Introduction

Copper weight, expressed in ounces per square foot (oz/ft²), directly determines current-carrying capacity, thermal performance, and mechanical reliability of printed circuit boards. IPC-2221B and IPC-6012E establish the minimum requirements and acceptance criteria for copper foil and plated copper thickness in all classes of rigid PCBs. Understanding these standards prevents under-sized traces, excessive heating, plating cracks, and field failures. This article details the exact IPC requirements for outer and inner-layer foil, finished plated-through-hole copper, and how fabricators achieve compliance.

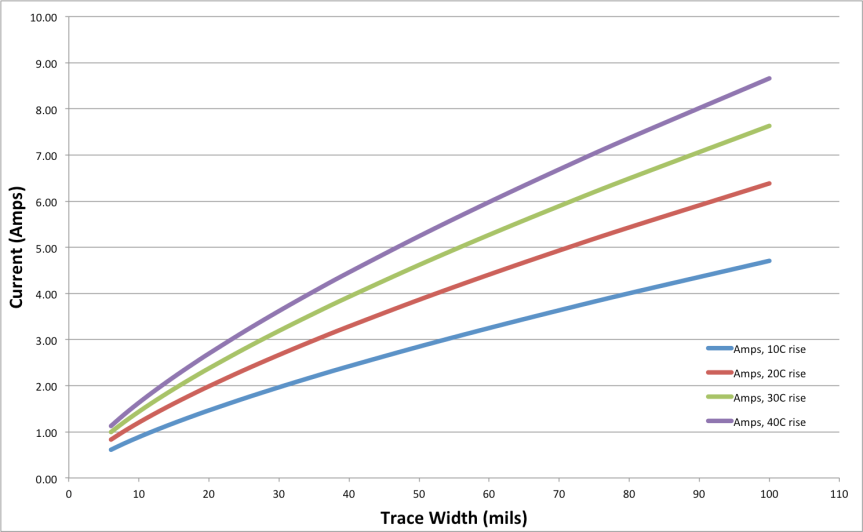

IPC-2221B Copper Weight Selection Guidelines

IPC-2221B Annex A provides the current-carrying capacity charts based on:

- Copper weight (0.5 oz, 1 oz, 2 oz, 3 oz, etc.)

- Allowed temperature rise (10 °C, 20 °C, 30 °C typical)

- External or internal traces

Common starting copper weights:

- 0.5 oz (18 µm) – inner layers of high-density boards

- 1 oz (35 µm) – standard outer and inner layers

- 2 oz (70 µm) – power and ground planes, high-current traces

- 3 oz and above – heavy copper boards

IPC-6012E Minimum Finished Copper Thickness Requirements

| Feature | Class 1 & 2 Minimum | Class 3 Minimum | Notes |

|---|---|---|---|

| Outer foil (starting) | 18 µm (0.7 mil) | 25 µm (1.0 mil) | After processing |

| Finished external trace | ≥ 20 µm average | ≥ 25 µm average | Including plating |

| Plated-through hole wall | ≥ 20 µm average | ≥ 25 µm average | IPC-6012E Table 3-7 |

| Hole wall (minimum corner) | ≥ 18 µm | ≥ 20 µm | Critical for reliability |

| Inner-layer foil (starting) | No minimum | No minimum | Must meet current & thermal requirements |

Plating Process and Final Thickness Build-Up

Typical 1 oz outer-layer construction:

- Base copper foil: 35 µm (1 oz)

- Electroless copper: 1–3 µm

- Electroplated copper: 20–30 µm (pattern + panel plating)

- → Finished external trace thickness: 55–65 µm total

After etching, the finished trace copper equals base foil + plating thickness.

Class 3 vs Class 2 Differences

Class 3 (high-reliability: aerospace, medical, automotive) requires:

- Thicker minimum plating (25 µm average vs 20 µm)

- Starting outer foil ≥ 1 oz when 25 µm finished plating is needed

- 100 % hole-wall thickness measurement on coupons

- Additional thermal stress and microsection requirements

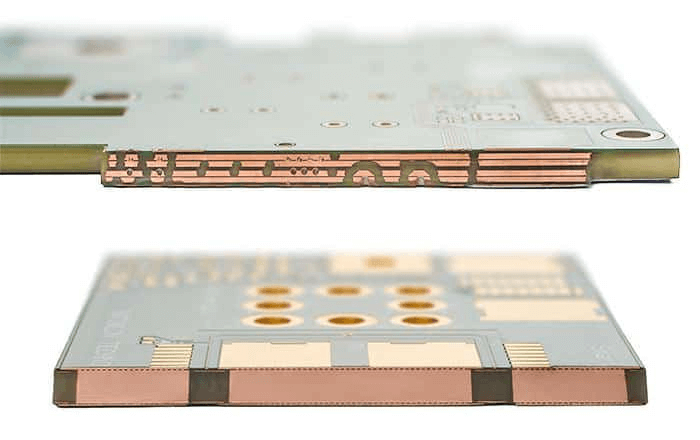

Heavy Copper and Extreme Copper Boards

IPC-6012E Section 3.6.2.13 defines heavy copper:

- ≥ 3 oz (105 µm) finished copper on traces or in holes

- Special process controls required

- Reduced current density limits due to poorer adhesion

Practical Compliance Checklist

- Specify starting copper weight for each layer in the fabrication drawing

- State required finished hole copper (20 µm or 25 µm average)

- Include IPC-6012E Class 2 or Class 3 callout

- Request plated copper thickness measurement report from coupon

- Verify fabricator uses IPC-TM-650 2.2.12 for foil thickness and 2.3.28 for plating thickness

Common Misunderstandings

- “1 oz copper” refers to starting base foil weight, not finished thickness

- Hole-wall copper is almost never 35 µm when starting with 1 oz foil (typical 23–28 µm average)

- Ordering “2 oz finished” on outer layers requires > 2.5 oz starting foil plus plating

- Inner layers receive no additional plating → finished thickness = starting foil only

Conclusion

IPC-2221B guides designers in selecting appropriate copper weight for current and thermal needs, while IPC-6012E ensures fabricators deliver minimum plated thickness for long-term reliability. Specifying correct starting foil weight, finished plating requirements, and the proper IPC-6012E performance class eliminates the most common causes of overheating, plating cracks, and field failures in modern PCB designs.

FAQs

Does 1 oz copper on outer layers give 35 µm in the holes?

No. Typical finished hole-wall copper with 1 oz starting foil is 23–28 µm average. To guarantee ≥ 25 µm average (Class 3), start with 1 oz foil + panel plating or specify higher plating thickness.

When must I use 2 oz copper?

When trace current exceeds the 1 oz limit at acceptable temperature rise, or when mechanical strength or heat spreading is critical (power converters, LED boards, motor drives).

Is it acceptable to have less than 20 µm hole copper for Class 2?

No. IPC-6012E requires ≥ 20 µm average and ≥ 18 µm minimum at corners for all rigid boards, regardless of class, unless otherwise agreed (AABUS).

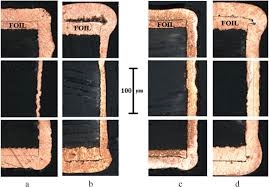

How do fabricators prove compliance?

Through microsection analysis of test coupons per IPC-TM-650 2.1.1 and 2.3.28, performed on every panel or lot.

References

IPC-2221B — Generic Standard on Printed Board Design. IPC, 2015.

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2017.

IPC-TM-650 2.3.28 — Plating Thickness Measurement. IPC, 2016.

IPC-TM-650 2.2.12 — Copper Foil Thickness Determination. IPC, 2010.