Overview

Acrel's precision power distribution system provides a multi-circuit monitoring device for centralized monitoring requirements in data centers. It monitors multi-circuit electrical parameters and issues alarms for various faults. The system is suitable for monitoring end distribution equipment such as row-head cabinets, precision distribution cabinets, power distribution cabinets, and UPS output cabinets. Based on data center cabinet distribution objectives, this article analyzes traditional distribution schemes and their problems to provide reference for new cabinet distribution designs and to help ensure safe, reliable power distribution in data center facilities.

Trends in Intelligent Micro-modules

Micro-modules typically include environmental and infrastructure monitoring systems that provide real-time monitoring of access control, video, temperature and humidity, smoke detection, water leakage, and energy consumption, enabling easier management and control. The development of intelligent micro-modules for data centers aims for three-dimensional visualized management.

Environment Visualization

Capabilities include: virtual simulation of geographical campuses; virtual building exteriors; 3D modeling based on actual building structures; and the ability to horizontally or vertically split and display the structure of each micro-module.

Capacity Management Visualization

Real-time statistics on space, load-bearing capacity, and power utilization for rooms and cabinets, enabling more rational use of facility resources. Dynamic multi-condition queries for space height, load-bearing, and power.

Asset Management Visualization

Visual search and localization supporting multi-condition queries and rapid device location. Integrated information queries consolidate distributed management information, automatic statistics, and device lists.

Monitoring Information Visualization

Status visualization presents device alarm information and availability status for quick fault localization and reduced troubleshooting time. Performance visualization extracts device performance data from monitoring subsystems and integrates it for improved information interaction efficiency.

Each cabinet needs an integrated monitoring system including a monitoring host, touch display, and sensors to centrally monitor power equipment and environmental variables, detect faults promptly, and inform maintenance staff to take corrective actions. This supports automation and intelligent management of the facility.

The deployment architecture comprises a data acquisition and processing layer, a centralized monitoring management layer, and a remote browsing and interaction layer.

Data Acquisition and Processing Layer

Monitoring units collect and process cabinet-level data and status for facilities such as UPS, precision air conditioning, temperature and humidity, and water leakage. Devices perform data acquisition, processing, and storage, and present cabinet running parameters and status via a touch display. Data is uploaded over the network to the centralized monitoring management layer for unified monitoring.

Centralized Monitoring Management Layer

This layer consists of a centralized monitoring management system responsible for consolidated monitoring and management of all cabinet data. It receives uploaded data and alarms from the data acquisition layer and performs secondary processing and analysis to implement data analysis, alarm management, report generation, asset management, and capacity management functionalities.

Remote Browsing and Interaction Layer

This layer provides operations staff with a unified alarm notification and data publication platform and supports web-based interaction and operation.

Cabinet Components

Monitoring Host

A data acquisition terminal developed for cabinet monitoring. It includes multiple device ports to enable on-site data acquisition, protocol conversion, and intelligent alarm functions. It hosts a web service so users can view and manage the monitoring system through a web browser.

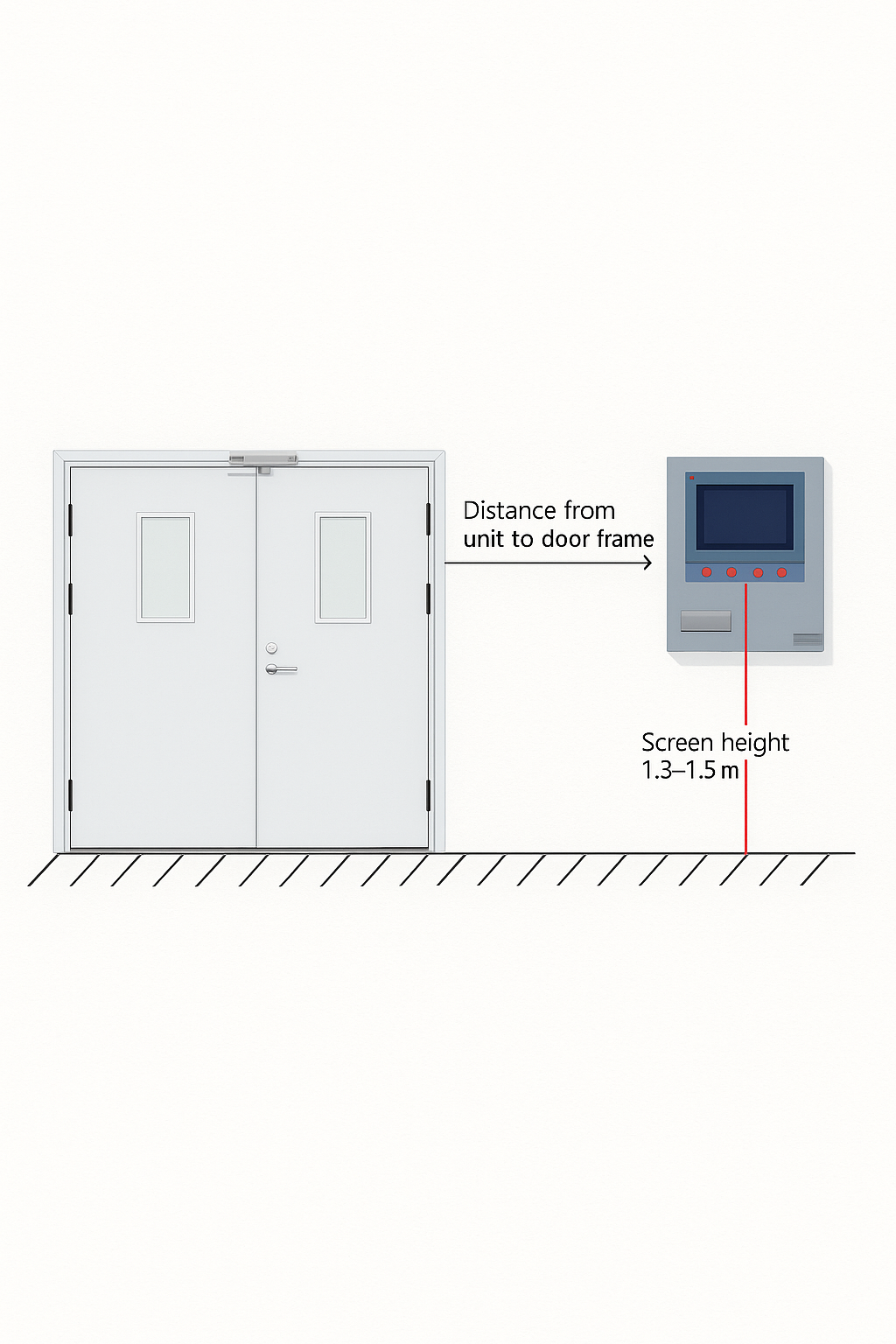

Touch Display

A multi-touch capacitive display embedded in the cabinet front door. It connects to the monitoring system to provide real-time monitoring of cabinet environmental parameters.

Sensor Monitoring Module

Facilities monitored include rack distribution boxes, rack UPS units, precision air conditioners, sensors, and cabinet door status.

Facility Monitoring Functions

Distribution Monitoring

Supports monitoring of mains input voltage, frequency, current, power, and UPS input voltage, frequency, and current.

Precision Air Conditioning Monitoring

Supports real-time monitoring of supply and return temperature and humidity, fan speed and display of running percentage, and compressor operation status.

Sensor Data Monitoring

Monitors cabinet internal environmental sensors such as temperature and humidity sensors and battery module status.

Security and Fire Monitoring

Cabinets can be manually opened from the top or rear. Cabinet status includes front door, rear door, top hatch, water leakage detection, and smoke detection. Water leakage and smoke monitoring at the cabinet base provide real-time alarm signals.

Alarm Notification

The alarm module must support monitoring of air conditioning, power distribution, and environmental states and issue real-time alarms on faults or parameter anomalies. It must support querying the lifecycle of an event, including event occurrence, handling, and alarm dispatch. Alarms should be presented as a list with a real-time alarm window, filterable by alarm level and confirmation status, and support customization of displayed items and single or batch confirmation.

Depending on alarm severity, the monitoring system should support multiple alarm methods such as email, SMS, phone call, and audible/visual alarms.

Wiring Management Visualization

Port management: present patch panel and device front/rear panel and port occupancy information in a 3D visual environment. Link management: display physical connections between managed devices in 3D. Support import/export of wiring tables and direct manipulation of link configuration in the visual management environment.

Case: Micro-module Row-head Cabinet Monitoring Requirements

An intelligent monitoring board for precision distribution cabinets must monitor multiple main and branch circuits and provide a visual interface. A 7-inch color LCD touch screen should display a system mimic diagram showing the real-time status of switches and SPD devices and show electrical data for all main and branch circuits. The monitoring board must support MODBUS or SNMP for integration with third-party network management systems and should include the following features.

Busbar Monitoring Parameters

1) Three-phase input voltage, current, frequency, reactive power, active power, power factor, harmonic percentages, energy, three-phase unbalance, zero-to-earth voltage, neutral current, and busbar temperature.

2) Main switch status and load percentage.

3) Main circuit voltage and current measurement accuracy no worse than 0.5%; active/reactive power accuracy no worse than 1%; energy measurement accuracy no worse than 1%.

Branch Monitoring Parameters

1) Branch rated current and actual current, branch load percentage, branch switch status, and branch temperature measurement.

2) Branch current measurement accuracy no worse than 0.5%; active power measurement accuracy no worse than 2%; energy measurement accuracy no worse than 2%.

Alarm Signals

The system must support audible and visual alarms on the LCD, with touch-screen mute. Alarm severity should be classified into three levels: advisory, important, and critical. Required alarms include:

- Main under-voltage, over-voltage, phase loss, input breaker trip, single-circuit power loss, and current transformer wiring error alarms.

- Main circuit current limit and over-limit alarms, main circuit overload alarms, and three-phase imbalance alarms.

- Main frequency limit alarms, high total harmonic voltage alarms, and high total harmonic current alarms.

- Branch switch status change alarms, overload alarms, and large inrush current alarms.

- Branch current two-stage threshold alarms with adjustable thresholds.

- Monitoring module faults and internal communication failure alarms on the monitoring board.

Alarm history must retain at least 2,500 records. Monitoring modules must support hot-swap and include fault indicator LEDs; when a module fails, it must indicate an alarm and support maintenance without powering down the system.

Acrel AMC100 Solution for Row-head Cabinet Monitoring

The Acrel AMC100 series precision distribution monitoring device is designed for data center server power management. The compact device monitors dual A/B inputs and up to 192 output circuits, capturing full electrical parameters, input/output switch and SPD status in real time. Alarm thresholds for each measurement channel are configurable. Output overlimit events immediately trigger audible/visual alarms. The system can be paired with an insulation monitoring module to monitor DC bus and branch insulation status online, achieving high integration of monitoring circuits within a compact instrument footprint.

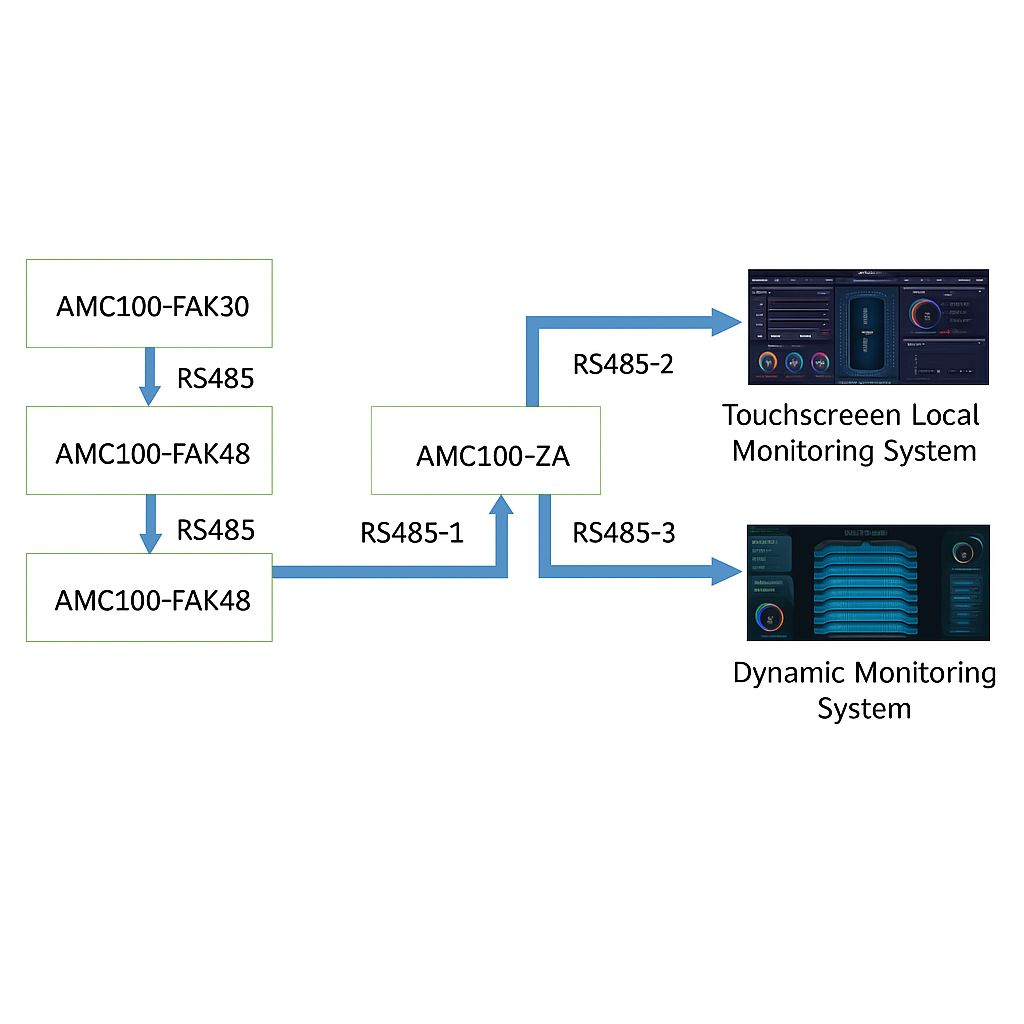

Networking Scheme

The host module AMC100-ZA provides RS485 ports to connect slave devices, touch-screen systems, and the infrastructure monitoring system.

Recommended Capabilities

The AMC100 series can monitor up to four input lines and 192 output lines for full electrical parameters, input/output switch and SPD status in real time. Each measurement channel has an independently configurable alarm threshold and triggers immediate audible/visual alarms on output overlimit events, providing a high degree of circuit monitoring integration within a small instrument size.

The monitoring set does not require an external switch-mode power supply. If either A or B of the main input modules has power, the system can output DC 24V to supply the touch screen and branch modules, reducing cabinet layout space and ensuring continuous monitoring without external relay switching. Compared with alternative vendor solutions, this reduces module count and overall cost for certain cabinet configurations.

Single output modules can provide electrical isolation between A and B outputs. For cabinets with fewer than A24+B24 branch circuits, full monitoring can be achieved with one input module plus one output module, further reducing required module count and cost.

A single touch screen can collect and display power parameters, switch status, and alarms for systems with 1 to 4 input lines, meeting diverse operational needs.

For dual-input row-head cabinets, the touch screen supports one-click switching between AABB and ABAB wiring methods for branch modules, facilitating wiring adjustments due to cabinet layout differences.

Virtual meters can be grouped and customized for aggregated reporting by group name, enabling user-based data aggregation and display.

The system can be extended with customer-specific value-added functions, such as touch-screen operation locking, cabinet ambient lighting control (door/open or alarm state indicators), custom operation display interfaces (currently two styles), and simultaneous AC and DC monitoring on the same touch screen.

Conclusion

The Acrel solution for centralized data center monitoring helps ensure the safety and reliability of data center power distribution. The approach supports comprehensive analysis of internal and external environments, aligns with industry trends, and provides configurable application solutions to meet diverse customer needs.