What is a Solder Mask and How Does Its Color Impact PCB Functionality?

The Protective Role of Solder Mask

A solder mask functions as a crucial protective layer applied to a Printed Circuit Board (PCB). Its primary purpose is to prevent solder bridges between adjacent conductive traces and to shield the board from environmental hazards such as moisture, dust, and minor physical abrasions. Beyond its protective qualities, the solder mask significantly contributes to both the visual appeal and operational ease of the board. While the color of the solder mask doesn't directly influence the PCB's electrical performance, it plays a vital role in how easily the board can be managed during assembly, testing, and subsequent inspection stages.

Why Solder Mask Color Matters

The chosen solder mask color directly affects the contrast with the silkscreen layer—the text, symbols, and markings printed on the PCB—and the overall visibility of traces and components. Achieving high contrast between the solder mask and the silkscreen ensures that labels, component designators, and other crucial information are easily decipherable. This is precisely where a blue solder mask demonstrates its value, offering distinct advantages over the more commonly used green option. The visual clarity it provides can streamline various processes involved in PCB manufacturing and quality assurance.

How Does Blue Solder Mask Enhance Silkscreen Contrast?

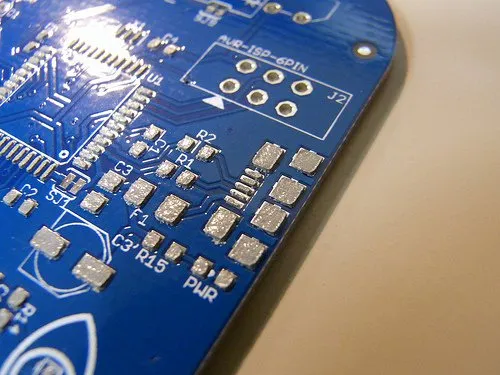

One of the most notable advantages of a blue solder mask is its superior silkscreen contrast. The silkscreen layer on a PCB conveys essential details, including component identifiers, pin numbers, and assembly guidelines. When this text is rendered in white or yellow against a blue background, it achieves remarkable clarity. This heightened contrast significantly aids technicians and engineers in reading markings, even in sub-optimal lighting conditions or on boards with high component density.

Beyond mere aesthetics, this contrast directly correlates with increased productivity. During manual assembly or troubleshooting procedures, distinct markings substantially reduce the potential for errors. Research in visual ergonomics suggests that high-contrast color combinations can boost reading accuracy by up to 40%. The sharp distinction provided by a blue solder mask minimizes eye strain and accelerates the process of component identification, making the workflow more efficient.

Blue Solder Mask vs. Green: A Detailed Comparison

Silkscreen Contrast and Readability

When directly comparing blue and green solder masks, several key differences emerge that can influence the optimal choice for a PCB project. Blue consistently offers superior contrast with white or yellow silkscreen text compared to green. While green solder masks are traditional and widely prevalent, they often result in lower contrast, particularly under specific lighting. This can render small or intricate text challenging to read. Blue, with its darker, cooler hue, creates a striking differentiation that significantly improves text visibility and overall readability. This enhanced readability is particularly beneficial for complex boards with extensive labeling, as it reduces the likelihood of misinterpreting instructions or component identifiers, thereby preventing costly assembly errors.

Inspection and Defect Detection

During the crucial PCB inspection phase, whether performed manually or through automated systems, the solder mask color can heavily influence the ease with which defects are identified. Blue solder masks tend to reveal surface imperfections—such as scratches, misalignments, or solder bridges—more distinctly than green. This is largely due to their uniform tone and reduced reflective glare, which makes flaws more apparent under magnification or with Automated Optical Inspection (AOI) systems. In contrast, green solder masks can sometimes obscure minor defects due to their less uniform appearance under certain lighting conditions, potentially allowing flaws to go unnoticed.

Aesthetic Appeal and Branding

Beyond their functional benefits, blue solder masks also offer a distinct aesthetic advantage. They present a modern, professional appearance that diverges from the conventional green, making them particularly attractive for consumer electronics or products where the PCB is visible to the end-user. Choosing a blue solder mask can also align with specific brand colors, contributing to a cohesive and polished product image. This visual appeal can be a subtle yet effective differentiator in the marketplace.

Where Does Blue Solder Mask Provide the Most Benefit?

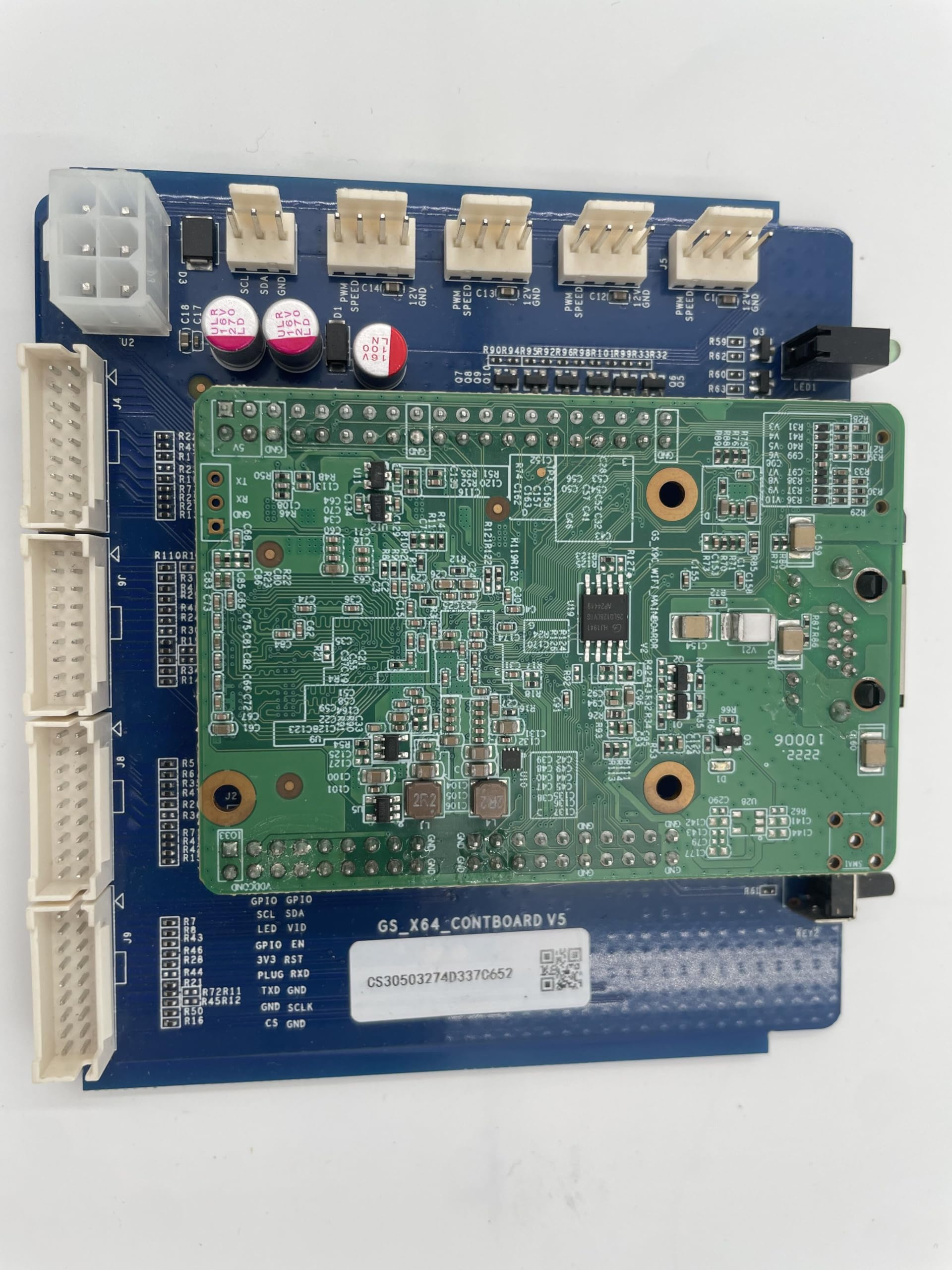

While blue solder masks are versatile and suitable for a broad spectrum of projects, they offer distinct advantages in certain applications:

● High-Density Designs: For boards characterized by tight component spacing and numerous elements, the superior silkscreen contrast of blue ensures precise assembly and significantly reduces error rates.

● Prototyping and Testing: During the product development and testing phases, the clear readability and simplified inspection offered by blue solder masks help engineers quickly pinpoint and resolve issues, accelerating the debugging process.

● Consumer Electronics: Blue solder masks lend a sleek, contemporary aesthetic that resonates with end-users, particularly in gadgets or devices where the PCB is visible.

● Harsh Environments: Blue solder masks can be formulated to possess the same robust protective qualities as their green counterparts, making them suitable for applications exposed to moisture, heat, or chemicals.

Are There Any Downsides to Using a Blue Solder Mask?

While blue solder masks offer numerous benefits, it's prudent to consider potential drawbacks before making a final decision. One factor is cost; blue solder masks can occasionally be slightly more expensive than green due to their less ubiquitous use and potentially more specialized manufacturing processes. However, this price differential is often marginal, especially for larger production volumes.

Another consideration is availability. While most PCB manufacturers provide blue as an option, some may have limited stock or longer lead times compared to the pervasively available green. It is always advisable to confirm color options and any potential delays directly with your manufacturing partner.

Finally, in environments with very bright or reflective lighting, blue solder masks can sometimes appear darker, which might affect visibility under specific conditions. This can often be mitigated by adjusting workspace lighting or by strategically using high-contrast silkscreen colors like white or yellow to ensure maximum legibility.

How to Select the Optimal Solder Mask Color for Your Project

The decision between a blue solder mask and other colors, such as green, should be guided by the specific requirements of your project. Consider the following key factors:

● Visibility Needs: If achieving high silkscreen contrast and superior readability are primary concerns, blue is an excellent choice.

● Inspection Demands: For projects where efficient defect detection is critical, blue can significantly enhance both manual and automated inspection processes.

● Budgetary Constraints: If cost is a significant factor, compare pricing for various solder mask colors with your manufacturer to find the most economical yet effective option.

● Aesthetic Objectives: Evaluate how the solder mask color aligns with your product’s overall design or brand identity.

By carefully evaluating these factors, you can make a well-informed decision that effectively balances functionality, cost-efficiency, and visual appeal for your PCB project.

Conclusion: The Advantages of Choosing a Blue Solder Mask

In the intricate world of PCB design and manufacturing, every detail holds significance, and the choice of solder mask color is no exception. A blue solder mask delivers unparalleled advantages in silkscreen contrast, readability, and inspection, establishing itself as a powerful tool for producing high-quality, reliable PCBs. Whether you are developing a complex prototype or designing a consumer-facing product, blue offers both practical benefits and a contemporary aesthetic that distinguishes your board.

Compared to the conventional green solder mask, blue notably improves visibility and streamlines both assembly and quality control operations. While there might be minor considerations regarding cost or availability, the advantages often outweigh these smaller drawbacks for a wide array of applications.

At AIVON, we understand the critical importance of selecting the appropriate solder mask color to perfectly align with your project's needs. With a comprehensive range of options, including blue, green, and others, we are dedicated to assisting you in crafting PCBs that not only perform exceptionally but also possess an appealing visual design. Consider adopting a blue solder mask for your next design and personally experience the remarkable difference in contrast and clarity.