Introduction

In the fast-paced world of electronics, quick-turn PCB production is essential for meeting tight project deadlines. However, speed must not compromise quality, especially when reliability and performance are critical for electrical engineers. This is where IPC standards for PCBs come into play. These globally recognized guidelines ensure consistency, durability, and functionality in printed circuit board manufacturing and assembly. By adhering to PCB quality standards like IPC Class 2 and IPC Class 3, manufacturers can deliver boards that meet stringent requirements even under accelerated timelines. This article explores how IPC standards shape quick-turn PCB manufacturing, their role in maintaining high standards, and why they matter to engineers working on time-sensitive projects. Understanding these quick turn PCB fabrication standards helps in selecting the right processes and ensuring product reliability.

What Are IPC Standards and Why Do They Matter?

IPC, a leading organization in electronics manufacturing, develops standards to guide the design, production, and assembly of printed circuit boards. These guidelines, often referred to as PCB quality standards, cover every aspect of PCB creation, from material selection to final inspection. For electrical engineers, IPC standards for PCBs provide a framework to ensure that boards function as intended, regardless of the production speed.

In quick-turn PCB manufacturing, where boards are often produced within days or even hours, the risk of defects increases due to compressed timelines. IPC standards mitigate this risk by setting clear benchmarks for acceptability and performance. They help manufacturers maintain consistency, reduce errors, and meet the expectations of engineers who rely on these boards for prototyping or urgent production runs. Without such PCB manufacturing standards, variations in quality could lead to costly failures or project delays.

Technical Principles of IPC Standards in PCB Manufacturing

IPC-A-600K: Acceptability of Printed Boards

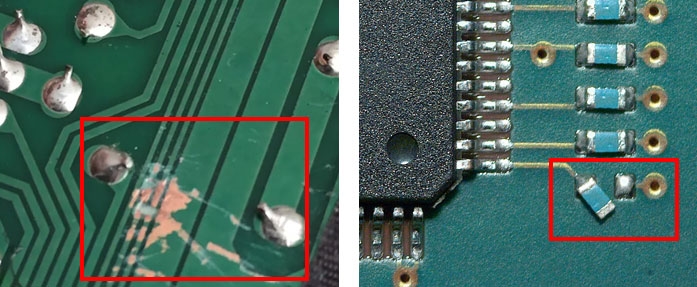

This standard defines the visual criteria for assessing PCB quality. It categorizes defects into acceptable, marginal, or unacceptable based on their impact on performance. In quick-turn scenarios, where thorough testing might be limited, IPC-A-600K ensures that visual inspections catch critical issues like improper plating or surface defects before boards reach engineers.

IPC-6012E: Qualification and Performance Specification for Rigid Printed Boards

Focused on the performance and durability of rigid PCBs, IPC-6012E sets requirements for materials, construction, and testing. It ensures that boards produced quickly still meet structural integrity standards, which is vital for engineers needing reliable prototypes or small-batch runs.

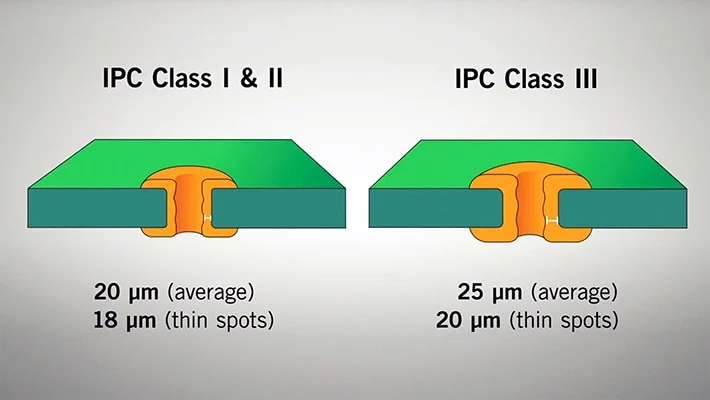

IPC Class 2 and IPC Class 3: Defining Quality Levels

IPC standards classify PCBs into different performance levels, with IPC Class 2 and IPC Class 3 being the most relevant for professional applications. IPC Class 2 applies to dedicated service electronics, where uninterrupted performance is expected but not critical. This class is often suitable for consumer electronics or less demanding industrial applications. In contrast, IPC Class 3 is reserved for high-reliability products, such as medical devices or aerospace systems, where failure is unacceptable. For quick-turn PCBs, selecting between IPC Class 2 and IPC Class 3 depends on the application’s requirements, as higher classes demand stricter manufacturing controls, potentially affecting turnaround time.

IPC-J-STD-001: Requirements for Soldered Electrical and Electronic Assemblies

This standard governs the PCB board assembly process, ensuring proper soldering techniques and component placement. In quick-turn production, where assembly might be rushed, adherence to IPC-J-STD-001 prevents issues like cold solder joints or misalignment, which could compromise functionality.

By integrating these PCB manufacturing standards, quick-turn processes maintain a balance between speed and quality. Engineers can trust that even rapidly produced boards meet industry benchmarks, reducing the likelihood of field failures.

Impact of IPC Standards on Quick-Turn PCB Quality

Quick-turn PCB manufacturing prioritizes speed, often for prototyping or urgent production needs. However, accelerated timelines can introduce risks such as skipped inspections or inconsistent processes. IPC standards for PCBs address these challenges by providing a structured approach to quality control.

Consistency Across Production Runs

One key benefit of IPC standards is their emphasis on repeatability. Even in a high-speed environment, manufacturers following PCB quality standards can replicate results across multiple batches. This consistency is crucial for engineers testing designs or scaling production after prototyping.

Reduction of Defects and Rework

Adhering to standards like IPC-A-600K and IPC-6012E minimizes common defects such as delamination, improper via plating, or trace damage. In quick-turn scenarios, where time for rework is limited, these PCB manufacturing standards ensure that boards are usable on the first attempt, saving time and resources.

Meeting Application-Specific Requirements

The distinction between IPC Class 2 and IPC Class 3 allows engineers to specify quality levels based on project needs. For instance, a prototype for a consumer gadget might suffice with IPC Class 2, while a board for a critical medical device requires IPC Class 3. Quick-turn manufacturers adhering to these classifications can deliver tailored solutions without sacrificing speed.

Enhanced Communication Between Engineers and Manufacturers

IPC standards provide a common language for engineers and manufacturers. When specifying PCB quality standards in design files or purchase orders, engineers ensure that manufacturers understand the expected quality level. This clarity prevents misunderstandings, especially in quick-turn projects with limited time for back-and-forth communication.

Best Practices for Implementing IPC Standards in Quick-Turn Manufacturing

For electrical engineers and manufacturers aiming to balance speed and quality, following best practices aligned with IPC standards is essential. These actionable steps help maintain PCB quality standards even under tight deadlines.

Define Clear Quality Requirements Upfront

Before initiating a quick-turn order, engineers should specify the desired IPC class and relevant standards. Clearly stating whether IPC Class 2 or IPC Class 3 is required helps manufacturers adjust processes accordingly and avoid quality mismatches.

Conduct Pre-Production Reviews

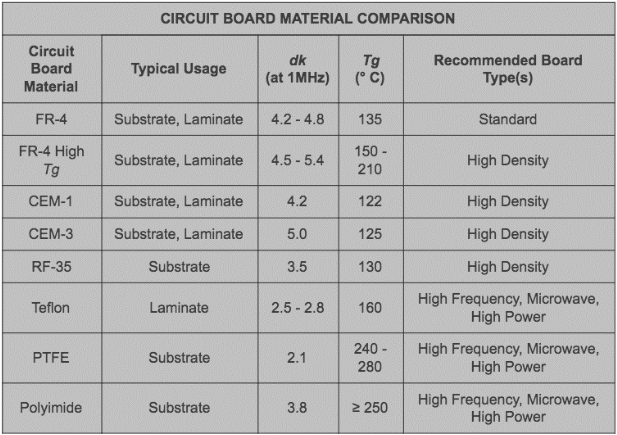

Even in rushed timelines, a brief design review against IPC-6012E guidelines can identify potential issues like inadequate trace spacing or material incompatibilities. Addressing these early prevents delays during manufacturing.

Prioritize Key Inspections

While comprehensive testing might not be feasible in quick-turn production, focusing on critical inspections outlined in IPC-A-600K, such as surface finish and via integrity, ensures major defects are caught before delivery.

Collaborate on Material Selection

Materials play a significant role in meeting PCB manufacturing standards. Engineers should work with manufacturers to choose materials that comply with IPC-6012E specifications, ensuring durability without slowing down production.

Maintain Documentation for Traceability

Documenting adherence to IPC standards for PCBs provides a record of quality control steps. This traceability is valuable for engineers troubleshooting issues or validating performance in critical applications.

Challenges and Solutions in Quick-Turn PCB Production Under IPC Standards

While IPC standards elevate quality, applying them in quick-turn manufacturing presents unique challenges. Addressing these hurdles ensures that speed and compliance coexist.

Challenge: Limited Time for Testing

Quick-turn production often skips extensive testing to meet deadlines. This can risk overlooking subtle defects not visible during basic inspections.

Solution: Automated Inspection Tools

Using automated optical inspection systems aligned with IPC-A-600K criteria can quickly identify surface-level issues without slowing down the process. These tools enhance defect detection in time-constrained environments.

Challenge: Higher Costs for Higher Classes

Achieving IPC Class 3 quality in quick-turn production often requires additional resources, increasing costs and potentially affecting turnaround time.

Solution: Strategic Planning

Engineers can reserve IPC Class 3 for applications where high reliability is non-negotiable, opting for IPC Class 2 in less critical projects to optimize cost and speed.

Conclusion

IPC standards for PCBs are indispensable in ensuring quality during quick-turn manufacturing. By adhering to PCB quality standards like IPC-A-600K, IPC-6012E, and classifications such as IPC Class 2 and IPC Class 3, manufacturers can deliver reliable boards even under tight schedules. These PCB manufacturing standards provide a structured approach to consistency, defect reduction, and application-specific performance, benefiting electrical engineers working on urgent projects. Understanding and implementing these guidelines fosters collaboration, enhances trust in rapid production, and ultimately supports successful outcomes in electronics development.

FAQs

Q1: What are IPC standards for PCB manufacturing?

A1: IPC standards for PCBs are globally recognized guidelines that define quality, reliability, and consistency in printed circuit board production. They cover design, materials, assembly, and inspection, ensuring boards meet performance expectations. Standards like IPC-A-600K and IPC-6012E are crucial for engineers to ensure durability, especially in quick-turn scenarios where speed might otherwise compromise quality.

Q2: How do IPC Class 2 and IPC Class 3 differ in PCB quality?

A2: IPC Class 2 applies to electronics requiring dedicated service with expected reliability, suitable for consumer products. IPC Class 3 demands higher reliability for critical applications like medical or aerospace systems. For quick-turn PCBs, choosing between these classes impacts manufacturing rigor, cost, and time, with Class 3 requiring stricter controls.

Q3: Why are PCB manufacturing standards important for quick-turn production?

A3: PCB manufacturing standards ensure quality isn’t sacrificed for speed in quick-turn production. Guidelines like IPC-6012E set benchmarks for materials and performance, reducing defects despite tight timelines. They provide engineers with confidence that rapidly produced boards will function reliably in prototypes or final products.

Q4: How do IPC standards improve PCB reliability?

A4: IPC standards for PCBs enhance reliability by enforcing consistent processes, material quality, and inspection criteria. Standards such as IPC-J-STD-001 ensure proper assembly, while IPC-A-600K identifies acceptable defect levels. This systematic approach minimizes failures, crucial for engineers relying on quick-turn boards for critical testing or deployment.

References

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-J-STD-001H — Requirements for Soldered Electrical and Electronic Assemblies. IPC, 2021.