Introduction

Mixed assembly, combining Surface Mount Technology (SMT) and Through-Hole Technology (THT), is a cornerstone of modern electronics manufacturing. This approach allows electrical engineers to leverage the compactness of SMT components alongside the mechanical strength of THT parts. However, achieving robust connections in such assemblies demands advanced soldering techniques tailored to the unique challenges of each method. Soldering techniques for mixed assembly must address thermal profiles, material compatibility, and process sequencing to prevent defects. Issues like uneven heating or poor joint formation can compromise reliability. This article explores SMT and THT soldering methods, focusing on reflow soldering for mixed assembly and wave soldering for THT components. By understanding these processes, engineers can optimize assembly for durability and performance in demanding applications.

What Is Mixed Assembly and Why It Matters

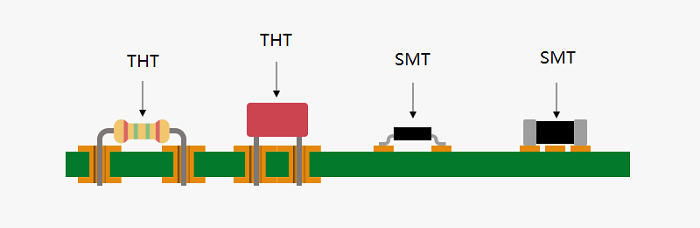

Mixed PCBA assembly refers to the integration of SMT and THT components on a single printed circuit board (PCB). SMT components, mounted directly onto the board surface, enable high-density designs critical for compact devices. THT components, inserted through holes and soldered on the opposite side, provide superior mechanical stability for connectors or high-power elements. This combination is prevalent in industries like automotive, aerospace, and industrial controls, where space efficiency and reliability are paramount. The challenge lies in soldering these diverse components without inducing thermal stress or defects. Proper soldering techniques for mixed assembly ensure signal integrity and long-term performance. Without precise methods, issues like tombstoning in SMT or insufficient hole fill in THT can lead to failures. Mastering these techniques is essential for engineers aiming to meet stringent quality standards.

Technical Principles of Soldering in Mixed Assembly

Soldering in mixed assembly involves distinct mechanisms for SMT and THT components, often requiring multiple processes. SMT relies on reflow soldering, where solder paste is applied to pads, components are placed, and the board is heated in a controlled oven. The solder melts, forming joints as it cools. THT typically uses wave soldering, passing the board over a molten solder wave to fill through-holes and create connections. In mixed assembly, sequencing is critical. Reflow soldering for mixed assembly often precedes wave soldering to avoid damaging SMT parts. Thermal profiles must be tailored to prevent excessive heat exposure. Standards like IPC-J-STD-001H provide guidelines for acceptable solder joint criteria, ensuring reliability. Understanding these principles helps engineers mitigate risks like component misalignment or solder voids during production.

Challenges in Mixed Assembly Soldering

Combining SMT and THT introduces unique hurdles. SMT components are sensitive to high temperatures, risking damage during wave soldering for THT components. Conversely, THT parts may not achieve proper hole fill if thermal profiles are optimized only for SMT. Solder joint stress can occur due to differing coefficients of thermal expansion between components and the board. Additionally, shadowing effects in wave soldering can leave some THT pins unsoldered. Adhering to standards such as IPC-7530A, which outlines thermal profiling for reflow and wave soldering, is vital for consistency. Engineers must balance process parameters to address these issues, ensuring both component types form reliable connections without compromising board integrity.

SMT and THT Soldering Methods: Key Approaches

Reflow Soldering for Mixed Assembly

Reflow soldering is the primary method for SMT components in mixed assembly. It involves applying solder paste, placing components, and heating the board in a multi-zone oven. The process includes preheating, soaking, reflow, and cooling stages, each governed by a thermal profile. For mixed assembly, profiles must account for THT components if present during reflow. Overheating can cause THT leads to oxidize, while underheating risks poor SMT joints. IPC-7530A emphasizes maintaining peak temperatures and ramp rates within specified limits to avoid defects like tombstoning. Engineers should use nitrogen atmospheres in reflow ovens if oxidation is a concern, enhancing joint quality for SMT parts.

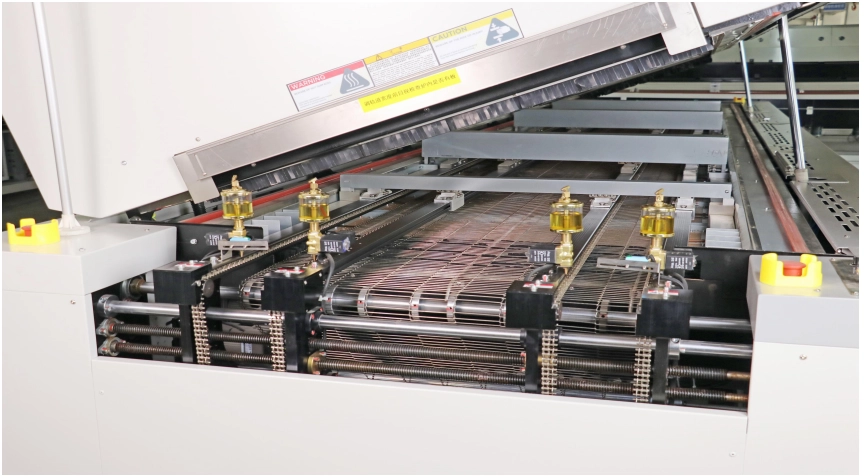

Wave Soldering for THT Components

Wave soldering is ideal for THT components, especially in mixed assembly after reflow. The process passes the PCB over a molten solder wave, filling through-holes and forming joints. Key parameters include solder temperature, conveyor speed, and flux application. Typical solder pot temperatures range within limits defined by IPC-J-STD-001H to ensure proper wetting without thermal shock. For mixed assembly, protective masking or pallets may shield SMT components from the wave. Incomplete hole fill or bridging are common defects if parameters are not optimized. Engineers must adjust dwell time and preheat settings to achieve uniform soldering across THT leads.

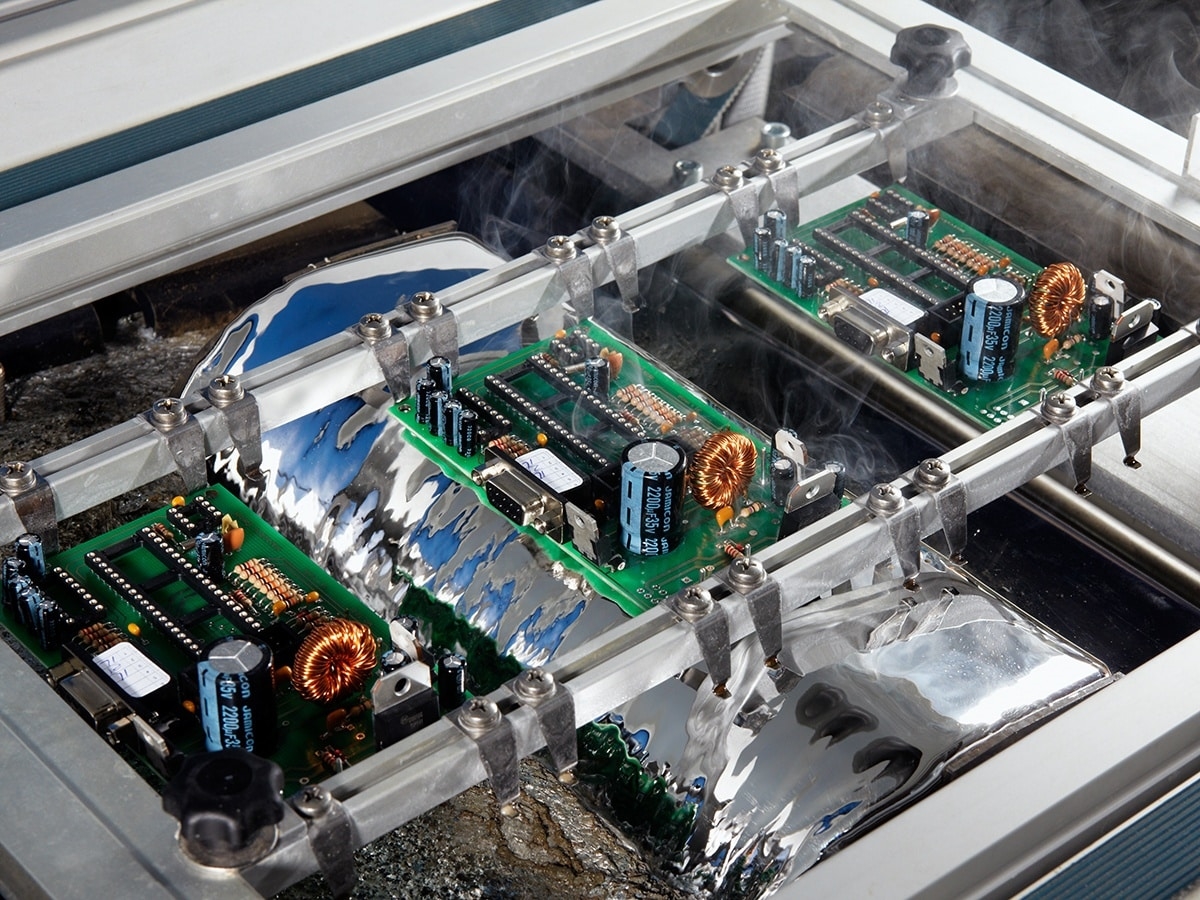

Selective Soldering as an Alternative

Selective soldering offers precision for mixed assembly when wave soldering risks damaging SMT parts. This method uses a targeted solder fountain to address specific THT areas, minimizing thermal exposure elsewhere. It is slower than wave soldering but ideal for complex boards with dense SMT populations. Process control, guided by standards like IPC-J-STD-001H, ensures accurate joint formation. Engineers can program selective soldering machines to handle varying component heights, reducing the need for manual rework. This technique enhances flexibility in mixed assembly, especially for prototypes or low-volume production.

Suggested Reading: A Comprehensive Guide to FR 4 PCB Soldering Techniques and Best Practices

Best Practices for Robust Connections in Mixed Assembly

Achieving reliable solder joints in mixed assembly requires strategic planning and execution. Below are actionable practices for engineers to implement during design and production phases.

- Optimize Assembly Sequencing: Perform reflow soldering for mixed assembly first, followed by wave soldering for THT components. This minimizes thermal stress on SMT parts.

- Tailor Thermal Profiles: Use guidelines from IPC-7530A to create reflow profiles that accommodate both SMT and THT components if processed together. Monitor peak temperatures to prevent damage.

- Apply Protective Measures: Use heat-resistant tapes or custom pallets during wave soldering to shield SMT components from excessive heat or solder contact.

- Ensure Material Compatibility: Select solder alloys and fluxes compatible with both SMT and THT requirements. Follow IPC-J-STD-006C for solder material specifications.

- Inspect and Test Joints: Post-soldering inspection per IPC-A-610H standards helps identify defects like voids or insufficient hole fill. Automated optical inspection can enhance accuracy.

Consistency in applying these practices reduces the likelihood of defects. Regular calibration of equipment and adherence to process controls are equally important for maintaining quality.

Troubleshooting Common Issues in Mixed Assembly Soldering

Mixed assembly soldering often encounters specific defects that impact reliability. Tombstoning, where SMT components lift on one end, results from uneven heating or pad design. Adjusting reflow profiles per IPC-7530A can mitigate this. For THT, insufficient hole fill during wave soldering may occur due to low solder temperature or inadequate flux. Verifying pot temperature and flux coverage resolves this issue. Solder bridging, another concern in wave soldering, often stems from excessive solder or improper board orientation. Reducing wave height and optimizing conveyor angle helps. Engineers should document defects and correlate them with process parameters for continuous improvement. Standards like IPC-A-610H provide acceptance criteria to classify and address these issues systematically.

Conclusion

Mastering soldering techniques for mixed assembly is critical for electrical engineers seeking robust connections in complex PCB designs. By integrating SMT and THT soldering methods, such as reflow soldering for mixed assembly and wave soldering for THT components, reliable assemblies can be achieved. Understanding the technical principles, addressing challenges, and applying best practices ensure joint integrity. Standards like IPC-J-STD-001H and IPC-7530A offer essential guidance for process control and quality assurance. With careful planning and precise execution, engineers can overcome the intricacies of mixed assembly, delivering high-performance electronics for diverse applications. Continuous learning and process refinement remain key to success in this evolving field.

FAQs

Q1: What are the key soldering techniques for mixed assembly?

A1: Soldering techniques for mixed assembly include reflow soldering for SMT components and wave soldering for THT parts. Reflow uses controlled heating to melt solder paste, while wave soldering fills through-holes with a molten solder wave. Sequencing these processes correctly prevents thermal damage. Adhering to industry standards ensures reliable joints across both component types.

Q2: How does reflow soldering for mixed assembly differ from standard reflow?

A2: Reflow soldering for mixed assembly requires thermal profiles that account for both SMT and THT components if processed together. Unlike standard reflow, it demands careful temperature control to avoid damaging THT leads or SMT parts. Guidelines from recognized standards help tailor profiles for balanced heating and robust connections.

Q3: What challenges arise when using wave soldering for THT components in mixed assembly?

A3: Wave soldering for THT components in mixed assembly risks damaging SMT parts due to high temperatures or solder contact. Shadowing effects can also lead to unsoldered pins. Using protective pallets and optimizing preheat settings can mitigate these issues, ensuring consistent hole fill and joint quality.

Q4: How can engineers ensure robust SMT and THT soldering methods in mixed assembly?

A4: Engineers can ensure robust SMT and THT soldering methods by optimizing process sequencing, tailoring thermal profiles, and using protective measures during wave soldering. Regular inspection per industry standards identifies defects early. Consistent equipment calibration and adherence to material specifications further enhance connection reliability in mixed assembly.

References

IPC-J-STD-001H - Requirements for Soldered Electrical and Electronic Assemblies. IPC, 2021.

IPC-7530A - Guidelines for Temperature Profiling for Mass Soldering Processes (Reflow & Wave). IPC, 2017.

IPC-A-610H - Acceptability of Electronic Assemblies. IPC, 2021.

IPC-J-STD-006C - Requirements for Electronic Grade Solder Alloys and Fluxed and Non-Fluxed Solid Solders for Electronic Soldering Applications. IPC, 2013.