Introduction

Selecting the right material for a printed circuit board (PCB) is a critical decision in electronics design and prototype design. The choice between aluminum and FR4 PCB materials can significantly impact performance, durability, and prototype costs. Aluminum PCBs, known for their thermal conductivity, and FR4, a widely used fiberglass laminate, each offer unique benefits and challenges. For electronic hobbyists venturing into CAD design and building electronics components, understanding these materials is essential. This article provides a detailed comparison of aluminum and FR4 PCBs, exploring their properties, applications, and suitability for various projects. By examining technical aspects and practical considerations, hobbyists can make informed decisions to optimize their designs for efficiency and cost effectiveness.

What Are Aluminum and FR4 PCB Materials?

PCBs serve as the foundation for electronics components, providing mechanical support and electrical connections. The substrate material used in a PCB influences its thermal, mechanical, and electrical properties. Two common materials in electronics design are aluminum and FR4.

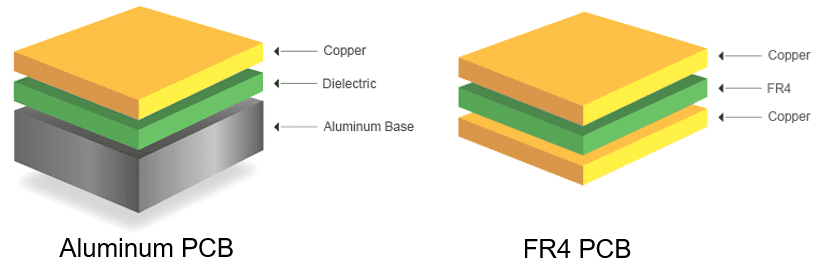

Aluminum PCBs feature a metal core, typically made of aluminum, combined with a thin dielectric layer and copper circuitry. This structure enhances heat dissipation, making them ideal for high power applications. In contrast, FR4 is a composite material made of woven fiberglass cloth with an epoxy resin binder. It is flame retardant, as indicated by the FR designation, and is the most common PCB substrate due to its versatility and affordability.

Both materials play a vital role in prototype design, but their differing properties cater to distinct needs in electronics projects. Understanding their characteristics helps hobbyists align material selection with design goals and prototype costs.

Technical Properties of Aluminum and FR4 PCBs

Thermal Conductivity

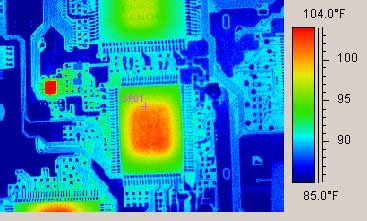

Thermal management is a key factor in electronics design, especially for components generating significant heat. Aluminum PCBs excel in this area with a thermal conductivity ranging from 1 to 2 W/mK for the dielectric layer, allowing efficient heat transfer away from critical components. This property reduces the risk of overheating in high power circuits.

FR4, however, has a much lower thermal conductivity, typically around 0.3 W/mK. It struggles to dissipate heat effectively, often requiring additional cooling solutions like heat sinks in demanding applications. For hobbyists working on LED lighting or power electronics, aluminum may be the better choice to ensure reliability.

Mechanical Strength and Durability

Mechanical strength is crucial for PCBs subjected to physical stress or vibration. Aluminum PCBs offer superior durability due to their metal core, which provides rigidity and resistance to bending. They are less prone to cracking under mechanical load, making them suitable for rugged environments.

FR4, while reasonably strong for standard applications, is more flexible and can warp or crack under excessive stress. Its fiberglass composition provides adequate support for most electronics components, but it may not withstand harsh conditions as effectively as aluminum.

Electrical Performance

Electrical insulation and signal integrity are vital in CAD design. FR4 has a dielectric constant of about 4.5, which supports stable signal transmission in high frequency circuits. It is widely used in consumer electronics due to its reliable electrical properties.

Aluminum PCBs, while offering good electrical performance, have a slightly different dielectric behavior due to the metal core. The proximity of the conductive aluminum layer requires careful design to avoid interference, especially in high frequency applications. Hobbyists must consider these factors when selecting materials for prototype design.

Weight and Size Considerations

Weight can influence the overall design, particularly in portable devices. Aluminum PCBs are heavier due to the metal core, which may be a drawback in weight sensitive projects. FR4 is lighter, offering an advantage for compact or handheld electronics.

In terms of size, both materials can be fabricated into various shapes and thicknesses. However, aluminum PCBs often have limitations in multilayer configurations compared to FR4, which supports complex, multilayer designs with ease.

Applications in Electronics Design

When to Use Aluminum PCBs

Aluminum PCBs are ideal for applications requiring efficient thermal management. They are commonly used in LED lighting, power converters, and automotive electronics where heat dissipation is critical. For hobbyists building high power prototypes, aluminum ensures components operate within safe temperature limits, extending lifespan and reliability.

Their mechanical strength also suits projects exposed to vibration or impact, such as outdoor or industrial equipment. However, the added weight and potential cost may not justify their use in low power or lightweight designs.

Related Reading: Aluminum PCBs: An Essential Solution for High-Performance Electronics

When to Use FR4 PCBs

FR4 is the go to material for most standard electronics design projects. Its versatility supports a wide range of applications, from simple hobbyist circuits to complex multilayer boards in consumer devices. FR4 is often preferred in prototype design due to its lower cost and compatibility with intricate CAD design layouts.

Hobbyists working on general purpose electronics components, such as microcontrollers or audio circuits, will find FR4 sufficient. It also allows for easier modifications during prototyping, as drilling and cutting are more straightforward compared to aluminum.

Prototype Costs and Manufacturing Considerations

Cost is a significant concern for hobbyists managing prototype costs. FR4 PCBs are generally more affordable due to their widespread use and simpler manufacturing process. They are available in various grades and thicknesses, allowing flexibility in balancing quality and budget.

Aluminum PCBs tend to be more expensive because of the specialized materials and fabrication techniques required. The metal core adds to the raw material cost, and manufacturing often involves additional steps to ensure proper insulation and bonding. For small scale prototype design, this cost difference can be notable.

Manufacturing complexity also affects lead times. FR4 boards can be produced quickly with standard processes, while aluminum boards may require longer turnaround due to their unique construction. Hobbyists must weigh these factors against project deadlines and thermal needs.

For more knowledege about aluminum PCBs, see our comprehensive guide: Aluminum PCBs: The Comprehensive Guide to Metal Core Circuit Boards

Practical Tips for Choosing Between Aluminum and FR4

Selecting the right material for your electronics design involves evaluating project requirements. Consider the thermal demands of your circuit. If your design includes high power components like LEDs or power transistors, aluminum offers better heat dissipation. For low to medium power applications, FR4 is typically sufficient and more cost effective.

Assess the mechanical environment. If your project will face physical stress or harsh conditions, aluminum provides added durability. For standard indoor or static applications, FR4 meets most needs without unnecessary expense.

Evaluate prototype costs against performance goals. While aluminum may enhance reliability in heat intensive designs, FR4 often delivers adequate performance at a lower price, especially for initial prototypes. Use CAD design tools to simulate thermal and electrical behavior before finalizing material choice.

Finally, consider manufacturing capabilities. Ensure your design aligns with standard fabrication processes to avoid delays or compatibility issues. Consulting industry standards can guide material selection and ensure compliance with best practices.

Conclusion

Choosing between aluminum and FR4 PCB materials is a pivotal decision in electronics design and prototype design. Aluminum excels in thermal management and mechanical strength, making it suitable for high power and rugged applications. FR4, with its affordability and versatility, remains the standard choice for most hobbyist projects involving electronics components. By understanding the technical properties and practical applications of each material, hobbyists can optimize their CAD design for performance and prototype costs. Careful evaluation of project needs ensures the selected material aligns with both functional requirements and budget constraints, leading to successful and reliable designs.

FAQs

Q1: What are the main differences between aluminum and FR4 PCB materials for electronics design?

A1: Aluminum PCBs feature a metal core for superior heat dissipation and durability, ideal for high power electronics design projects. FR4, a fiberglass epoxy laminate, offers versatility and lower cost, suitable for general purpose circuits. Aluminum is heavier and costlier, while FR4 supports complex multilayer designs with ease. The choice depends on thermal and mechanical needs of your project.

Q2: How do prototype costs differ between aluminum and FR4 PCBs?

A2: Prototype costs for FR4 PCBs are typically lower due to widespread availability and simpler manufacturing processes. Aluminum PCBs are more expensive because of the metal core and specialized fabrication requirements. For hobbyists managing budgets in prototype design, FR4 often provides a cost effective solution, while aluminum may be justified for heat intensive applications.

Q3: Which PCB material is better for high power electronics components?

A3: Aluminum PCBs are better suited for high power electronics components due to their excellent thermal conductivity, which helps dissipate heat effectively. This prevents overheating and extends component life. FR4, with lower thermal performance, may require additional cooling solutions. Hobbyists working on LED or power circuits should prioritize aluminum for reliability.

Q4: Can FR4 PCBs be used in CAD design for complex multilayer projects?

A4: Yes, FR4 PCBs are widely used in CAD design for complex multilayer projects. Their electrical properties and manufacturing compatibility support intricate layouts and high density circuits. Aluminum PCBs, while strong in thermal management, are less common for multilayer configurations. FR4 remains the preferred choice for most hobbyist multilayer designs due to its flexibility.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

ISO 9001:2015 — Quality Management Systems. ISO, 2015.