In the pulse-racing world of 5G base stations, automotive radar, and satellite communications, FR-4 has long been the go-to laminate—but its days are numbered for frequencies above 10 GHz. As signal speeds climb and wavelengths shrink, the demand for high-speed PCB materials with ultra-low dielectric constants (Dk) and dissipation factors (Df) is exploding. Enter advanced alternatives like PTFE-based laminates and ceramic-filled composites, which promise minimal signal loss and thermal resilience without breaking the bank on prototypes.

From my factory consultations, I've seen these materials transform yield rates from 70% to over 95% in mmWave runs, thanks to tighter control over insertion loss. With the global high frequency PCB market projected to hit $14.2 billion by 2025, driven by 5G rollouts and radar tech, it's time to look beyond FR-4. This guide, drawing on IPC standards and real production insights, dives into Rogers PCB material alternatives, PTFE PCB fabrication nuances, ceramic PCB advantages, and dielectric constant PCB material selections. We'll equip you with practical strategies to select and fab these for your next high-stakes design.

Why Go Beyond FR-4? The Push for High-Speed PCB Materials

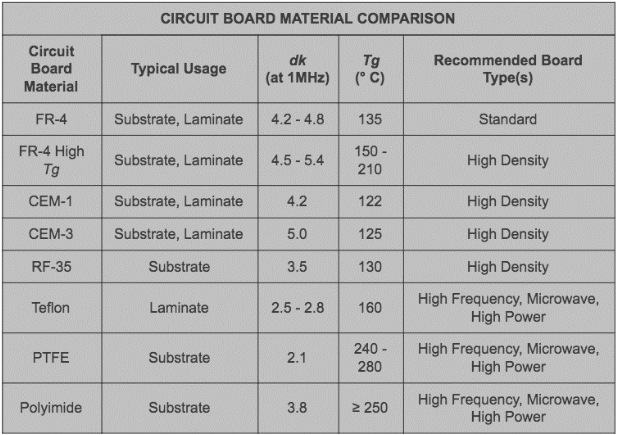

FR-4, the epoxy-glass staple per IPC-4101B, serves most apps with a Dk of 4.0-5.0 and Df around 0.02 at 1 GHz (Note 1). But in high-frequency realms, these specs spell trouble: Higher Dk slows signals (velocity = c / sqrt(Dk)), while elevated Df devours power as heat—up to 1 dB/inch loss at 20 GHz. For 5G's sub-6 GHz to mmWave bands or radar's 77 GHz pulses, you need high-speed PCB materials with Dk under 3.0 and Df below 0.005 to keep phase shifts and crosstalk in check.

This shift matters for performance and cost. In factories I've audited, FR-4 boards in RF apps rack up 15-20% rework from signal degradation, per IPC-6018 high-frequency quals (Note 2). Advanced dielectric constant PCB materials, like those from Rogers or PTFE blends, stabilize impedance (50-100 Ω) across temps (-55°C to 125°C), aligning with JEDEC JESD22 reliability (Note 3). As 2025 trends spotlight nanocomposites and eco-friendly low-loss laminates for sustainable 6G prototypes, these materials aren't luxuries—they're essentials for staying competitive in a market growing at 10% CAGR.

Key Advanced Materials: From PTFE to Ceramics and Beyond

High-speed PCB materials fall into families tailored for low loss and stability. Let's break them down, focusing on Rogers PCB material alternatives, PTFE PCB fabrication, and ceramic PCB advantages, with real specs for context.

PTFE-Based Laminates: The Gold Standard for Ultra-Low Loss

Polytetrafluoroethylene (PTFE), often ceramic-filled, dominates high-frequency with Dk 2.2-2.6 and Df 0.0003-0.001 at 10 GHz—far below FR-4's (Note 4). Rogers RO3000 series exemplifies this: RO3035 (Dk 3.5) suits microwave filters, while pure PTFE like RT/duroid excels in phased arrays.

But PTFE PCB fabrication poses hurdles. Its low modulus (0.5-1 GPa) demands specialized tooling—standard drills smear resin, so use carbide bits at 50-80 krpm with peck cycles. Lamination at 350-400°C under vacuum prevents voids, but CTE mismatch (z-axis 100-200 ppm/°C) risks warpage >0.75% if not balanced (IPC-TM-650, Note 5). Factories mitigate with bondplys for multilayers, boosting yields 20%.

Rogers PCB material alternatives like Taconic's TLX series offer similar Dk (2.55) but easier processing—no bake-out needed—cutting fab time 30%. For dielectric constant PCB material selection, PTFE shines where loss trumps cost, like in satellite downconverters.

Ceramic-Filled Composites: Powerhouses for Thermal and RF Demands

Ceramic PCB advantages lie in their thermal conductivity (1.7-2.5 W/mK vs. FR-4's 0.3) and stability, ideal for radar power amps. Alumina (Al2O3) or aluminum nitride (AlN) substrates, per IEC 61249, deliver Dk 9-10 but ultra-low Df (0.0005) and Tg >500°C, shrugging off 200°C hotspots without delam.

Fabrication favors thick-film printing over etching—laser trimming for precision resistors—but via drilling needs diamond tools to avoid chipping. In high-speed apps, ceramic hybrids with PTFE overclads (Dk gradient 2.5-9.5) blend low loss with heat sinking, per IPC-6012DS for space quals (Note 6). A factory case: Switching to AlN cut thermal resistance 40% in 77 GHz radar modules, per JEDEC thermal cycling.

Compared to PTFE, ceramics trade higher Dk for robustness—Dk 9.8 for Al2O3 vs. 2.2 for RO3003—making them dielectric constant PCB material picks for mixed-signal boards.

Other High-Speed Contenders: Hybrids and Modified FR-4

Rogers PCB material alternatives extend to hydrocarbon-ceramic like RO4000 (Dk 3.38-3.48, Df 0.0027), a PTFE-lite for cost-sensitive 5G antennas—faster lamination at 200°C, no special drills. Isola's Astra MT77 (Dk 3.0) or Taconic's CER-10 mimic this, with Df 0.0017 for 20 GHz stability.

Modified FR-4 variants, like low-loss epoxies (Dk 3.5, Df 0.005), bridge the gap for sub-10 GHz, but for true high-speed, liquid crystal polymers (LCP, Dk 2.5-3.0) flex for wearables. 2025 trends favor eco-hybrids: Nanofilled laminates reduce Df 15% while hitting UL 94 V-0 flammability (Note 7).

| Material Type | Typical Dk @10 GHz | Df @10 GHz | Key Advantage | Drawback |

|---|---|---|---|---|

| PTFE (e.g., RO3003) | 3.0 | 0.0013 | Lowest loss for mmWave | High fab cost, CTE sensitivity |

| Ceramic (Al2O3) | 9.8 | 0.0005 | Superior thermal (2 W/mK) | Higher Dk, brittle |

| Hydrocarbon-Ceramic (RO4003) | 3.38 | 0.0027 | FR-4-like processing | Moderate loss vs. pure PTFE |

| Modified FR-4 | 3.5 | 0.005 | Affordable entry to high-freq | Limited to <10 GHz |

Practical Solutions: Fabricating Advanced High-Frequency PCBs

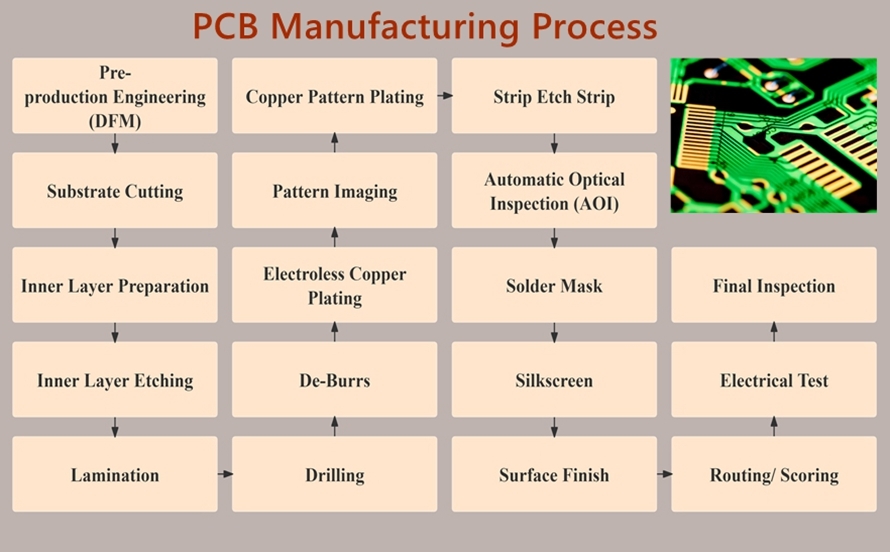

Transitioning to these materials requires fab tweaks—here's a friendly roadmap, grounded in ISO 9001 workflows.

Material Selection and Prep

Start with dielectric constant PCB material specs: Target Dk <3 for >20 GHz; use Rogers' data sheets for CTE matching (<20 ppm/°C variance to copper). For PTFE PCB fabrication, precondition at 100°C/24 hours to desorb moisture <0.1%, avoiding blisters.

Process Optimizations

- Lamination: For Rogers alternatives, 180-200°C/300 psi with slow ramps (2°C/min); ceramics need hybrid presses for overclad bonding.

- Drilling/Plating: PTFE: CO2 lasers for blind vias (aspect <6:1); ceramics: Mechanical with coolant to <5 μm roughness (IPC-6018).

- Etching/Finishes: Use ENIG (0.05-0.1 μm Au) for low-loss surfaces; avoid HASL's flux traps.

In audits, these yield <2% defects, with plasma desmear cutting smear 50% in PTFE.

Testing and Qualification

Validate per IPC-TM-650: Measure Df via split-post resonators; thermal quals to 1000 cycles (-40°C to 125°C). For high-speed PCB materials, TDR scans ensure impedance ±10%.

Tip: AI-driven DFM tools simulate loss, slashing prototypes 25%.

Case Study: Deploying Ceramic-PTFE Hybrids in a 5G Radar Sensor

A 2025 client fabricating 28 GHz automotive radar sensors faced 18% signal loss with RO4003—Dk stability faltered at 85°C. Root: Thermal hotspots from poor conductivity.

We pivoted to AlN-PTFE hybrid (Dk 2.8 effective, 2.2 W/mK): PTFE overclad on ceramic core, fabricated via vacuum lamination and laser vias. Per IPC-6018, loss dropped to 0.3 dB/inch, with 98% yields after ENIG finish. Result? MTBF tripled to 10^7 hours, saving $100K in field fixes—mirroring 5G trends where ceramic advantages enable denser arrays.

Conclusion

Beyond FR-4, high-speed PCB materials like PTFE, ceramics, and Rogers alternatives unlock the low-loss, stable world needed for 5G and radar triumphs. By nailing dielectric constant PCB material choices and PTFE PCB fabrication tweaks, factories deliver boards that perform without the premium pain.

As your advisor, I urge specifying these in RFQs with IPC-6018 quals upfront—it future-proofs your supply chain amid 2025's nanomaterial wave. Let's fab smarter, signal stronger.

FAQs

Q1: What are effective Rogers PCB material alternatives for high-frequency apps?

A1: Strong Rogers PCB material alternatives include Taconic TLX (Dk 2.55, Df 0.0019) and Isola Astra MT77 (Dk 3.0, Df 0.0017), offering similar low loss with easier lamination at 200°C. They suit 5G antennas where cost trumps pure PTFE, per IPC-4101 specs, reducing fab time 30%.

Q2: What challenges arise in PTFE PCB fabrication?

A2: PTFE PCB fabrication struggles with smear from low modulus—use carbide drills at 50-80 krpm and plasma desmear. Moisture bake-out (<0.1%) prevents voids during 350°C lamination, aligning with IPC-TM-650 for <0.75% warpage in mmWave boards.

Q3: What are the main ceramic PCB advantages for high-speed designs?

A3: Ceramic PCB advantages include high thermal conductivity (2-2.5 W/mK) and low Df (0.0005), ideal for radar power handling up to 200°C. Al2O3 hybrids with PTFE yield stable Dk 2.5-9.5, boosting MTBF 2x per JEDEC JESD22 in automotive apps.

Q4: How does dielectric constant PCB material impact high-speed performance?

A4: Lower dielectric constant PCB material (Dk <3) speeds signals (velocity >0.6c) and cuts loss in high-speed PCB materials. PTFE at Dk 2.2 minimizes phase error at 20 GHz, vs. FR-4's 4.5 causing 20% more attenuation—key for 5G per IPC-6018.

Q5: What trends shape high-speed PCB materials in 2025?

A5: 2025 high-speed PCB materials trends feature nanocomposites for 15% lower Df and eco-laminates for sustainability. Low-loss hybrids for automotive radar and 6G push Dk to 2.0, with AI DFM optimizing fab, per market forecasts to $14.2B.

References

[IPC-4101B — Specification for Base Materials for Rigid and Multilayer Printed Boards. IPC – Association Connecting Electronics Industries, 2006.]

[IPC-6018 — Qualification and Performance Specification for High Frequency (Microwave) Printed Boards. IPC, 2018.]

[JEDEC JESD22 — Reliability Test Methods for Semiconductor Devices. JEDEC Solid State Technology Association, 2019.]

[Rogers Corporation. RO3000 Series Laminates Data Sheet. Rogers, 2023.]

[IPC-TM-650 — Test Methods Manual. IPC, 2020 (Method 2.5.5 for Warpage).]

[IPC-6012DS — Qualification and Performance Specification for Rigid Printed Boards (Space Addendum). IPC, 2017.]

[UL 94 — Standard for Tests for Flammability of Plastic Materials. UL, 2013.]