Overview

Wide-field cameras are the core instruments of wide-field telescopes. Because the size of a single sensor is limited, a single sensor cannot cover the required large focal plane. Therefore, tiling of large-area detectors is a key technology for building wide-field cameras. High-precision focal-plane tiling requires both high-precision fabrication and measurement. Since detectors typically operate at low temperatures to reduce dark current, measurements must be performed at both room temperature and operating low temperature to ensure good flatness of the detector at operating temperature and thus improve imaging quality.

WFST and the Prime-Focus Camera

Based on developments in astronomical science and technology, and leveraging existing research capabilities, the University of Science and Technology of China and the Purple Mountain Observatory proposed to jointly build a 2.5 m wide-field survey telescope (Wide Field Survey Telescope, WFST) to provide leading time-domain survey capability in the Northern Hemisphere.

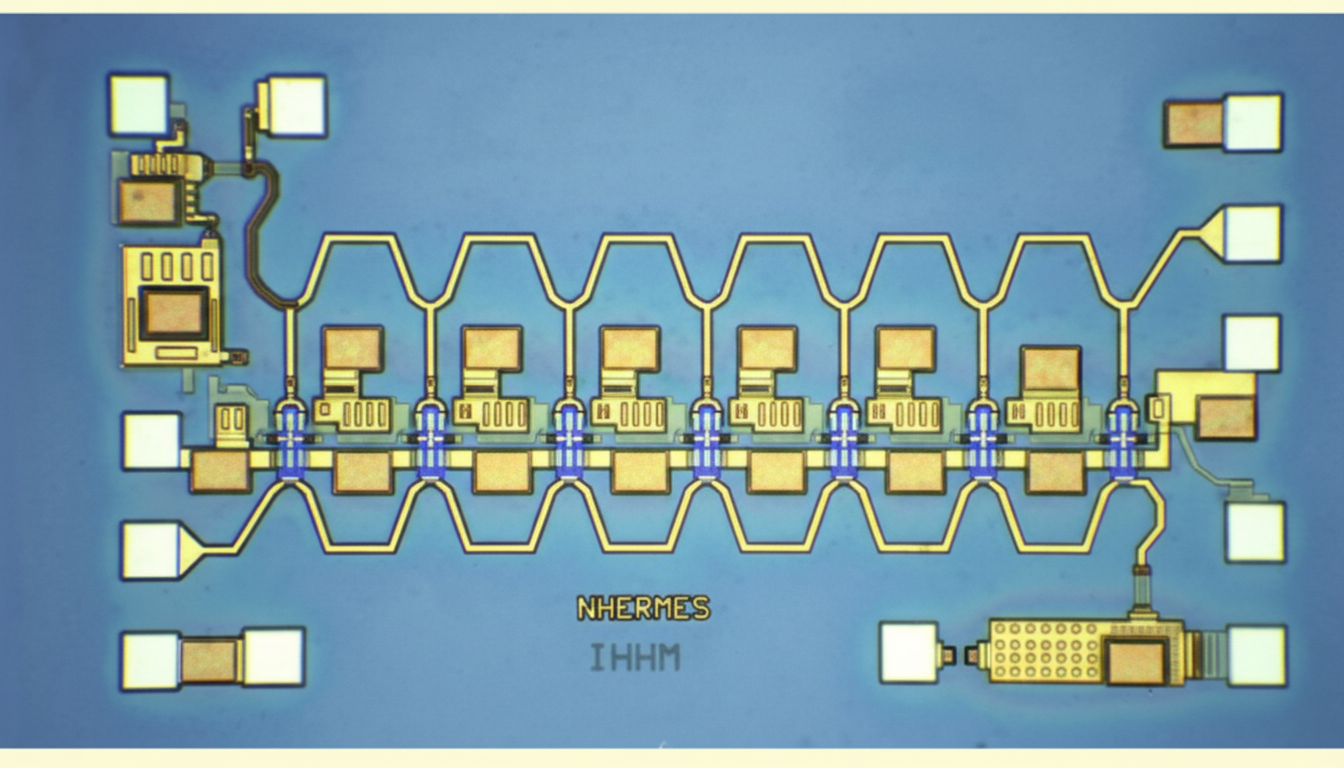

The large focal-plane tiled prime-focus camera is a key instrument of the WFST. The science imager is formed by tiling nine 9k × 9k CCD chips, producing a designed focal-plane diameter of D325 mm and a tiling flatness of less than PV 20 μm. It is the largest prime-focus camera in China and reaches internationally competitive performance. Figure 1 shows the camera. Table 1 indicates that WFST has the most stringent focal-plane flatness requirements. The main development challenge is achieving high-precision measurements, especially under low.

Measurement Method

Under the leadership of Professor Jian Wang, deputy chief designer of the WFST and of the Laboratory of Nuclear Detection and Electronics at the University of Science and Technology of China, the camera team addressed key technologies for the prime-focus camera, including vacuum cryogenic packaging of detectors, high-precision measurement and tiling of large-area detectors, low-noise low-power detector readout and drive electronics, and efficient camera control.

For high-precision measurement of large-area detectors, the team solved the challenge of non-contact flatness measurement at low temperatures. Based on laser triangulation, they proposed a differential triangulation measurement method suitable for sensors under cryogenic packaging. Under vacuum packaging, measurement error does not exceed 0.5%, and repeatability reaches ±2 μm.

DTS Instrument and Results

On this basis, the DTS measurement instrument was developed, and final measurements of the WFST prime-focus camera under low-temperature conditions were completed. The WFST prime-focus camera development is now complete and has been shipped to the observatory for installation and integration testing.

Publication

Related results were published in July 2023 in IEEE Transactions on Instrumentation and Measurement.