Introduction

Scaling from prototype to production is a critical journey for electrical engineers working on printed circuit board (PCB) development. This process involves transitioning from initial designs and small batch testing to low volume PCB manufacturing and eventually high volume PCB manufacturing. Quick turn for production runs plays a pivotal role in accelerating timelines while maintaining quality. For engineers, the challenge lies in balancing speed, cost, and compliance with industry standards. This article explores the mechanisms of scaling PCB production, focusing on the role of quick turn manufacturing in moving from prototype to production. It provides practical insights into overcoming common hurdles and ensuring designs are ready for larger scales without compromising performance or reliability.

What Is Quick Turn PCB Manufacturing and Why It Matters

Quick turn PCB fabrication refers to the rapid production of printed circuit boards, often within 24 to 72 hours for prototypes or small batches. This approach is essential for engineers aiming to test designs swiftly and iterate based on real world feedback. The significance of quick turn for production runs lies in its ability to shorten development cycles, allowing projects to move from prototype to production seamlessly. In industries where time to market is a competitive factor, such as consumer electronics or medical devices, delays in testing or validation can impact success. By leveraging quick turn services, engineers can validate designs early, identify flaws, and prepare for scaling PCB production without extended lead times. This process also supports low volume PCB manufacturing, bridging the gap to high volume PCB manufacturing when demand grows.

Technical Principles of Scaling PCB Production

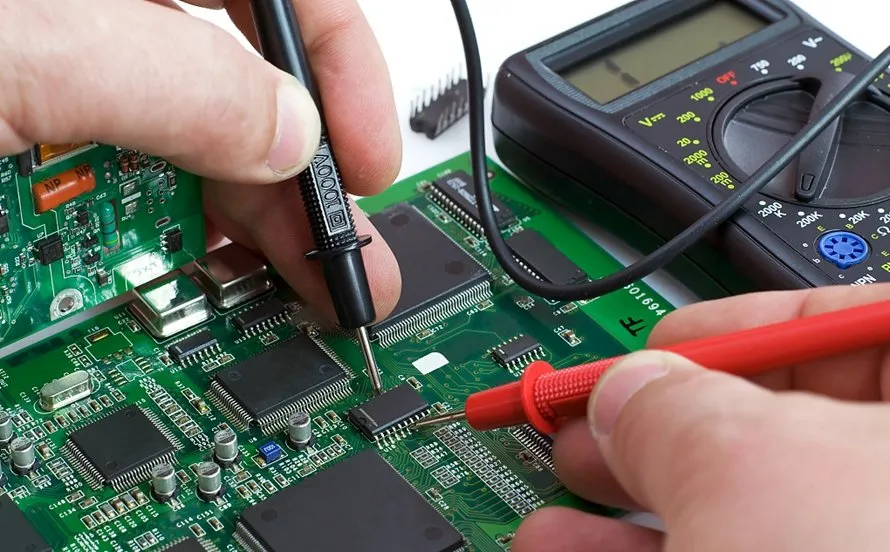

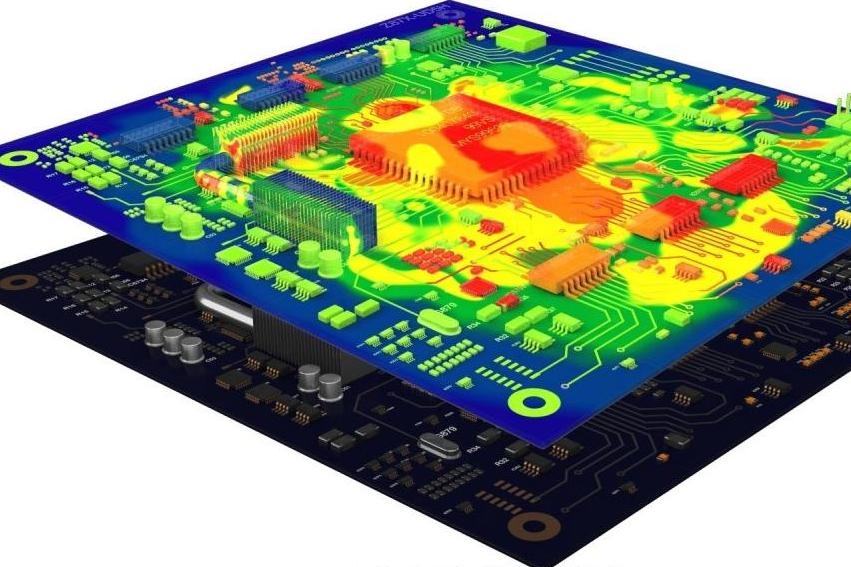

Scaling PCB production from prototype to full scale manufacturing involves several technical considerations. At the prototype stage, the focus is on design validation and functionality. Engineers often work with small batches to test electrical performance, thermal behavior, and mechanical fit. Standards such as IPC-6012E guide the qualification and performance specifications for rigid printed boards during this phase, ensuring that initial designs meet baseline requirements.

As production scales to low volume PCB manufacturing, the emphasis shifts to process repeatability. Consistency in fabrication and assembly becomes critical to avoid variations that could affect performance. Compliance with IPC-A-600K, which outlines acceptability criteria for printed boards, helps engineers ensure that each unit meets visual and structural standards. Material selection also plays a role, as prototypes may use different substrates or finishes compared to production runs due to cost or availability constraints.

In high volume PCB manufacturing, efficiency and yield optimization take precedence. Engineers must account for potential defects, supply chain logistics, and equipment capabilities. Adhering to ISO 9001:2015 for quality management systems provides a framework for maintaining process control at scale. Additionally, thermal and mechanical stress testing, often guided by JEDEC J-STD-020E for moisture and reflow sensitivity, ensures components withstand the rigors of mass production environments. Understanding these principles is key to moving from prototype to production without unexpected failures.

Challenges in Moving from Prototype to Production

Transitioning from prototype to production presents several challenges for electrical engineers. One primary issue is design for manufacturability (DFM). A prototype may function well in a controlled setting but fail under mass production conditions due to unoptimized layouts or component placement. Following DFM guidelines, often aligned with IPC standards, can mitigate risks of assembly errors or material incompatibilities.

Another challenge is supply chain management. During prototyping, components may be sourced in small quantities with little concern for long term availability. However, scaling PCB production requires securing reliable suppliers for high volume PCB manufacturing. Engineers must also anticipate lead times for critical parts to avoid production delays.

Testing and validation requirements also evolve. While prototypes undergo basic functional checks, production runs demand comprehensive quality assurance. Standards like IPC-6012E specify performance criteria that must be met consistently across batches. Engineers often need to implement automated testing to handle the volume, ensuring defects are caught early.

Lastly, cost management becomes more complex. Quick turn for production runs can be expensive in small batches, and transitioning to larger scales requires balancing upfront investments with per unit costs. Engineers must optimize designs to reduce waste and improve yield without sacrificing quality.

Practical Solutions for Scaling with Quick Turn Manufacturing

To address the challenges of moving from prototype to production, engineers can adopt several best practices centered around quick turn PCB manufacturing. First, prioritize early collaboration with fabrication and assembly teams. Sharing design files and receiving feedback on manufacturability helps identify potential issues before scaling PCB production begins. This step is especially crucial for low volume PCB manufacturing, where adjustments can still be made without significant cost.

Second, implement robust documentation. Clear specifications for materials, tolerances, and testing protocols ensure consistency as production ramps up. Referencing standards such as IPC-A-600K for acceptability criteria provides a common language for quality expectations across teams. Detailed records also simplify troubleshooting if issues arise during high volume PCB manufacturing.

Third, leverage quick turn for production runs to validate each stage of scaling. For instance, after prototyping, produce a small batch under low volume conditions to test assembly processes. Use the results to refine designs or adjust parameters before committing to larger orders. This iterative approach minimizes risks and builds confidence in the design's readiness for mass production.

Finally, invest in simulation tools to predict performance under production conditions. Thermal and signal integrity simulations can reveal weaknesses that might not appear in prototype testing. Aligning these simulations with standards like JEDEC J-STD-020E ensures components are rated for the stresses of reflow soldering in high volume scenarios.

Best Practices for Low Volume and High Volume PCB Manufacturing

Navigating low volume PCB manufacturing and high volume PCB manufacturing requires tailored strategies. In low volume scenarios, flexibility is key. Engineers should focus on quick turn services to produce small batches for pilot testing or early market feedback. Maintaining close oversight of each unit, guided by IPC-6012E performance specifications, ensures quality before scaling.

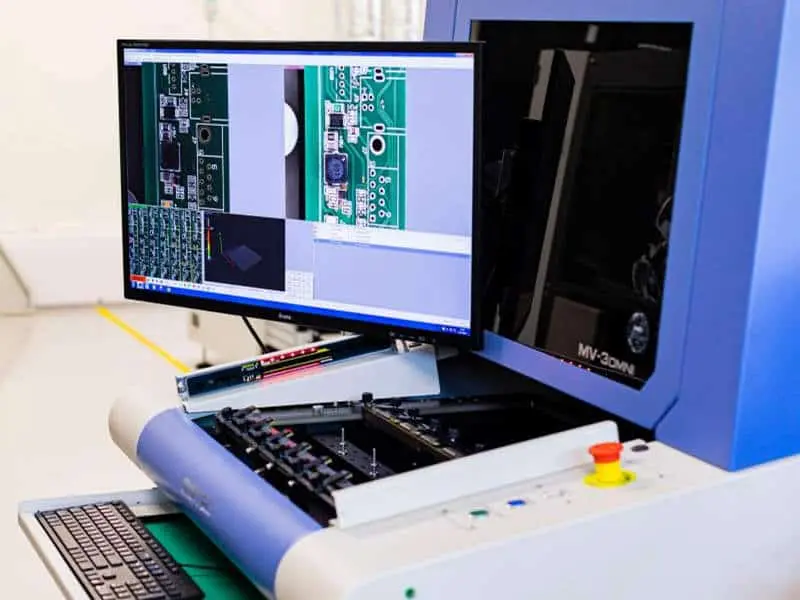

For high volume PCB manufacturing, automation becomes essential. Automated optical inspection and in circuit testing, aligned with IPC-A-600K acceptability standards, help maintain consistency across thousands of units. Engineers should also establish strong supplier relationships to secure materials and components, preventing bottlenecks that could halt production.

Regardless of volume, traceability is critical. Implementing batch tracking and serial numbering allows for rapid identification of issues if defects occur. Adhering to ISO 9001:2015 for quality management provides a structured approach to documentation and process control, ensuring reliability as production scales.

Insights on Quick Turn for Production Runs

Quick turn for production runs offers a strategic advantage in scaling PCB mass production. Beyond speeding up prototyping, it serves as a bridge during the transition to larger volumes. Engineers can use quick turn batches to test production ready designs under real world conditions, identifying issues like warpage or soldering defects before full scale manufacturing begins. This approach is particularly valuable when timelines are tight or when market validation is needed urgently.

Moreover, quick turn services allow for parallel development. While one team finalizes a design, another can prepare production workflows, using quick turn batches to simulate assembly line conditions. This reduces idle time and accelerates the move from prototype to production. However, engineers must ensure that quick turn processes still comply with industry standards like IPC-6012E to avoid quality trade offs.

Conclusion

Scaling from prototype to production is a complex but manageable process for electrical engineers, provided they leverage quick turn PCB manufacturing effectively. By understanding the technical principles behind scaling PCB production, addressing challenges with practical solutions, and adhering to recognized standards, teams can ensure a smooth transition. Whether focusing on low volume PCB manufacturing or preparing for high volume PCB manufacturing, quick turn for production runs offers the speed and flexibility needed to meet tight deadlines without sacrificing quality. With careful planning and a commitment to best practices, engineers can confidently bring innovative designs to market at any scale.

FAQs

Q1: What are the key benefits of quick turn for production runs in scaling PCB production?

A1: Quick turn for production runs accelerates the development cycle by enabling rapid prototyping and small batch testing. This approach helps engineers validate designs early, identify issues, and make adjustments before full scale production. It supports faster time to market, especially in competitive industries, while maintaining compliance with standards like IPC-6012E for performance and quality.

Q2: How does low volume PCB manufacturing differ from prototyping in terms of challenges?

A2: Low volume PCB manufacturing focuses on process repeatability and consistency, unlike prototyping which prioritizes design validation. Challenges include ensuring manufacturability and managing component availability for small batches. Engineers must align with standards like IPC-A-600K to maintain quality across units, preparing for potential scaling to larger production volumes.

Q3: What standards should guide moving from prototype to production in high volume PCB manufacturing?

A3: Standards such as IPC-6012E for performance specifications, IPC-A-600K for acceptability criteria, and ISO 9001:2015 for quality management are essential. JEDEC J-STD-020E also helps ensure components withstand production stresses. These provide a framework for consistency, reliability, and defect prevention during high volume manufacturing.

Q4: How can engineers optimize costs when scaling PCB production with quick turn services?

A4: Engineers can optimize costs by using quick turn services for iterative testing in small batches before scaling. Early collaboration with fabrication teams, guided by DFM principles and standards like IPC-6012E, reduces redesign expenses. Focusing on yield improvement and material efficiency also lowers per unit costs in larger production runs.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

JEDEC J-STD-020E — Moisture/Reflow Sensitivity Classification. JEDEC, 2014.

ISO 9001:2015 — Quality Management Systems. ISO, 2015.