Introduction

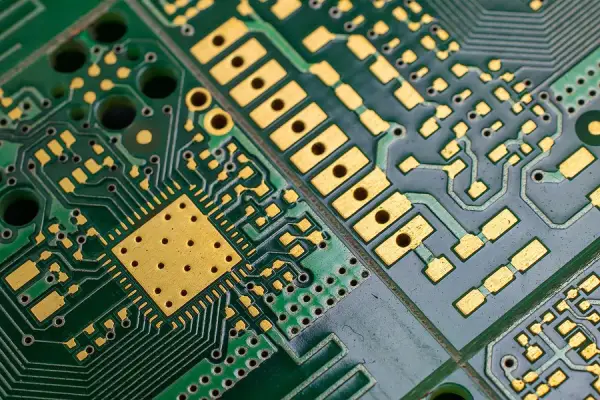

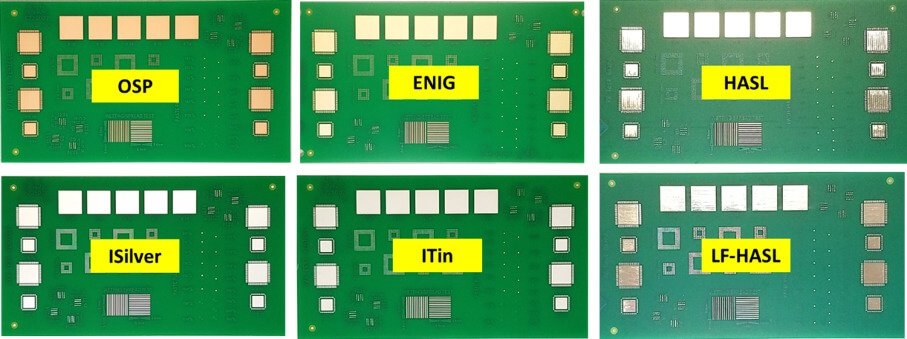

FR-4 printed circuit boards form the backbone of modern electronics, offering a reliable substrate for countless applications. A critical aspect of their performance and longevity lies in the surface finish applied to the copper traces. FR-4 PCB surface finishes protect against oxidation, enhance solderability, and ensure compatibility with assembly processes. Options like HASL, ENIG, immersion silver, and OSP finish each bring unique benefits and challenges to the table. For electrical engineers, selecting the right finish is vital to meeting design specifications and reliability standards. This article explores the characteristics of FR-4 PCB HASL finish, FR-4 PCB ENIG finish, FR-4 PCB immersion silver, and FR-4 PCB OSP finish, providing insights into their properties, applications, and compliance with industry standards. Understanding these finishes helps engineers make informed decisions for optimal performance.

What Are FR-4 PCB Surface Finishes and Why Do They Matter?

FR-4 PCB surface finishes refer to the protective coatings applied to the exposed copper on a printed circuit board. These finishes serve multiple purposes, including preventing oxidation, improving solder joint formation, and extending shelf life. Without a proper finish, copper traces can corrode, leading to poor connections and potential circuit failure. For FR-4 boards, the most common material in PCB manufacturing due to its cost-effectiveness and mechanical strength, the choice of finish directly impacts assembly quality and long-term reliability.

Surface finishes matter because they influence soldering performance, environmental resistance, and compatibility with various assembly techniques. Electrical engineers must consider factors like thermal cycling, humidity exposure, and lead-free soldering requirements when selecting a finish. Industry standards, such as those from IPC, guide the application and performance expectations of these coatings, ensuring consistency across designs and manufacturing processes.

Technical Properties of Common FR-4 PCB Surface Finishes

Hot Air Solder Leveling (HASL)

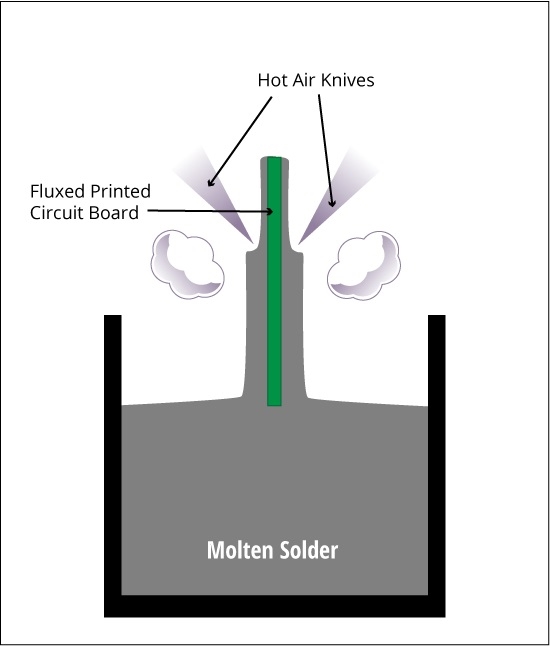

FR-4 PCB HASL finish is one of the oldest and most widely used surface finishes. It involves dipping the board into molten solder and then using hot air to remove excess material, leaving a thin, uniform layer on the copper. This finish provides excellent solderability, making it ideal for through-hole components and traditional soldering methods. However, its uneven surface can pose challenges for fine-pitch surface-mount components due to potential inconsistencies in thickness.

HASL is cost-effective and durable, often chosen for prototypes or less complex designs. Its primary limitation is thermal stress during application, which may affect board flatness. It also has a shorter shelf life compared to other finishes due to potential oxidation over time. Engineers often rely on standards like IPC-6012E to ensure HASL meets performance criteria for rigid boards.

Electroless Nickel Immersion Gold (ENIG)

FR-4 PCB ENIG finish consists of a layer of nickel beneath a thin gold coating, applied through a chemical process. This finish offers superior corrosion resistance and a flat surface, making it suitable for fine-pitch components and high-density designs. The gold layer ensures excellent solderability and protects the nickel from oxidation, while the nickel acts as a barrier to prevent copper diffusion.

ENIG is widely used in applications requiring high reliability, such as telecommunications and medical devices. Its uniform thickness supports precise soldering, and it complies with lead-free assembly requirements. However, the process is more expensive than HASL, and there is a risk of "black pad" defects if not applied correctly. Adherence to IPC-4552A standards helps mitigate such issues by defining acceptable thickness and quality parameters.

Immersion Silver

FR-4 PCB immersion silver involves depositing a thin layer of silver onto the copper through a chemical reaction. This finish provides excellent solderability and a flat surface, ideal for high-frequency applications due to its low signal loss. It is also cost-effective compared to ENIG and supports lead-free soldering processes.

However, immersion silver is prone to tarnishing when exposed to sulfur-containing environments, which can degrade solderability over time. Proper storage and handling are essential to maintain its effectiveness. It is often evaluated against standards like IPC-4553A, which outlines performance and thickness requirements to ensure reliability in various conditions.

Organic Solderability Preservative (OSP)

FR-4 PCB OSP finish uses a water-based organic compound to coat the copper, acting as a temporary barrier against oxidation. This finish is environmentally friendly, cost-effective, and provides a flat surface for fine-pitch components. It is often preferred for lead-free soldering and applications where simplicity is key.

OSP has a limited shelf life and can degrade after multiple reflow cycles, making it less suitable for complex assemblies or long-term storage. Its performance is guided by standards such as IPC-4555, which specifies application methods and expected durability under defined conditions.

Practical Considerations for Selecting FR-4 PCB Surface Finishes

Application Requirements

When choosing among FR-4 PCB surface finishes, engineers must evaluate the specific needs of their project. For high-reliability applications, such as aerospace or medical electronics, FR-4 PCB ENIG finish often stands out due to its corrosion resistance and consistent performance. In contrast, FR-4 PCB HASL finish suits cost-sensitive projects with simpler designs, where budget constraints outweigh the need for precision.

For high-frequency circuits, FR-4 PCB immersion silver may be ideal due to minimal signal loss. Meanwhile, FR-4 PCB OSP finish works well for quick-turn projects with short storage times and straightforward assembly processes. Matching the finish to the application ensures optimal performance and avoids issues during manufacturing or operation.

Environmental and Assembly Conditions

Environmental factors play a significant role in finish selection. Exposure to humidity or corrosive gases can degrade finishes like immersion silver, necessitating protective packaging or alternative coatings. Thermal cycling, common in automotive or industrial applications, may favor more robust finishes like ENIG, which withstands repeated heat exposure without degradation.

Assembly conditions also influence the decision. Multiple reflow cycles, often required in double-sided SMT assemblies, can compromise OSP coatings, while HASL and ENIG maintain integrity under such stress. Engineers should consult standards like IPC-A-600K to assess acceptability criteria for surface finishes under various assembly scenarios.

Cost and Manufacturing Compatibility

Budget considerations cannot be overlooked. HASL remains the most economical option among FR-4 PCB surface finishes, suitable for low-cost consumer electronics. ENIG, while more expensive, justifies its cost in applications demanding high precision and reliability. Immersion silver offers a middle ground, balancing cost with performance, whereas OSP prioritizes affordability but requires careful handling.

Manufacturing compatibility is equally important. Some finishes, like ENIG, require specialized processes that may not be available at all facilities. Engineers must verify that the chosen finish aligns with the capabilities of their manufacturing partners while meeting standards such as IPC-6012E for performance specifications.

Troubleshooting Common Issues with FR-4 PCB Surface Finishes

Surface finishes can encounter problems during manufacturing or assembly, impacting board performance. For FR-4 PCB HASL finish, uneven coating thickness may lead to soldering inconsistencies, especially with fine-pitch components. Inspecting boards per IPC-A-600K guidelines helps identify such defects early.

With FR-4 PCB ENIG finish, the risk of black pad syndrome, a defect caused by improper nickel deposition, can result in weak solder joints. Adhering to IPC-4552A during application minimizes this issue. FR-4 PCB immersion silver may tarnish if exposed to contaminants, requiring controlled storage conditions to preserve solderability. Finally, FR-4 PCB OSP finish can degrade after multiple heat cycles, necessitating careful planning of assembly processes to avoid rework.

Conclusion

Selecting the right surface finish for FR-4 PCBs is a critical decision that affects solderability, reliability, and overall performance. FR-4 PCB surface finishes like HASL, ENIG, immersion silver, and OSP each offer distinct advantages tailored to specific applications and budgets. Electrical engineers must weigh factors such as environmental exposure, assembly requirements, and cost to ensure compatibility with design goals. By adhering to industry standards like those from IPC, professionals can mitigate risks and achieve consistent results. Understanding the properties of FR-4 PCB HASL finish, FR-4 PCB ENIG finish, FR-4 PCB immersion silver, and FR-4 PCB OSP finish empowers engineers to optimize their designs for success.

FAQs

Q1: What are the main advantages of FR-4 PCB HASL finish for electrical designs?

A1: The FR-4 PCB HASL finish offers excellent solderability and durability at a low cost. It suits through-hole components and simpler designs, making it ideal for prototypes or budget-conscious projects. Its robust coating withstands basic environmental conditions, though it may not be suitable for fine-pitch components due to uneven thickness. Following IPC standards ensures consistent quality during application.

Q2: How does FR-4 PCB ENIG finish improve reliability in high-density boards?

A2: FR-4 PCB ENIG finish enhances reliability with its flat surface and corrosion-resistant gold layer over nickel. This combination supports fine-pitch components and high-density designs by ensuring precise soldering. It resists oxidation effectively, making it suitable for demanding applications. Compliance with IPC-4552A during manufacturing prevents defects and maintains performance in critical systems.

Q3: When should engineers choose FR-4 PCB immersion silver for their projects?

A3: Engineers should opt for FR-4 PCB immersion silver in high-frequency applications due to its low signal loss and good solderability. It provides a cost-effective alternative to more expensive finishes while supporting lead-free processes. However, it requires careful storage to avoid tarnishing. It is best for projects with controlled environments and shorter shelf life expectations.

Q4: What limitations does FR-4 PCB OSP finish present in complex assemblies?

A4: FR-4 PCB OSP finish has a limited shelf life and can degrade after multiple reflow cycles, posing challenges in complex assemblies. Its organic coating may not withstand prolonged storage or harsh conditions, risking solderability issues. It works best for quick-turn projects with minimal thermal stress, requiring strict adherence to handling guidelines for optimal results.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

IPC-4552A — Specification for Electroless Nickel/Immersion Gold (ENIG) Plating for Printed Boards. IPC, 2017.

IPC-4553A — Specification for Immersion Silver Plating for Printed Boards. IPC, 2009.

IPC-4555 — Specification for Organic Solderability Preservative (OSP) Coating for Printed Boards. IPC, 2012.