Introduction

In the field of printed circuit board design, selecting the right material is a critical decision that impacts both performance and budget. Electrical engineers often face the challenge of balancing thermal performance with cost constraints. The choice of material influences heat dissipation, reliability, and overall system efficiency, especially in high power or high frequency applications.

This article explores key considerations for PCB material selection, focusing on thermal conductivity, cost effectiveness, and practical applications. By comparing standard options like FR4, metal core PCBs, and high TG materials, we aim to provide clear guidance for engineers seeking optimal solutions. Understanding the interplay between material properties and project requirements ensures designs meet performance goals without exceeding budget limits.

Why Thermal Performance Matters in PCB Material Selection

Thermal performance is a cornerstone of reliable PCB design. As electronic devices become more compact and power dense, effective heat dissipation prevents component failure and extends product lifespan. Poor thermal management can lead to overheating, reduced efficiency, and even safety hazards in critical applications.

PCB materials play a pivotal role in conducting heat away from sensitive components to maintain operational stability. For electrical engineers, choosing a material with suitable thermal conductivity is essential for applications like power supplies, LED lighting, and automotive electronics. Beyond performance, material selection also affects manufacturing costs and design complexity. Striking a balance between thermal efficiency and affordability is a common challenge that requires a deep understanding of material properties and application needs.

Technical Principles of PCB Material Thermal Conductivity

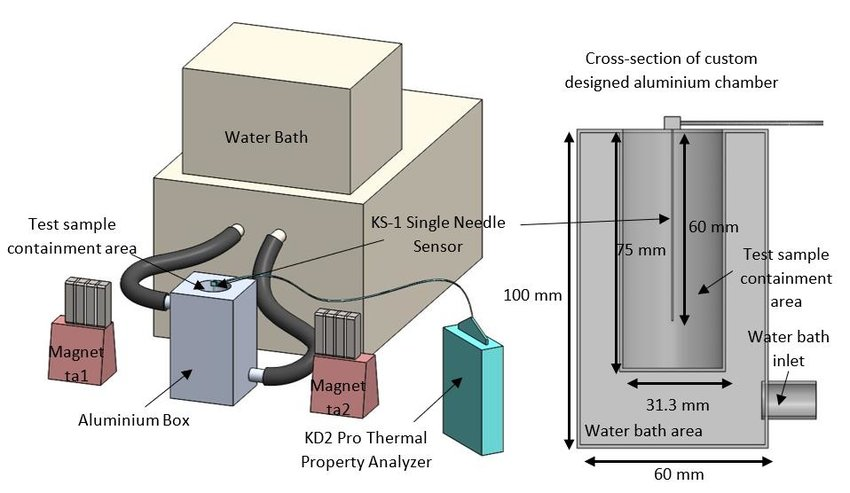

Thermal conductivity, measured in watts per meter Kelvin, defines a material's ability to transfer heat. In PCB design, this property determines how effectively heat generated by components is dissipated through the board. Materials with high thermal conductivity reduce temperature hotspots and improve overall system reliability. Several factors influence a material's thermal performance, including its composition, structure, and thickness.

Standard PCB substrates vary widely in their ability to manage heat. For instance, traditional epoxy based laminates offer lower thermal conductivity, often below 0.3 watts per meter Kelvin, making them less suitable for high heat applications. In contrast, materials with metal or ceramic content can achieve values exceeding 1 watt per meter Kelvin, providing superior heat dissipation. Engineers must also consider the glass transition temperature, or TG, which indicates a material's ability to withstand thermal stress without deforming.

Another critical aspect is the coefficient of thermal expansion, which affects how a material expands or contracts under temperature changes. Mismatched expansion rates between layers can lead to mechanical stress and potential failure, as outlined in standards like IPC-6012E. Understanding these principles helps engineers predict material behavior under operating conditions and select options that align with design goals.

Comparing FR4 vs Metal Core PCB for Thermal Management

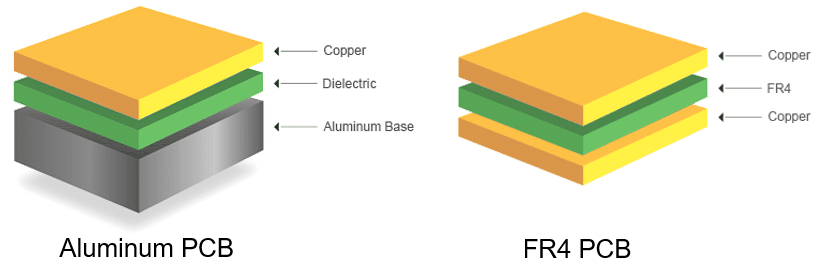

When selecting PCB materials, the comparison between FR4 and metal core PCBs often arises due to their distinct thermal properties. FR4, a widely used epoxy based laminate, is favored for its affordability and versatility in general purpose applications. However, its low thermal conductivity limits its effectiveness in high heat scenarios, making it less ideal for power intensive designs.

Metal core PCBs, on the other hand, incorporate a metal layer, typically aluminum or copper, to enhance heat dissipation. This construction allows them to handle significantly higher thermal loads, often found in LED lighting and automotive systems. The trade off comes in the form of increased weight and manufacturing complexity, which can elevate costs. While FR4 suits budget conscious projects with moderate thermal demands, metal core options are preferred when heat management is a priority over cost.

Engineers must weigh these factors based on specific application requirements. For instance, in environments with tight space constraints and high power density, the superior thermal performance of metal core PCBs may justify the added expense. Standards like IPC-A-600K provide guidelines on material acceptability and performance, ensuring designs meet industry benchmarks for reliability.

High TG PCB Material for Enhanced Thermal Stability

High TG PCB materials are engineered to offer improved thermal stability by raising the glass transition temperature above standard levels. Typically, standard laminates have a TG around 130 to 140 degrees Celsius, while high TG variants exceed 170 degrees Celsius. This property allows the material to maintain structural integrity under elevated temperatures, reducing the risk of warping or delamination during operation or assembly processes.

These materials are particularly valuable in applications exposed to harsh thermal environments, such as industrial controls or telecommunications equipment. While high TG options provide better resistance to thermal stress, they often come at a premium compared to standard laminates. The increased cost reflects the specialized manufacturing processes and raw materials required to achieve these properties. For engineers, selecting high TG PCB material involves assessing whether the thermal demands of the project justify the additional investment. Compliance with standards like IPC-6012E ensures that chosen materials meet performance and reliability criteria for demanding applications.

Cost Effective PCB Thermal Solutions for Engineers

Balancing thermal performance with cost remains a primary concern for many electrical engineers. While advanced materials like metal core PCBs and high TG laminates offer superior heat dissipation, their higher price points may not be feasible for all projects. Exploring cost effective PCB thermal solutions requires a strategic approach to material selection and design optimization.

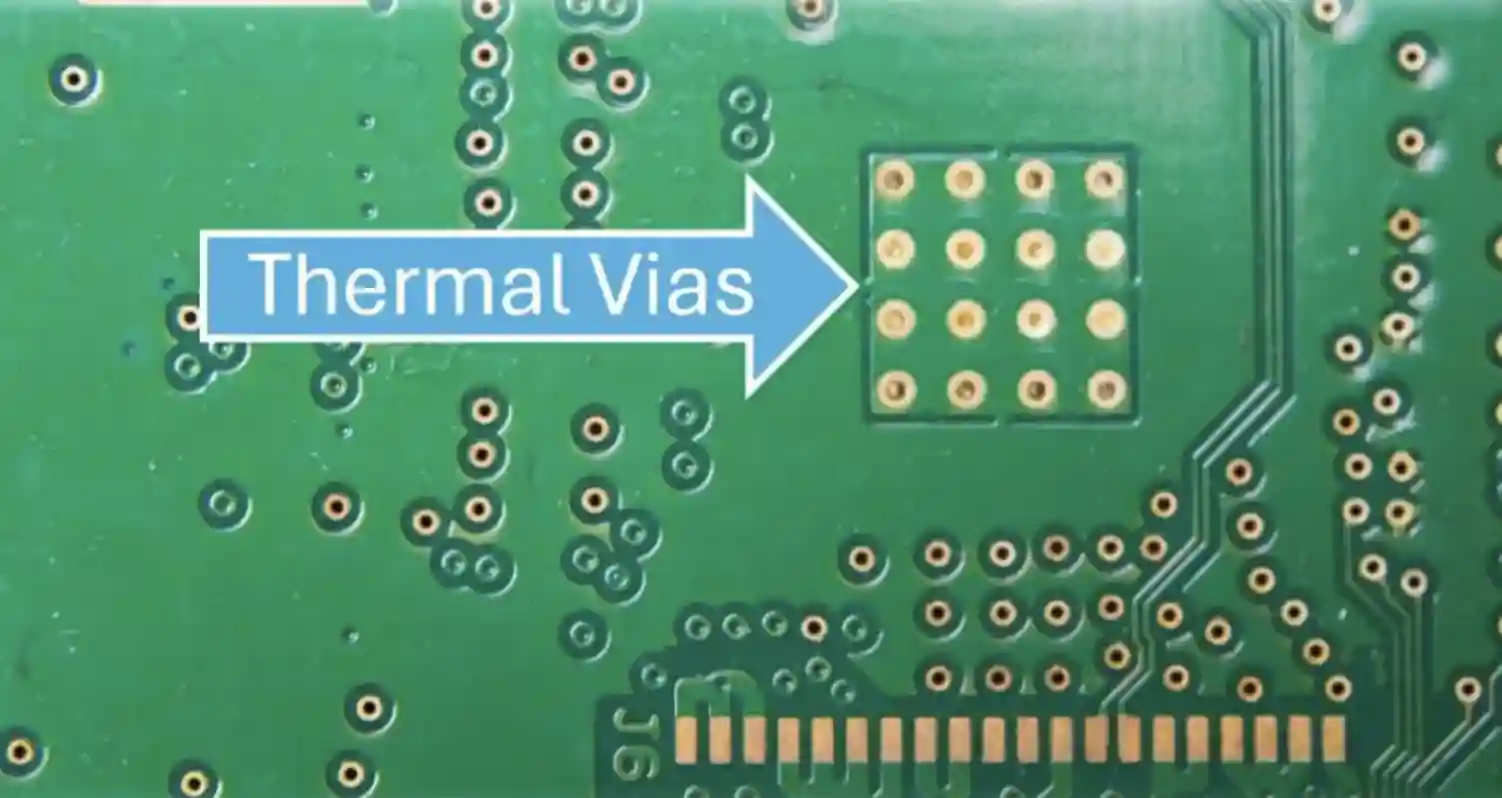

One practical method is to use standard FR4 laminates in combination with design techniques that enhance heat dissipation. Increasing copper thickness or adding thermal vias can improve heat transfer without significantly raising costs. Thermal vias, for instance, create pathways for heat to move from components to other layers or heat sinks. Additionally, optimizing component placement to minimize heat concentration can reduce the need for expensive materials.

For projects requiring moderate thermal performance, hybrid designs that combine different materials in specific board areas may offer a balanced solution. Engineers can consult standards like IPC-6012E to ensure that chosen methods and materials align with industry expectations for quality and performance.

Choosing PCB Laminate for Heat Dissipation in Specific Applications

Selecting the right PCB laminate for heat dissipation depends on the unique demands of each application. Different industries and use cases present varying thermal challenges that influence material choice. In LED lighting systems, for example, high heat generation necessitates materials with excellent thermal conductivity, often leading to the use of metal core PCBs. These materials efficiently transfer heat away from sensitive components, ensuring consistent performance.

In contrast, consumer electronics with lower power requirements may perform adequately with standard FR4 laminates. Cost considerations often drive material selection in such cases, as thermal demands are less critical. For high reliability applications like aerospace or medical devices, high TG PCB materials are frequently chosen to withstand extreme conditions without compromising structural integrity.

Engineers should evaluate operating temperatures, power density, and environmental factors when making decisions. Thermal simulation tools can aid in predicting material performance under specific conditions, reducing the risk of design failures. Adhering to standards like IPC-A-600K helps ensure that selected laminates meet necessary quality and durability thresholds for the intended application.

Related Reading: Comparing Aluminum vs Copper Core PCBs for Optimal Heat Dissipation

Practical Tips for Balancing Thermal Performance and Cost

Achieving an optimal balance between thermal performance and cost requires careful planning and informed decision making. Engineers can follow several practical tips to ensure their designs meet both technical and budgetary goals.

First, clearly define the thermal requirements of the project by analyzing power dissipation and ambient conditions. This step helps narrow down material options to those that match the necessary performance level.

Second, prioritize design optimization before resorting to high cost materials. Techniques like adding heat sinks, improving airflow, or using thermal pads can enhance heat dissipation without changing the base laminate.

Third, consider the total cost of ownership, including manufacturing, assembly, and potential failure costs. Investing in a slightly more expensive material may prevent costly redesigns or field failures in critical applications.

Finally, collaborate with material suppliers to understand the latest options and pricing trends. While avoiding specific commercial entities, referencing industry standards like IPC-6012E can guide discussions on material specifications and performance expectations. These strategies enable engineers to make informed choices that align with project constraints.

Conclusion

Selecting the right PCB material involves a delicate balance between thermal performance and cost considerations. Understanding the thermal conductivity of materials like FR4, metal core PCBs, and high TG laminates allows electrical engineers to tailor their choices to specific application needs. While cost effective solutions are vital for many projects, thermal demands in high power or harsh environments may necessitate advanced materials. By leveraging design techniques and adhering to industry standards, engineers can optimize heat dissipation without exceeding budget limits. Thoughtful material selection ensures reliable performance, longevity, and efficiency in electronic designs, meeting both technical and financial objectives.

FAQs

Q1: What factors should engineers consider for PCB material thermal conductivity?

A1: When evaluating PCB material thermal conductivity, engineers must assess operating temperatures, power density, and heat dissipation needs. Materials with higher conductivity, like metal core options, suit high heat applications but cost more. Standards like IPC-6012E provide guidelines for performance expectations. Balancing these factors with budget constraints ensures optimal material selection for reliability and efficiency in specific designs.

Q2: How does FR4 compare to metal core PCB in terms of cost and thermal performance?

A2: FR4 is a cost effective choice with lower thermal conductivity, suitable for moderate heat applications. Metal core PCBs offer superior heat dissipation, ideal for high power designs, but come at a higher price due to complex manufacturing. Engineers must prioritize thermal needs versus budget, using standards like IPC-A-600K to ensure material quality aligns with project requirements.

Q3: When should high TG PCB material be used for thermal stability?

A3: High TG PCB material is recommended for applications with elevated temperatures, such as industrial or telecommunications equipment. With a glass transition temperature above 170 degrees Celsius, it resists thermal stress better than standard laminates. Though more expensive, it prevents warping or delamination, ensuring reliability in harsh conditions as per IPC-6012E specifications.

Q4: What are some cost effective PCB thermal solutions for heat dissipation?

A4: Cost effective PCB thermal solutions include using standard FR4 with design enhancements like thermal vias or increased copper thickness to improve heat dissipation. Optimizing component layout and adding heat sinks also help manage temperatures without high material costs. Referencing IPC-6012E ensures these methods meet industry standards for performance and reliability in budget conscious projects.

References

IPC-6012E - Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K - Acceptability of Printed Boards. IPC, 2020.