For experienced professionals in automation and senior mechatronics engineers, choosing an appropriate robot may be straightforward. Designers or factories preparing to purchase or introduce robots for the first time may feel uncertain.

Below, we cover nine technical parameters to help you choose a suitable industrial robot.

01 Application scenarios

Start by evaluating the intended application and the manufacturing process the robot will serve.

For tasks where the robot works alongside people in a semi-automated line, or where stations and layouts change frequently and torque sensing is required, collaborative robots (cobots) are often a good option.

For compact pick-and-place tasks, SCARA robots are commonly chosen.

For small parts and very fast pick-and-place, delta robots are typically the best fit.

The rest of this discussion focuses on multi-axis articulated robots. These robots cover a wide range of applications, from pick-and-place and palletizing to painting, deburring, and welding. Robot manufacturers generally provide solutions tailored to specific processes. Your task is to define the work you need the robot to perform and select the model that matches that task.

02 Payload

Payload is the maximum load a robot can carry within its workspace, ranging from a few kilograms to over a ton. When evaluating payload, add the weight of the workpiece and the weight of the gripper or end effector to determine the total working load.

Also pay attention to the robot's payload curve: the available payload can vary depending on the distance from the robot base.

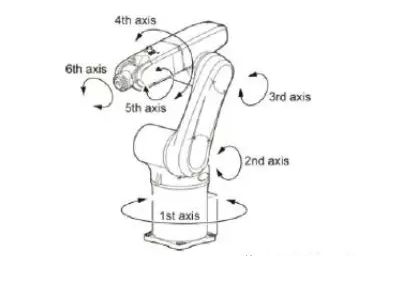

03 Degrees of freedom (axes)

The number of configured axes determines the robot's degrees of freedom. For simple linear transfers, a 4-axis robot is often sufficient. In confined spaces where the arm needs to twist and turn, 6-axis or 7-axis robots provide better flexibility.

Axis naming varies by manufacturer. Typically, the first joint (J1) is closest to the robot base and subsequent joints are labeled J2, J3, J4, and so on, up to the wrist. Some manufacturers use letter-based names for axes.

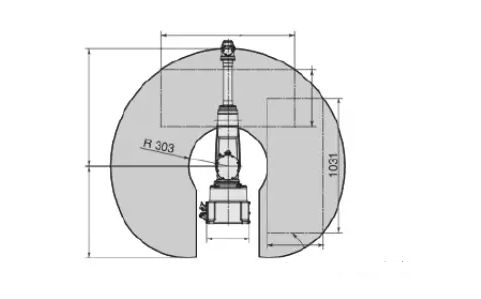

04 Maximum reach

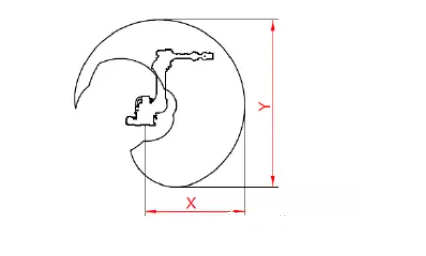

When assessing an application, determine the maximum distances the robot needs to reach. Select a robot based not only on payload but also on its exact reach. Manufacturers provide reach diagrams that show whether a robot can serve a specific layout. Pay attention to the robot's horizontal working envelope and to non-working zones near the base and behind the robot.

The maximum vertical reach is measured from the lowest reachable point (often below the robot base) to the maximum height the wrist can reach (Y). The maximum horizontal reach is measured from the robot base center to the furthest horizontal point the wrist can reach (X).

05 Repeatability

Repeatability describes the robot's ability to return to the same position during routine tasks. Typical values range from ±0.05 mm to ±0.02 mm, with higher precision available for demanding tasks. Assembly tasks such as placing components on printed circuit boards may require very high repeatability, while packaging or palletizing can tolerate lower precision.

Selection for assembly also depends on positional tolerances passed through the process chain, such as incoming part positioning and fixture repeatability. Because robot motion is three-dimensional, the repeatability is often expressed as a tolerance radius around the target point.

Vision systems and motion compensation can reduce dependency on incoming part precision and improve overall assembly accuracy.

06 Speed

Speed is closely related to the required cycle time for a task. Specification sheets list maximum joint speeds, but actual operating speed depends on acceleration and deceleration between points. Speed is typically given in degrees per second, and some manufacturers also list maximum joint accelerations.

07 Robot mass

Robot mass is an important factor when designing the robot cell. If the robot must be mounted to a custom frame or carried on a linear rail, you need the mass to design appropriate supports.

08 Brakes and moment of inertia

Manufacturers provide information about a robot's braking system. Some models have brakes on all axes, while others do not. Sufficient braking is necessary to maintain precise and repeatable positions in the workspace. Without brakes, heavy axes may not lock during a power loss, which can create safety risks.

Manufacturers may also provide moments of inertia for the robot. These values help with safety calculations and mechanical design. Check the maximum torque ratings on relevant axes: if torque capacity is exceeded, the robot may overload and stop.

09 Protection rating (IP)

Choose an IP protection rating suitable for the operating environment. Some manufacturers offer the same manipulator with different IP levels for different conditions. Robots used in food production, pharmaceuticals, medical devices, or explosive atmospheres require different IP and cleanliness standards. Typical examples include standard IP40, oil-mist resistant IP67, and cleanliness ISO class 3.