Why PCB Surface Finishes Are Critical for Board Reliability

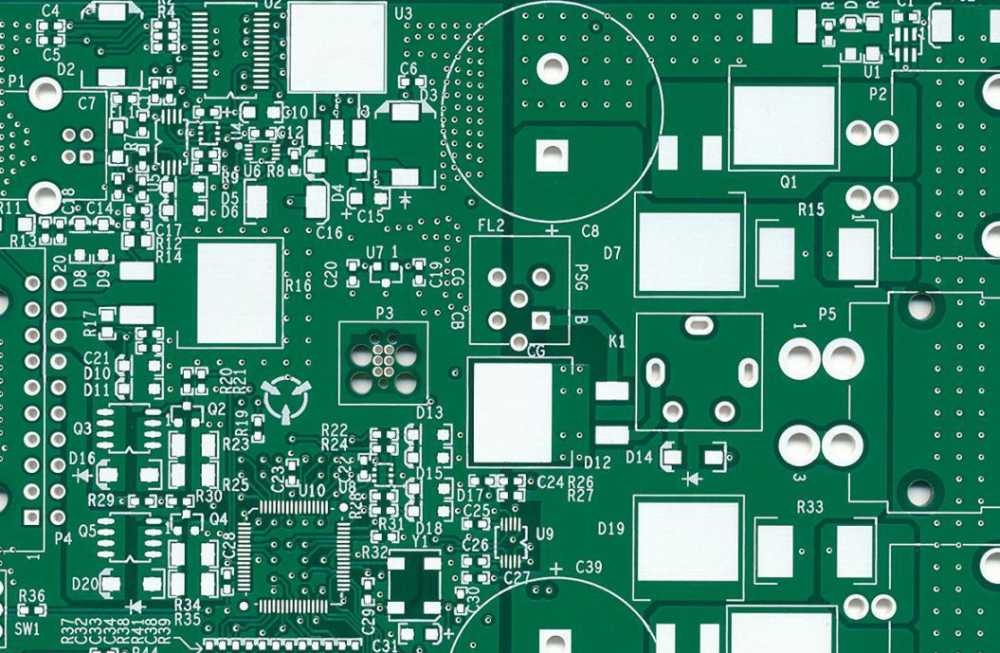

PCB surface finishes serve a vital function: they shield the exposed copper traces from environmental degradation and ensure the board can be reliably soldered during assembly. Without an appropriate protective layer, copper readily oxidizes or corrodes, leading to compromised electrical connections, a reduced shelf life, and potential failures in the final electronic product. Even with the selection of a suitable finish, defects can still manifest due to improper application, environmental factors, or material inconsistencies. These imperfections not only detract from the board's appearance but also negatively impact its functionality and long-term durability.

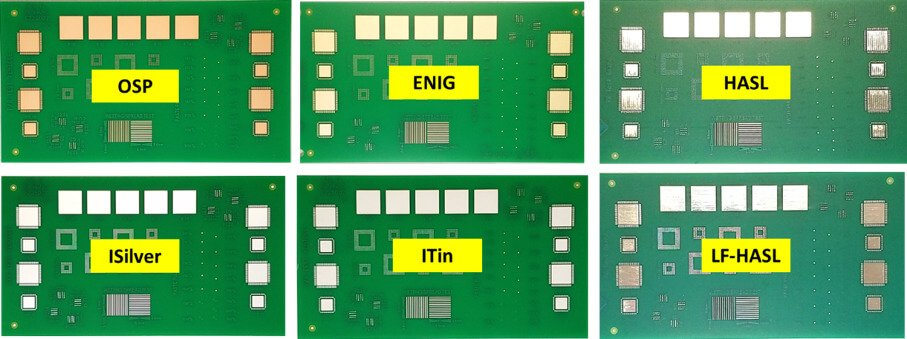

This detailed guide will cover prevalent PCB surface finish issues, specifically addressing uneven Hot Air Solder Leveling (HASL) coatings, Electroless Nickel Immersion Gold (ENIG) "black pad," Organic Solderability Preservative (OSP) oxidation, and immersion silver tarnishing. We will also provide practical advice for diagnosing and rectifying these defects, helping you to maintain high-quality PCBs for all your projects.

Common PCB Surface Finish Defects and Their Causes

Before delving into troubleshooting and repair methods, it's essential to understand the typical types of surface finish defects and their underlying causes. Each major finish—HASL, ENIG, OSP, and Immersion Silver—possesses distinct characteristics and susceptibility to particular issues. Let's examine the most frequently encountered defects associated with each.

Uneven HASL Coatings

Hot Air Solder Leveling (HASL) is a popular surface finish known for its cost-effectiveness and good solderability. However, a common problem encountered is an uneven coating, where the solder layer varies significantly in thickness across the board. This inconsistency can lead to unreliable solder joints during assembly or misalignment of components.

Causes:

● Incorrect air knife pressure during the HASL process, leading to inconsistent solder distribution.

● Contamination on the PCB surface prior to coating, which prevents uniform solder adhesion.

● Inadequate flux application, impacting how the molten solder flows and wets the copper.

● Design variations, such as contrasting areas of dense circuitry versus open spaces, causing uneven heat transfer.

Impact: Uneven HASL can compromise solder joint reliability; even minor thickness variations (1-2 micrometers) can increase failure risk by up to 15% in demanding applications.

ENIG Black Pad Phenomenon

Electroless Nickel Immersion Gold (ENIG) is a premium finish valued for its exceptional flatness and corrosion resistance. Nevertheless, it is susceptible to a notorious defect known as "black pad," where the underlying nickel layer corrodes, resulting in a dark, blackened appearance. This issue commonly leads to poor solderability and weak intermetallic connections.

Causes:

● Excessive phosphorus content within the nickel layer, making it more prone to corrosion during the subsequent gold plating.

● Insufficient control over the immersion gold bath parameters, leading to an aggressive etching of the nickel surface.

● Contaminants in the plating solution disrupting the delicate chemical balance.

● Incomplete rinsing between plating stages, leaving corrosive residues that promote nickel degradation.

Impact: Black pad defects can reduce solder joint strength by 20-30%, significantly raising the probability of field failures in critical sectors like aerospace or medical devices.

OSP Oxidation Issues

Organic Solderability Preservative (OSP) offers an environmentally friendly and economical finish, providing a thin organic protective layer over copper to prevent oxidation. Despite its advantages, OSP itself can oxidize if exposed to high humidity or extended storage, resulting in a tarnished appearance and reduced solderability.

Causes:

● Exposure to excessive moisture or elevated temperatures, which degrades the organic coating over time.

● Improper storage conditions, such as leaving boards unpackaged in humid environments.

● Insufficient coating thickness (typically below 0.2 micrometers) failing to provide adequate protection.

● Handling contamination, such as fingerprints or oils, which can compromise the OSP layer's integrity.

Impact: Oxidized OSP surfaces can increase soldering defects by up to 25% because the degraded layer prevents proper solder wetting during assembly.

Immersion Silver Tarnishing

Immersion Silver is a popular finish due to its excellent solderability and flatness, but it is highly vulnerable to tarnishing when exposed to sulfur or chloride in the environment. Tarnished silver typically appears yellow or brown and can severely impair soldering performance.

Causes:

● Exposure to sulfur-containing environments, such as industrial areas or during storage in non-sealed packaging.

● High humidity levels accelerating the chemical reaction between silver and airborne contaminants.

● Inadequate anti-tarnish treatment applied immediately after the silver plating process.

● Prolonged shelf life without proper protective packaging, leading to surface degradation.

Impact: Tarnished immersion silver can reduce solder joint reliability by 10-15%, as the tarnish layer creates an undesirable barrier between the solder and the base metal.

Related Reading: Advanced Surface Finishes: Choosing the Right Option for PCB Mass Production

Troubleshooting PCB Surface Finish Defects

Having identified the common defects and their causes, the next step is to implement practical troubleshooting procedures to diagnose and rectify these issues. The objective is to pinpoint the root cause of the defect and apply effective corrective measures to prevent its recurrence.

Diagnosing HASL Uneven Coating

● Inspect the Coating Process: Verify the air knife settings during the HASL process, ensuring consistent pressure (e.g., 2-4 psi) for uniform solder distribution.

● Pre-Cleaning the PCB: Confirm that the board surface is free of contaminants before HASL application. Utilize a pre-cleaning step with solutions like isopropyl alcohol to remove oils or residues.

● Optimizing Flux Application: Check for even flux application, aiming for a thickness of approximately 1-2 micrometers, to ensure proper solder flow and wetting.

● Reviewing Board Design: If uneven coating persists in specific areas, consider design modifications to balance the thermal mass across the board, reducing localized hot spots during soldering.

Diagnosing ENIG Black Pad

● Analyzing Nickel Composition: Test the nickel layer for its phosphorus content, ideally targeting a range of 7-9% to minimize corrosion risk during gold plating.

● Monitoring Gold Bath Parameters: Ensure the immersion gold bath operates within its recommended pH (4.5-5.5) and temperature (80-85°C) ranges to prevent aggressive nickel etching.

● Enhancing Rinsing Procedures: Implement thorough rinsing with deionized water between all plating stages to remove chemical residues effectively.

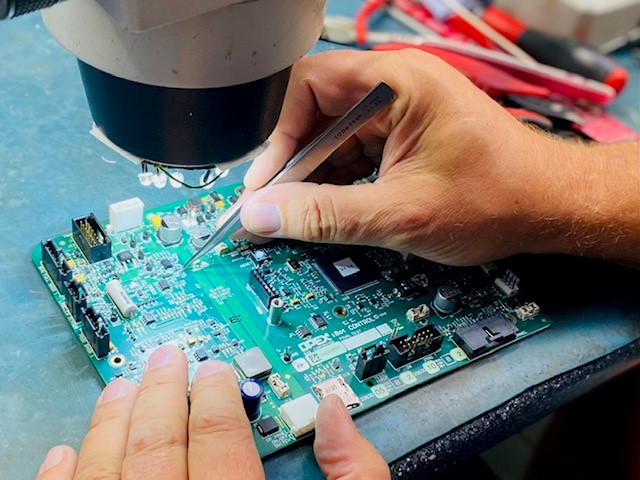

● Visual and Microscopic Inspection: Utilize a microscope at 50x magnification to detect early indications of black pad before assembly, allowing for potential rework.

Diagnosing OSP Oxidation Issues

● Checking Storage Conditions: Store OSP-finished PCBs in vacuum-sealed bags with desiccants to minimize humidity exposure. Maintain storage temperatures below 30°C.

● Verifying Coating Thickness: Use a coating thickness gauge to confirm the OSP layer is at least 0.2-0.5 micrometers thick, providing adequate protection.

● Limiting Handling: Ensure personnel wear gloves when handling OSP boards to prevent contamination from skin oils or residues.

● Reapplying OSP: If oxidation is detected pre-assembly, consider stripping the existing layer with a mild acid solution and reapplying OSP under controlled conditions.

Diagnosing Immersion Silver Tarnishing

● Assessing Environmental Exposure: Determine if boards are stored or assembled in sulfur-rich environments. Employ sulfur-free packaging materials to mitigate tarnishing risks.

● Applying Anti-Tarnish Treatment: Confirm that an anti-tarnish coating (typically 0.1 micrometers thick) is applied immediately after silver plating.

● Controlling Storage Conditions: Maintain humidity levels below 50% in storage areas and use sealed packaging to protect boards from airborne contaminants.

● Performing Surface Testing: Conduct a tarnish test (e.g., exposure to hydrogen sulfide gas under controlled conditions) to evaluate the silver layer’s resistance to degradation.

Related Reading: Troubleshooting and Repairing Common PCB Surface Finish Defects

Practical PCB Defect Repair Solutions

While preventing defects is always the most desirable outcome, issues can sometimes arise despite best efforts. In such scenarios, repairing the PCB surface finish can significantly save time and resources. Below are practical repair methodologies for each type of defect, aimed at restoring the board's functionality for assembly and end-use.

Repairing Uneven HASL Coating

For minor unevenness, localized rework can be effective. Use a soldering iron with a fine tip to carefully apply additional solder to thin areas, ensuring a uniform layer. Maintain a temperature between 260-300°C to avoid damaging the PCB. In severe cases, it may be necessary to chemically strip the existing HASL layer using a specialized solder stripper solution and then reapply the finish under strictly controlled conditions.

Repairing ENIG Black Pad

Repairing black pad defects is particularly challenging due to the underlying nickel corrosion. If the defect is highly localized, the affected gold and nickel layers can be precisely removed using a chemical etchant, followed by replating the area with fresh nickel and gold. However, for widespread black pad issues, it is often more economically viable to scrap the affected boards and implement corrective adjustments to the plating process for subsequent manufacturing batches.

Repairing OSP Oxidation Issues

Oxidized OSP layers can frequently be restored by gently cleaning the surface with a mild acid solution (e.g., 5% citric acid) to remove the degraded organic layer. After this cleaning step, the board must be thoroughly dried, and a fresh OSP coating should be applied, typically via a dip process. It is crucial to ensure the board is assembled promptly after reapplication to prevent re-oxidation.

Repairing Immersion Silver Tarnishing

For tarnished immersion silver, a silver cleaner or a mild abrasive pad can be used to carefully remove the tarnish layer, exposing the fresh silver underneath. Care must be taken not to over-scrub, as this can remove excessive amounts of silver (typically reducing layer thickness by 0.05-0.1 micrometers per cleaning cycle). Following cleaning, an anti-tarnish coating should be applied, and the board must be stored appropriately.

Strategies for Preventing PCB Surface Finish Defects

While the ability to troubleshoot and repair defects is essential, preventing their occurrence in the first place offers significant time and cost savings. Here are some best practices to minimize the risk of surface finish issues.

● Strict Quality Control in Manufacturing: Implement rigorous process controls for surface finish application, including routine calibration of equipment and thorough testing of all chemical baths.

● Optimal Storage Conditions: Store finished PCBs in controlled environments characterized by low humidity (below 50%) and minimal exposure to airborne contaminants.

● Informed Material Selection: Choose surface finishes based on the specific environmental and performance requirements of the application. For instance, opt for ENIG in high-reliability applications despite its higher cost, or OSP for short-shelf-life, cost-sensitive projects.

● Comprehensive Training and Handling Protocols: Provide thorough training to personnel on correct handling techniques to prevent contamination, and mandate the use of protective gear, such as gloves, when working with sensitive finishes like OSP or immersion silver.

Conclusion: Achieving High-Quality PCBs Through Proactive Defect Management

PCB surface finish defects, including uneven HASL, ENIG black pad, OSP oxidation, and immersion silver tarnishing, can present substantial challenges in both manufacturing and assembly. Nevertheless, by understanding their root causes, employing systematic troubleshooting methodologies, and utilizing effective repair techniques, you can consistently maintain the quality and reliability of your printed circuit boards. At AIVON, we are dedicated to supporting engineers and manufacturers with the necessary resources and expertise to confidently address these issues. By adhering to the practical steps outlined in this guide, you can minimize defects, reduce costly rework, and ensure your boards consistently meet the most stringent performance standards.

Whether you are actively addressing a specific defect or aiming to enhance your overall manufacturing process, a proactive approach is key. Implement robust quality control measures, ensure proper board storage, and meticulously select the appropriate surface finish for your application. With these strategies firmly in place, you will be well-equipped to manage any surface finish challenge that arises.