Introduction

The growing adoption of electric vehicles is making multi-gear electric drive systems an increasingly common design direction. Bench testing of gearshift behavior in electric drive systems not only advances drive technology but also helps clarify how to integrate new energy sources and support more efficient and lower-emission mobility.

Why Drive-System Electrification Is Inevitable

Electrification of the drive train responds to environmental requirements, energy transitions, technological progress, economic factors, and regulatory pressure. Development of electrified drive technology supports vehicle trends toward electrification, intelligence, connectivity, and shared mobility.

The operating state of an electric drive system can be precisely controlled by electronic control units, which improves vehicle performance and enables advanced functions such as autonomous driving. From an economic perspective, operating costs for electric vehicles tend to be lower than for conventional internal-combustion vehicles. Electrifying the drive system improves energy efficiency and reduces operating cost, improving market competitiveness.

Trend Toward Multi-Gear Electric Drive Systems

An electric drive motor must deliver high torque at startup and operate at high speed for maximum vehicle velocity. A single-speed drive requires a motor with greater size and mass to cover the full operating range, increasing cost; at high vehicle speeds a single-speed motor can operate at excessively high RPM where efficiency drops.

To reduce motor size, mass, and cost while optimizing driving performance and efficiency, electric drive systems are evolving toward multi-gear configurations. Multi-gear systems better match the motor to varying speed conditions, allowing the motor to operate in its efficient range and deliver a more efficient, economical, and comfortable driving experience.

Developing multi-gear electric drive systems poses significant challenges, particularly for shift control. Ensuring smooth, fast shifts while maintaining efficient use of motor energy throughout the shift process is a primary research problem. For this reason, bench testing of gearshift behavior in electric drive systems is an important research focus.

Multi-Gear Electric Drive System Architecture

A multi-gear electric drive system is a key component of an electric vehicle and typically includes the electric motor, a multi-gear reducer, and the control system.

1) The motor is the core of the drive axle system, converting electrical energy into mechanical energy to drive the vehicle. In a multi-gear system the motor must cooperate with the reducer to meet different driving conditions.

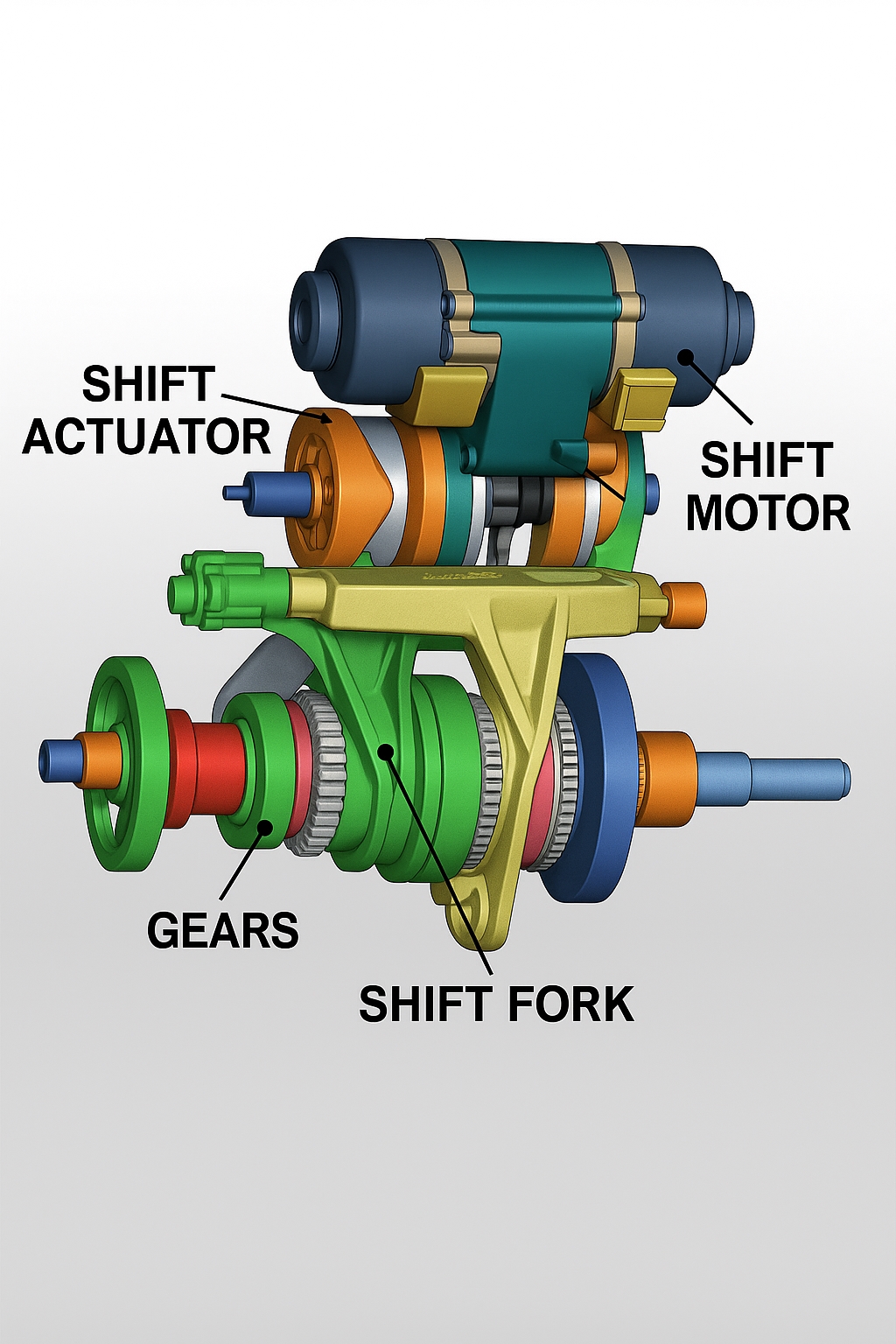

2) The multi-gear reducer is a defining element of the system and normally comprises the reducer, shift motor, shift actuator, and shift forks. It changes the torque and speed output from the motor and delivers them to the wheels. The shift motor actuates the shift mechanism and the shift fork selects gears, enabling the motor to remain as close as possible to its optimal operating state across vehicle speeds.

3) The control system is the system "brain" that controls motor operation to achieve stable, efficient vehicle operation. The shift TCU collects data from various sensors and control units to precisely control shift timing and the shift process, ensuring shift smoothness and minimizing energy loss.

Multi-gear systems eliminate major friction elements such as clutches and synchronizers, simplifying mechanical structure, and through coordinated operation of the main components enable multi-condition driving. Compared with single-speed systems, multi-gear drive systems better adapt to varying driving conditions and improve vehicle performance and energy utilization.

Shift Mechanism and Control

Multi-gear drive systems implement gear changes by using the shift motor to drive the shift actuator and move a coupling sleeve between gear positions. These structures typically do not use synchronizers; synchronization of sleeve and gear-ring speeds is achieved through motor torque control. This process requires precise control to ensure smooth and efficient shifts.

In practice, a gear change includes detection, decision, execution, and stabilization stages. The control system continuously monitors motor status and vehicle conditions such as motor speed and torque, vehicle speed, and acceleration. When motor speed or torque reaches preset shift thresholds, the control unit decides whether to shift and calculates the optimal shift moment and target motor output. After issuing a shift command, the motor adjusts torque and speed and the reducer alters gear engagement status to complete the shift. After the shift, the control system continues to monitor motor and reducer states and makes adjustments if abnormalities are detected.

During the shift process, precise coordination among components enables smooth, fast gear changes. Compared with traditional mechanical shifting, this method produces minimal perceptible gear transitions and improves driving comfort.

Advantages and Limitations of Multi-Gear Electric Drive Systems

Advantages

Multi-gear electric drive systems show clear benefits, particularly for commercial vehicles.

First, they can automatically adjust gear ratios to keep the motor within its optimal operating region, improving motor efficiency and reducing energy consumption.

Second, they provide appropriate torque and speed across different driving conditions to deliver smoother and more efficient performance in acceleration, climbing, and high-speed driving.

Third, by keeping the motor out of prolonged extreme operating states, multi-gear systems reduce wear and extend motor life.

Fourth, precise gear management helps maintain high-efficiency operation and extend driving range.

Finally, smoother shifting improves driving comfort. Multi-gear systems also enable optimization of the transmission layout, support lighter and more compact drive assemblies, and can reduce total system cost through better matching of components.

Limitations

Despite their advantages, multi-gear systems have drawbacks.

Compared with single-speed drives, multi-gear systems have more complex structures, raising design and manufacturing difficulty and increasing maintenance requirements.

Structural complexity also increases manufacturing cost.

The motor's torque and speed control capability affects automated mechanical transmission (AMT) shift time and may cause temporary power interruption during a shift.

Shift control strategies for multi-gear systems are more complex and require more advanced algorithms to ensure shift smoothness and efficiency, increasing development and calibration efforts. Structural and control complexity introduce potential reliability issues, such as premature wear from frequent shifting, which can impact vehicle reliability.

As technology matures, design and control strategies for multi-gear systems are expected to improve and address many of these issues.

Gearshift Bench Testing for Multi-Gear Drive Systems

Why Shift Testing Is Necessary

Shift tests evaluate shift performance and durability under various conditions, assessing smoothness, responsiveness, and effects on motor operation. These tests are critical for optimizing shift control strategies and improving shift behavior.

Shift testing validates design choices by observing shift timing, shift shock, and shift efficiency, verifying the correctness and practicality of the shift mechanism, and identifying design issues for correction.

Testing in early development helps identify and resolve anomalies, improving development efficiency and avoiding extensive later-stage modifications. Tests also assess system safety in extreme conditions such as high-speed or high-frequency shifting to ensure stability and durability.

In some regions, shift tests and compliance with performance metrics may be required for vehicle road approval. Overall, shift testing is an essential step in the development process to improve shift performance, durability, and safety.

Test Rig Structure

A shift test rig for a drive axle typically includes the electric drive system, a battery simulator, cooling equipment, a wheel-end dynamometer, a data acquisition system, the control system, and supporting fixtures.

The drive system is the primary test object. A battery simulator provides a power supply for the rig. The cooling system cools the motor and reducer. The wheel-end dynamometer provides controlled output speed. The data acquisition system measures parameters such as speed, current, voltage, and displacement. The control system manages the shift process. Fixtures secure and support all components to ensure stability and load capacity.

Appropriately designed and configured test rigs can simulate real driving conditions and accurately measure performance across operating scenarios, providing reliable data for optimizing shift mechanism design and control strategies.

Shift Test Procedure

Shift testing focuses on shift timing, method, and success rate, so test control centers on the shift strategy. Tests exercise the shift motor to achieve transitions between gear positions.

Control of the test must consider the drive system state, shift duration, shift smoothness, and vehicle speed. During testing, acquired data such as speed, current, and shift displacement are used to evaluate shift performance and durability. These control principles rely on a suitable control system and algorithms to ensure precise, reliable, and accurate testing.

Before testing, the drive system is mounted on the rig in a configuration equivalent or similar to vehicle installation. The wheel end is connected to the dynamometer and the power source, cooling, control, and data acquisition systems are connected. Communication between the drive system and control/acquisition systems is debugged, and the test plan is followed.

During a shift, the dynamometer maintains stable wheel-end speed while the drive motor provides the required input speed. The control system issues a command to place the drive system in neutral; the input motor then adjusts speed within a specified time to achieve synchronization with the target speed, after which the drive system is engaged into the new gear, completing the shift.

Throughout the test, data such as speed, current, and displacement are recorded and monitored to evaluate shift success rate and smoothness. If the system experiences incomplete shifts, abnormal shift noise, unexpected input-shaft speed fluctuations, lubrication temperature spikes, or other uncontrolled anomalies, the test is stopped. After testing, data analysis assesses shift life and performance and provides a basis for improving design and control strategy.

Conclusion

With rapid advances in electric vehicle technology, multi-gear electric drive systems have become a major research area. They can reduce demands on batteries and motors while improving vehicle acceleration, top speed, and driving range, enhancing driving performance and comfort to meet diverse driving needs.

Advances in control technology will require more efficient shift strategies to achieve smoother and faster shifts and improve the driving experience. Increasingly complex multi-gear architectures will be needed to adapt to varied driving environments and provide more driving modes while improving energy utilization. Integrated energy management strategies will allow the vehicle to select the most appropriate gear based on driving conditions and battery state.

Shift performance and durability directly affect the driving experience, so shift testing is crucial in developing and optimizing multi-gear drive systems. Testing assesses shift performance and life, identifies potential problems during shifting, and provides data to validate and refine shift control strategies. As such, shift testing is an indispensable stage in multi-gear drive system development and contributes to improving system performance and advancing electric vehicle technology.