Introduction

At low temperatures, electric vehicles must heat both the passenger cabin and the battery. Batteries are more sensitive to cold than to heat. In cold conditions, battery range drops significantly and available power is reduced.

1. Heating methods used across Tesla models

Tesla's thermal management has evolved continuously. The Model S and Model X used first-generation thermal management with direct PTC heating. From Model 3 onward, Tesla began collecting waste heat from power electronics to heat the battery, representing a second-generation approach. Model Y introduced an important addition: a heat pump. Although Tesla publicized its use of a heat pump, it was not the first OEM to adopt the technology.

Internal combustion engine and hybrid vehicles have long used engine waste heat to warm the cabin and batteries. Engine thermal efficiency above 40% is difficult, so a large fraction of fuel energy becomes waste heat that can be used for heating. Fuel cell electric vehicles similarly have usable waste heat. Pure battery electric vehicles, however, have much less usable waste heat, limited to cooling losses from the motor and inverter. Electric motors achieve efficiencies of 80–90%, so available waste heat is comparatively limited.

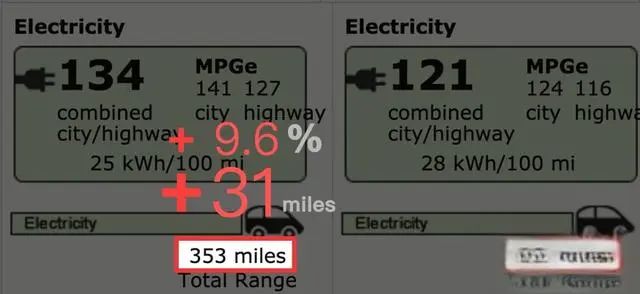

PTC heating directly converts electrical energy to heat by warming coolant or a heater film, and its maximum conversion efficiency is 100% (1 kJ electrical energy produces at most 1 kJ of heat). Heat pumps, however, can achieve effective efficiencies of 200–400% by moving heat from the environment, so adding a heat pump can greatly improve energy utilization. For example, a revised Model 3 with a heat pump gained about 31 miles of range, a 9.6% improvement.

2. Heat pump operating principle

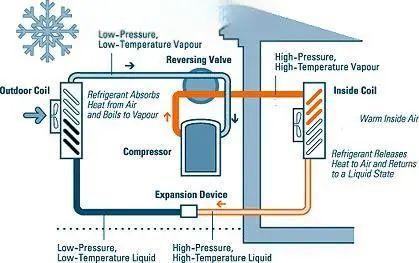

Heat pump air conditioning is based on the reversed Carnot cycle. In heating mode, the system extracts heat from a lower-temperature source and transfers it to a higher-temperature sink using work input from a compressor.

The system efficiency is (heat absorbed from the air + work input to the refrigerant) / compressor power, which can exceed 100%. At very low ambient temperatures the refrigerant evaporation temperature becomes close to the environment, reducing absorbed heat and lowering heat pump efficiency. Many control strategies therefore switch off the heat pump below about -10°C and use high-voltage PTC heating instead.

The coefficient of performance (COP) measures the ratio of heat output to input energy. Higher COP means higher conversion efficiency and lower energy consumption. PTC heating has a COP of 1, while heat pumps have theoretical COPs above 1 and typically achieve 2–4 in practice, producing 2–4 times the heat for the same energy input.

For example, consider a typical EV with 300 km nominal range and a 35 kW energy baseline. If heating power is reduced to 1 kW by using a heat pump, the driving range drops to about 233 km, which is much better than the 192 km with PTC heating. When battery technology is not undergoing step changes, heat pump air conditioning is one of the few effective ways to achieve low-energy heating.

Heat pump technology has been used on many EVs, including the Nissan Leaf, Renault ZOE, VW e-Golf, BMW i3, Jaguar I-PACE, Audi e-tron, KIA Soul EV, and several other models.

3. Model Y heat pump implementation

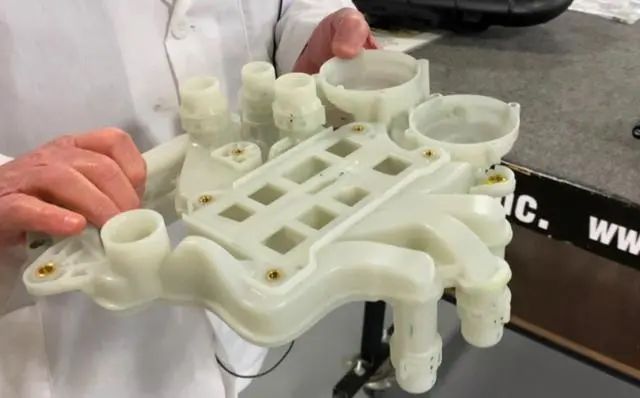

A detailed teardown by Munro highlighted the Model Y thermal management assembly. The thermal management section is highly integrated and compact; the core assembly fits in an area smaller than a small suitcase.

The assembly is located behind the front trunk area and contains the high-pressure compressor, accumulator, coolant expansion tank, condenser, and other components.

The refrigerant module includes a gas-liquid separator, water-cooled condenser, evaporator, and refrigerant bracket. Munro noted that Tesla uses friction stir welding for the aluminum parts of the gas-liquid separator.

The temperature of the thermal control components varies widely during operation. Over time, thermal cycling can degrade parts, and exposure to high temperatures during manufacturing can worsen these effects. This is one reason Tesla uses a partial SpaceX-level approach in some manufacturing steps.

Tesla uses friction stir welding for aluminum refrigeration parts. According to Munro, this process bonds aluminum and compatible materials by stirring and forging the materials in a plasticized state, producing a strong joint with trimmed external edges.

The refrigerant bracket is the core of the refrigerant system. It directs refrigerant flow independently of coolant and uses multiple expansion valves and solenoid valves to route refrigerant through different heat exchangers. The refrigerant alternates between high temperature after the compressor and low temperature after expansion valves. Thermal expansion and contraction can stress the bracket, so engineers added many fine slots to the bracket to mitigate thermal deformation and prevent damage.

A plastic coolant bracket is nested below the refrigerant bracket and handles only coolant flow. This layered design is similar to printed circuit board design, where different layers carry signals, power, and ground. Routing refrigerant on the top layer and coolant on the bottom layer achieves a level of integration that would be difficult with conventional coolant piping.

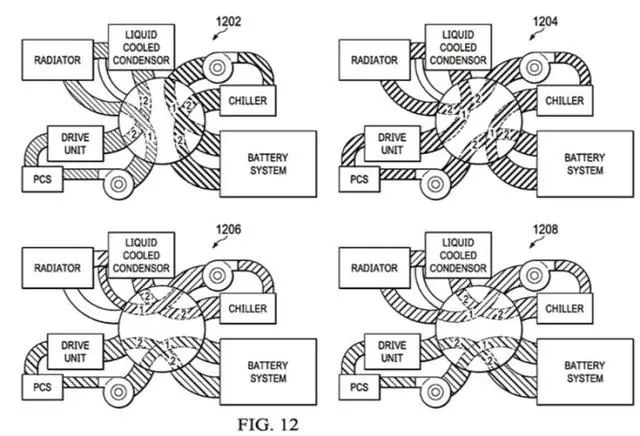

On the rear of the coolant bracket Tesla connects an eight-channel valve, nicknamed the "octovalve." By controlling a stepper motor, the octovalve positions the internal passages to direct coolant flow through different systems for heating or cooling.

For many traditional OEMs, coordinating cabin and battery thermal management across departments is challenging. Producing a compact, highly integrated assembly like Tesla's requires strong organizational support to drive cross-discipline work.

Model 3 refresh may add heat pump with octovalve

Recent overseas media exposures suggest a refreshed Model 3 could include multiple hardware upgrades rather than just software or algorithm updates. Images of the refresh show subtle headlight changes and a thicker trunk support rod, which suggests an electric trunk actuator may be added.

The most significant change appears to be a reduced front trunk volume. The likely reason is that the refreshed Model 3 may adopt the same patented Tesla heat pump plus auxiliary PTC air conditioning system used on the Model Y. Compared with conventional water- or air-based PTC systems, this architecture significantly reduces heating power consumption in cold conditions, improving real-world winter range.

Why does a heat pump plus auxiliary PTC deliver much lower consumption than liquid-cooled or air-cooled PTC? The key difference is that PTC converts electrical energy directly into heat, while a heat pump moves ambient heat into the cabin. PTC is a positive temperature coefficient resistive heater that consumes electrical energy to generate heat, which is then transferred to air (air heating) or coolant (water heating). In other words, PTC is a heat conversion approach, while a heat pump is a heat transport approach.

PTC heating typically has COP around 1. Heat pumps have COPs well above 1 and typically operate between 2 and 4 in real conditions, meaning a heat pump produces 2–4 times the heat for the same energy input. On the same conditions, a heat pump-equipped vehicle can save tens of kilometers of range compared with a PTC-only vehicle in winter operation.

Why many EVs still use PTC

Heat pumps have two main drawbacks: reduced efficiency at very low temperatures and higher cost. At very low ambient temperatures, for example -20°C, a heat pump's COP can be close to 1 because ambient heat is scarce and the system is effectively near a non-working state. In the -10°C to 0°C range, COP is typically 1–2, offering only a modest improvement over PTC. The high-efficiency operating range is above 0°C, and after about 10°C COP can exceed 2.5.

To address low-temperature performance, Tesla's octovalve-based system integrates the heat pump with the battery and drive systems, extracting and combining multiple heat sources. The system is supported by a 12 V auxiliary PTC heater to handle extreme low temperatures. According to Tesla patents and implementations, this integration enables up to 12 operational modes. Importantly, the system operates autonomously, selecting modes based on ambient conditions and vehicle state. Achieving this level of integration requires both advanced control algorithms and an appropriate electronic architecture; currently, Tesla's domain controller approach enables such tight system integration.

Cost is also a factor. Traditional automotive air conditioning units have approximate component costs near 2,000 RMB, while conventional heat pump air conditioning units cost around 3,300 RMB. The Model 3/Y octovalve system is more complex than a standard four-way valve heat pump and requires additional piping and components, which increases system cost and could affect vehicle pricing.

Final notes

The refreshed Model 3 exposure so far is from overseas sources; the author in China speculates the refresh could coincide with variants using CATL battery cells and LFP chemistry. Given potential decreases in battery cost and rising localization of vehicle components, future refreshed models could see lower prices and improved real-world range thanks to the heat pump system.