Introduction

Automation in PCB assembly has become a pivotal strategy for companies aiming to enhance efficiency and reduce costs. As the electronics industry grows more competitive, understanding the return on investment (ROI) on automated PCB assembly is essential for electrical engineers and management teams. This article explores the financial benefits of PCB automation, provides a framework for cost justification for automation projects, and offers insights on presenting the case for PCB automation to management. By focusing on practical data and industry standards, this discussion aims to equip technical professionals with the knowledge to make informed decisions about integrating automation into their assembly processes. The goal is to highlight how automation can transform production while ensuring quality and profitability.

What is Automated PCB Assembly and Why It Matters

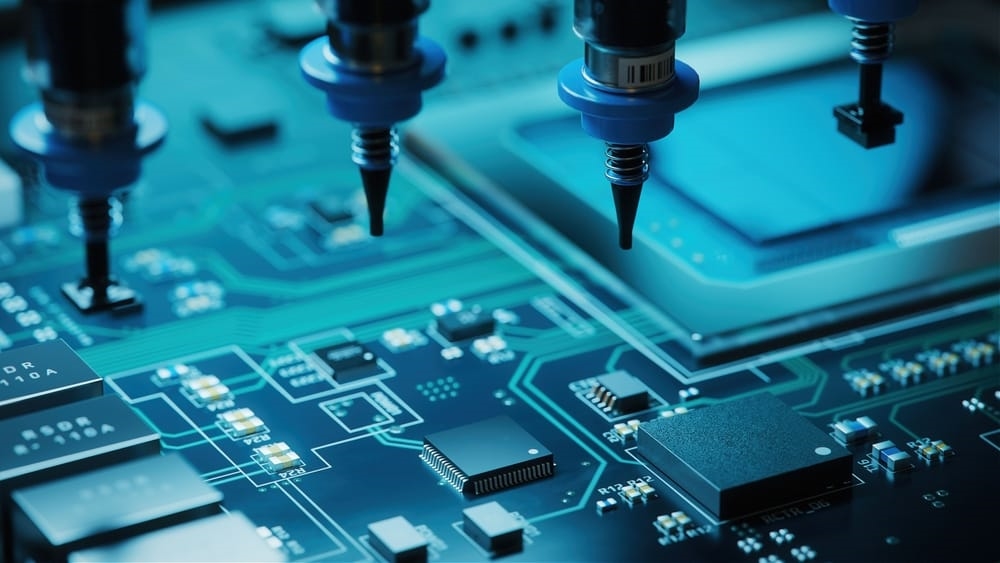

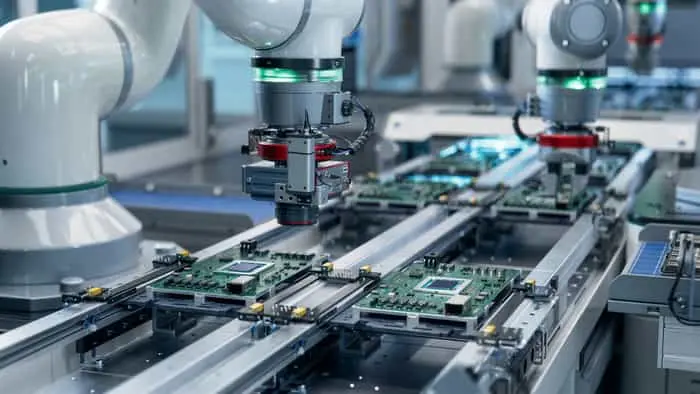

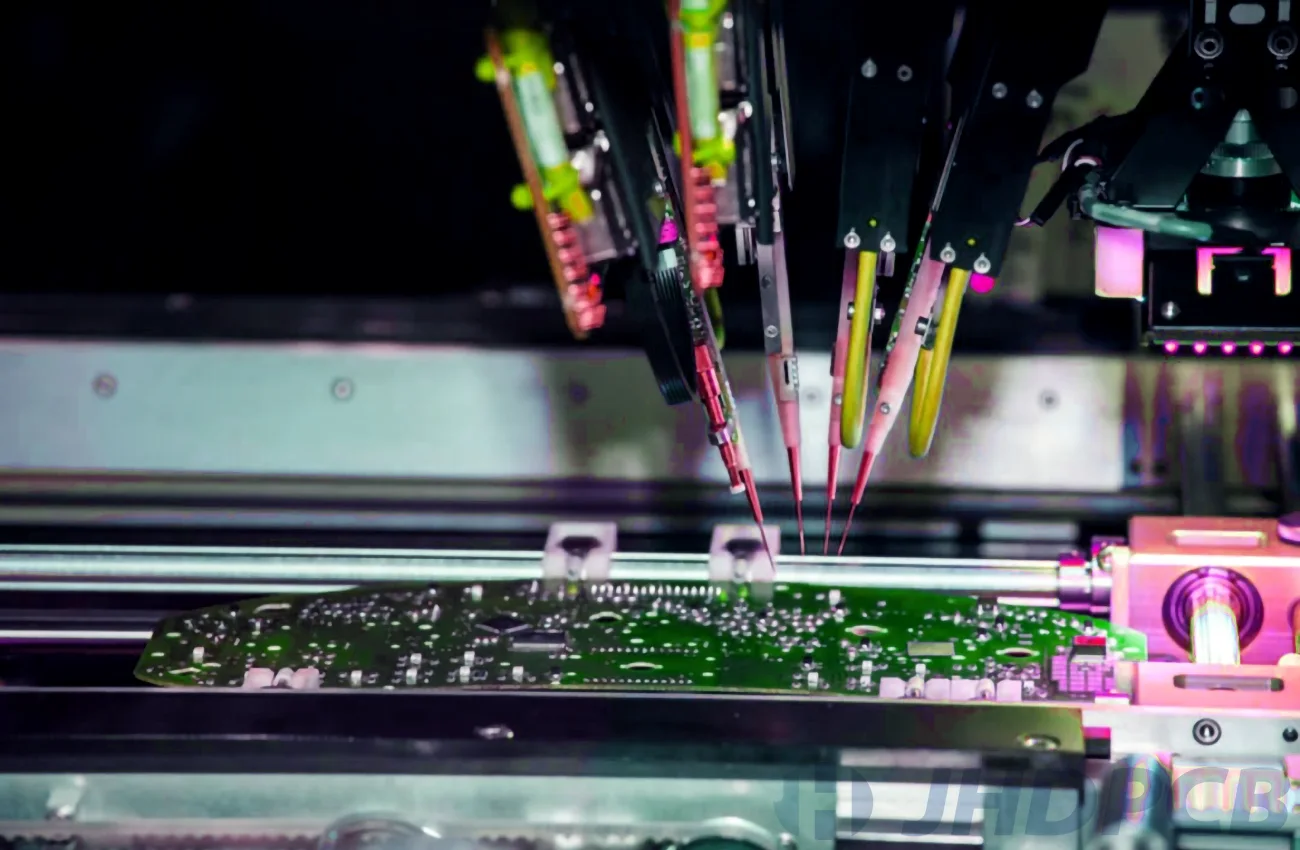

Automated PCB assembly refers to the use of advanced machinery and robotic systems to perform tasks such as component placement, soldering, and inspection during the production of printed circuit boards. This approach contrasts with manual assembly, which relies heavily on human labor. The relevance of automation in the electronics industry cannot be overstated. It addresses challenges like increasing demand for precision, faster production cycles, and consistent quality.

The primary reason automation matters is its capacity to scale production while minimizing errors. With the rise of complex designs and smaller components, manual processes struggle to maintain accuracy. Automation ensures repeatability, aligning with stringent industry standards such as IPC-A-610, which governs the acceptability of electronic assemblies. For electrical engineers, adopting automation means meeting market demands without compromising on reliability or performance.

Related Reading: Implementing Automated Conformal Coating for Improved PCB Reliability

Technical Principles Behind Automated PCB Assembly

At its core, automated PCB assembly relies on several key technologies. Surface mount technology (SMT) machines place components onto boards with high precision. These systems use vision systems and software to align parts accurately, often handling thousands of placements per hour. Automated soldering, through wave or reflow processes, ensures consistent joint quality, adhering to standards like IPC-J-STD-001 for soldered electrical and electronic assemblies.

Inspection systems, such as automated optical inspection (AOI), play a crucial role. They detect defects like misaligned components or solder issues, ensuring compliance with IPC-A-600K for acceptability of printed boards. Robotics also handle material transfer between assembly stages, reducing human intervention. These technologies collectively minimize variability, a critical factor for engineers focused on maintaining design integrity.

Related Reading: PCB Prototyping Assembly: Ensuring Quality with Automated Optical Inspection (AOI)

Financial Benefits of PCB Automation

The financial benefits of PCB automation are substantial, making it a compelling choice for many organizations. One of the most immediate advantages is the reduction in labor costs. Manual assembly requires skilled workers, whose wages can be a significant expense. Automation replaces repetitive tasks, allowing staff to focus on higher value activities like design or quality assurance.

Another key benefit is the increase in production speed. Automated systems operate continuously, significantly reducing cycle times compared to manual methods. This efficiency translates into higher output, enabling companies to meet larger orders without additional resources. Moreover, automation reduces error rates, cutting down on rework and scrap costs. Consistency in assembly also lowers warranty claims and returns, further enhancing profitability.

Energy efficiency is another often overlooked advantage. Modern automated systems are designed to optimize power usage, aligning with sustainability goals while reducing operational expenses. For engineers, these savings collectively contribute to a stronger bottom line, making automation a strategic investment.

Cost Justification for Automation Projects

Justifying the cost of automation projects requires a structured approach to demonstrate ROI on automated PCB assembly. The initial investment in equipment and software can be significant, but the long term savings often outweigh these expenses. Engineers and managers must focus on quantifiable metrics to build a compelling case.

Start by calculating labor cost reductions. Compare current wages for manual assembly against the projected costs of operating automated systems, including maintenance. Next, assess throughput improvements. Determine how many more units can be produced in the same timeframe with automation, and estimate the revenue from this increased capacity.

Error reduction is another critical factor. Use historical data to quantify the cost of defects and rework in manual processes, then project the savings from automation’s higher accuracy. Additionally, consider downtime reductions. Automated systems often have predictive maintenance features, minimizing unexpected halts compared to manual setups.

Finally, factor in compliance with industry standards like ISO 9001:2015 for quality management systems. Automation ensures consistent adherence to such benchmarks, reducing the risk of costly non conformance issues. By presenting these data points, engineers can clearly illustrate the financial rationale for automation.

Presenting the Case for PCB Automation to Management

When presenting the case for PCB automation to management, clarity and data driven arguments are essential. Electrical engineers must tailor their approach to address both technical and financial concerns, ensuring alignment with organizational goals. Begin with a concise overview of the current challenges in manual assembly, such as inconsistent quality or slow production rates.

Next, introduce automation as a solution, emphasizing its alignment with industry standards like IPC-6012E for rigid printed board performance. Highlight specific technologies, such as SMT or AOI, and their proven impact on efficiency. Use visual aids like charts to compare manual versus automated workflows, showing reductions in cycle time and error rates.

Focus on the financial benefits of PCB automation by presenting the cost justification analysis. Break down the initial investment against projected savings over a defined period, typically three to five years. Include intangible benefits, such as improved customer satisfaction due to reliable products. Conclude with a clear action plan, outlining implementation steps and expected timelines, to provide management with a roadmap for decision making.

Practical Steps to Implement Automation in PCB Assembly

Implementing automation in PCB assembly requires careful planning to ensure a smooth transition. Begin by conducting a thorough needs assessment. Identify the specific processes that would benefit most from automation, such as component placement or inspection. Evaluate current production volumes and defect rates to prioritize areas with the highest potential ROI on automated PCB assembly.

Next, research equipment that complies with relevant standards, such as IPC-J-STD-020E for moisture and reflow sensitivity classification. Ensure the selected systems integrate with existing workflows to avoid disruptions. Collaborate with cross functional teams, including design and quality control, to address potential compatibility issues.

Pilot testing is a critical step. Start with a small scale deployment to validate performance and identify bottlenecks. Collect data on speed, accuracy, and maintenance needs during this phase. Use these insights to refine processes before full implementation. Training staff on new systems is equally important to maximize efficiency and minimize resistance to change.

Finally, establish key performance indicators to monitor post implementation success. Track metrics like production output, defect rates, and operational costs to continuously assess the financial benefits of PCB automation. Adjust strategies as needed to optimize results.

Conclusion

Automation in PCB assembly offers a transformative opportunity for electrical engineers and organizations aiming to improve efficiency and profitability. By understanding the ROI on automated PCB assembly, professionals can build a strong case for investment, focusing on the financial benefits of PCB automation and cost justification for automation projects. Presenting the case for PCB automation to management with clear data and actionable plans ensures alignment with business objectives. As the industry evolves, adopting automation not only enhances production capabilities but also positions companies to meet stringent quality standards and market demands with confidence.

FAQs

Q1: How can I calculate the ROI on automated PCB assembly for my facility?

A1: Calculating ROI on automated PCB assembly involves comparing initial costs against long term savings. Assess labor cost reductions, increased production output, and decreased defect rates. Use historical data to estimate manual process expenses, then project savings with automation over a specific timeframe. Include maintenance costs for accuracy. This method provides a clear financial picture for decision making.

Q2: What are the key financial benefits of PCB automation in high volume production?

A2: The financial benefits of PCB automation in high volume production include reduced labor costs, faster cycle times, and lower error rates. Automation minimizes rework and scrap, cutting material waste. It also ensures consistent quality, reducing warranty claims. These factors collectively enhance profitability, making automation a viable choice for scaling operations efficiently.

Q3: How do I approach cost justification for automation projects with limited budget?

A3: For cost justification for automation projects on a limited budget, focus on phased implementation. Prioritize high impact areas like component placement for initial investment. Highlight labor savings and error reduction using small scale pilot data. Emphasize compliance with standards like ISO 9001:2015 to show long term value. Present a multi year payback plan to spread costs over time.

Q4: What strategies work best when presenting the case for PCB automation to management?

A4: When presenting the case for PCB automation to management, use data driven insights. Start with current manual assembly challenges, then showcase automation’s impact on speed and quality. Provide a detailed cost benefit analysis, referencing standards like IPC-A-610. Use visuals to simplify complex data. Offer a clear implementation timeline to build confidence in the proposal.

References

IPC-A-610H — Acceptability of Electronic Assemblies. IPC, 2020.

IPC-J-STD-001H — Requirements for Soldered Electrical and Electronic Assemblies. IPC, 2021.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2020.

IPC-J-STD-020E — Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices. IPC, 2014.

ISO 9001:2015 — Quality Management Systems. ISO, 2015.