As vehicle safety and comfort features increase, the number of electrical circuits rises accordingly, leading to more wiring. The resulting increase in harness weight has become a significant concern.

To reduce harness mass, aluminum conductors are increasingly used to replace copper. Aluminum's low specific gravity helps lower harness weight. Aluminum can also reduce material costs, particularly as copper prices rise.

Aluminum's application is expected to expand, but traditional aluminum conductors have limitations in mechanical strength. In particular, at small cross sections such as 0.35 mm2 or 0.5 mm2, aluminum often cannot match copper's performance. In engine compartments with strong vibration, aluminum faces additional challenges. Therefore, although aluminum helps reduce harness weight, the achievable reduction is limited and depends on matching conductor performance to the application.

01 High-strength aluminum alloy development

The development goal for small-gauge aluminum conductors is to provide a 0.35 mm2 aluminum wire equivalent to conventional copper of the same cross section. Automotive wires require both high tensile strength and good electrical conductivity.

Sumitomo Electric has extensive research experience on small-gauge, high-strength aluminum conductors.

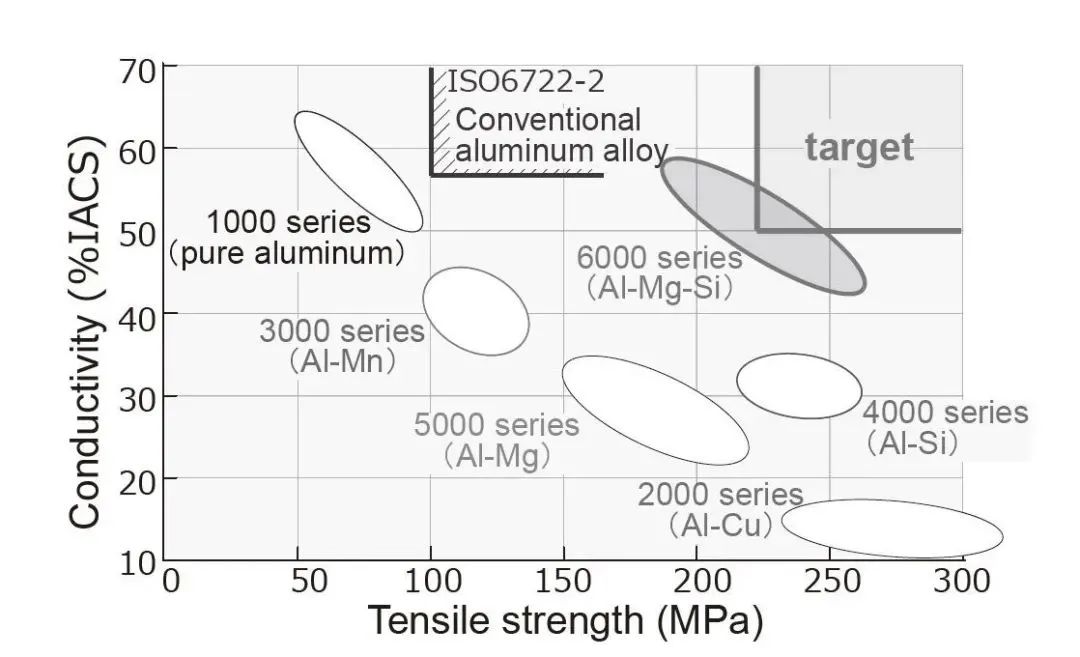

The objective is to ensure small-gauge aluminum wires exhibit vibration electrical resistance equivalent to or better than conventional copper. Based on past terminal crimp strength data, targets were set at 220 MPa tensile strength and 50% IACS conductivity so that, even when increasing a size compared with a conventional copper ISO wire, fuse matching would not change.

Additionally, material properties were targeted to meet ISO and other official standards.

02 Alloy design

Commercial pure aluminum (1060: 99.6% purity) has high conductivity around 62% IACS but low tensile strength near 70 MPa. For automotive use, the strength must be increased.

Adding strengthening elements to aluminum alloys for conventional wires can raise strength to about 120 MPa, roughly half that of copper, making it difficult to reduce conductor size below 0.75 mm2.

Sumitomo Electric compared various aluminum alloys and selected the 6000 series because its properties were closest to the targets. Magnesium (Mg) and silicon (Si) were chosen as alloying elements.

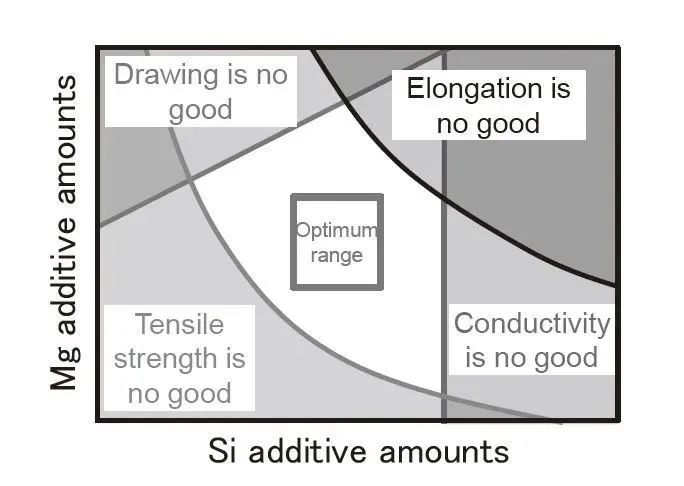

To determine Mg and Si contents, prototype alloys were cast and evaluated for strength, conductivity, and elongation, since these properties affect wire drawability and workability.

Figure 1 Characteristics of various aluminum alloys

Based on the evaluation, the composition range meeting the targets was narrowed. The additive amounts required to reach 220 MPa tensile strength and 50% IACS conductivity were determined. Considering refining methods and production manageability, the alloy design value chosen was Al-0.6 mass% Mg-0.5 mass% Si.

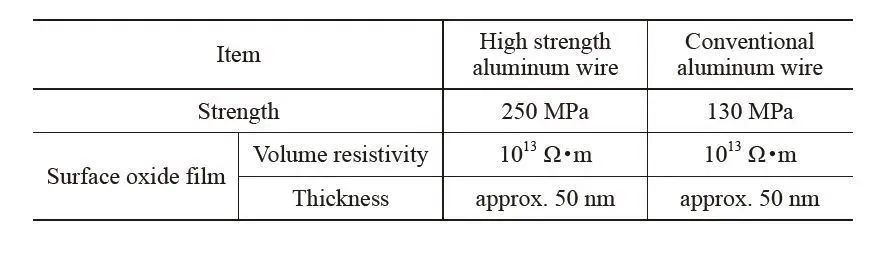

With this composition, Sumitomo Electric obtained an alloy with 250 MPa tensile strength and 52% IACS conductivity, exceeding the targets.

03 High-strength aluminum wire structure

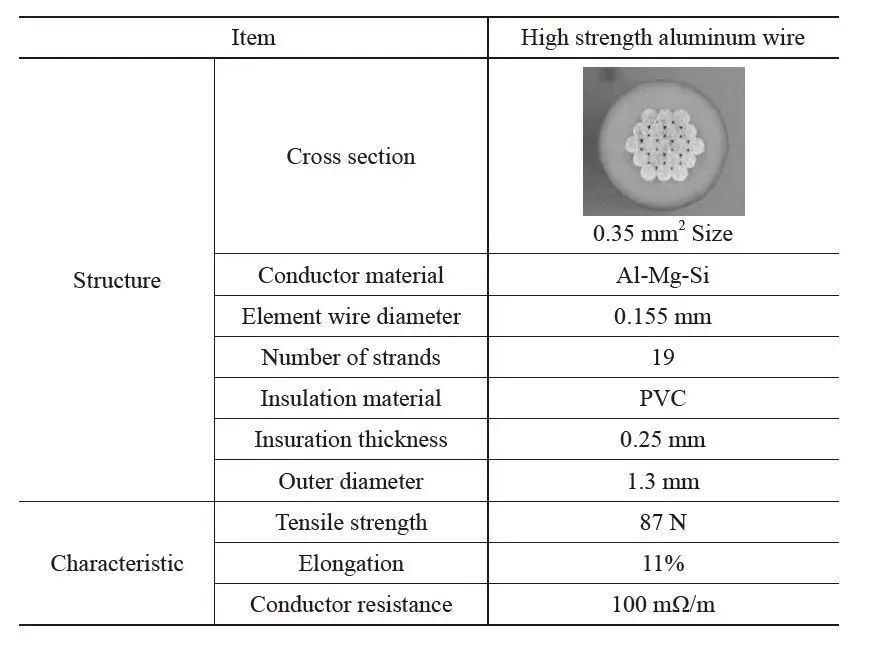

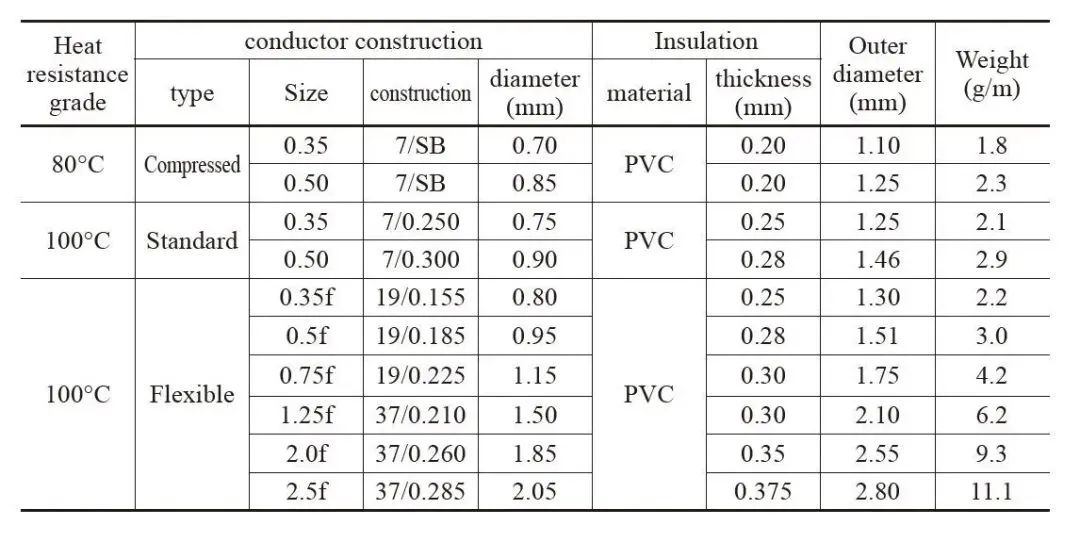

The 0.35 mm2 specification developed by Sumitomo Electric uses a conductor composed of 19 strands of 0.155 mm2 each. The flexible strand structure improves resistance to engine vibration. Compared with copper of the same specification, the aluminum wire reduces weight by 53%.

Table: High-strength 0.35 mm2 aluminum wire (specification)

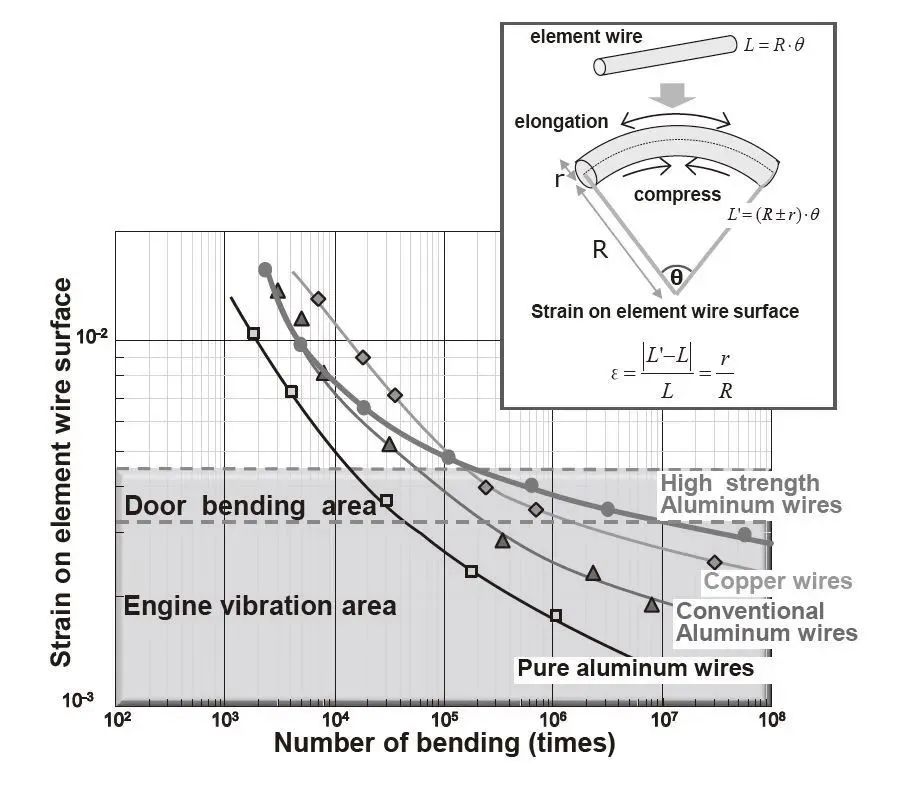

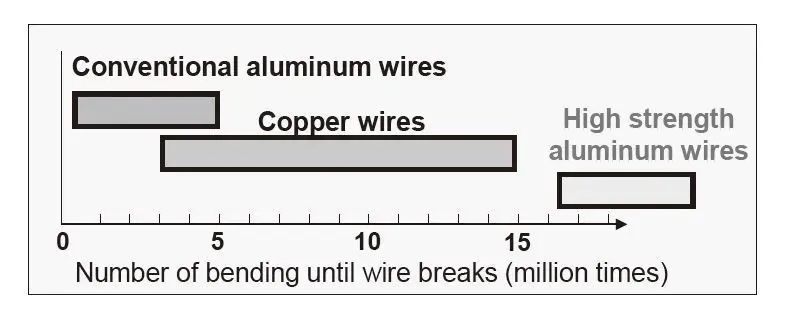

The S-N curves (strain amplitude versus number of bending cycles) for the high-strength aluminum alloy show that, at low strain amplitudes, fatigue life is greatly improved compared with conventional aluminum alloys. Strain amplitude here refers to the relative change in conductor length at the surface during bending.

Results indicate the high-strength alloy outperforms conventional copper and aluminum in terms of fatigue under engine-vibration strain. At low strain, higher material strength yields longer life, demonstrating the benefit of raising strength above copper levels.

The high-strength alloy also shows better bending tolerance for door open/close cycles than copper, making it an effective conductor for both bending and vibration tolerance.

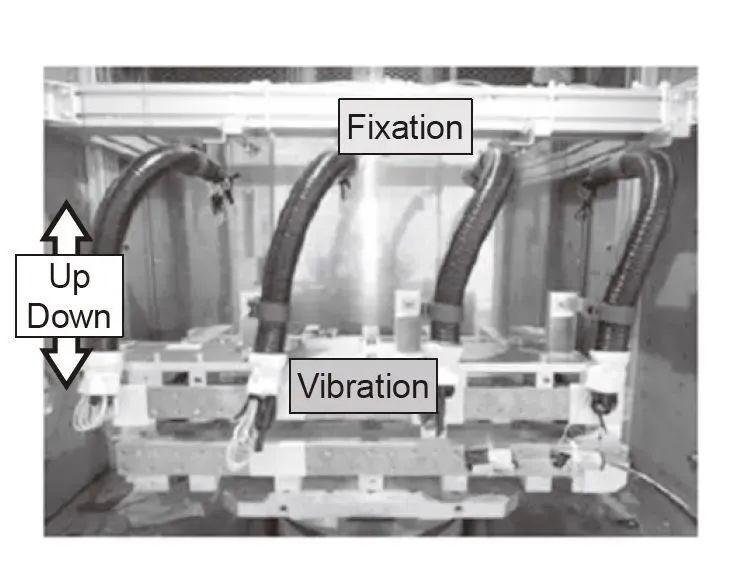

Sumitomo Electric tested the high-strength aluminum wire under simulated engine vibration conditions representative of wiring harness use. The developed wire showed significantly higher strength and endured more cycles than conventional aluminum and more cycles than conventional copper.

Test setup for simulated engine vibration

Figure: Test results under simulated engine vibration

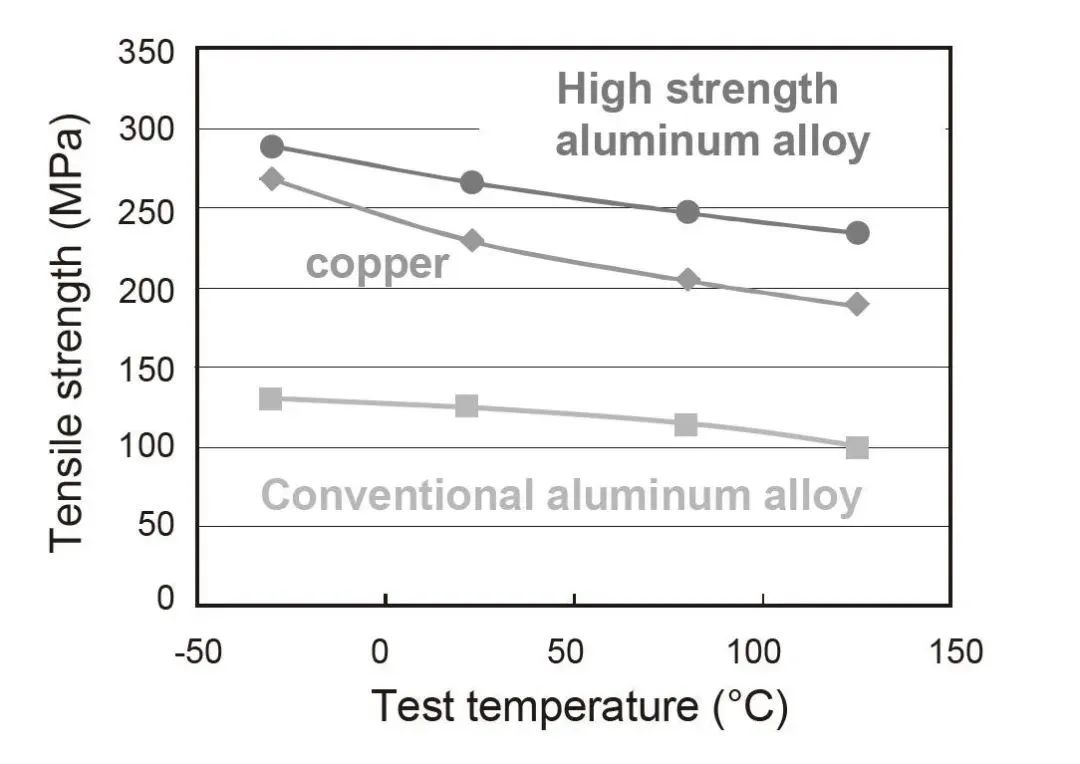

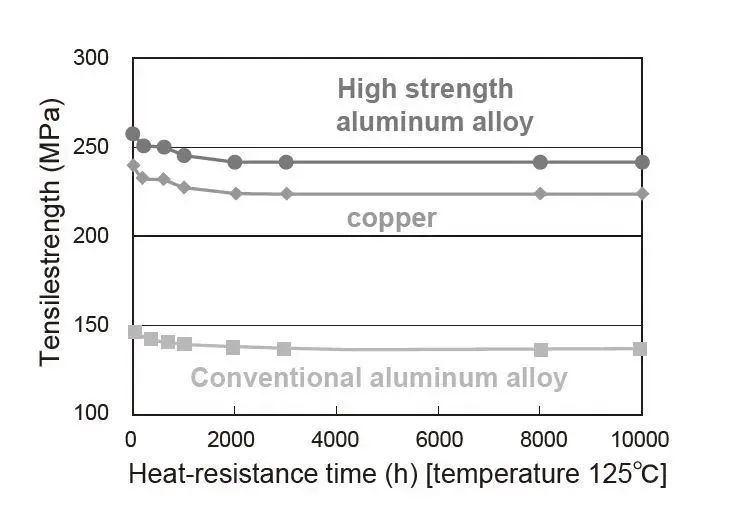

Assuming engine compartment conditions, Sumitomo Electric studied conductor strength during and after exposure at 125°C. The developed alloy is stronger than conventional aluminum; although strength decreases with increasing temperature, it does not fall below copper's strength. Even at 125°C the developed alloy maintains strength exceeding copper. After high-temperature storage, the retained strength also remains above copper at room temperature.

Temperature dependence of strength

Strength after high-temperature storage

04 Crimping aluminum wire

Terminal design is specific to aluminum.

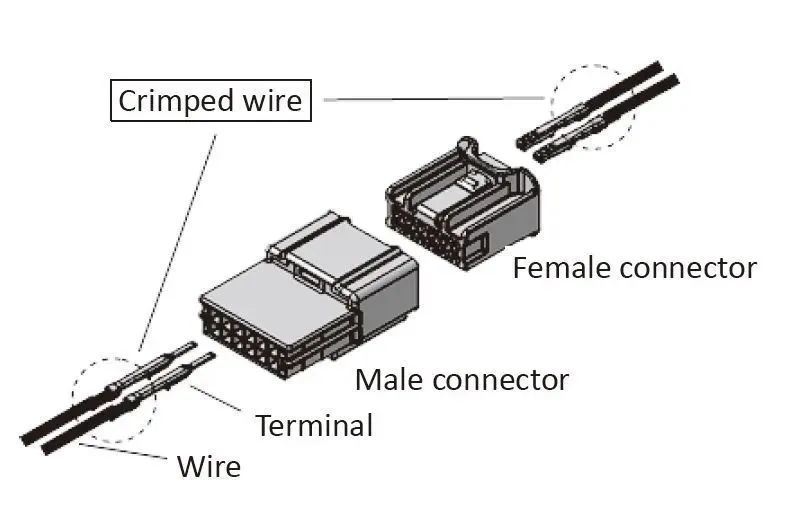

Typical connection in automotive harnesses uses a terminal crimped onto the wire and then inserted into a connector. To expand aluminum harness use, terminals dedicated for aluminum must be available so that crimping—a common assembly method—remains reliable. This requires new crimping approaches for aluminum conductors.

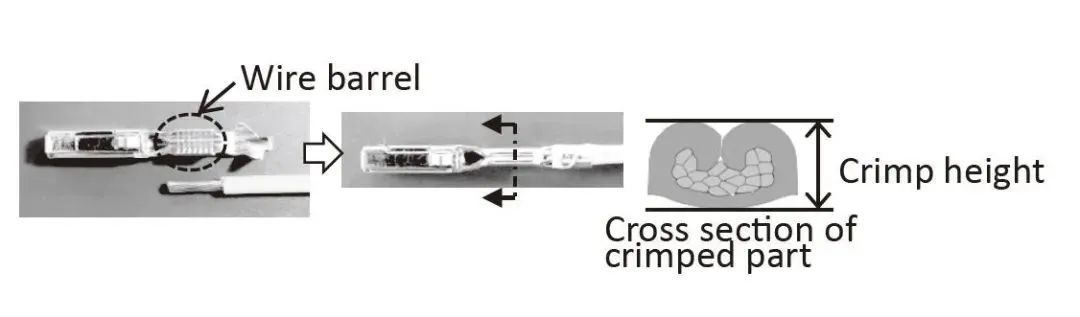

Traditional crimping strips the composite conductor, compresses a U-shaped barrel on the terminal to achieve contact resistance and retention force.

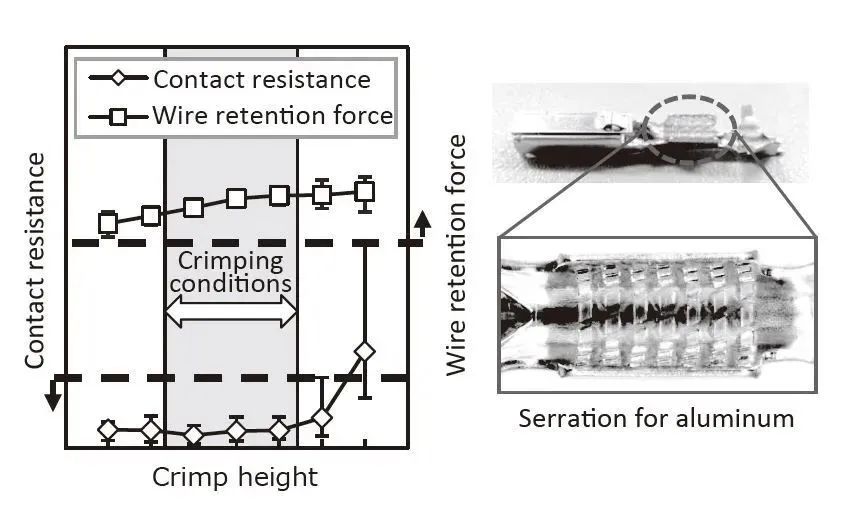

Because aluminum surfaces form a tenacious insulating oxide film, stronger compression than for copper is required to obtain stable contact resistance. Sumitomo Electric studied the physical properties of the oxide film on the developed conductor and verified whether conventional crimping methods could be applied to the new wire. The study found the oxide film on the developed conductor is similar to that of conventional aluminum conductors. Since conventional crimping methods are likely applicable, a new crimp pattern was developed to meet contact resistance and retention standards.

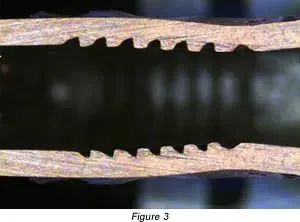

The terminal structure includes many serrations.

TE Connectivity's aluminum crimping technology

TE Connectivity introduced the LITEALUM crimping technology in 2009 to enable reliable, durable crimps for all cross-section aluminum stranded conductors used in automotive applications. The concept is similar to Sumitomo Electric's crimping approach.

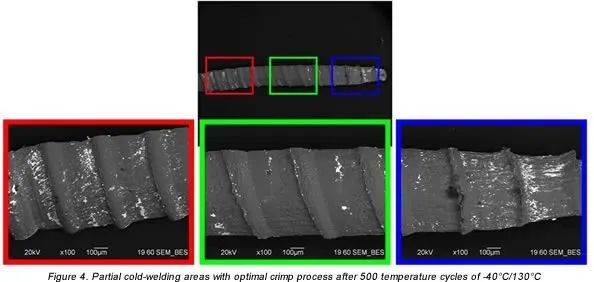

The LITEALUM crimp barrel design and surface characteristics, especially in the crimp zone, are precisely tailored for aluminum conductor material requirements. The interior of the LITEALUM barrel has sharp serrations that create a washboard-like surface. The so-called "shark-fin" serrations describe the ridge contours. During crimping, these serrations disrupt the oxide layer and expose underlying pure aluminum, allowing local cold welding to establish electrical contact.

During crimping, aluminum's inherent ductility is utilized. The low yield point causes greater plastic deformation in the conductor material during crimping compared with copper. The volume flow caused by this deformation axially displaces and forces material into the micro-serration valleys in both directions.

Therefore, specific terminals and serrated crimp barrels are required for reliable aluminum crimps.

05 Applications of high-strength aluminum wire

Small-gauge aluminum wires are particularly suitable for engine compartment applications.

Sumitomo Electric began manufacturing high-strength aluminum wire from April 2015, starting with 0.35 mm2 wire.

Product series of high-strength aluminum wires

06 Summary

Aluminum conductors are increasingly used in automotive manufacturing, especially as energy efficiency and environmental requirements tighten.

Adoption of aluminum is not limited to specific brands or models. As technology advances and environmental awareness grows, more vehicle manufacturers are replacing copper with aluminum to reduce vehicle weight and improve energy efficiency.

However, aluminum applications face challenges such as reliable aluminum-to-copper connections and aluminum's higher coefficient of thermal expansion. Automotive manufacturers must continue to innovate and improve techniques to address these challenges and expand aluminum use.

In summary, the use of aluminum conductors in automotive wiring harnesses is growing, and with further technical progress and stricter environmental requirements, wider adoption is expected.