Introduction

For electronic hobbyists, prototyping is a critical step in bringing innovative ideas to life. Whether you’re designing a custom circuit for a personal project or testing a concept before scaling up, PCB batch production for prototyping offers a practical way to create multiple boards quickly and economically. This process allows hobbyists to refine designs, test functionality, and ensure reliability without breaking the bank. In this article, we explore the essentials of PCB prototype batch production, focusing on quick-turn options, cost considerations, and how to access efficient PCB prototyping services. By understanding these aspects, hobbyists can streamline their projects and achieve results faster. Let’s dive into why batch production matters and how it can benefit your next electronics endeavor.

What Is PCB Batch Production for Prototyping?

PCB batch production for prototyping refers to manufacturing a small number of printed circuit boards in a single run to test designs before full-scale production. Unlike single-board prototyping, batch production creates multiple units, often ranging from five to fifty boards, depending on the project’s needs. This approach is ideal for hobbyists who need several copies to experiment with different configurations or share with collaborators.

The significance of quick PCB prototype batch lies in its ability to bridge the gap between concept and reality. It helps identify design flaws, verify component compatibility, and ensure the board meets functional requirements. For hobbyists, producing a small batch reduces the risk of costly errors in larger runs and provides a hands-on way to iterate designs efficiently. This process is often supported by quick turn PCB batch services that prioritize speed without compromising quality.

Why PCB Batch Production Matters for Hobbyists

For electronic hobbyists, time and budget are often limited. PCB batch production addresses both by offering a cost-effective way to produce multiple boards at once, reducing the per-unit cost compared to single-board orders. It also saves time by allowing simultaneous testing of various design tweaks or applications. Moreover, having extra boards on hand means you can troubleshoot issues or replace damaged units without waiting for another manufacturing cycle.

Adhering to industry standards during batch production ensures that even hobbyist projects maintain a level of reliability. Standards like IPC-6012E, which governs the qualification and performance of rigid printed boards, provide guidelines for consistent quality. By following such frameworks, hobbyists can create prototypes that are not only functional but also aligned with professional expectations, making future transitions to larger production smoother.

Technical Principles Behind PCB Batch Production

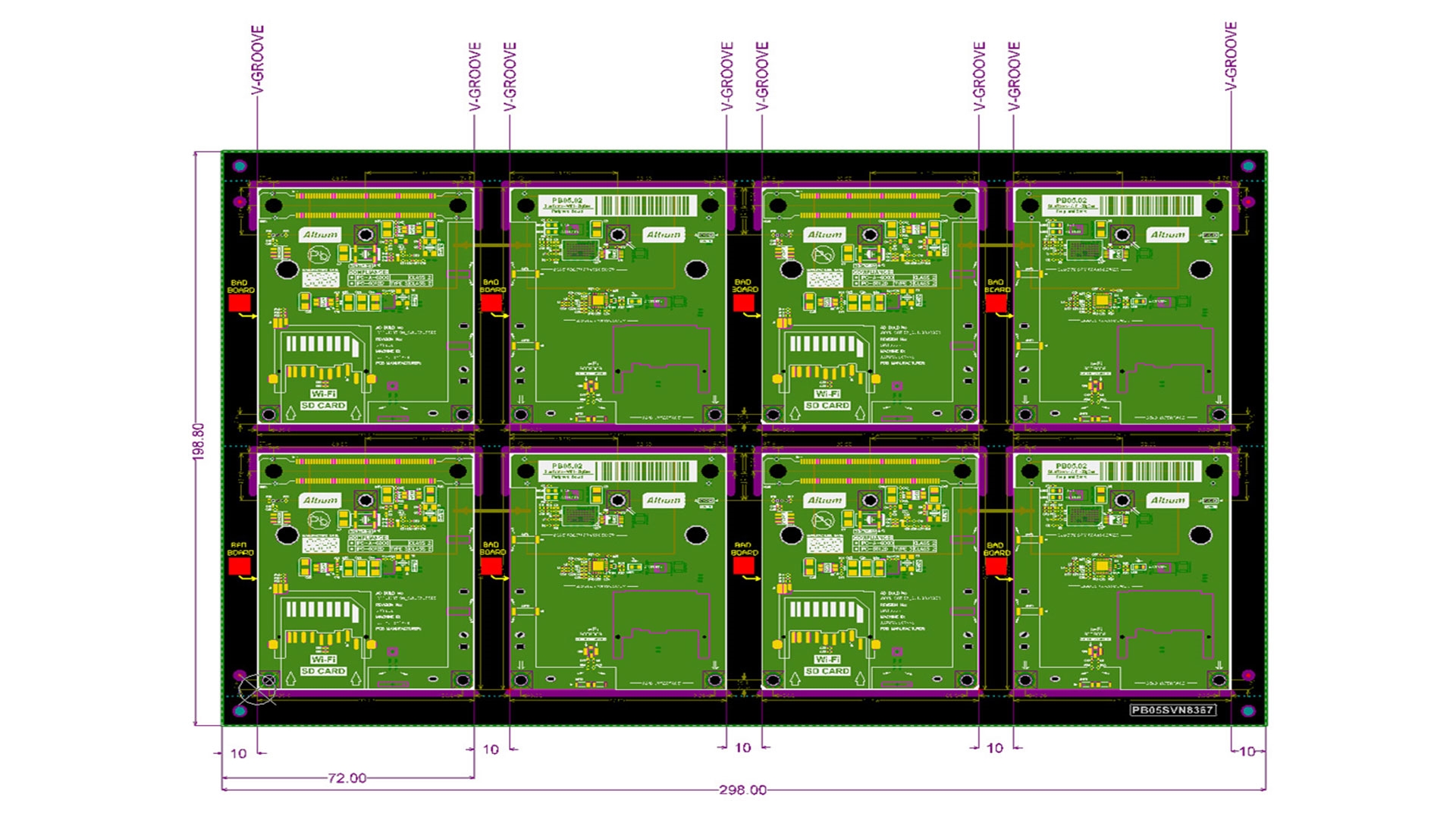

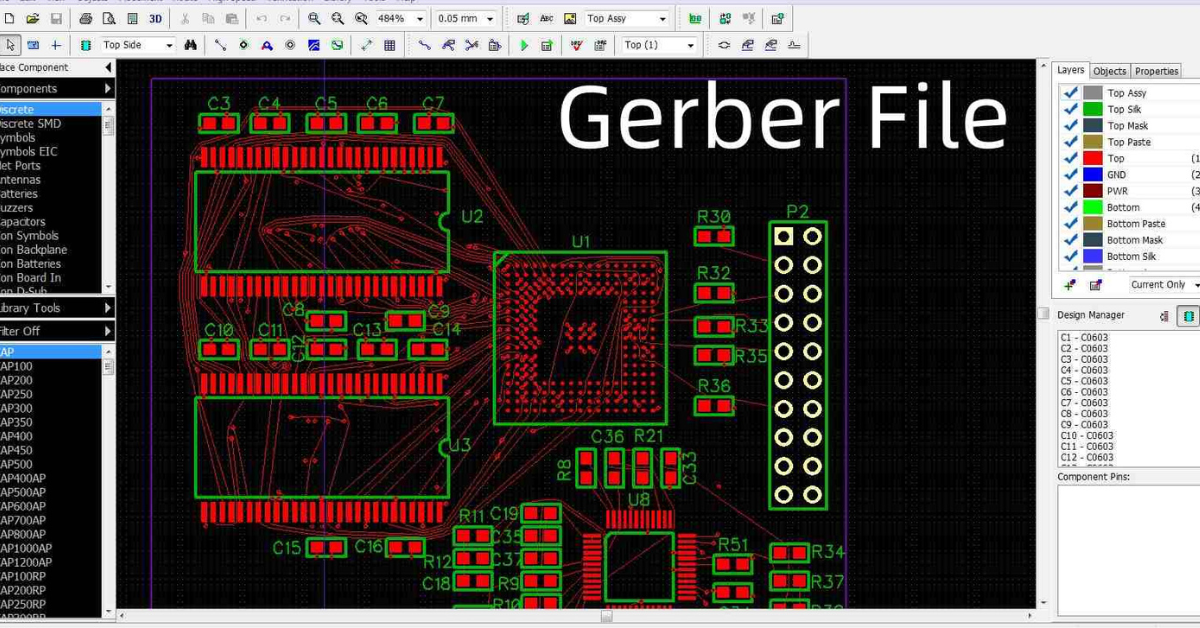

Understanding the technical foundation of PCB batch production helps hobbyists make informed decisions. The process begins with design file preparation, typically in formats like Gerber, which detail the board’s layout, layers, and drilling specifications. These files are then used to create a panel, a larger sheet containing multiple identical boards arranged to maximize manufacturing efficiency.

During production, the panel undergoes several steps, including etching to form copper traces, drilling for vias and mounting holes, and applying a solder mask for protection. Quality checks, often guided by standards like IPC-A-600K for acceptability of printed boards, ensure each board meets dimensional and visual criteria. For quick-turn PCB batch services, manufacturers optimize these steps by using automated equipment and streamlined workflows to reduce turnaround time.

Batch production also considers material choices, such as standard FR-4 substrates for cost-effectiveness or specialized materials for unique requirements. Layer count, board thickness, and copper weight are tailored to the design’s complexity. By grasping these principles, hobbyists can better communicate their needs and avoid common pitfalls during prototyping.

Factors Influencing PCB Prototyping Costs

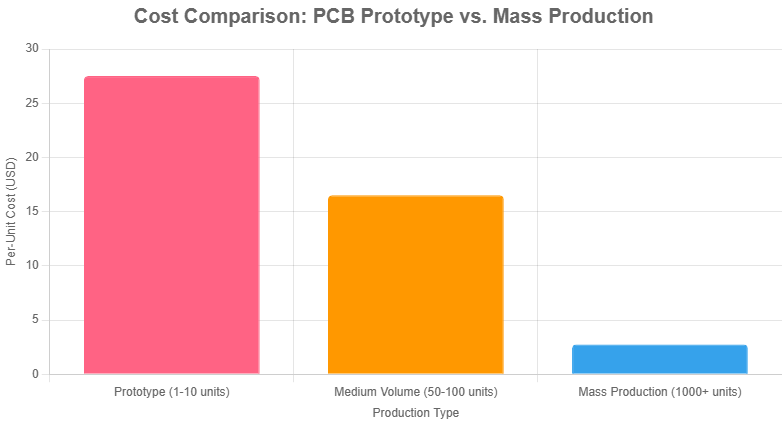

Cost is a major concern for hobbyists engaging in PCB prototyping. Several factors determine PCB prototyping costs, and understanding them can help manage expenses effectively. The primary factor is the number of boards in the batch. Larger batches often lower the cost per unit due to economies of scale, though the initial setup fees remain fixed.

Board size and complexity also play a role. Larger boards or those with multiple layers require more materials and processing time, increasing costs. Similarly, features like fine-pitch traces or tight tolerances demand advanced manufacturing techniques, adding to the expense. Material selection impacts the budget as well, with standard options being more affordable than high-performance alternatives.

Turnaround time is another cost driver. Quick-turn PCB batch options, which promise delivery in days rather than weeks, often come with a premium. Additional services, such as electrical testing or specific surface finishes, further influence the final price. Hobbyists can balance costs by prioritizing essential features and opting for standard specifications where possible.

Best Practices for Fast and Affordable PCB Prototyping Services

Securing fast and affordable PCB prototyping services requires careful planning and clear communication. Start by preparing accurate design files to avoid delays caused by errors or revisions. Ensure your layout adheres to basic design rules, such as maintaining adequate spacing between traces and avoiding overly complex features unless necessary.

Choose a batch size that aligns with your project needs. Ordering a slightly larger PCB prototype batch can reduce per-unit costs while providing spare boards for testing. When selecting a service, prioritize providers offering quick-turn PCB batch options if time is critical, but compare pricing to avoid overpaying for speed.

Review the manufacturing capabilities to confirm they meet your requirements. Check for compliance with standards like IPC-6012E to ensure quality. Request a design-for-manufacturability analysis if available, as it can highlight potential issues before production begins. Finally, communicate timelines and expectations clearly to prevent misunderstandings and ensure a smooth process.

Common Challenges in PCB Batch Prototyping and Solutions

Hobbyists often encounter challenges during PCB batch prototyping, but proactive steps can mitigate these issues. One common problem is design errors, such as incorrect component footprints or misaligned layers, leading to non-functional boards. To address this, double-check your design against datasheets and use simulation tools to verify functionality before submission.

Another issue is unexpected delays in quick-turn PCB batch production. These can arise from incomplete documentation or high demand periods. Providing comprehensive files and confirming lead times upfront can help avoid setbacks. Additionally, inconsistent quality across the batch may occur if manufacturing controls are lax. Referencing standards like IPC-A-600K during discussions with the service provider can set clear quality expectations.

Cost overruns are also frequent when hobbyists underestimate additional fees for expedited shipping or testing. Request a detailed quote covering all aspects of PCB prototyping costs to maintain budget control. By anticipating these challenges, hobbyists can navigate the prototyping process more effectively.

Tips for Electronic Hobbyists Starting with Batch Prototyping

For hobbyists new to PCB batch production, starting on the right foot is essential. Begin with a simple design to minimize errors and keep costs low. Focus on core functionality rather than adding unnecessary features that complicate manufacturing. Use freely available design software with built-in rule checks to catch mistakes early.

When planning a PCB prototype batch, order a small quantity initially to test the design. This approach limits financial risk if issues arise. Document every step of your design process, including component choices and layout decisions, to streamline troubleshooting or future iterations. Engage with online communities of hobbyists for advice on reliable PCB prototyping services and practical tips.

Pay attention to standard specifications, such as those outlined in JEDEC J-STD-020E for moisture sensitivity during soldering, to ensure your boards withstand assembly. By adopting these habits, hobbyists can build confidence in batch prototyping and achieve better outcomes with each project.

Conclusion

PCB batch production for prototyping offers electronic hobbyists a powerful way to test and refine their designs without significant expense or delay. By leveraging quick-turn PCB batch services, managing PCB prototyping costs, and following best practices, hobbyists can bring their ideas to fruition efficiently. Understanding the technical aspects, anticipating challenges, and adhering to industry standards like IPC-6012E and IPC-A-600K ensures consistent quality. With the right approach, batch prototyping becomes a valuable tool in any hobbyist’s toolkit, paving the way for innovation and success in electronics projects.

FAQs

QX: What is a PCB prototype batch, and why should hobbyists consider it?

AX: A PCB prototype batch involves producing a small set of boards to test a design before larger runs. For hobbyists, it’s a cost-effective way to experiment with multiple units, identify flaws, and refine projects. This approach saves money by reducing errors in full production and allows simultaneous testing of different configurations.

QX: How can I reduce PCB prototyping costs for my hobby projects?

AX: To lower PCB prototyping costs, opt for standard materials and simpler designs with fewer layers. Order a slightly larger batch to benefit from per-unit savings. Avoid rush orders unless necessary, as quick-turn options often carry higher fees. Always review quotes to understand all associated expenses.

QX: What should I look for in quick-turn PCB batch services as a hobbyist?

AX: When choosing quick-turn PCB batch services, prioritize clear communication about lead times and quality assurance processes. Ensure the provider follows recognized standards for manufacturing. Check if they offer design reviews to catch errors early. Balance speed with affordability to meet your project’s needs.

QX: How do industry standards impact PCB prototyping services for hobbyists?

AX: Industry standards like IPC-6012E ensure that PCB prototyping services deliver reliable and consistent boards, even for hobbyist projects. These guidelines cover design, materials, and performance, helping prevent issues like defects or failures. Following them prepares your prototype for potential scaling to larger production.

References

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

JEDEC J-STD-020E — Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices. JEDEC, 2014.