What is a Capacitive Sensor and How Does it Detect Materials?

A capacitive sensor functions by emitting an electric field from its sensing surface, allowing it to detect the presence of both solid and liquid targets without requiring direct physical contact. Any object that causes a change in this generated electric field can be successfully identified. This non-contact approach makes capacitive sensors versatile for a wide array of applications.

Capacitive sensors are capable of detecting a broad range of materials. For solids, examples include metals, various plastics, wood, paper, glass, and different types of fabrics. When it comes to liquids, they can sense water, oils, and paints. A notable feature of these sensors is their ability to determine the presence or even the fill level of materials within sealed containers, adding a layer of convenience and functionality.

How Do Capacitive Sensors Operate for Water Leak Detection?

Fundamental Operating Principle

Capacitive water leak sensors identify water presence or changes in liquid levels by measuring variations in capacitance. Capacitance is defined as a component’s ability to store an electrical charge between two conductive plates. When the dielectric material—the insulating substance between these conductors—changes, for instance, from air to water, the capacitance value shifts proportionally.

When water either touches or comes close to the sensor's electrodes, the dielectric constant in the space between these electrodes significantly increases. This is because water possesses a much higher permittivity compared to air. The sensor's circuitry is designed to detect this specific change in capacitance and translate it into an electrical signal, which then indicates the presence of water or a shift in its level. Essentially, capacitive water leak sensors gauge the alteration in the effective dielectric constant between their electrodes. This method enables high precision and enhances immunity to electrical noise, ensuring reliable operation.

Key Benefits of Capacitive Water Leak Sensors

Capacitive water leak sensors offer distinct advantages, making them a preferred choice for various monitoring applications.

Their benefits include:

● High Sensitivity and Accuracy: These sensors can detect even minute quantities of water by precisely measuring capacitance changes.

● Non-Contact Measurement: The sensing element can be completely isolated from the liquid, which significantly improves resistance to corrosion and extends the sensor's operational lifespan. This also allows them to function reliably in dirty or contaminated water without direct electrode wetting.

● Broad Applicability: They are well-suited for diverse scenarios, ranging from industrial monitoring and environmental surveillance to smart home leak detection systems.

● Robust Environmental Adaptability: They maintain stable performance across wide ranges of temperature and humidity, with minimal degradation due to environmental variations.

● Simplified Integration and Scalability: Their design facilitates straightforward integration into existing monitoring systems and supports multi-point monitoring setups, allowing for complex deployments.

Capacitive vs. Resistive Water Sensors: A Detailed Comparison

Detection Sensitivity and Accuracy

Resistive water sensors typically have limitations in terms of sensitivity and accuracy, especially when tasked with detecting pure water or liquids with low electrical conductivity. Their operation relies on the medium's ability to conduct electricity between two exposed electrodes.

Capacitive sensors, in contrast, measure the influence of the surrounding medium on an electric field and are not constrained by the medium's conductivity. This enables them to accurately detect pure water and low-conductivity liquids with superior sensitivity and precision.

Resistance to Corrosion

The exposed electrodes characteristic of resistive sensors are prone to corrosion over time, particularly when exposed to saltwater or corrosive liquids. This can lead to a degradation in performance and significantly reduce their operational lifespan.

Capacitive sensors can be designed as fully sealed units, where the sensing electrodes never make direct contact with the liquid. This design effectively prevents corrosion, supporting extended, stable operation even in harsh environmental conditions.

Environmental Stability

The performance of resistive sensors can be influenced by ambient environmental factors such as temperature fluctuations, which may alter their resistance values and compromise detection accuracy.

Capacitive sensor designs often incorporate features that provide greater tolerance to environmental variations. Temperature effects, for example, can be mitigated through careful design choices or integrated compensation techniques, enhancing stability and accuracy across different conditions.

Susceptibility to Contamination

Resistive sensors are highly sensitive to dirt, deposits, or residues that can accumulate on their exposed electrodes. Such contamination can severely impair their performance.

Due to their non-contact measurement principle, capacitive sensors are considerably less affected by surface contamination. Minor amounts of surface fouling typically do not substantially impact their measurements, thereby reducing maintenance requirements.

Customization and Scalability

The design of resistive sensors may offer less flexibility for complex or highly varied water level detection requirements.

Capacitive sensors provide a higher degree of customizability in terms of shape, size, and circuit design. This adaptability enables precise monitoring of liquid levels in containers of diverse geometries and supports a broader spectrum of application needs.

Total Cost of Ownership

A comprehensive cost analysis of capacitive versus resistive water sensors involves more than just the initial component prices. While the electronic components for a capacitive sensor might initially cost more than those for a basic resistive sensor, capacitive designs frequently offer a better total cost of ownership over their lifetime when considering installation, maintenance, and durability.

Because capacitive sensors can be fully enclosed and operate without direct contact, they generally exhibit greater durability and are less susceptible to degradation from corrosive or contaminated liquids. This can lower the quality requirements for materials used in exposed parts and reduce the frequency of replacements. Resistive sensors, on the other hand, necessitate exposed electrodes made from corrosion-resistant materials and often require more complex sealing and mechanical assemblies, which contributes to higher material and installation costs. Additionally, resistive sensors typically require extra connectors, structural elements, and cabling to link the electrodes to the control electronics, thereby increasing overall system complexity and cost. Capacitive sensors can simplify mechanical design and installation, leading to fewer parts and reduced assembly expenses. Ultimately, despite a potentially higher initial electronic component cost, the non-contact nature and reduced structural and maintenance needs of capacitive sensors can result in lower long-term operational costs.

What Integrated Solutions Are Available for Capacitive Sensing?

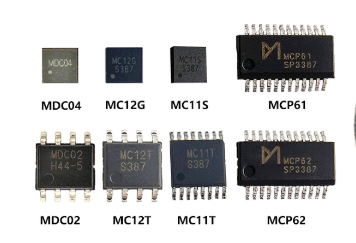

The MC11 Series Chip

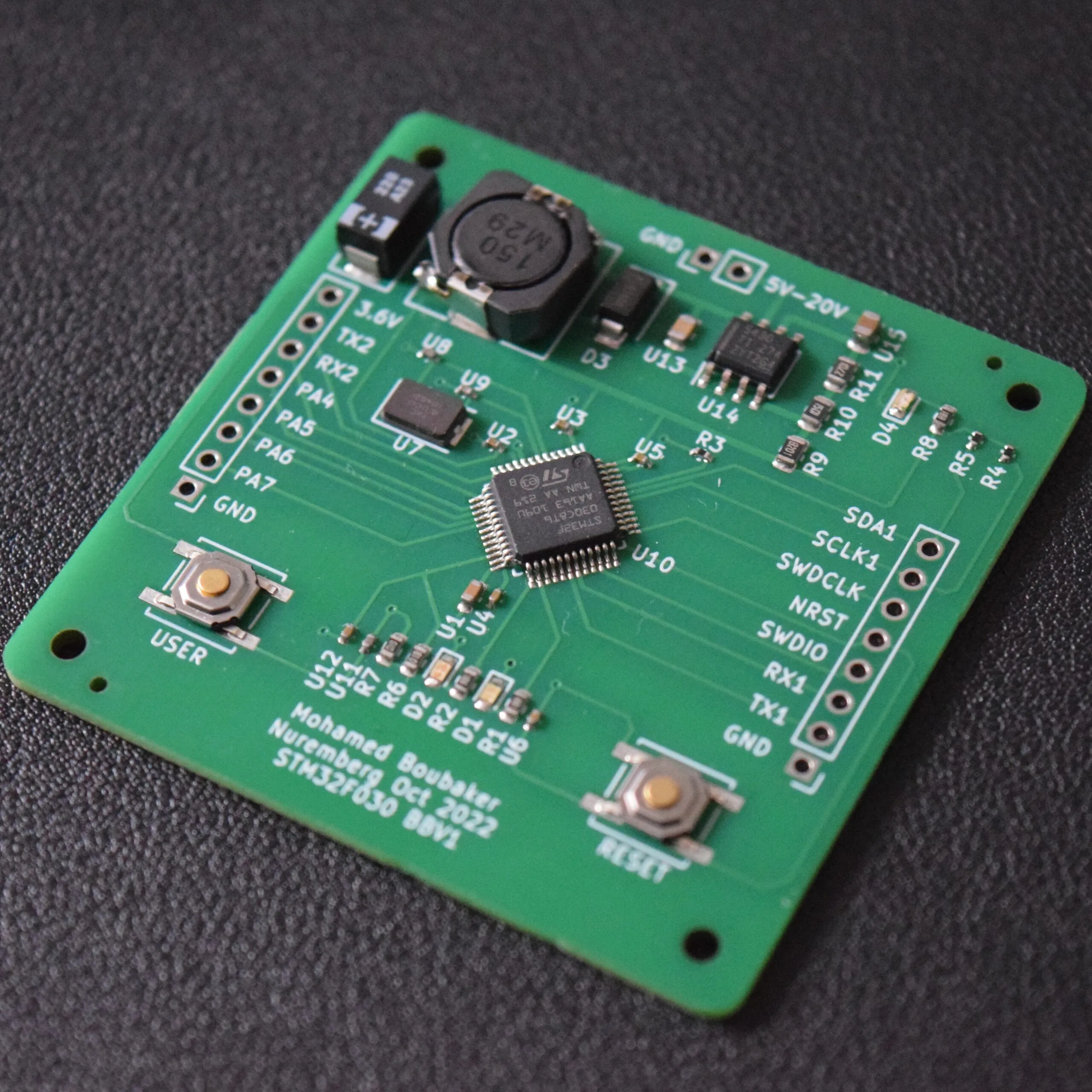

The MC11 series represents a highly integrated, dual-channel capacitive sensing chip. This chip connects directly to sensing electrodes and is capable of measuring minute capacitance changes through a process of resonant excitation and frequency decoding. It also includes an integrated temperature sensor, which facilitates temperature compensation and other related sensing tasks.

In advanced system designs—especially where high routing density, signal integrity, and compact form factors are required—the MC11 can be effectively implemented on an HDI PCB, enabling shorter signal paths, improved EMI control, and enhanced measurement stability in space-constrained layouts.

Compared to other similar products available on the market, the MC11 series requires relatively simple peripheral circuitry, supports a broader range of excitation frequencies and operating voltages, and provides flexible configuration options for reference frequency and operating modes. Its integrated temperature sensing feature aids in compensation. The chip’s independent dual-channel measurement circuits can be configured to reference or compensate each other, and they also support alarm logic settings. The compact package size and cost-effective characteristics make this chip particularly suitable for applications such such as liquid level measurement, touch interfaces, and water leak detection.

The MCP61 Microcontroller SOC

The MCP61 is a microcontroller System-on-Chip (SOC) that integrates a dual-channel capacitive analog front end (AFE CAP). This AFE can connect to differential capacitive electrodes positioned near the object being measured, sensing small capacitance changes via resonant excitation and decoding techniques. The chip also incorporates an Arm Cortex-M0 core microcontroller, which supports embedded signal processing algorithms. These algorithms convert raw oscillation frequency values into capacitance and derived physical quantities like liquid level, moisture content, or displacement. Additionally, the AFE includes an integrated temperature sensor for compensation purposes.

Product Family for Liquid Level and Leak Detection

A comprehensive family of modules and finished sensors has been developed, specifically tailored for liquid level and leak detection applications across various deployment scenarios.

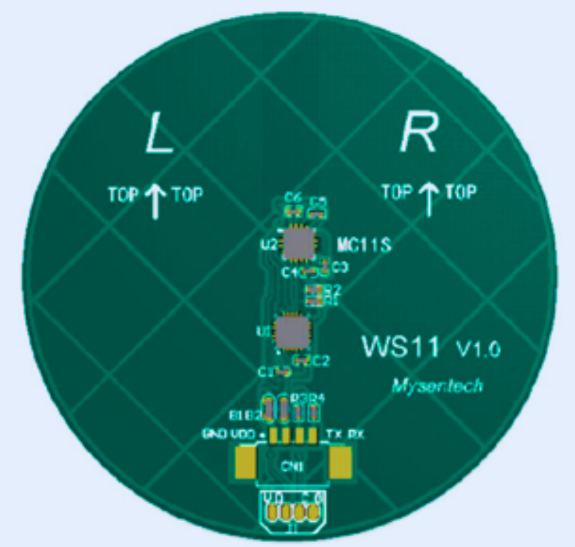

WS11 Series: Non-Contact Leak Sensors

The WS11 series comprises capacitive, non-contact water leak sensors available as either modules or finished products, catering to diverse integration needs. The WS11 communicates with a host or gateway via a UART interface, making it suitable for integration into smart home systems, industrial monitoring, or flood mitigation systems for real-time level monitoring and leak detection.

The WS11 supports ultra-low-power standby modes, significantly extending battery life and reducing maintenance requirements. This series offers configurable sleep and wake strategies, allowing users to balance monitoring frequency and power consumption. For instance, users can set higher monitoring frequencies during critical periods and lower frequencies during low-risk times. The WS11 also provides a continuous digital output that quantifies water presence, enabling precise reflection of leak severity or water level. This continuous data output facilitates detailed data analysis and trend assessment, supporting proactive maintenance and optimization of mitigation measures. These features make the WS11 series an ideal choice for low-power IoT applications.

WS11 Example Use Cases

The versatility of the WS11 series makes it suitable for numerous applications.

● Underground Manhole Water Monitoring: Real-time monitoring of water accumulation beneath manhole covers helps prevent road flooding and pedestrian hazards.

● Server and Telecommunication Rooms: Monitoring for water ingress around sensitive equipment protects electronics and ensures service stability.

● Building Infrastructure: Monitoring for potential leaks, such as pipe bursts, helps protect building structures and reduces costly repairs.

● Smart Homes: Monitoring areas like kitchens and bathrooms for leaks provides timely notifications to occupants.

WLD-485 and WLD-OW: Networked Leak Detection

For applications requiring multi-point leak detection and precise localization, the WLD-485 and WLD-OW sensors are designed for networked deployments. The WLD-485 utilizes an RS-485 bus, while the WLD-OW employs a single-wire bus, enabling daisy-chaining and large-scale network configurations suitable for factories, commercial buildings, data centers, and smart buildings.

By using either RS-485 or a single-wire bus, hundreds of sensors can be connected along a single communication line, forming a distributed monitoring network that simplifies installation. This cascading capability allows alarms to propagate throughout the network when a leak is detected. These sensors can also provide accurate localization of leak points within the network, significantly reducing response time for remediation efforts.

WLD-485 and WLD-OW Example Use Cases

● Underfloor Heating Leak Detection: Early-stage leak detection in buried piping helps limit potential damage and repair costs.

● Tunnel Water Monitoring: Monitoring water ingress in underground tunnels allows for prompt activation of drainage or mitigation measures when abnormal water levels are detected.

WLD-NC/NO: Integrated Relay Output Sensor

The WLD-NC/NO water leak sensor integrates a relay output, converting leak detection into a direct switch signal. This relay can be used to control electrical equipment directly, triggering actions such as automatic power cut-off, activation of drainage pumps, or other safety protocols. The sensor offers both Normally Closed (NC) and Normally Open (NO) output modes for flexible integration into various systems.

This integrated relay simplifies installation and allows for seamless integration into existing safety, automation, or smart home systems without the need for additional intermediary devices. Users can also configure specific trigger thresholds for more precise control.

WLD-NC/NO Example Use Case

● Power Cabinets: Deploying water leak sensors within power cabinets enables the detection of water intrusion. The integrated relay outputs can then automatically disconnect power, thereby reducing the risk of equipment damage, short circuits, or fire.