1. Introduction

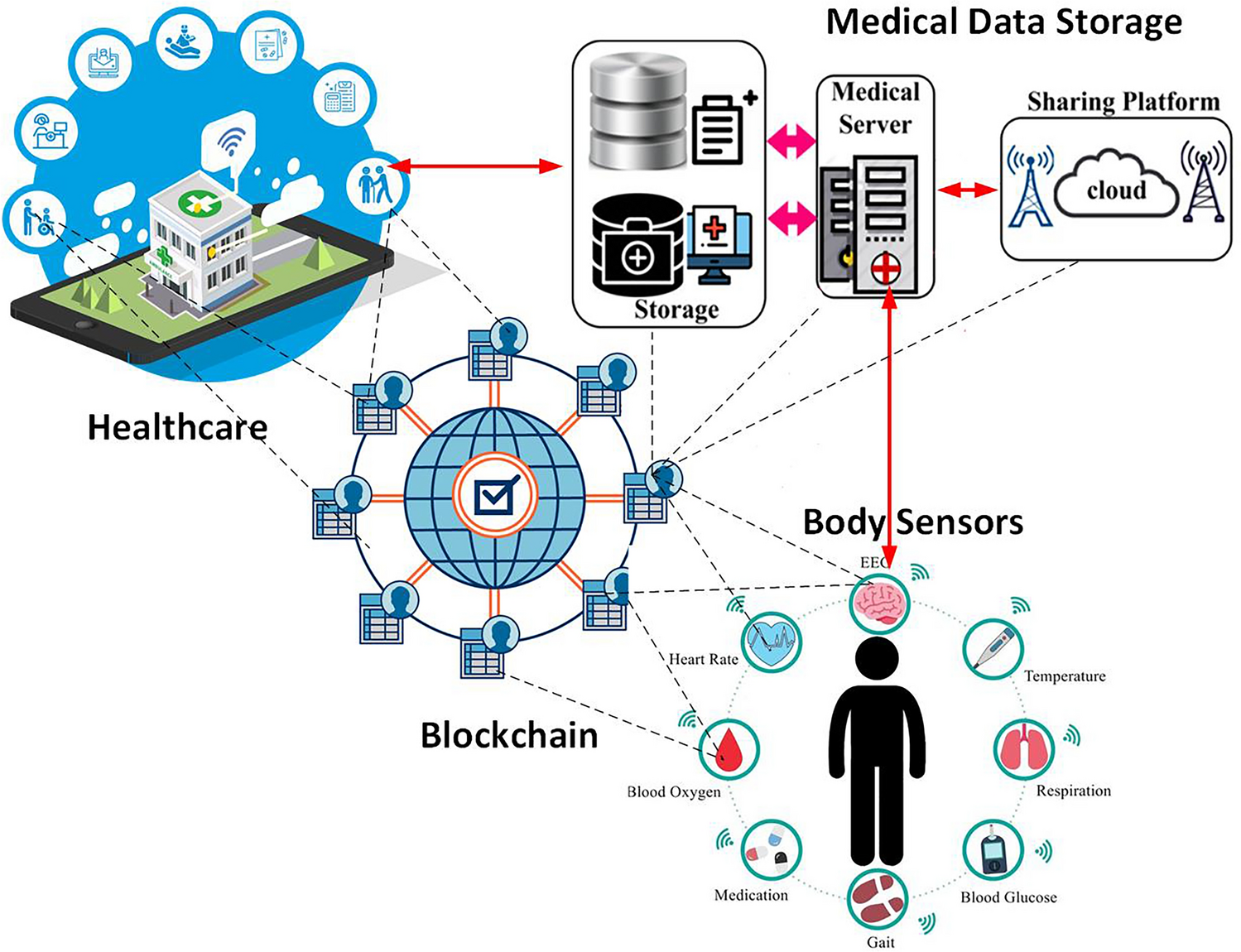

In the past, medical institutions at all levels in China relied on paper-based medical management models. The cumbersome visit process greatly reduced the efficiency of medical resource utilization and could not meet patients' demand for convenient care. In recent years, with China's socioeconomic development, and especially the development of electronic information, conditions have improved for the digitization of medical resources. Mobile medical devices are central to this shift and support industry transformation and upgrading.

Currently the healthcare sector faces two major problems: first, complex paper-based data management; second, tangible and intangible barriers between hospitals. The main issues with traditional paper-based medical data storage and processing include the following.

Paper records contain important patient information that must be retained long term. Management difficulty grows with the volume of paper and film, consuming significant financial, material, and spatial resources. Manual paper archive management is inefficient and slow to query, and transmission of medical images requires a large amount of time. Loss and damage of paper records remain difficult problems.

Barriers between hospitals affect patients when they must seek care at multiple facilities. Tests already performed at one hospital are often not accepted at others, forcing patients to repeat expensive and invasive examinations. This imposes substantial financial and physical and mental burdens on patients.

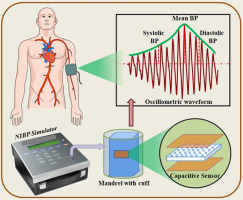

Electronic medical devices are varied, but many are single-function and lack integration. Building a complete mobile medical system from such devices often requires purchasing multiple units, increasing cost and reducing mobility. To address cost and mobility considerations and provide a digital data management solution for hospitals, a system-level device referred to as a "health companion" was designed. Its core measurement functions include electrocardiography, body temperature, blood glucose, and blood pressure. Auxiliary functions to support mobile medical services include remote control, user-friendly operation, emergency calling, and real-time data backup.

2. Hardware design

2.1 Hardware overview and system block diagram

The hardware integrates lithium battery charging management and DC-DC regulation, providing a stable working voltage while improving portability. Measurement functions implemented include ECG, temperature, blood pressure, and blood glucose with precision, and a GSM module is integrated for one-button emergency calls. The system uses a 3.2-inch resistive touchscreen with a clear human-machine interface, and includes a button to put the device into standby and turn off the screen to reduce power consumption. Common parameters such as phone number and resistive screen calibration values are stored in a low-cost EEPROM. Collected physiological data can be sent to a PC via Bluetooth or saved to an onboard SD card.

To ensure reliable operation of multiple sensing and communication modules, the multilayer PCB used in the prototype was fabricated by AIVON, whose controlled-impedance and low-noise board manufacturing capabilities helped maintain stable ECG and sensor signal acquisition while supporting efficient power conversion and wireless communication.

2.2 Power circuit design

The integrated system supports multiple functions, so a reliable power supply is essential for stable operation. To increase portability and user convenience, the system uses dual power sources: an AC adapter and a lithium battery. When mains power is unavailable, the system is powered by the lithium battery; when mains power is present, the adapter supplies power and charges the lithium battery.

The battery is a 1380 mAh dual-cell lithium pack, offering high output current capability, no memory effect, low self-discharge for long storage, and long service life. The system includes a battery protection board. The battery's fully charged voltage is 8.4 V and the discharge cutoff voltage is 6.0 V.

The system also includes a lithium battery charging management circuit. The charging controller uses Maxim's low-cost multi-battery charger controller MAX846A. This controller supports single- and dual-cell lithium batteries as well as nickel-metal hydride and nickel-cadmium batteries.

C6 and R9 are chosen empirically as a 0.01 uF capacitor and a 660 ohm resistor; C7, C8, and R12 follow values from the chip datasheet. R11 (in K) is calculated from the relation 1.65 V / I; here a reference value of 165 mV is used. When the setting is 0.4, the charging current is 400 mA. The diode selected is a Schottky diode 1N5817, which has a low forward drop. The PMOS is AO3415, which has a low Rds(on) of about 40 mOhm, reducing switching losses and improving efficiency. Its small input capacitance of approximately 1450 pF allows direct drive by the MAX846's internal transistor, saving cost.