Overview

Compared with driving-range anxiety, safety concerns are a higher priority for many electric vehicle owners. Data indicate that around 80% of vehicle fire incidents involving new energy vehicles occur during charging or within one hour after a full charge. Battery thermal management can affect more than 40% of vehicle range. Ignoring battery safety and focusing only on high range or high energy density can lead to serious consequences. Effective prevention of charging-related fires would significantly reduce safety incidents. At the center of this effort is the battery management system.

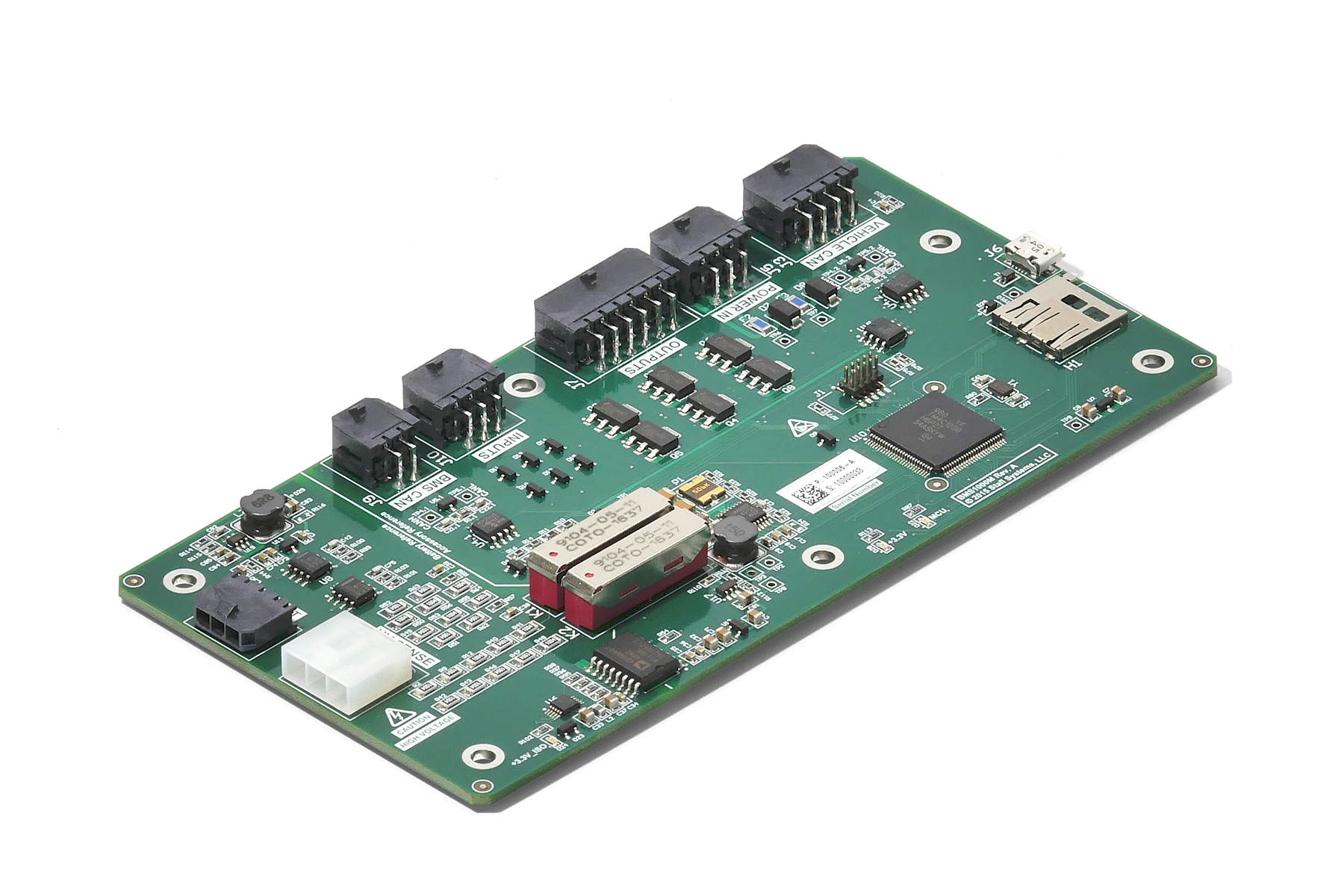

In the rapidly evolving New energy vehicle sector, the BMS (battery management system) is a critical component that connects the traction battery to the vehicle. Its primary functions include real-time monitoring of battery physical parameters, state estimation, online diagnostics and alerts, charge/discharge and precharge control, cell balancing, and thermal management. Failure in any of these functions can cause severe battery damage.

Main BMS Functions

The BMS is the central control for the battery and vehicle interface. It handles a wide range of signals, including cell-level inputs, collision detection, CAN bus, charging, coolant pumps, high-voltage systems, and insulation monitoring. A single deep discharge can permanently damage cells. In extreme cases, lithium cells that overheat or are overcharged can enter thermal runaway, rupture, or even explode. Therefore, the BMS must strictly control charging and discharging to prevent overcharge, overdischarge, and overheating.

Battery performance varies with temperature. The optimal operating temperature for lithium-ion cells is roughly 25–40°C. The BMS also uses balancing algorithms to reduce inconsistency among cells and thus improve overall battery performance.

Why BMS Matters

The BMS is essential to electric vehicle safety and performance. It protects individual cells from damage, keeps the battery within safe operating limits to extend lifetime, and maintains battery status to meet vehicle power requirements. Because cells produced in mass quantities may show small variations in capacity and performance, inconsistency increases over time and with environmental changes. Unbalanced cells, overcharge, or overdischarge can accelerate degradation and raise safety risks such as fire.

The BMS accurately measures battery pack status, prevents excessive charging or discharging, balances cell states, and estimates remaining capacity to present interpretable range information, ensuring safe operation of the traction battery.

Related Reading: Optimizing PCB Layout for EV BMS High-Voltage Connectors

Case Study: Tesla vs Chevrolet Bolt

Without an effective BMS, an electric vehicle is at high safety risk. The BMS aims to guarantee the designed battery performance from safety, durability, and power perspectives. Tesla's BMS is widely regarded as highly developed. It benefits from the application of deep learning and artificial intelligence, allowing Tesla to collect large-scale driving data and continually refine algorithms to improve pack range.

For the Tesla Model 3, notable BMS characteristics include:

- Use of many small-capacity cells (4,416 cells in a 75 kWh pack) to support system stability.

- In-house developed management that enables per-cell temperature control.

- A two-stage cell balancing approach that improves utilization and reduces degradation rate.

- The use of non-conductive materials and embedded sensors to reduce relative flammability of NCA cells.

- Accumulation of operational BMS data including driving patterns, charging behavior, cell temperatures, and capacity changes.

These characteristics deliver several advantages: many vehicles maintain higher retained capacity over several years, the system tolerates higher risk through large-data management of many cells, and the same battery architecture can be adapted across vehicle types. Weaknesses include relative cell-level safety concerns, higher module replacement costs if modules are damaged, and potential transient control failures that could disable safety and temperature control functions.

By comparison, the Chevrolet Bolt's BMS has different characteristics: monitoring chips for cell voltage and temperature were designed by LG Chem and manufactured by STMicroelectronics; the Bolt uses more distributed MCUs for monitoring compared with some Tesla implementations; and it relies on single-stage cell balancing, which can lead to faster capacity fade if the pack size increases. Overall, Tesla's BMS implementations are often considered highly effective.

Battery Thermal Management: Air, Liquid, or Direct Cooling?

Battery thermal management strongly affects both range and lifetime. Thermal systems are generally classified by heat-transfer medium: air cooling, direct cooling, and liquid cooling. Liquid cooling tends to be more effective than air cooling and is currently the mainstream choice due to its balance of cost and performance. Thermal management focuses on the battery pack, HVAC, motor and inverter cooling, and gearbox cooling. Ideal cell operating temperature is roughly 0–38°C. Excessive heat or cold accelerates degradation, so maintaining a uniform temperature across the pack is important.

Air cooling is suitable for low-power applications and favorable operating conditions. Some electric vehicles on the Chinese market still use air-cooled pack designs. Liquid cooling, using fluid convection to remove heat, has wide adoption across many models globally. Direct cooling, which leverages refrigerant phase change to remove heat quickly and efficiently, is used in some higher-end models; it offers the highest cooling power but is more challenging to control, making it suitable for high-range and fast-charging requirements. Some models provide both liquid and direct cooling options.

Thermal systems people often ask about winter operation. In cold climates, using electric resistance heating for cabin comfort can consume a large portion of battery energy. Heat pump systems transfer heat from a colder environment to a warmer one and can reduce HVAC energy consumption by roughly 50% compared with resistive heating. In winter use, a heat pump can improve driving range by approximately 10–15% versus resistive heating, which is significant for vehicles with 300–500 km nominal range. Several manufacturers have offered heat pump HVAC systems across price segments.

Note that heat pump efficiency degrades below about -5°C, at which point supplemental charging and alternative heating strategies may be required. With modern thermal management technologies, electric vehicles can be practical for year-round commuting in most climates if the vehicle's systems are chosen to match intended use.