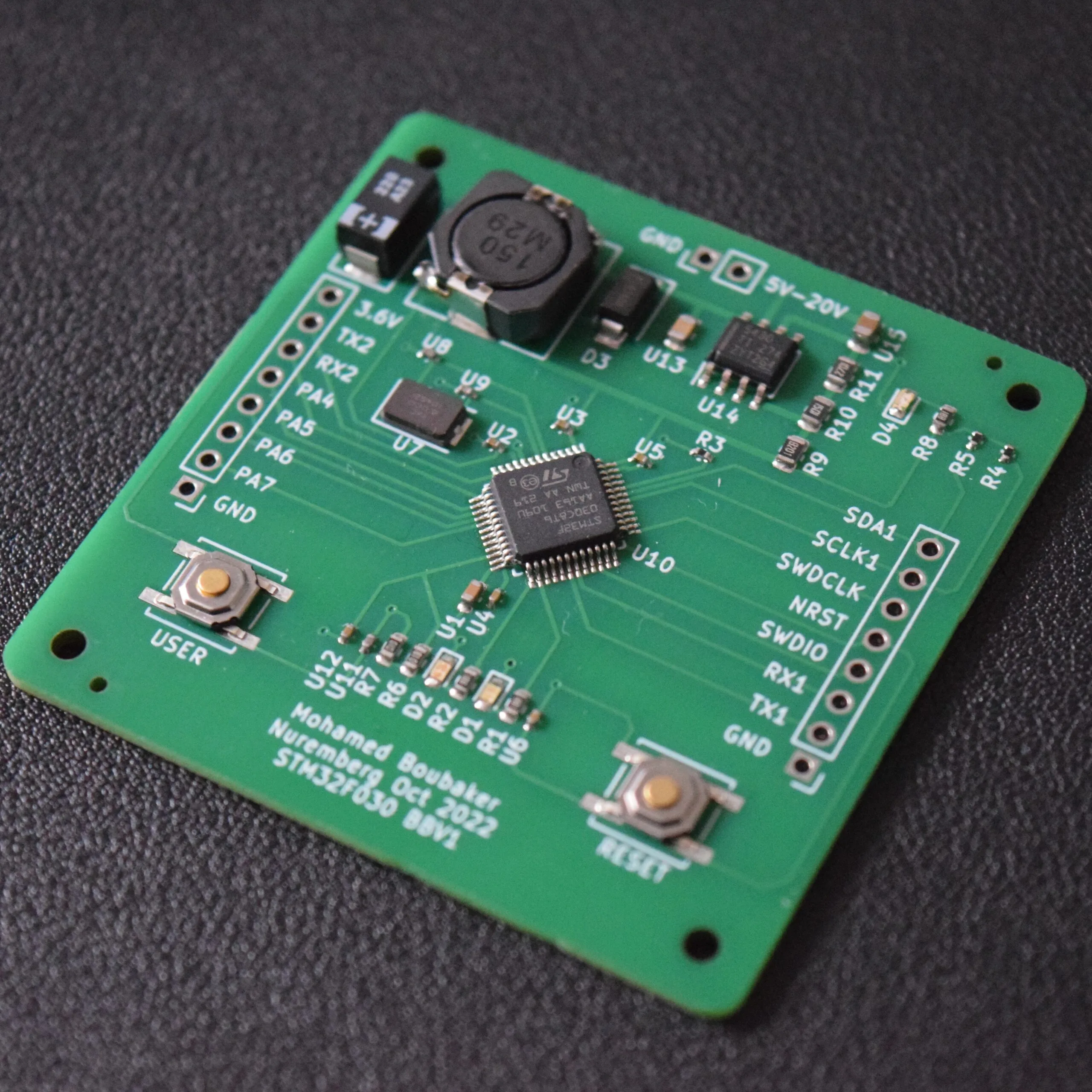

What Are the Core Components for a Minimal STM32 Microcontroller System?

Many developers, when learning about STM32 microcontrollers, often focus heavily on software development while inadvertently neglecting the crucial hardware aspects. This can lead to proficiency in using pre-made development boards but significant challenges when attempting to design a custom STM32 system from the ground up. This article aims to bridge that gap by providing a comprehensive guide to designing a truly minimal, yet functional, system for an STM32 microcontroller.

A minimal STM32 system comprises the fundamental components necessary for the microcontroller to operate correctly and provides the essential environment for the STM32 MCU to execute its functions. The primary building blocks of such a system include:

● Power Supply Circuit: Provides the correct operating voltages.

● Clock Circuit: Generates the necessary timing signals.

● Programming and Debug Circuit: Allows for code upload and debugging.

● Reset Circuit: Enables system initialization and recovery.

● Boot Mode Selection: Configures the MCU’s startup behavior.

While an STM32 MCU can technically function with just a power supply and a reset circuit, leveraging its internal clock, practical applications typically necessitate the other circuits to ensure the system is flexible, stable, resilient to interference, and fully debuggable. The minimal system outlined here is based on the popular STM32F103RCT6 microcontroller.

Designing the Power Supply and Clock Circuits for STM32

Power Supply Circuit Essentials

When initiating the power supply design, the first step involves determining the input voltage source. In this specific design, a 5V USB power source is utilized. Given that the microcontroller's core operating voltage is 3.3V, a voltage regulator becomes indispensable. The AMS1117-3.3 chip is a common choice, effectively stepping down the 5V input to the required 3.3V for the MCU.

In applications demanding a high signal-to-noise ratio, it's critical to isolate the analog and digital power domains to prevent mutual interference. VDDA serves as the power supply for the Analog-to-Digital Converter (ADC) and Digital-to-Analog Converter (DAC) modules. VREF+ is the positive voltage reference input, while VREF- is the negative. It is standard practice to connect VREF+ to VDDA and VREF- to VSSA (analog ground). Generally, a simple low-pass filter, such as an RC (Resistor-Capacitor) or Pi filter, placed between the digital power supply (VDD) and the analog power supply (VDDA) is sufficient for effective isolation. The digital and analog grounds can be separated using a 0Ω resistor or a ferrite bead. In less demanding applications, they can be directly connected to a common ground plane.

Clock Circuit Configuration

According to official STM32 datasheets, the High-Speed External (HSE) clock can be driven by a crystal oscillating anywhere from 4MHz to 16MHz. An 8MHz crystal is frequently chosen due to its ease of multiplication by the Phase-Locked Loop (PLL) to generate higher frequencies for various internal peripherals. The clock circuit typically comprises the crystal itself, along with essential load capacitors, and often includes an optional feedback resistor in the megaohm (MΩ) range. If an external high-speed clock is not used, the OSC_IN pin should be grounded, and the OSC_OUT pin should be left floating to prevent unwanted noise or oscillations.

The Low-Speed External (LSE) clock utilizes a 32.768kHz crystal. This specific frequency is chosen because 2^15 equals 32768, allowing it to be easily divided down in a register to produce a precise 1Hz signal. This makes it an ideal clock source for the Real-Time Clock (RTC) module, crucial for timing applications such as perpetual calendars.

Understanding Crystal Oscillators vs. Crystal Resonators

The choice between crystal types is important for clock circuits:

● Passive Crystal (Resonator): These are flexible, generally offer sufficient precision for many applications, are cost-effective, and require external load capacitors to function correctly.

● Active Crystal (Oscillator): These offer superior stability, include internal oscillation circuitry, require an external power supply for operation, and do not need additional external support components like load capacitors.

Essential Reset and Boot Mode Selection for STM32 Systems

The Importance of a Reset Circuit

A robust reset circuit is fundamental to ensuring the stable and reliable operation of any STM32 system. Its primary function is to return the microcontroller to a known initial state. This is critically important for recovering from unforeseen program faults, ensuring proper initialization upon power-up, and preparing the system to receive new instructions or firmware updates without errors.

Configuring Boot Mode Selection

STM32 microcontrollers incorporate configurable BOOT0 and BOOT1 pins, which determine the memory area from which the MCU will attempt to fetch its instructions upon reset. This allows for flexible startup options:

● Main Flash Memory: This is the default boot mode, where the microcontroller executes the user application code stored in its internal Flash memory.

● System Memory (Bootloader): Selecting this mode causes the MCU to execute a built-in bootloader program, typically used for serial programming or firmware updates via interfaces like UART or USB without the need for a dedicated debugger.

● Embedded SRAM: In this mode, the MCU executes code that has been loaded into its internal Static Random-Access Memory (SRAM). This is often used for fast, temporary code execution or during early development stages.

Practical Considerations for STM32 Chip Selection and Pin Functions

Strategic STM32 Chip Selection

When embarking on an STM32 project, the initial step involves selecting the most appropriate chip based on the project's specific functional requirements. After clearly defining all necessary features and performance criteria, developers can utilize STMicroelectronics' official selection guides or download detailed datasheets to identify a suitable microcontroller that aligns with their needs. This systematic approach ensures that the chosen MCU has the necessary peripherals, memory, and processing power.

Understanding Chip Pin Functions

During the system design phase, it is absolutely imperative to consult the chip's datasheet to confirm the precise functions of every pin intended for use. For example, if an external low-speed crystal is required, the datasheet will explicitly identify the corresponding pins (e.g., PC14 and PC15 for the STM32F103RCT6, a 64-pin package). This critical information is then directly translated into the schematic diagram to correctly connect all external circuitry, ensuring proper functionality and avoiding potential wiring errors.