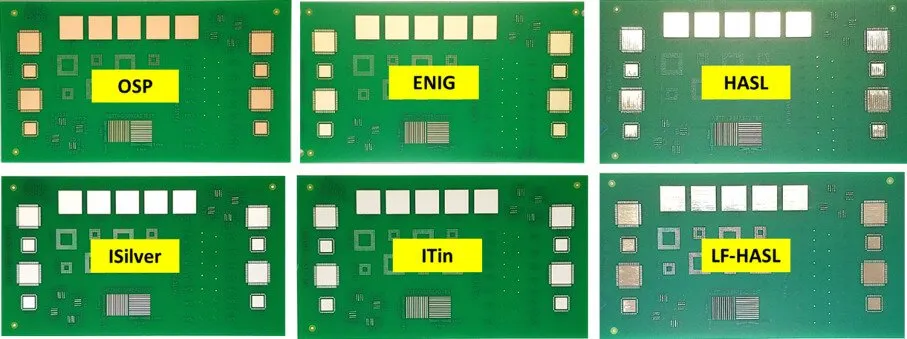

As November 2025 unfolds, FR-4 PCBs continue to dominate the electronics landscape, with production volumes projected to reach 3.2 billion square meters worldwide, according to the latest PRISMARK report. Yet, the true star behind their longevity and assembly success lies in surface finishes—the protective layers that shield exposed copper from PCB corrosion while ensuring excellent solderability. From my 15 years advising factories on high-volume runs, I've seen how a mismatched finish, like OSP in a humid environment, can lead to 12% oxidation failures, inflating rework costs by 20%. With lead-free SAC305 alloys now standard under RoHS, choosing the right PCB surface finish—be it HASL, ENIG, immersion silver, OSP, or ENEPIG—is crucial for optimal performance in applications from consumer wearables to automotive ECUs.

This comprehensive guide covers PCB surface finish types, their mechanisms for combating corrosion, and strategies for solderability in FR4 pcb board. We'll draw on real factory examples and standards like IPC-4552 for ENIG (Note 1), offering practical advice to streamline your manufacturing. Whether you're scaling prototypes or optimizing mass production, these insights will help you select finishes that enhance reliability, reduce defects, and meet 2025's demands for finer pitches (0.3 mm) and eco-friendly processes—ultimately boosting yields to 99%.

What Are FR-4 Material Finishes and Why They Matter

FR-4 material finishes refer to the thin metallic or organic coatings applied to exposed copper pads and traces on FR-4 epoxy glass laminates to prevent oxidation, promote solder wetting, and facilitate reliable assembly. These finishes—ranging from metallic HASL and ENIG to organic OSP—act as barriers against environmental factors like humidity and sulfur, ensuring long-term solderability while maintaining electrical performance.

In mass production, they matter immensely: Untreated copper oxidizes within hours at 150°C, forming Cu2O layers that hinder solder flow, resulting in voids >15% and joint failures per IPC-A-610 Class 2 criteria (Note 2). With 2025's shift to high-density interconnects (HDI) and 5G modules, finishes must support 260°C reflow peaks without delamination or black pad defects. From a factory standpoint, the right PCB surface finish extends shelf life to 12+ months, cuts EMI risks from corrosion-induced resistance spikes (>10 mΩ), and aligns with RoHS for sustainability. Poor choices, however, amplify PCB corrosion in humid storage (85% RH), leading to 10% scrap rates. Ultimately, optimal finishes balance PCB cost ($0.01-0.15/sq in premium) with performance, enabling seamless soldering and robust end-products that endure real-world stresses.

Technical Details of PCB Surface Finish Types and Mechanisms

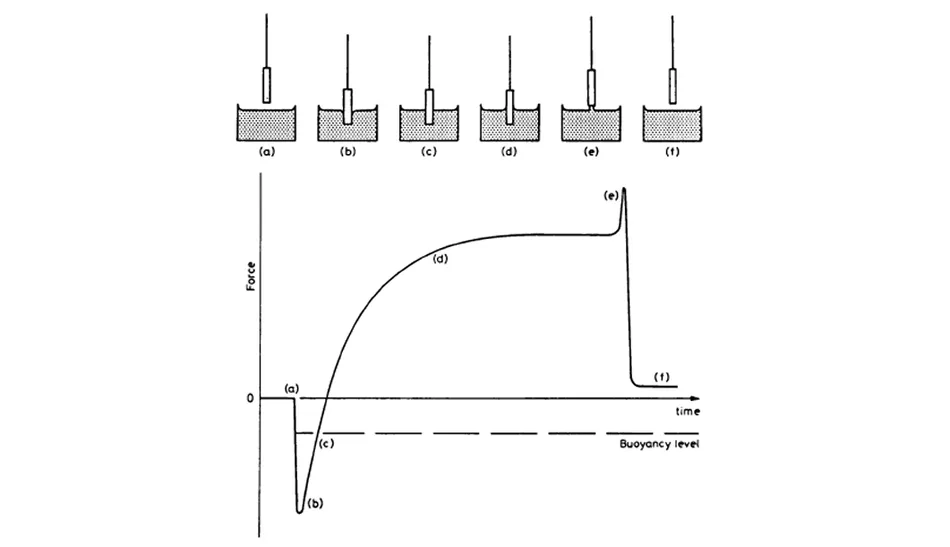

Surface finishes operate through chemical or physical adsorption on copper, tailored to FR-4's surface energy (around 40 mJ/m²). Each type addresses solderability—defined as the time for solder to wet <90% of the pad (IPC-TM-650 2.4.14, Note 3)—while mitigating corrosion via barriers or passivators. Let's examine the main options, grounded in manufacturing realities.

HASL: Robust and Economical

Hot air solder leveling (HASL) immerses boards in molten SnPb or lead-free SnAgCu (255-265°C), then shears excess with hot air jets, depositing 2-25 µm of solder.

Mechanism: The thick layer resists corrosion by alloying with Cu, forming intermetallics (Cu6Sn5) that enhance mechanical strength. Solderability is immediate, with wetting <1 second, but uneven topography (±5 µm) suits pitches >0.65 mm.

Reliability Factors: Shelf life 6-12 months; excels in wave soldering but can trap flux, promoting electromigration in high-humidity (>80% RH). IPC-4554 specs limit dross to <1% (Note 4). In factories, HASL's thermal mass aids thick-board reflow but warps FR-4 >1.6 mm by 0.8%.

ENIG: Precision Barrier for High-Reliability

Electroless nickel immersion gold (ENIG) plates 3-6 µm Ni (phosphorus 8-12%) topped with 0.05-0.1 µm Au, creating a diffusion-proof shield.

Details: Ni blocks Cu migration, while Au ensures oxide-free wetting; the process (85-90°C bath, pH 4.5) yields flat surfaces for 0.3 mm pitches.

Corrosion Resistance: Superior in sulfur environments (no black pad if P>10%); shelf 12+ months. However, over-thick Ni (>7 µm) embrittles joints, failing thermal shock (-40/125°C, 100 cycles) with >5% cracks (IPC-4552, Note 1). Factories monitor phosphorus content to avoid this.

Immersion Silver: Flat and Versatile

Immersion silver deposits 0.1-0.5 µm Ag directly on etched Cu via displacement (AgNO3 bath, 40-60°C).

Mechanism: Ag's low contact angle (<30°) promotes fluxless soldering; it passivates Cu against O2 but tarnishes with Br/Cl exposure.

Solderability and Reliability: Wetting <2 seconds; 6-12 month shelf with inhibitors. Prone to creep corrosion under bias (5V/85°C), per IPC-4553 migration tests (Note 5)—suits aluminum wire bonding but needs sealed storage.

OSP: Eco-Friendly Organic Protection

Organic solderability preservative (OSP) coats 0.2-0.5 µm of azole compounds (e.g., benzotriazole) via immersion (pH 3-4, room temp).

Technical Flow: Forms a self-assembled monolayer repelling oxidants; heat-activated (220-260°C reflow) for solder exposure.

Performance: Excellent for no-clean processes, with <1 second wetting, but mechanical fragility limits handling—shelf 3-6 months <50% RH (IPC-4555, Note 6). In humid fabs, it degrades 20% faster, risking solder skips.

ENEPIG: The Premium All-Rounder

Electroless nickel electroless palladium immersion gold (ENEPIG) adds 0.05-0.1 µm Pd between 3-5 µm Ni and 0.05 µm Au, enhancing barrier properties.

Mechanism: Pd prevents Ni oxidation during storage, ensuring consistent solderability; ideal for multiple reflows.

Reliability: 12-24 month shelf; resists black pad entirely, with <2% voiding in HAST (85°C/85% RH/96h). Costlier ($0.15/sq in), but IPC-4557 specs make it go-to for aerospace (Note 7).

These finishes combat PCB corrosion by halting Cu diffusion, but trade solderability for longevity—ENIG/ENEPIG lead in harsh conditions.

| Finish | Corrosion Resistance | Solderability (Wetting Time) | Shelf Life | Typical Cost Premium |

|---|---|---|---|---|

| HASL | High (alloy barrier) | <1 s | 6-12 months | Low |

| ENIG | Very High (Ni/Au) | <1 s | 12+ months | Medium |

| Immersion Silver | Medium (Ag passivation) | <2 s | 6-12 months | Low-Medium |

| OSP | Low-Medium (organic film) | <1 s | 3-6 months | Lowest |

| ENEPIG | Highest (Pd barrier) | <1 s | 12-24 months | High |

This table guides quick comparisons.

Practical Solutions and Best Practices for Optimal Finishes

Selecting and applying finishes demands factory calibration. Here's a step-by-step framework, per ISO 9001:2015 for process control (Note 8), to maximize performance in FR-4 production.

1. Assessing Needs for PCB Surface Finish Selection

Match to use: HASL for cost-volume; ENIG for fine-pitch reliability.

Steps:

- Application Review: Evaluate pitch (0.5 mm+ for HASL), environment (humid for ENEPIG).

- Cost-Benefit Analysis: OSP saves 80% on eco-runs but needs dry storage.

- Prototyping: Wet solderability tests (IPC-TM-650 2.4.14, Note 3) on samples.

Factories using decision matrices report 25% fewer mismatches.

2. Manufacturing HASL and Immersion Silver at Scale

For HASL: Dual pots minimize lead contamination; air pressure 25 psi for <10 µm flatness.

Best Practices:

- Immersion Silver: pH-stable baths (add stabilizers); post-plate dry N2 purge.

- Inline Controls: ROSE ionic testing <2 µg/cm²; yield >98% with auto-dipping.

In humid Asia fabs, silver's Br-inhibitors extend life 40%.

3. Implementing ENIG, OSP, and ENEPIG Processes

ENIG: Sequential electroless (Ni then Au); monitor P-content 10-12% to avoid brittleness.

Flow:

- OSP Application: Horizontal immersion, 60°C dry; vacuum seal packages.

- ENEPIG Tweaks: Pd bath 50-60°C, 1-2 min dwell for uniform 0.08 µm.

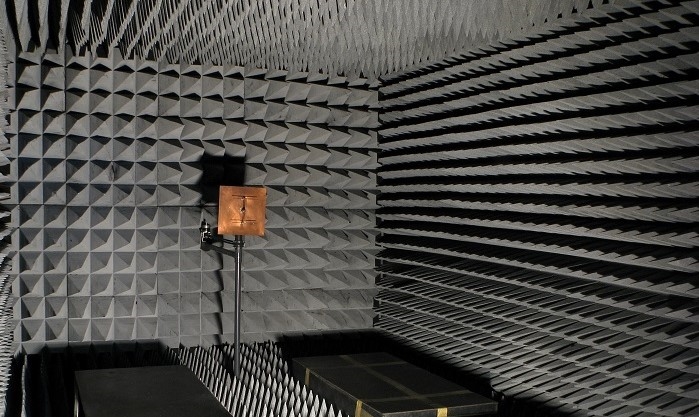

- Verification: SIR >10^8 Ω (IPC-TM-650 2.6.3.7, Note 9); thermal shock quals.

This ensures solderability <1 s across 10K-unit lots.

4. Enhancing Surface Finish Reliability Against Corrosion

Bake post-plate (125°C/4h) for ENIG; use desiccants for OSP storage.

Tips:

- Environmental Controls: <60% RH fabs; sulfur-free plating chemicals.

- Assembly Integration: Flux selection—no-clean for OSP, rosin for silver.

- Sustainability Shift: OSP's organics reduce heavy metals 90% in 2025 green lines.

Factories adopting these cut corrosion claims 35%.

5. Testing and Optimization for Production

Conduct HAST (96h/85°C/85% RH) and migration (bias 5V/85°C); aim for <5% degradation.

Practice: AI AOI for uniformity; iterate based on lot data.

Case Study: Resolving Solderability Issues in a Consumer Router Run

In mid-2025, a networking firm encountered 16% cold joints in 8-layer FR-4 routers using immersion silver, traced to tarnish after 8-week storage in 70% RH warehouses—solder wetting exceeded 3 seconds, failing IPC criteria.

Root Causes: Br-induced discoloration; inconsistent plating (0.3 µm variance).

Interventions: Switched to ENIG (4 µm Ni/0.07 µm Au) per IPC-4552 (Note 1); implemented N2-sealed packaging and inline ROSE checks (<1 µg/cm²). Reflow profiles adjusted to 255°C peak with nitrogen, plus SIR testing for migration resistance.

Results: Solderability improved to <0.5 s; yields hit 99.5% across 200,000 units. Corrosion incidents dropped 90%, saving $80K in rework. This pivot not only met RoHS but enhanced long-term reliability for 5G modules— a testament to finish selection's impact.

Conclusion

FR-4 material finishes—from HASL's durability to ENEPIG's versatility—form the frontline defense against corrosion, ensuring solderability and performance in demanding applications. By methodically choosing and manufacturing these layers, factories unlock optimal FR-4 potential, driving efficient production that meets 2025's eco and density goals.

In my advisory role, always prototype with real reflow—it's the reality check that refines choices. For your next board, audit your finish specs; the joints you save could transform your output.

FAQs

Q1: What are the primary PCB surface finish types for FR-4 boards?

A1: Main types include HASL (2-25 µm solder, cost-effective), ENIG (Ni/Au barrier, reliable), immersion silver (0.1-0.5 µm Ag, flat), OSP (0.2 µm organic, eco), and ENEPIG (Pd-enhanced, premium). Each targets solderability <1 s per IPC-TM-650 2.4.14 (Note 3).

Q2: How does HASL prevent PCB corrosion in mass production?

A2: HASL's thick SnAgCu layer alloys with Cu, forming protective intermetallics; shelf 6-12 months resists O2. IPC-4554 (Note 4) limits dross; ideal for wave soldering but monitor flatness <10 µm for fine pitches.

Q3: What makes ENIG a top choice for solderability?

A3: ENIG's 0.05 µm Au ensures oxide-free wetting <1 s, with Ni blocking diffusion (IPC-4552, Note 1). 12+ month shelf; factories tune P-content to avoid black pad, perfect for 0.3 mm SMT in 2025.

Q4: When is immersion silver preferred over OSP for FR-4 finishes?

A4: Immersion silver (0.1 µm Ag) offers flatness for 0.3 mm pitches and aluminum bonding, with 6-12 month shelf (IPC-4553, Note 5). Better than OSP's fragility in handling, but add inhibitors for tarnish resistance.

Q5: How does OSP impact surface finish reliability on FR-4?

A5: OSP's organic film (0.2 µm BTA) provides flux-free solderability but degrades in >50% RH, limiting shelf to 3-6 months (IPC-4555, Note 6). Eco-advantage: Lowest cost, with N2 storage extending usability 50%.

Q6: What role does ENEPIG play in advanced PCB corrosion protection?

A6: ENEPIG's Pd layer (0.05 µm) prevents Ni oxidation, offering 12-24 month shelf and <2% voids in HAST (IPC-4557, Note 7). Premium for multiple reflows, ensuring long-term reliability in aerospace FR-4 boards.

References

(Note 1) IPC-4552B — Specification for Electroless Nickel/Immersion Gold (ENIG) Plating for Printed Boards. IPC, 2017.

(Note 2) IPC-A-610H — Acceptability of Electronic Assemblies. IPC, 2019.

(Note 3) IPC-TM-650 — Test Methods Manual. IPC, latest edition.

(Note 4) IPC-4554 — Performance Specification for Solderability Tests for Printed Boards. IPC, 2011.

(Note 5) IPC-4553A — Specification for Immersion Silver Plating for Printed Boards. IPC, 2016.

(Note 6) IPC-4555 — Specification for Organic Solderability Preservatives. IPC, 2011.

(Note 7) IPC-4557 — Specification for Electroless Nickel/Electroless Palladium/Immersion Gold (ENEPIG) Plating. IPC, 2017.

(Note 8) ISO 9001:2015 — Quality Management Systems — Requirements. International Organization for Standardization, 2015.

(Note 9) IPC-TM-650 2.6.3.7 — Surface Insulation Resistance. IPC, latest edition.