing process. This precision ensures robust bonding and guarantees the long-term durability of the final product. Whether you are working with standard FR-4 or more specialized materials, a deep understanding and careful fine-tuning of the FR-4 lamination temperature are key to preventing common manufacturing defects such as delamination or voids.

Implementing the best practices and expert solutions outlined in this guide will empower you to achieve consistent, high-quality outcomes in your PCB manufacturing process. With truly precise temperature control, you can significantly enhance the reliability of your circuit boards, enabling them to meet the increasingly stringent demands of cutting-edge electronics applications.