Introduction

In the realm of high-power electronics, effective thermal management remains a critical challenge for engineers. As devices become more compact and power-dense, dissipating heat efficiently is vital to ensure reliability and performance. Aluminum PCBs, also known as insulated metal substrate (IMS) PCBs, have emerged as a preferred solution for addressing these thermal concerns. Their superior aluminum PCB thermal conductivity allows for rapid heat transfer away from sensitive components. This article explores the technical foundations of aluminum PCBs, their fabrication processes, and best practices for implementation in demanding applications. Aimed at electrical engineers, the content provides structured insights into leveraging these substrates for optimal thermal performance in high-power systems.

What Are Aluminum PCBs and Why Do They Matter

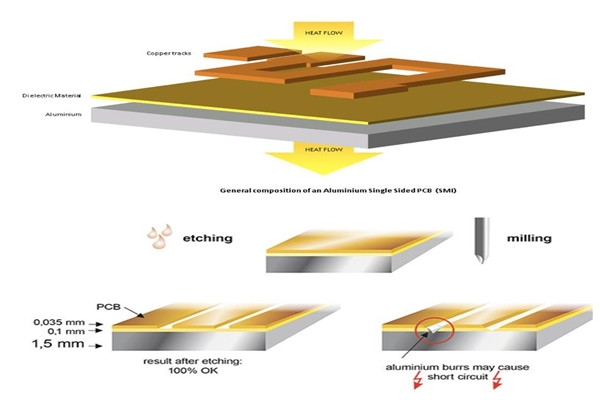

Aluminum PCBs are a specialized type of printed circuit board that utilize a metal base layer, typically aluminum, to enhance heat dissipation. Unlike traditional FR-4 substrates, which rely on epoxy glass with lower thermal conductivity, aluminum PCBs incorporate a thermally conductive dielectric layer between the metal base and the copper circuitry. This construction, often referred to as insulated metal substrate (IMS) PCB, facilitates efficient heat transfer from electronic components to the metal core, reducing thermal stress.

The importance of aluminum PCBs in high-power electronics cannot be overstated. Applications such as LED lighting, power converters, and automotive systems generate significant heat, which can degrade performance or cause failure if not managed properly. By using aluminum as a substrate, these boards offer a practical solution for maintaining operational stability in environments where heat buildup is a concern. Their ability to handle high thermal loads makes them indispensable in modern electronic design.

Technical Principles of Aluminum PCB Thermal Conductivity

Understanding the thermal behavior of aluminum PCBs requires a focus on their structural composition. The aluminum base layer typically exhibits a thermal conductivity ranging from 1 to 2 W/mK for the dielectric layer, while the metal itself can reach much higher values, often around 200 W/mK or more depending on the alloy. This performance gap is a critical factor in the Aluminum vs. FR4 PCB material decision, as standard FR-4 offers only about 0.3 W/mK, highlighting why aluminum substrates excel in heat dissipation.

The heat transfer mechanism in an aluminum PCB operates through conduction. Heat generated by components travels through the thin dielectric layer to the aluminum core, which then spreads the thermal energy across a larger surface area. This process minimizes localized hot spots and reduces the risk of component overheating. Additionally, the dielectric layer serves as an electrical insulator while maintaining sufficient thermal conductivity, ensuring both safety and performance.

Standards such as IPC-6012E provide guidelines for the qualification and performance of rigid printed boards, including those with metal cores. Adhering to such specifications ensures that the thermal and mechanical properties of aluminum PCBs meet industry expectations for high-power applications. Engineers must consider these principles when designing systems to balance electrical isolation with effective heat management.

Aluminum PCB Fabrication: Key Considerations

To ensure the manufacturing process meets design goals, it is crucial to first understand the pros and cons of aluminum PCBs. The process of aluminum PCB fabrication involves several distinct steps that influence the board's thermal and electrical performance. Initially, the aluminum base is prepared with a surface treatment to enhance adhesion of the dielectric layer. This layer, often a thermally conductive polymer or ceramic composite, is laminated onto the metal substrate under controlled conditions to avoid defects.

Next, the copper foil is applied over the dielectric layer, forming the circuit pattern through etching processes. Precision in this stage is critical to maintain electrical integrity and ensure proper heat transfer pathways. Fabrication must comply with standards like IPC-A-600K, which outlines acceptability criteria for printed boards, including surface finish and layer alignment. Any deviation can compromise the board's ability to manage thermal loads effectively.

Engineers should also note the importance of material selection during fabrication. The thickness of the aluminum base and dielectric layer must be optimized based on the application's thermal requirements. Thicker aluminum layers enhance heat spreading, while thinner dielectric layers improve thermal conductivity but may reduce electrical isolation. Balancing these factors is essential for achieving reliable performance in high-power electronics.

Practical Solutions for Thermal Management with Aluminum PCBs

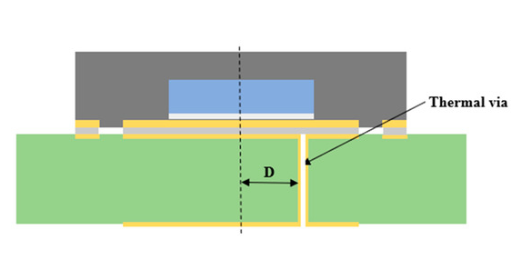

Implementing aluminum PCBs in high-power electronics requires strategic design practices to maximize their thermal benefits. One effective approach is the use of thermal via placement in aluminum PCB designs. Thermal vias are small holes filled with conductive material that connect the top copper layer to the aluminum base, creating direct heat paths. Proper placement of these vias near heat-generating components ensures efficient dissipation.

Another best practice involves optimizing the layout for heat distribution. Components with high power dissipation should be positioned to allow uniform heat spread across the aluminum substrate. Avoiding clustering of heat sources prevents localized temperature spikes. Additionally, engineers can integrate heat sinks or external cooling mechanisms directly with the aluminum base to further enhance thermal performance.

Surface finishes also play a role in thermal management. Finishes that comply with IPC-A-600K standards ensure minimal thermal resistance at interfaces. When designing, consider the operating environment and select materials that withstand thermal cycling without degradation. These solutions, grounded in engineering principles, help maintain system reliability under demanding conditions.

For more practical solutions for thermal management with aluminum PCBs, see our comprehensive guide: Aluminum PCBs: The Comprehensive Guide to Metal Core Circuit Boards

Aluminum PCB Applications in High-Power Electronics

Aluminum PCBs find extensive use in industries where thermal management is paramount. In LED lighting systems, for instance, these boards dissipate heat from high-intensity diodes, prolonging lifespan and maintaining brightness. Power electronics, such as inverters and converters, also benefit from aluminum substrates due to their ability to handle significant thermal loads during operation.

Automotive electronics represent another key area for aluminum PCB applications. With the rise of electric vehicles, managing heat in battery management systems and motor controllers is critical. Aluminum PCBs provide the necessary thermal conductivity to ensure stable performance under varying conditions. Furthermore, their lightweight nature contributes to overall vehicle efficiency, aligning with industry demands for sustainability.

Telecommunications equipment, particularly high-frequency amplifiers, also relies on aluminum PCBs to manage heat generated during signal processing. By adhering to design standards like IPC-6012E, engineers can ensure these boards meet the stringent requirements of such applications. The versatility of aluminum substrates makes them a go-to choice across diverse high-power electronic sectors.

Related Reading: Aluminum PCBs: An Essential Solution for High-Performance Electronics

Troubleshooting Thermal Issues with Aluminum PCBs

Even with optimal design, thermal challenges can arise in aluminum PCB implementations. A common issue is insufficient heat dissipation due to poor thermal via placement. If vias are not aligned with heat sources, localized overheating may occur. Engineers should use simulation tools to predict heat flow and adjust via positioning accordingly during the design phase.

Another concern is delamination of the dielectric layer under thermal stress. This can result from improper material selection or fabrication errors. Referencing standards like IPC-A-600K helps identify acceptable bonding criteria to prevent such failures. Regular inspection and testing during manufacturing ensure the integrity of the layers under expected operating temperatures.

Finally, mismatches in thermal expansion between the aluminum base and other materials can induce mechanical stress. Careful selection of compatible materials and adherence to design guidelines mitigate this risk. Addressing these issues proactively ensures that aluminum PCBs perform reliably in high-power electronics.

Conclusion

Aluminum PCBs stand as a cornerstone for thermal management in high-power electronics, offering unmatched heat dissipation through their superior aluminum PCB thermal conductivity. Their construction as insulated metal substrate (IMS) PCBs enables efficient heat transfer while maintaining electrical isolation. From fabrication techniques to strategic thermal via placement, engineers can leverage these substrates to enhance system reliability. Applications spanning LED lighting, automotive, and telecommunications underscore their versatility. By adhering to industry standards and best practices, designers can address thermal challenges effectively, ensuring optimal performance in demanding environments.

FAQs

Q1: How does aluminum PCB thermal conductivity compare to traditional FR-4 boards?

A2: Aluminum PCB thermal conductivity is significantly higher than that of FR-4 boards. While FR-4 typically offers around 0.3 W/mK, the dielectric layer in aluminum PCBs can reach 1 to 2 W/mK, and the metal base far exceeds this. This makes aluminum substrates ideal for high-power applications requiring efficient heat dissipation.

Q2: What are the key benefits of using insulated metal substrate (IMS) PCB in electronics?

A2: Insulated metal substrate (IMS) PCB provides excellent thermal management due to its metal core, which rapidly dissipates heat. It also offers mechanical stability and lightweight construction, making it suitable for demanding environments like automotive and LED systems. This ensures component longevity and system reliability.

Q3: What factors should be considered during aluminum PCB fabrication for thermal performance?

A3: During aluminum PCB fabrication, selecting the right dielectric material and thickness is crucial for balancing thermal conductivity and electrical isolation. Surface treatment of the aluminum base and precise lamination processes also impact performance. Adhering to industry standards ensures consistent quality and heat dissipation efficiency.

Q4: How does thermal via placement in aluminum PCB design affect heat management?

A4: Thermal via placement in aluminum PCB design directly influences heat management by creating conductive paths from components to the metal base. Positioning vias near heat sources minimizes thermal resistance and prevents hot spots. Proper layout enhances overall dissipation, ensuring stable operation in high-power systems.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.