Introduction

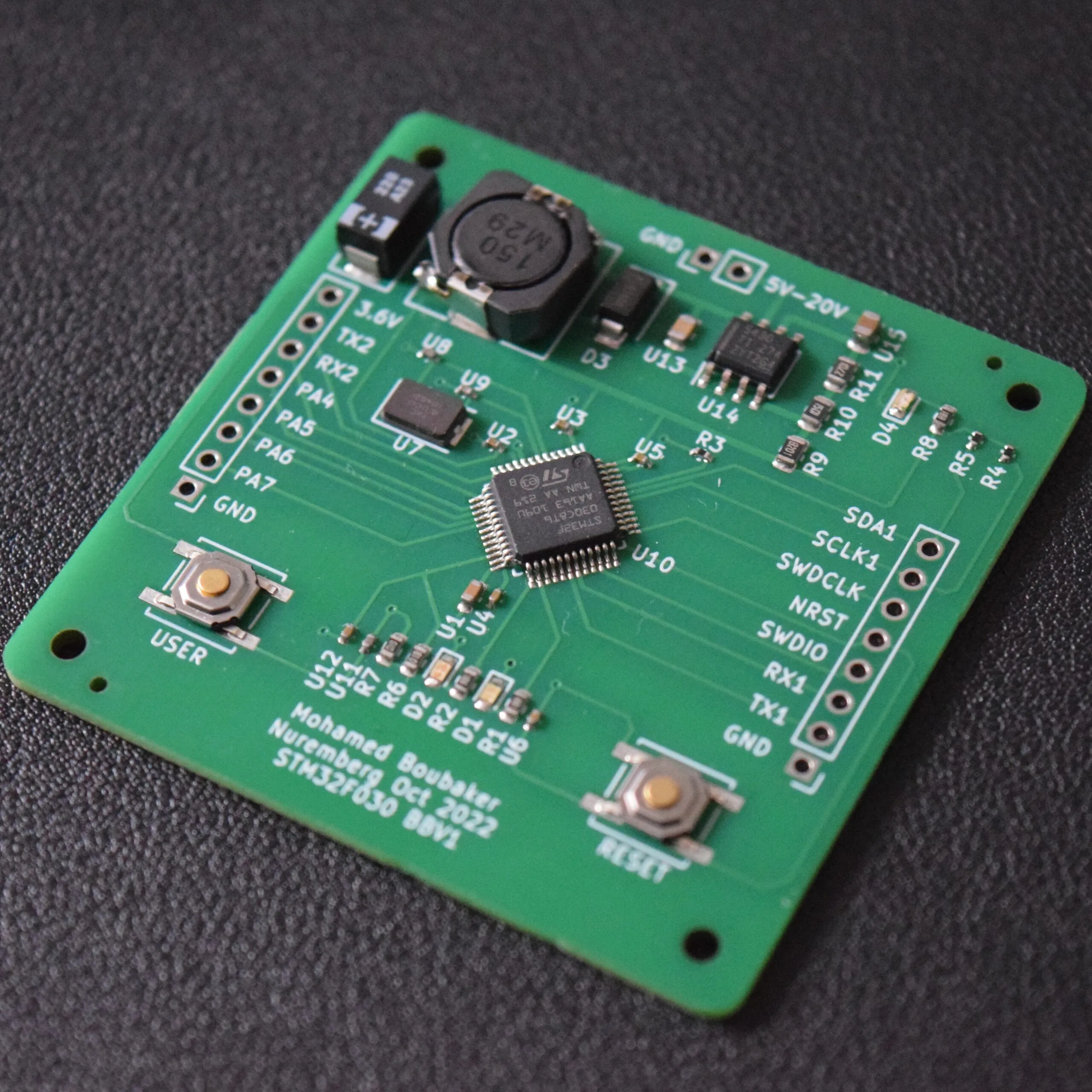

Building and repairing modern electronics at home is entirely practical when equipped with the right tools. Today’s PCBs contain tiny 0402 resistors, fine-pitch ICs, and multi-layer boards that demand precision and reliability. The five tools below form the core of every serious hobbyist and professional prototype bench. Each selection reflects daily production-line experience adapted for home-lab budgets and space.

1. Temperature-Controlled Soldering Station

(Best Soldering Irons for PCB Work)

A genuine temperature-controlled station with fast thermal recovery is non-negotiable. Popular Hakko, Weller, and JBC clones with genuine T12/T15 or 900M tips maintain ±2 °C stability even on large ground planes.

- Digital display and quick heat-up (under 15 s)

- ESD-safe tip grounding

- Interchangeable tips down to 0.2 mm conical for 0402 work

- Sleep/standby mode to extend tip life

Daily tip: keep a 1.0 mm chisel for general work and a 0.4 mm conical for fine-pitch drag soldering.

Related Reading: A Beginner's Guide to Through Hole Soldering: Techniques and Tools

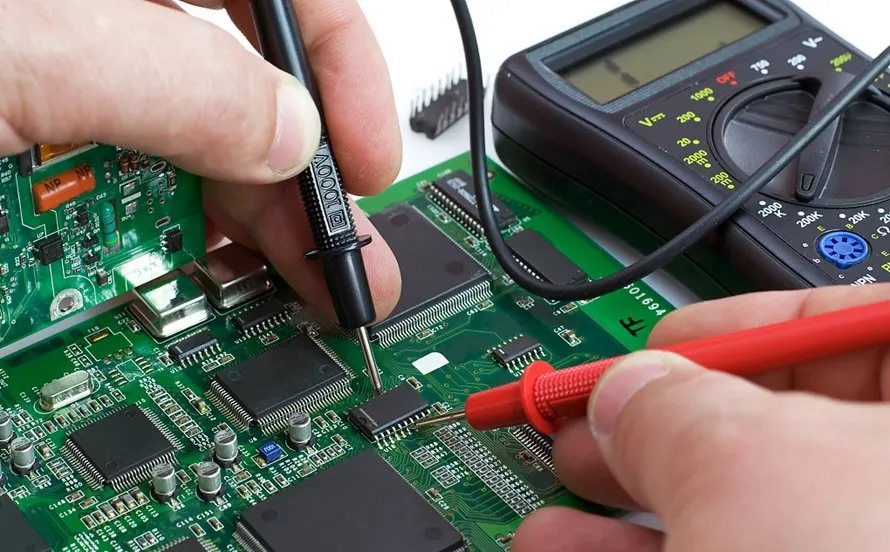

2. High-Quality Digital Multimeter

(Multimeter for Testing PCB Components)

A reliable multimeter with auto-ranging, true-RMS, and at least 6000-count resolution is essential for continuity checks, diode testing, and capacitor measurement.

- Fast continuity beeper (< 50 ms response)

- Diode test with > 2.5 V for LEDs

- Capacitance range to 10 mF

- Low-burden voltage on current ranges

Models such as UNI-T UT139C, ANENG AN870, or Brymen BM257s consistently outperform cheap $10 units when tracing intermittent faults.

3. Stereo Microscope or High-Quality Magnification

(Magnifying Tools for SMD Soldering)

Visual inspection at 10–40× magnification eliminates guessing games with 0402 and 0.4 mm pitch parts.

- 7–45× stereo trinocular microscope with ring light (gold standard)

- USB digital microscope + 10× headset loupe (budget-friendly combo)

Ring light or dual gooseneck LED eliminates shadows and reveals solder bridges instantly.

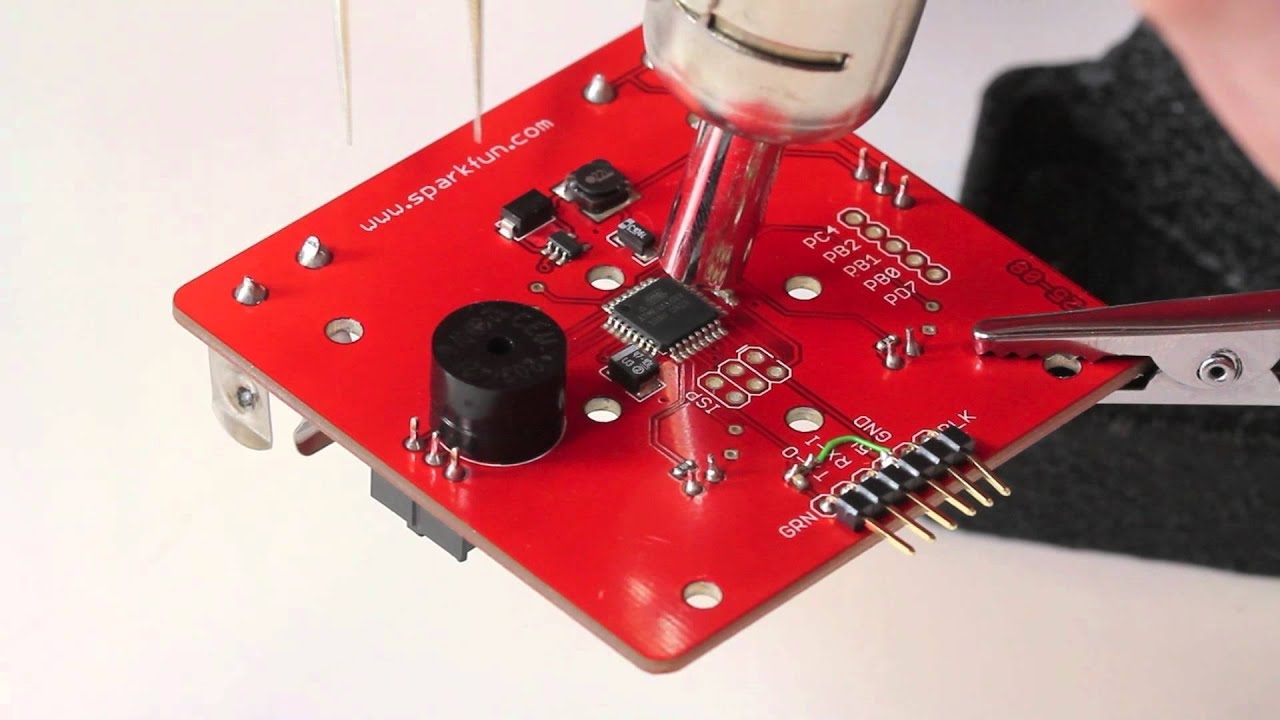

4. Hot Air Rework Station with Adjustable Airflow

(PCB Component Rework Station)

A compact 858D-style or genuine Quick/Atten 861D hot air station removes and installs QFN, SOIC, and 0402–1210 passives safely.

- Closed-loop temperature control (not just heater %)

- Genuine 4–8 mm nozzles

- Airflow adjustable down to 10–20 L/min for small parts

Pro technique: always preheat from the bottom with a 200 °C preheater plate when removing large BGAs or multi-row connectors.

5. Precision Tweezers and Flux Pen

(Essential Electronics Tools for Hobbyists – The Hidden Heroes)

Never underestimate quality reverse-action tweezers and tacky no-clean flux:

- ESD-safe stainless or titanium tweezers (curved + straight)

- RMA or no-clean tacky flux in pen form for perfect wetting

Flux turns difficult oxidized pads into easy joints and prevents bridges during drag soldering.

Bonus Supporting Tools That Save Hours

- Stainless steel helping hands with magnifier (for through-hole work)

- 99% IPA + soft brush for cleaning no-clean residue

- Solder wick 1.5–2.0 mm and quality 0.5–0.7 mm 63/37 or SAC305 wire

- Kapton tape for masking during hot-air work

Related Reading: Upgrading Your Home Batch Assembly Setup for Improved Efficiency

Conclusion

These five core tools (temperature-controlled iron, accurate multimeter, proper magnification, hot-air station, and precision tweezers/flux) enable hobbyists to solder, diagnose, and rework anything from simple Arduino shields to 0.4 mm pitch smartphone repairs. Invest in genuine temperature control and optics first; everything else becomes dramatically easier and more enjoyable.

FAQs

Q1: Can I start SMD soldering with just a basic $20 iron?

A1: Possible for 0603 and larger parts, but cold joints and lifted pads become frequent once ground planes appear. A real temperature-controlled station is the single biggest quality upgrade.

Q2: Is a $60 USB microscope good enough for daily work?

A2: Yes for 0603 and above. Below 0.5 mm pitch or when inspecting inner-layer defects, a 10–45× stereo microscope saves hours of frustration.

Q3: Do I really need hot air if I only hand-solder?

A3: For prototypes and occasional QFP/QFN removal, yes. Hot air is faster and far safer than flood-and-flick techniques with an iron.

Q4: Which multimeter function do hobbyists use most for PCB work?

A4: Fast continuity with audible beep and diode test mode are used multiple times per session when tracing shorts and checking component orientation.

References

IPC J-STD-001H — Requirements for Soldered Electrical and Electronic Assemblies. IPC, 2020.

IPC-A-610H — Acceptability of Electronic Assemblies. IPC, 2020.

IPC-7711/7721C — Rework, Modification and Repair of Electronic Assemblies. IPC, 2017.