Introduction

Should Formula Student teams build fully electric or hybrid cars? This has been a longstanding debate in the community. In April of this year, the organizing committees for the Formula Student events in Austria, Hungary, Czech Republic and other countries published technical rules for hybrid Formula Student entries. In October, the German event also incorporated the hybrid provisions into the international Formula Student regulations.

In this discussion, Zheng Hao, technical officer at the China Society of Automotive Engineers and the Formula Student series organizing committee, shares observations from the German Formula Student event and his experience as a team member. Zheng graduated from Wuhan University of Technology. He joined the university's combustion Formula Student team in his first year and later took responsibility for drivetrain, steering, and business roles. For his undergraduate thesis, he researched energy management and vehicle power control strategies for a parallel hybrid system. After graduation he joined the organizing committee as a technical officer, responsible for team technical document review and team operations. The following are his insights.

Context and Rule Changes

According to the "Energy Saving and New Energy Technology Roadmap 2.0" and automaker timelines for discontinuing internal combustion models, many manufacturers plan to end sales of pure internal-combustion vehicles around 2035. New energy powertrains are a clear direction, but distinctions remain across regions and OEMs. Many see pure electric as the future, while others view hybrid as an intermediate solution. Pure electric technology still faces challenges such as charging rates, urban energy capacity, and full-use-case deployment. Internal combustion engines will not disappear in the near term; hybrid and zero-carbon combustion solutions are viable approaches to extend their relevance.

In April, several national Formula Student organizers released hybrid technical rules. By September, Germany had formally included hybrid provisions in the World Formula Student rules. The FS 2024 rules published by Germany will be used at events such as the 2024 Austrian and Hungarian competitions.

In August I attended the Formula Student Germany event and met the High Speed team from Karlsruhe University of Applied Sciences, one of the teams that successfully developed a hybrid Formula Student car. Below I summarize design ideas based on those discussions and my prior team experience.

Design and Simulation Approach for Hybrid Formula Student Cars

Hybrid systems are commonly categorized as series, parallel, and power-split configurations. Parallel architectures can be further subdivided by motor location into P0, P1, P2, P3, P4, etc. Although the FS rules do not restrict configuration, the most likely mainstream FSAE hybrid architectures will be P0 and P4.

Compared with passenger car hybrids, Formula Student hybrid systems can be significantly simplified. One reason is that FSAE hybrid system voltages are relatively low, reducing electrical risk. Another reason is that challenging hybrid aspects for passenger cars—such as economy optimization and ride comfort—are less relevant for racecars. Teams typically do not need to design for features like engine start-stop for parking or shift smoothness.

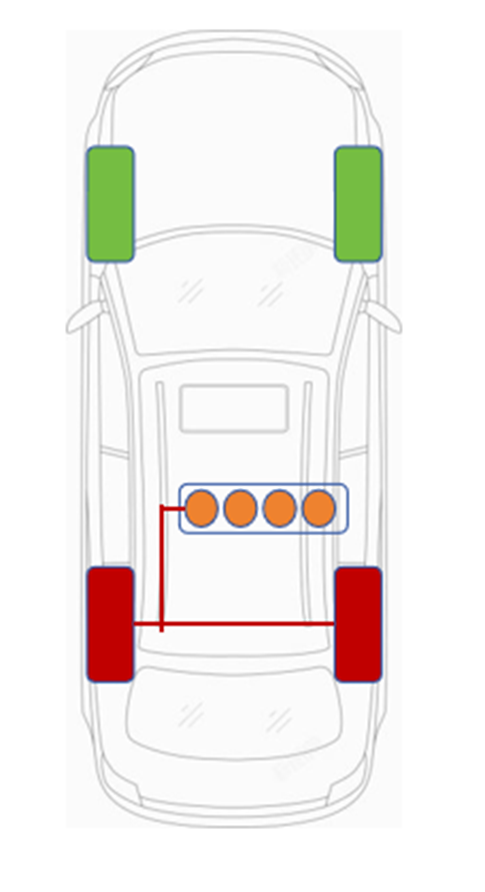

P4 is worth highlighting. In a P4 layout the internal combustion engine drives the rear axle while an electric motor drives the front axle. The main advantages are structural simplicity and the ability to achieve all-wheel drive, which can effectively exploit tire traction. For that reason, many European hybrid FSAE cars (Karlsruhe, Czech Technical University, Modena) use P4.

Across architectures, hybrid FSAE system design generally comprises: drivetrain design, drive control strategy, battery pack design, and vehicle electrical architecture. Below I outline considerations and simulation approaches for these areas in a P4 configuration.

1. Electric Drive and Drivetrain Design

Drivetrain work includes selecting gear ratios, mechanical modeling, and simulation validation. Traditional FSAE ratio selection often uses lap-time optimization software: teams simulate lap times or acceleration for different final drive ratios and choose the ratio that optimizes the target scenario, such as endurance or straight-line acceleration.

Hybrid drivetrain ratio design is more complex than single-power-source cars because lap simulation is tied directly to the hybrid control strategy. Many lap optimization tools do not natively simulate hybrid powertrains. A practical approach is to decouple the internal combustion engine and electric motor when selecting ratios. The engine final drive can be designed using standard lap-optimization tools by treating the car as purely engine-driven for that analysis.

For the motor-driven axle, initial gear selection should consider the torque requirement at maximum acceleration. Subtract the engine contribution from the total required torque to derive the maximum required gear ratio for the motor. The car's top design speed must fall within the motor's speed range, which gives the minimum motor gear ratio. After initial selection, verify that typical endurance-track speeds fall within the motor's constant-torque region. This yields an initial feasible gear-ratio range; subsequent refinement requires integrating the control strategy into simulation.

2. Control Strategy and Simulation

After the drivetrain layout, the control strategy is needed. For a P4 car, key control areas include engine-motor power split, torque distribution between the two front motors if dual motors are used, and regenerative braking strategy. Importantly, the hybrid control strategy can be implemented without modifying the engine ECU; the motor control can be coordinated to match the engine. As one team leader described, "Our engine does not know it is part of a hybrid vehicle."

Regenerative braking and electronic differential applications are already fairly mature in the FSAE community and are covered in many technical papers, so here I focus on power-split strategy between the engine and motor.

The first step in power-split design is mapping pedal demand to required power. Pedal demand mapping aims to smooth peaks and fill valleys so that the effective motor assistance compensates along the vehicle's external characteristics to achieve near-linear power output. From the pedal position and vehicle state, the required power for different pedal openings can be computed.

Next is matching engine power. Many student teams use cable-actuated throttles, so estimating engine output for a given throttle position is straightforward, enabling calculation of the motor drive power needed. The strategy should also account for load transfer and resulting traction distribution changes caused by vehicle pitch under acceleration and braking.

With a power-split strategy defined, teams can perform lap simulation. Standard lap-optimization software provides useful modeling ideas, but since it typically does not support hybrid control strategies, teams need to build a custom simulation platform using tools such as Simulink.

MATLAB and Simulink include components and reference models for hybrid power-split simulation, including mathematical models for engine, motor, transmission, and vehicle dynamics, which can be adapted for an FSAE hybrid car. MathWorks also provides tutorial series for hybrid vehicle development that teams may find helpful.

Summary

Matching and control across multiple power sources remains a challenging topic in the passenger car industry. Compared with pure internal combustion or pure electric cars, hybrid racecars place higher demands on simulation and control. This article presents an introductory technical path for transitioning from conventional internal-combustion FSAE cars to hybrids, describing practical design and simulation steps intended to help teams build a functional hybrid racecar. The goal is to produce a car that runs reliably within current constraints rather than one that achieves maximal lap-time optimization.

Formula Student is entering a new technical era. The future direction of the series depends on the next generation of teams. As one judge put it: "We hope Formula Student remains an engineering practice platform that trains students across disciplines, rather than a high-end machine shop exercise."