Introduction

Multi-layer PCBs form the foundation of nearly every modern electronic device from smartphones to industrial controllers. A multi-layer PCB contains three or more conductive copper layers separated by insulating material and interconnected through plated vias. Beginners can successfully design and order 4-layer, 6-layer, and even 8-layer boards once they understand the basic principles. This guide explains multi-layer PCB basics in simple terms and shows how to create easy multi-layer PCB designs that fabricate reliably and cost-effectively.

Why Choose Multi-Layer Instead of 2-Layer

Two-layer boards work perfectly for simple circuits, but routing becomes impossible when designs include:

- Fine-pitch ICs (0.5 mm or smaller)

- Multiple power rails (3.3 V, 5 V, 12 V)

- High-speed signals (USB, Ethernet, DDR)

- Dense component placement on both sides

A 4-layer board with solid ground and power planes instantly solves these problems while improving EMC performance and signal quality.

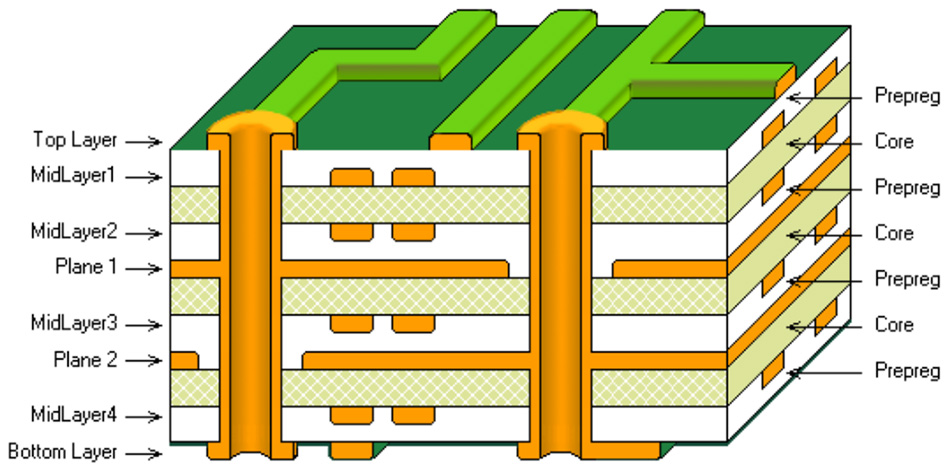

Standard Multi-Layer Stack-Ups for Beginners

4-Layer (Most Popular for Beginners)

- Layer 1: Signal (top)

- Layer 2: Ground plane (solid)

- Layer 3: Power plane (can be split)

- Layer 4: Signal (bottom)

6-Layer (Next Step)

- Layer 1: Signal

- Layer 2: Ground

- Layer 3: Signal

- Layer 4: Power

- Layer 5: Signal

- Layer 6: Ground

8-Layer (Advanced Hobby Projects)

Adds two more inner routing layers while keeping ground and power planes intact.

Simple Multi-Layer PCB Design Rules

- Keep ground and power planes completely solid when possible

- Route high-speed signals next to a reference plane (ground or power)

- Use through-hole vias for all connections (blind/buried vias increase cost)

- Place decoupling capacitors close to IC power pins

- Maintain 0.15–0.20 mm minimum trace width and spacing for hobby-friendly fabrication

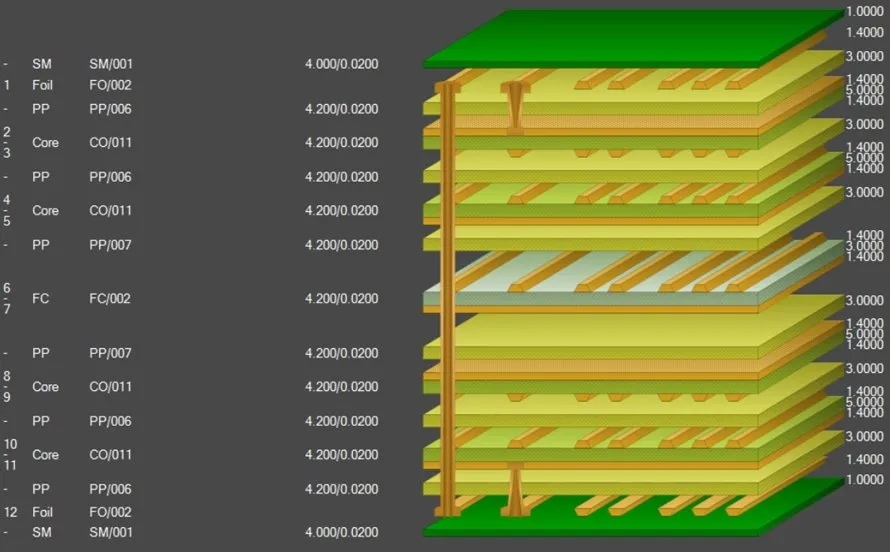

- Keep total board thickness at standard values (1.6 mm for 4-layer, 1.2–1.6 mm for 6-layer)

Step-by-Step Design Process

Step 1: Schematic

Complete the full circuit diagram first. Group related components and plan power distribution.

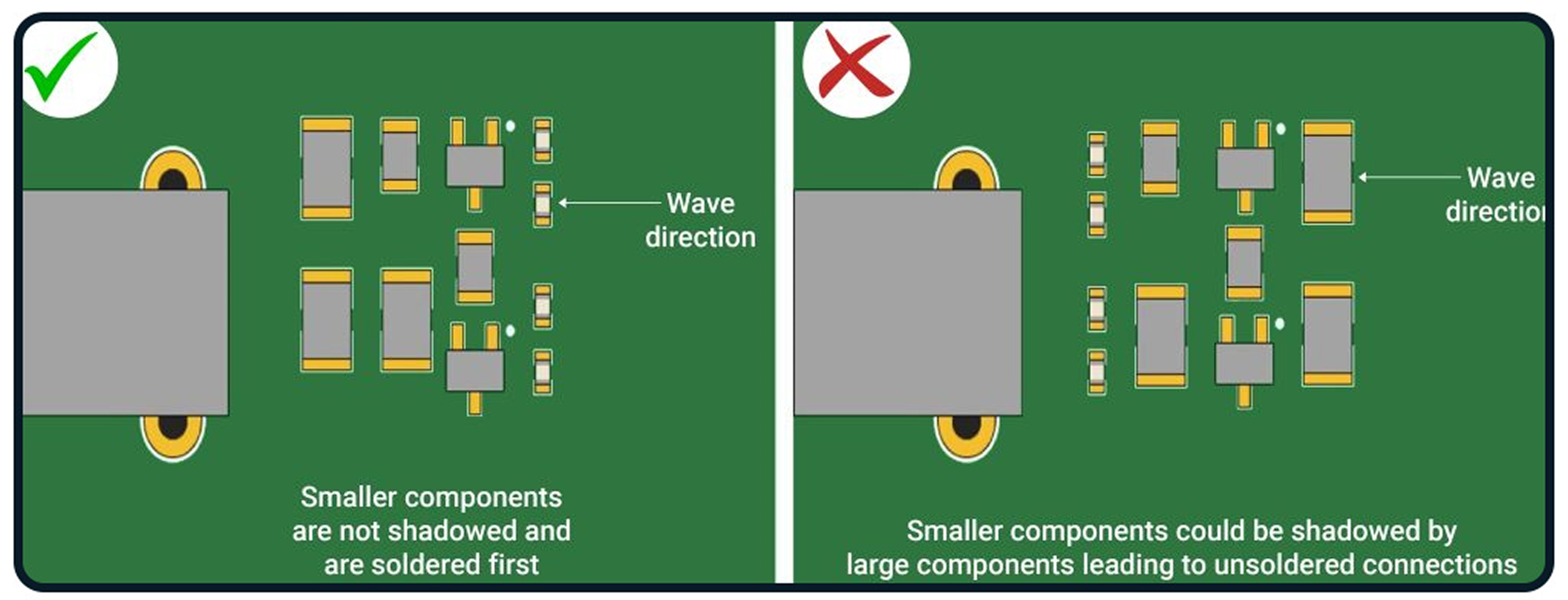

Step 2: Component Placement

- Place connectors on board edges

- Group ICs with their decoupling capacitors

- Keep analog and digital sections separate when needed

- Leave space for routing channels

Step 3: Layer Assignment

- Route horizontal traces on top/bottom layers

- Route vertical traces on inner layers (6+ layer boards)

- Keep clock and differential pairs short and direct

Step 4: Power Distribution

- Create large power pours on the power plane

- Connect IC power pins with short, wide traces or direct vias

- Add multiple vias when connecting to planes

Step 5: Grounding

- Pour ground on all layers when possible

- Connect all ground pads directly to ground plane with vias

- Stitch ground planes together around board edges

Easy Multi-Layer PCB Fabrication Tips

- Choose 1 oz copper on outer layers and 0.5–1 oz on inner layers

- Use standard FR-4 material (Tg 130–140 °C)

- Specify ENIG or HASL surface finish

- Request electrical test on every board

- Order from fabricators who accept standard Gerber and drill files

Typical cost for 10 pieces of 100 × 100 mm 4-layer board: $30–80 including shipping.

Common Beginner Mistakes to Avoid

- Splitting ground plane into analog/digital sections (creates EMI problems)

- Routing long traces across plane gaps

- Forgetting thermal relief on plane connections

- Using too thin traces (below 0.15 mm increases cost and defects)

- Placing vias under components without solder mask dams

When to Move from 4-Layer to 6-Layer

- More than two high-speed interfaces (USB + Ethernet + HDMI)

- BGA with pitch below 0.65 mm

- Three or more different power voltages with heavy current

- Extremely dense routing that forces trace width below 0.12 mm

Conclusion

Multilayer PCB design is far more approachable than most beginners expect. Start with a clean 4-layer stack-up, maintain solid reference planes, and follow basic routing discipline. Modern fabrication capabilities make reliable the 4-layer and 6-layer board available at the same price hobbyists paid for 2-layer boards five years ago. With these fundamentals, anyone can create professional-quality multi-layer designs on their first attempt.

FAQs

Q1: How many layers should my first multi-layer PCB have?

A1: Start with 4 layers. It provides ground and power planes while keeping fabrication simple and affordable.

Q2: Is 4-layer PCB fabrication much more expensive than 2-layer?

A2: Only slightly. Most fabricators charge 2–3× the 2-layer price for small quantities of 4-layer boards.

Q3: Do I need special software for multi-layer design?

A3: No. KiCad, EasyEDA, and DesignSpark PCB all handle 4-layer and 6-layer designs perfectly for beginners.

Q4: Can I mix through-hole and SMD components on multi-layer boards?

A4: Yes, absolutely. Multi-layer construction works perfectly with both component types.

References

IPC-2221B — Generic Standard on Printed Board Design. IPC, 2015.

IPC-6012E — Qualification and Performance Specification for Rigid Printed Boards. IPC, 2017.

IPC-A-600K — Acceptability of Printed Boards. IPC, 2020.

IPC-7351B — Generic Requirements for Surface Mount Design and Land Pattern Standard. IPC, 2010.