Overview

Environmental energy sources are abundant worldwide. Traditional energy harvesting approaches use solar panels and wind turbines, but newer harvesters can generate power from a variety of ambient sources. The primary design metric for these circuits is not absolute conversion efficiency but the average harvested energy available to power a circuit. Examples include thermoelectric generators that convert heat to electricity, piezoelectric elements that convert mechanical vibration, photovoltaic cells that convert sunlight or other photon sources, and hygroscopic generators that extract energy from moisture. These harvesters can power remote sensors, or charge energy storage devices such as capacitors or thin-film batteries, allowing microprocessors or transmitters to operate without a local power supply.

Requirements for Energy-Harvesting Power ICs

Because harvested energy is typically at the low end of the power spectrum, energy conversion at the microwatt to nanowatt level is increasingly important for wireless sensor networks and sensors. Power-conversion ICs must operate at very low power and current levels, often tens of microwatts and tens of nanoamps. Products that support operating currents below 1 μA, including battery chargers, are relatively scarce.

Key characteristics needed for adoption in these applications include:

- Low quiescent standby current, typically under 6 μA and down to hundreds of nA

- Low startup voltage, down to about 20 mV

- High input-voltage capability, up to 34 V continuous and 40 V transient

- Ability to handle AC inputs

- Multiple outputs and autonomous system power management

- Maximum power point control (MPPC) for solar inputs

- Small solution size with minimal external components

Energy Harvesting and System-Level Considerations

Wireless sensor networks are typically self-contained systems in which sensors convert ambient energy into electrical signals, and downstream DC/DC converters and power managers supply appropriate voltages and currents to electronics such as a microcontroller, sensor, and transceiver. A central design question is how much power the system needs. In practice this is complex: sampling interval, data packet size, and transmission energy all matter. Transceiver energy can account for roughly half of the energy required for a single sensor reading plus packet transmission. Many factors influence the power profile of an energy-harvesting system and must be considered in design.

Harvested power depends on how long the power source operates, so power density is the primary metric for comparing harvesters. Available power from harvesters is typically low, variable, and unpredictable. A common architecture combines an energy harvester with an auxiliary energy storage device. The harvester acts as the energy source but delivers limited instantaneous power, while the auxiliary storage (battery or capacitor) can supply higher output power for short bursts and is periodically recharged by the harvester. Designers must therefore determine how much energy to store to cover gaps in harvested power.

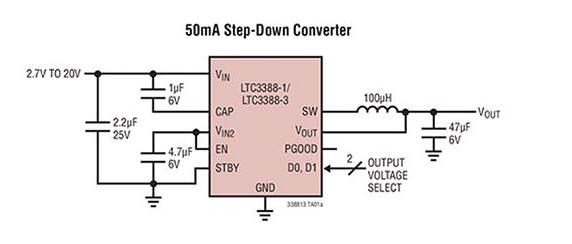

LTC3388-1 and LTC3388-3: Low-Quiescent Buck Converters

To support these low-power systems, Linear Technology developed the LTC3388-1/-3 and LTC4071. The LTC3388-1/-3 are synchronous buck converters that accept up to 20 V input and provide up to 50 mA continuous output current. They are available in a 3 mm x 3 mm package or MSOP10-E. The input operating range is 2.7 V to 20 V, making them suitable for various energy-harvesting and battery-powered applications, including always-on circuits, sensors, and industrial control power supplies.

The LTC3388-1/-3 use hysteretic synchronous rectification to optimize efficiency across a wide load current range. They deliver over 90% efficiency across 15 μA to 50 mA loads while drawing only 400 nA of static current, which helps extend battery life when a battery is used as auxiliary power.

The devices include accurate undervoltage lockout (UVLO) that disables the converter when input voltage falls below about 2.3 V, reducing static current to approximately 400 nA. In regulation with no load, the converters enter sleep mode to minimize static current to about 720 nA. The buck switches on and off as needed to maintain output regulation. An additional standby mode is provided to inhibit switching when the output must be regulated for short-term loads such as low-ripple wireless modem loads. This combination of high efficiency and low quiescent current suits energy-harvesting applications that require long charge periods and short burst loads for sensors and wireless modems.

LTC4071: Low-Current Battery Charger and Protector

Batteries are often used as auxiliary backup power in wireless sensor networks, but charging them from very low-power sources poses challenges. The LTC4071 is a parallel battery charger system with integrated battery-pack protection and low-battery disconnect to protect low-capacity batteries from damage due to self-discharge. It is a compact charger and protector suitable for lithium-ion and lithium-polymer batteries. Its ultra-low 550 nA operating current allows charging from extremely low-current, intermittent, or continuous sources such as energy harvesters. An internal battery thermal regulator reduces float voltage to protect Li-ion/Li-polymer cells, coin cells, or thin-film batteries as temperature rises. The LTC4071 is offered in a flat 8-pin 2 mm x 3 mm DFN package and requires only a single external resistor in series with the input voltage for a complete, compact charging solution.

Design Implications

Although portable and energy-harvesting applications span many power levels from a few microwatts to over 1 W, the choice of power-conversion ICs becomes limited at the very low end of the power range. Solutions such as the LTC3388-1/-3 and LTC4071 provide low static currents below 1 μA, helping extend battery life in low-power sensors and next-generation wireless sensor networks that require always-on operation.