What Makes Aluminum PCBs Unique and Challenging to Solder?

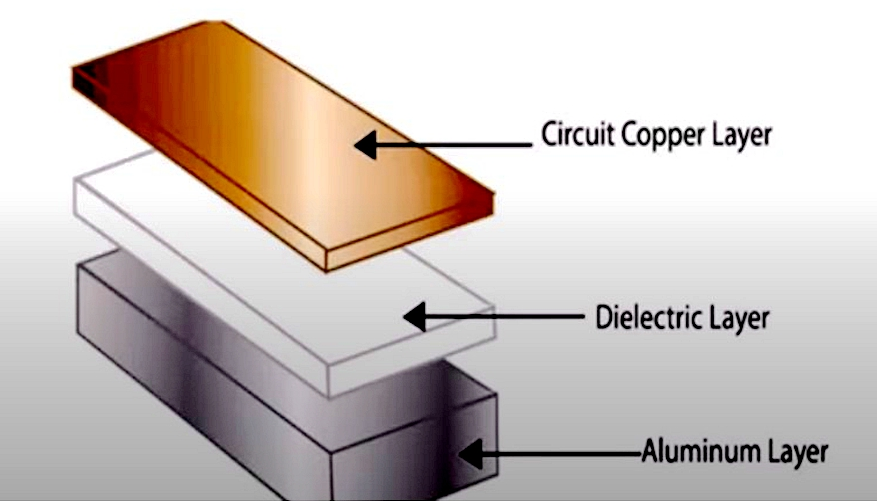

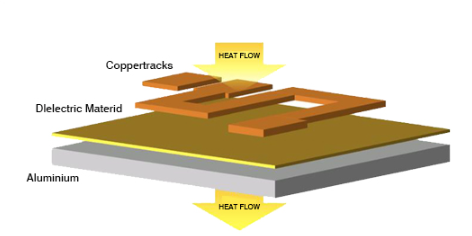

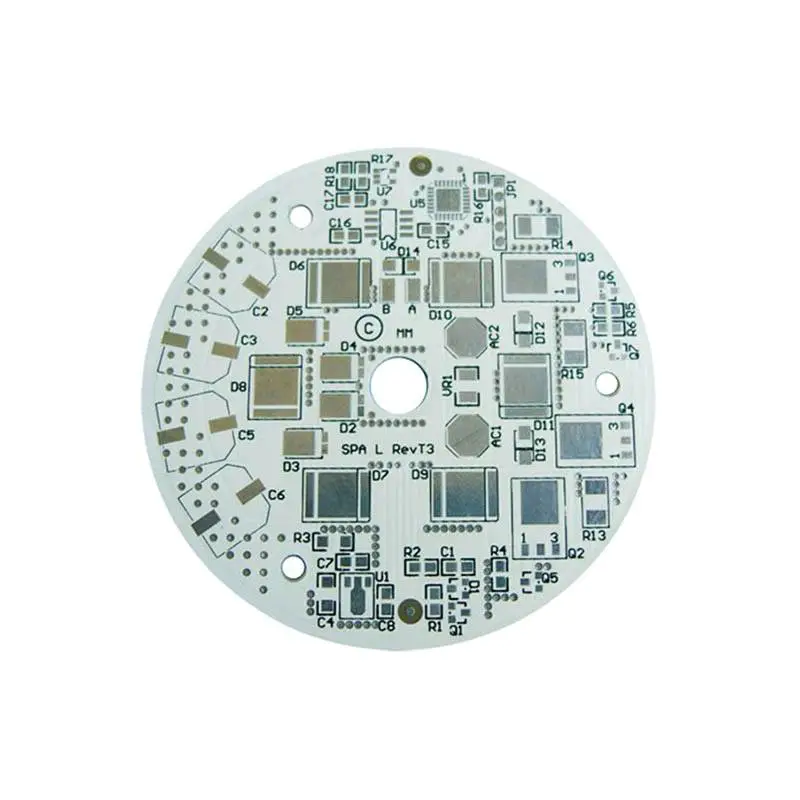

Aluminum PCBs, often referred to as metal core PCBs, fundamentally differ from traditional FR4 boards due to their base material. Instead of a fiberglass composite, they feature an aluminum core, which significantly enhances their thermal conductivity, typically ranging from 1 to 2 W/mK compared to FR4's mere 0.3 W/mK. This superior heat dissipation capability makes them indispensable in high-power applications, such as advanced LED lighting systems and various power electronics where efficient thermal management is critical.

However, this very advantage introduces specific hurdles during the soldering process. The rapid heat transfer through the aluminum core means that maintaining the precise temperature at the solder joint becomes a significant challenge. If not managed correctly, this quick heat dissipation can lead to "cold solder joints," which compromise both electrical conductivity and mechanical strength. Therefore, understanding these thermal characteristics is the first step toward mastering effective soldering techniques for aluminum PCB components.

What Are the Primary Obstacles in Soldering Aluminum PCBs?

Before delving into specific soldering strategies, it's crucial to identify the main difficulties inherent in working with the aluminum PCB. These challenges stem directly from the material's distinct physical properties, demanding specialized approaches to achieve reliable connections.

Rapid Heat Dissipation

The most prominent challenge is the aluminum's high thermal conductivity. Heat applied during soldering quickly disperses across the entire board, requiring significantly higher temperatures or more advanced heating equipment to ensure that the solder joint itself reaches and maintains the necessary reflow temperature. This rapid heat loss can easily lead to insufficient wetting and poor joint formation if not adequately compensated.

Risk of Thermal Damage

While aluminum PCBs are designed for heat, excessive or improperly managed heat during soldering can still pose risks. Sensitive components, especially those with low thermal mass, or the delicate dielectric layer situated between the aluminum core and the copper circuit board layer, can be susceptible to damage. Precision in temperature control is therefore paramount to protect both components and the board's structural integrity.

Solder Material Compatibility

Not all solder pastes and fluxes are suitable for aluminum-based substrates. The unique thermal and surface properties of aluminum demand specific chemical formulations to ensure proper adhesion, minimize oxidation, and prevent defects like voiding. Choosing the correct solder material is essential for forming robust and long-lasting solder joints.

How Do You Select the Best Solder Paste for Aluminum PCBs?

Choosing the right solder paste is a pivotal step for successfully soldering aluminum PCBs, directly influencing the strength and reliability of the final connections. Given the unique thermal profile of these boards, standard solder pastes may not yield optimal results.

Prioritizing Lead-Free Formulations

It is advisable to opt for lead-free solder pastes, typically those based on SAC (Tin-Silver-Copper) alloys like SAC305. These formulations generally have a melting point between 217°C and 221°C and offer superior wetting characteristics on aluminum PCB surfaces. Their widespread use also aligns with modern environmental and regulatory standards.

Ensuring Flux Compatibility

The flux component within the solder paste is critical for removing oxidation and promoting good adhesion. For high thermal conductivity materials like aluminum, selecting a no-clean or water-soluble flux specifically designed to perform effectively at higher temperatures and on such substrates is essential. The flux must remain active long enough to facilitate proper solder flow before evaporating.

Optimal Particle Size

For precision in solder paste application, especially with smaller components or tightly spaced pads, choosing a solder paste with a finer particle size (e.g., Type 4 or Type 5) is recommended. This allows for more consistent and accurate deposition via stenciling, reducing the likelihood of bridging or insufficient paste volume. Always consult the solder paste manufacturer's recommendations for compatibility with metal core boards to mitigate potential issues and ensure optimal performance.

What Are the Ideal Soldering Temperatures for Aluminum PCBs?

Maintaining the correct temperature profile is arguably the most critical factor when soldering aluminum PCBs. Due to aluminum’s high thermal conductivity, heat spreads rapidly, often necessitating higher process temperatures or extended preheat durations compared to other types of PCBs.

Preheat Stage Requirements

Initiate the process with a preheat temperature ranging from 150°C to 180°C, sustained for approximately 60 to 90 seconds. This step is vital for minimizing thermal shock to sensitive components and ensuring a uniform heat distribution across the entire board before the main soldering phase.

Soak Stage Specifications

Follow the preheat with a soak stage, maintaining temperatures between 180°C and 200°C for 30 to 60 seconds. This period allows the flux within the solder paste to fully activate, removing oxides, and prepares the solder paste for efficient reflow by equalizing temperatures across the board.

Reflow Stage Parameters

Elevate the temperature to the reflow range of 235°C to 250°C, holding for 20 to 40 seconds. This specific temperature window is engineered for most lead-free solder pastes, ensuring adequate melting and proper wetting across the aluminum surfaces to form robust connections.

Controlled Cooling Process

Conclude by allowing the board to cool gradually at a rate of 2-4°C per second. A controlled cooling phase is crucial to prevent thermal stress that could lead to cracking in the newly formed solder joints, ensuring their long-term reliability. These temperature guidelines serve as general recommendations. Always refer to the specific thermal profile provided by your chosen solder paste manufacturer and make adjustments based on the physical dimensions and thickness of your aluminum PCB. Utilizing a reflow oven with precise temperature control or a hot plate specifically designed for metal core PCBs can significantly enhance the effectiveness of these temperature management strategies.