Introduction

Rogers PCB materials are widely recognized in the electronics industry for their superior performance in high-frequency and high-speed applications. These substrates are critical for industries like telecommunications, aerospace, and automotive, where signal integrity and thermal stability are paramount. However, manufacturing defects can compromise the reliability of these boards, leading to costly failures. This article explores common Rogers PCB manufacturing defects, including delamination, etching problems, drilling issues, and plating defects. By understanding the root causes and implementing best practices, electrical engineers can mitigate risks and ensure consistent quality. The focus will be on technical insights and actionable solutions to address Rogers PCB manufacturing defects effectively, adhering to established industry standards for precision and reliability.

What Are Rogers PCB Manufacturing Defects and Why They Matter

Rogers PCB manufacturing defects refer to flaws that occur during the production of printed circuit boards using high-performance laminate materials designed for demanding applications. These defects can manifest as physical damage, dimensional inaccuracies, or electrical performance issues, directly impacting the functionality of the final product. Given the specialized nature of these materials, which often involve low dielectric constants and high thermal conductivity, even minor deviations can lead to signal loss, impedance mismatches, or complete circuit failure.

The significance of addressing these defects cannot be overstated. In high-stakes industries, a single defective board can result in system downtime, safety hazards, or project delays. For electrical engineers, ensuring defect-free manufacturing is essential to meet stringent performance requirements and maintain project timelines. This section sets the foundation for identifying and resolving common issues like Rogers PCB delamination, etching inconsistencies, drilling inaccuracies, and plating imperfections.

Causes of Rogers PCB Manufacturing Defects

Understanding the root causes of defects in Rogers PCB manufacturing is the first step toward prevention. These issues often stem from material properties, process control, or equipment limitations. Below are the primary causes associated with frequent defects.

Delamination Issues

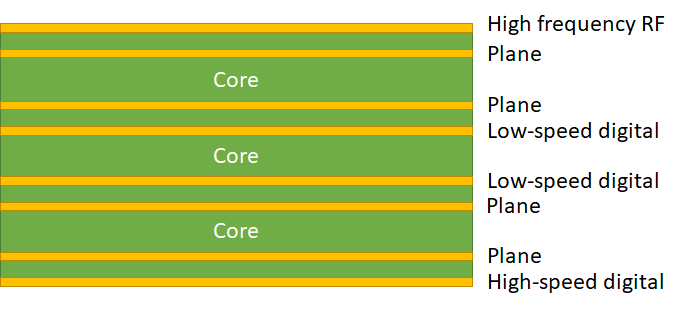

Delamination in Rogers PCB manufacturing occurs when layers of the board separate, often due to thermal stress or inadequate bonding during lamination. The unique composition of these materials, designed for low dielectric loss, can make them sensitive to moisture absorption if not handled properly. Poor storage conditions or excessive heat during processing can weaken interlayer adhesion, leading to separation.

Etching Problems

Rogers PCB etching problems arise when the chemical process used to remove unwanted copper fails to achieve precise patterns. Over-etching can result in trace thinning, while under-etching leaves excess copper, both affecting signal integrity. These issues are often caused by inconsistent etchant concentration, improper exposure during photolithography, or material incompatibilities with etching solutions.

Drilling Issues

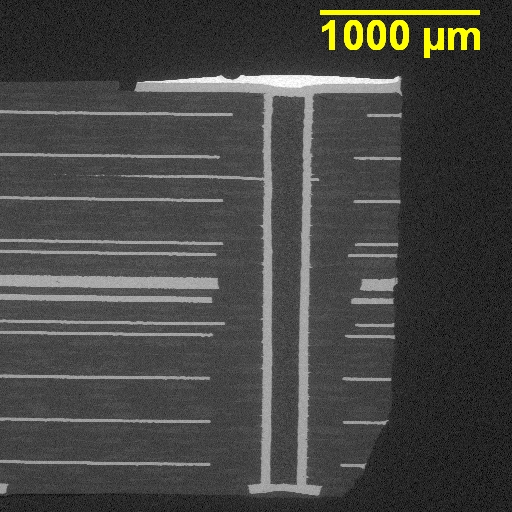

Drilling challenges, or Rogers PCB drilling issues, occur due to the material's unique mechanical properties. High-speed drilling can generate excessive heat, causing resin smear or burrs around via holes. Inadequate drill bit selection or worn tools can also lead to misalignment or rough edges, compromising electrical connections and structural integrity.

Plating Defects

Rogers PCB plating defects involve inconsistencies in the deposition of conductive layers, such as copper or gold, on vias and pads. Poor adhesion, uneven thickness, or contamination during electroplating can result in weak connections or open circuits. These defects often stem from improper surface preparation or suboptimal plating bath conditions, critical for high-frequency applications.

Practical Solutions to Avoid Rogers PCB Manufacturing Defects

Mitigating defects in Rogers PCB manufacturing requires a combination of process optimization, quality control, and adherence to industry standards. The following solutions target specific issues and provide actionable guidance for electrical engineers.

Preventing Delamination

To avoid Rogers PCB delamination, strict control over lamination parameters is essential. Maintain recommended temperature and pressure profiles during bonding to ensure strong interlayer adhesion. Pre-baking the material to remove moisture before processing can significantly reduce risks, as outlined in IPC-6012E standards for rigid printed boards. Additionally, store materials in controlled environments to prevent humidity exposure.

Addressing Etching Problems

For Rogers PCB etching problems, precise control of chemical processes is critical. Regularly monitor etchant concentration and temperature to achieve uniform copper removal. Use high-resolution photomasks and ensure proper alignment during exposure to avoid pattern deviations. Implementing process validation as per IPC-A-600K guidelines for acceptability of printed boards helps in maintaining consistent etching quality.

Solving Drilling Issues

Rogers PCB drilling issues can be minimized by selecting appropriate drill bits and optimizing spindle speeds. Use carbide drills designed for high-performance laminates to reduce heat buildup and prevent resin smear. Regular tool maintenance and inspection for wear are necessary to ensure clean, accurate holes. Following IPC-6012E specifications for via quality can guide engineers in achieving reliable results.

Correcting Plating Defects

To tackle Rogers PCB plating defects, thorough surface preparation before plating is vital. Clean the board to remove contaminants and ensure proper activation of surfaces for uniform deposition. Monitor plating bath chemistry and current density to avoid uneven thickness. Adhering to IPC-A-600K standards for plating acceptability ensures robust electrical connections in high-frequency designs.

Troubleshooting Insights for Electrical Engineers

When defects occur despite preventive measures, systematic troubleshooting is essential. For delamination, inspect lamination logs for deviations in temperature or pressure, and test material batches for moisture content. Etching inconsistencies often require reviewing exposure times and etchant refresh cycles. Drilling issues may need analysis of tool wear patterns and heat dissipation during the process. Plating defects can be traced to contamination or improper surface treatment, requiring a review of cleaning protocols.

A practical approach is to implement in-process inspections at critical manufacturing stages. Visual and automated optical inspections, as recommended by IPC-A-600K, can detect early signs of defects. Electrical testing for continuity and impedance after each process step ensures issues are identified before final assembly. These methods empower engineers to address Rogers PCB manufacturing defects promptly and maintain quality in demanding applications.

Conclusion

Manufacturing defects in Rogers PCB production, such as delamination, etching problems, drilling issues, and plating defects, pose significant challenges for electrical engineers. These flaws can compromise the performance of high-frequency and high-speed circuits, leading to costly failures in critical applications. By understanding the causes, from thermal stress to process inconsistencies, and implementing targeted solutions like optimized lamination and precise chemical controls, engineers can minimize risks. Adherence to industry standards ensures consistent quality and reliability. Through proactive measures and systematic troubleshooting, the integrity of Rogers PCB manufacturing can be upheld, supporting innovation in advanced electronics.

FAQs

Q1: What causes Rogers PCB delamination and how can it be prevented?

A1: Rogers PCB delamination often results from thermal stress or moisture absorption weakening interlayer bonds. To prevent it, control lamination parameters like temperature and pressure as per industry standards such as IPC-6012E. Pre-bake materials to eliminate moisture and store them in low-humidity environments. Regular process audits and material testing further reduce risks of separation during manufacturing.

Q2: How do Rogers PCB etching problems affect circuit performance?

A2: Rogers PCB etching problems, such as over-etching or under-etching, can alter trace dimensions, impacting signal integrity. Thinned traces increase resistance, while excess copper causes shorts, both disrupting high-frequency performance. Ensure precise control of etchant chemistry and exposure accuracy. Following IPC-A-600K guidelines for acceptability helps maintain consistent etching and reliable circuit functionality.

Q3: What are common Rogers PCB drilling issues in high-frequency designs?

A3: Rogers PCB drilling issues include resin smear, burrs, and misalignment due to heat buildup or tool wear. These defects can weaken via connections, critical for high-frequency signal paths. Use specialized drill bits and optimized speeds to minimize heat. Regular tool maintenance and adherence to IPC-6012E specifications ensure clean, accurate holes for dependable performance.

Q4: How can engineers address Rogers PCB plating defects effectively?

A4: Rogers PCB plating defects like uneven thickness or poor adhesion can lead to weak electrical connections. Thorough surface cleaning before plating and monitoring bath conditions are essential. Ensure consistent current density for uniform deposition. Adhering to IPC-A-600K standards for plating quality helps identify and correct issues, ensuring reliability in high-performance applications.

References

IPC-6012E - Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-A-600K - Acceptability of Printed Boards. IPC, 2020.